Research on Heat Transfer Characteristics of Corium Pool Under Oscillating Conditions

-

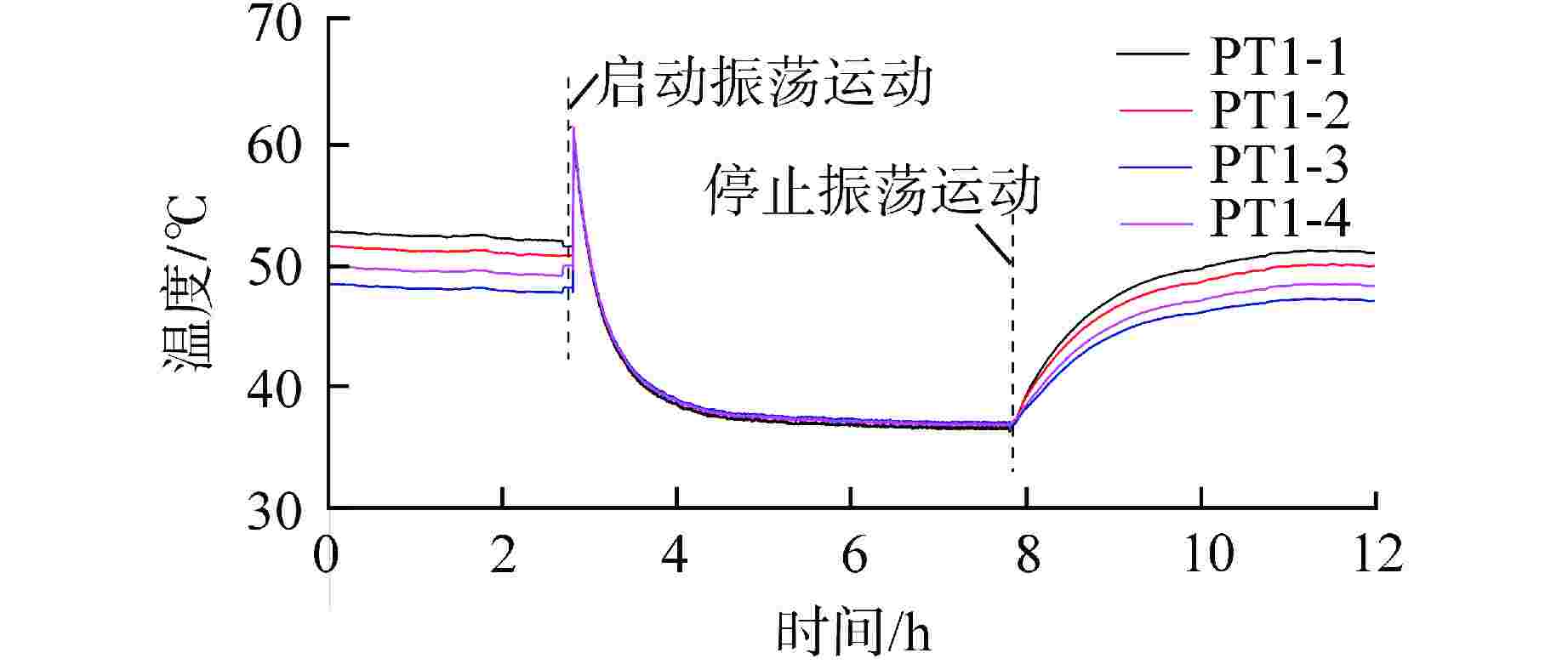

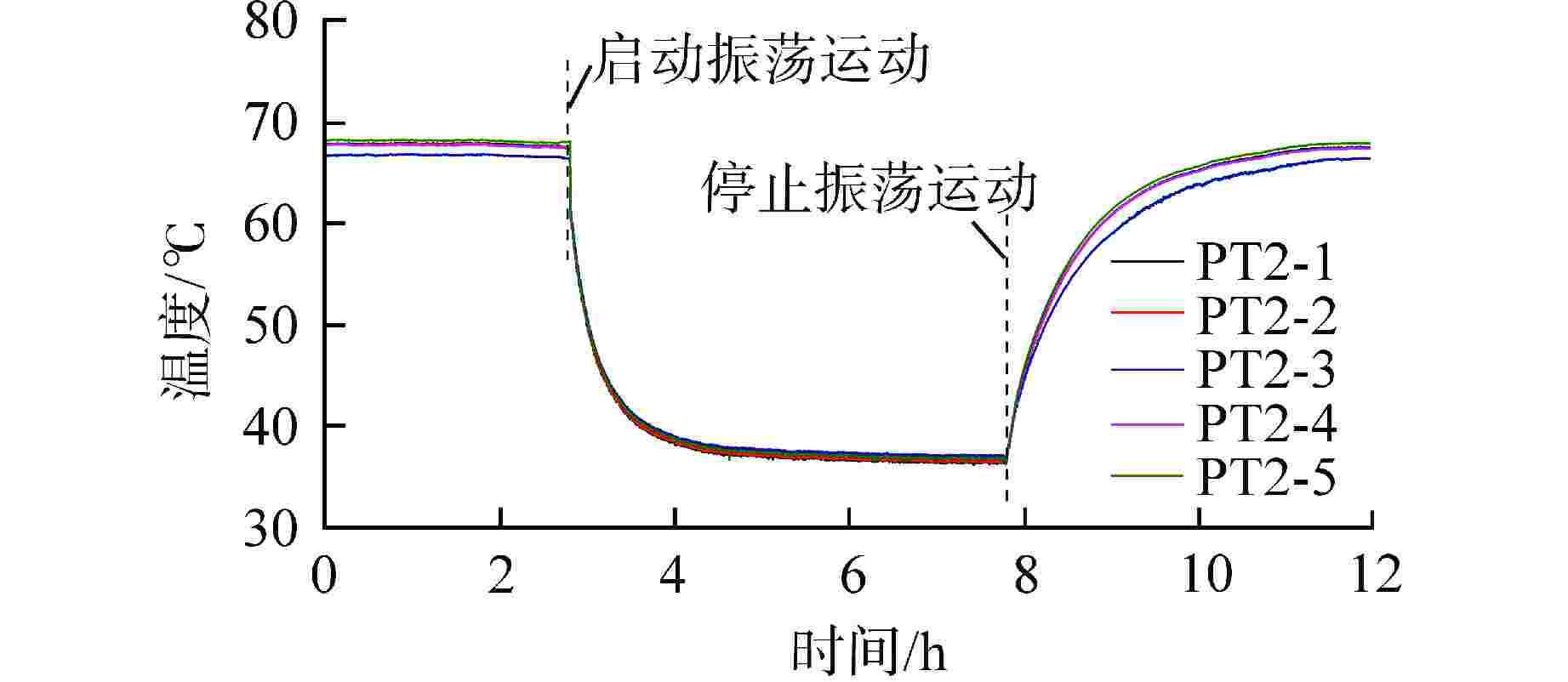

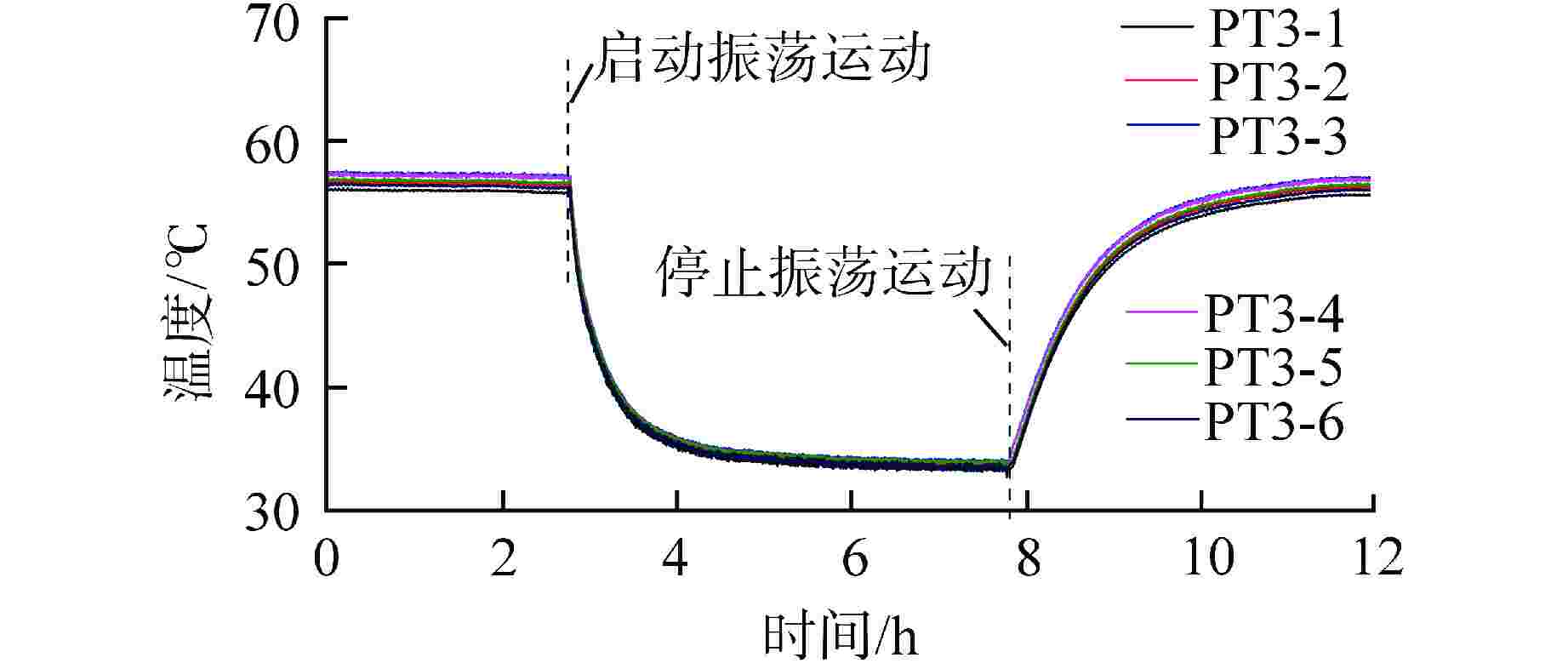

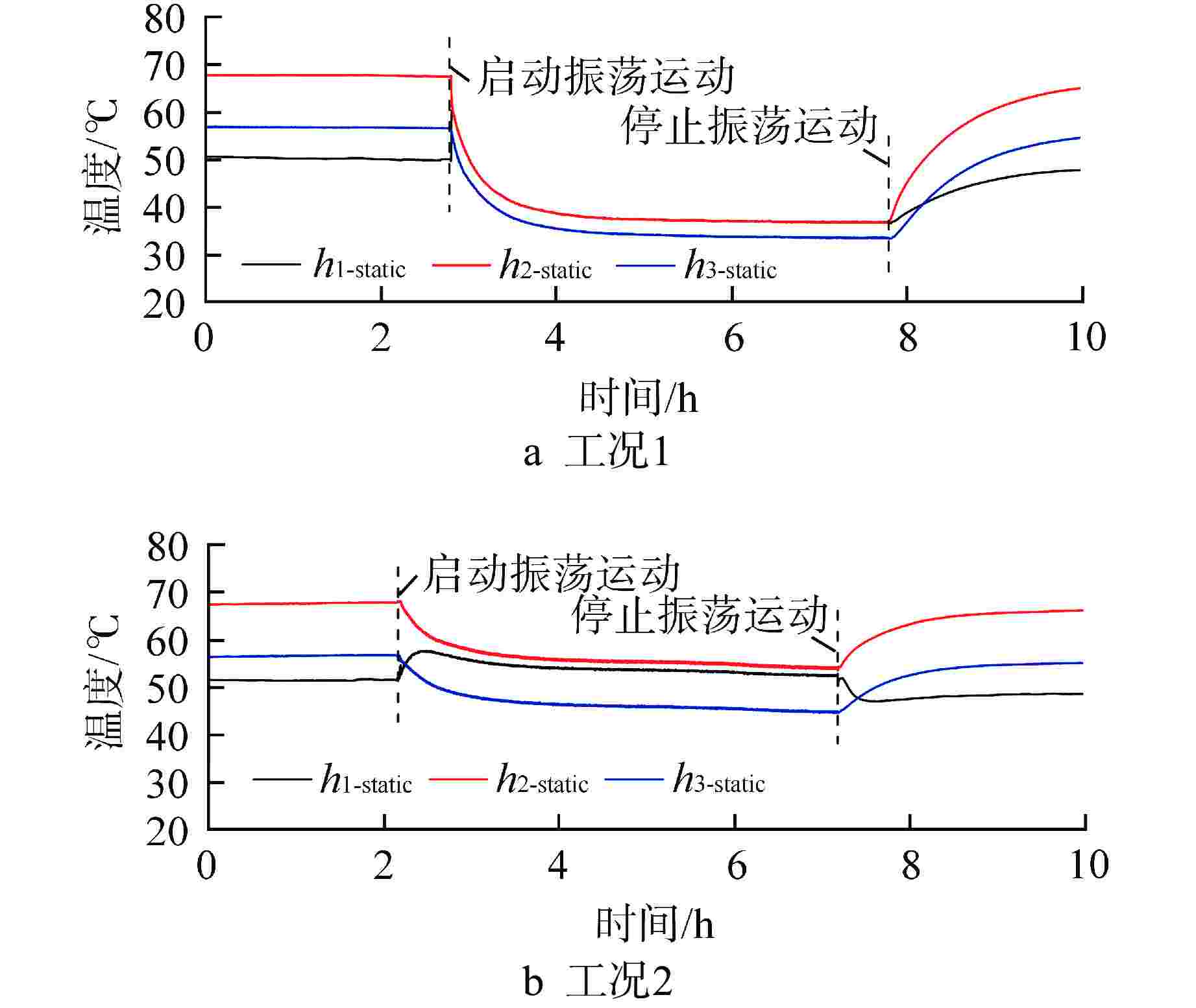

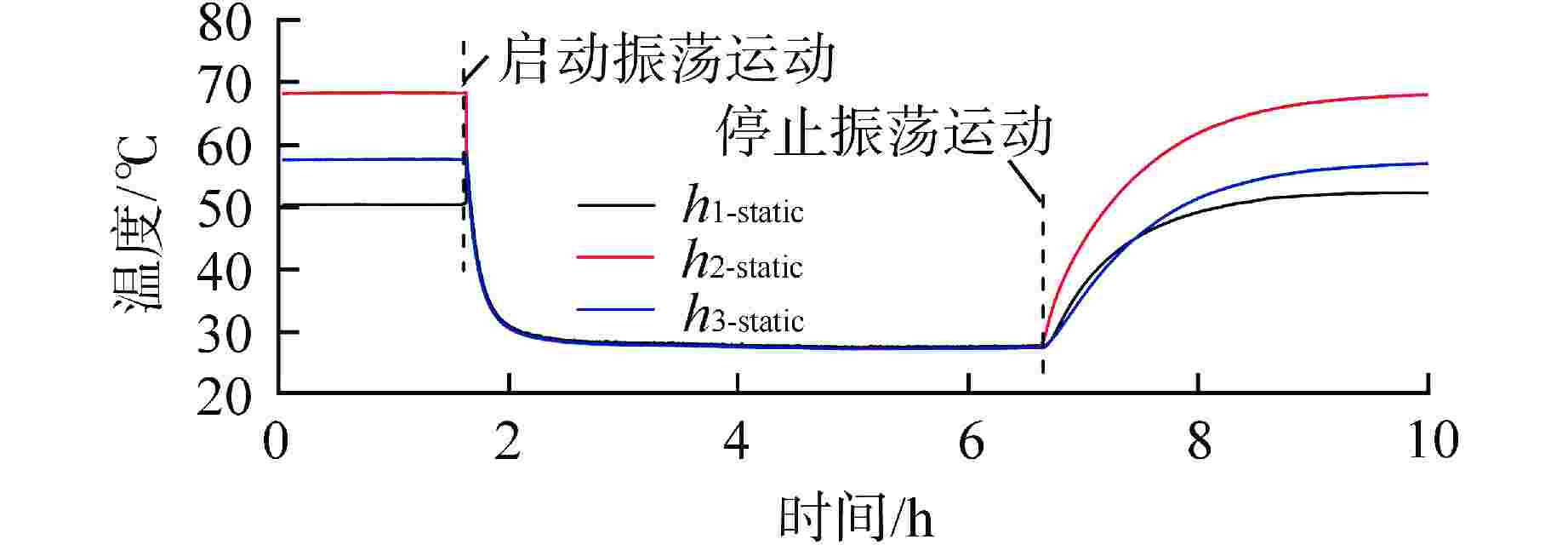

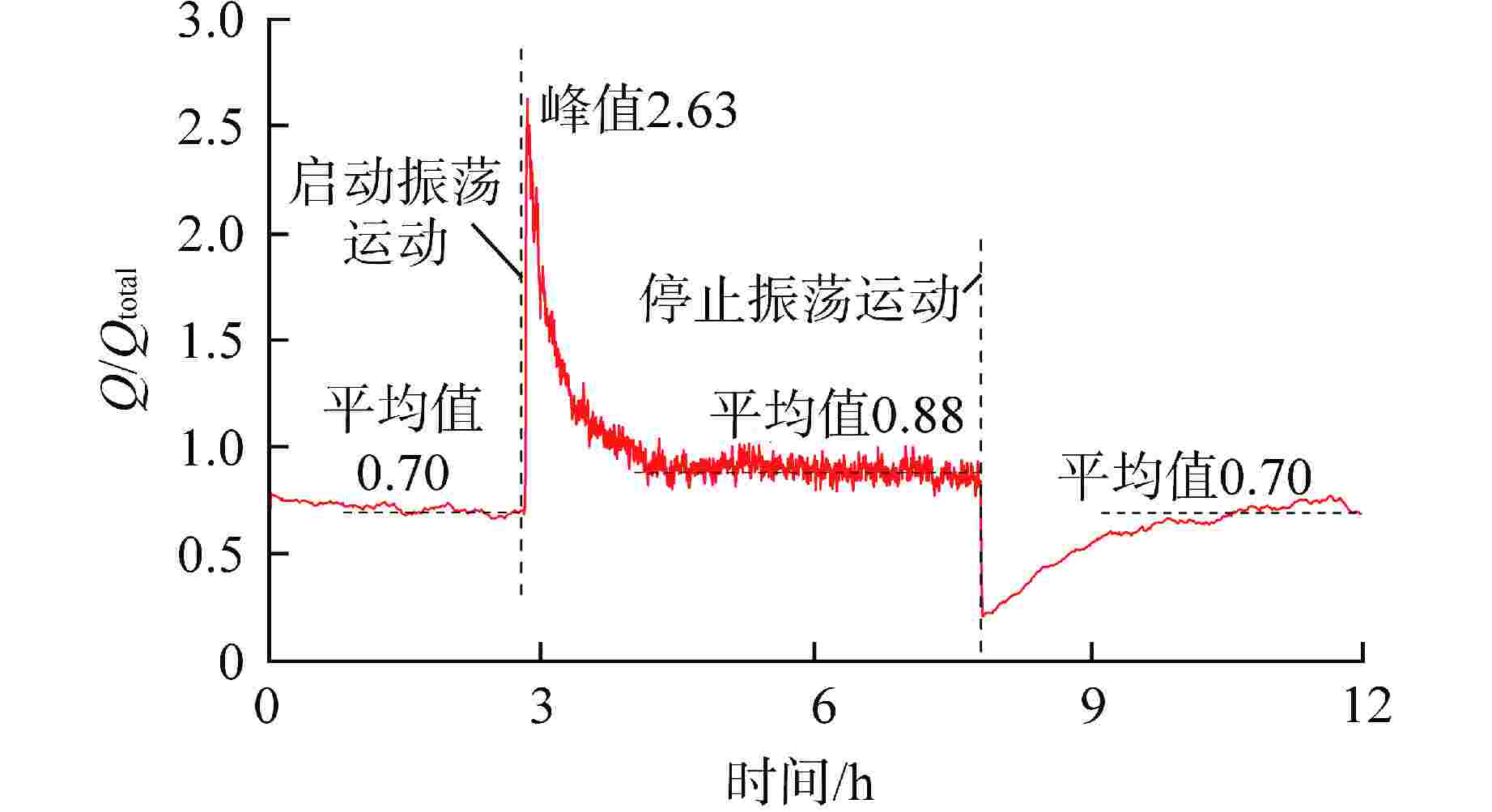

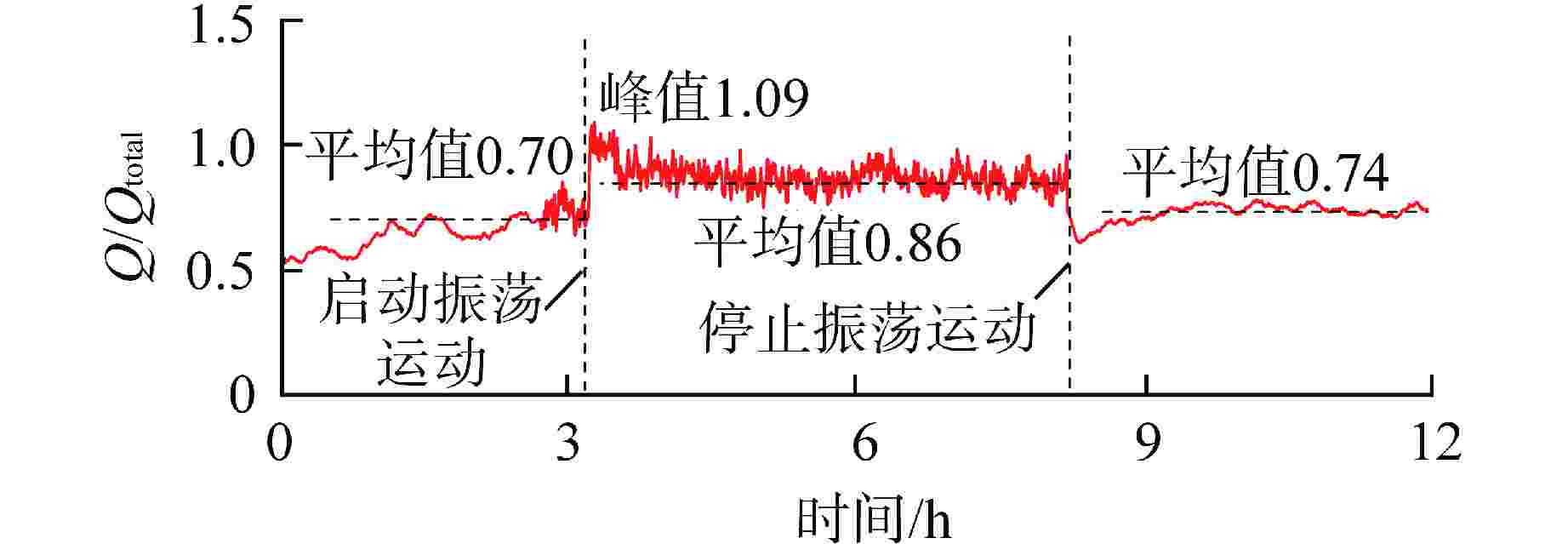

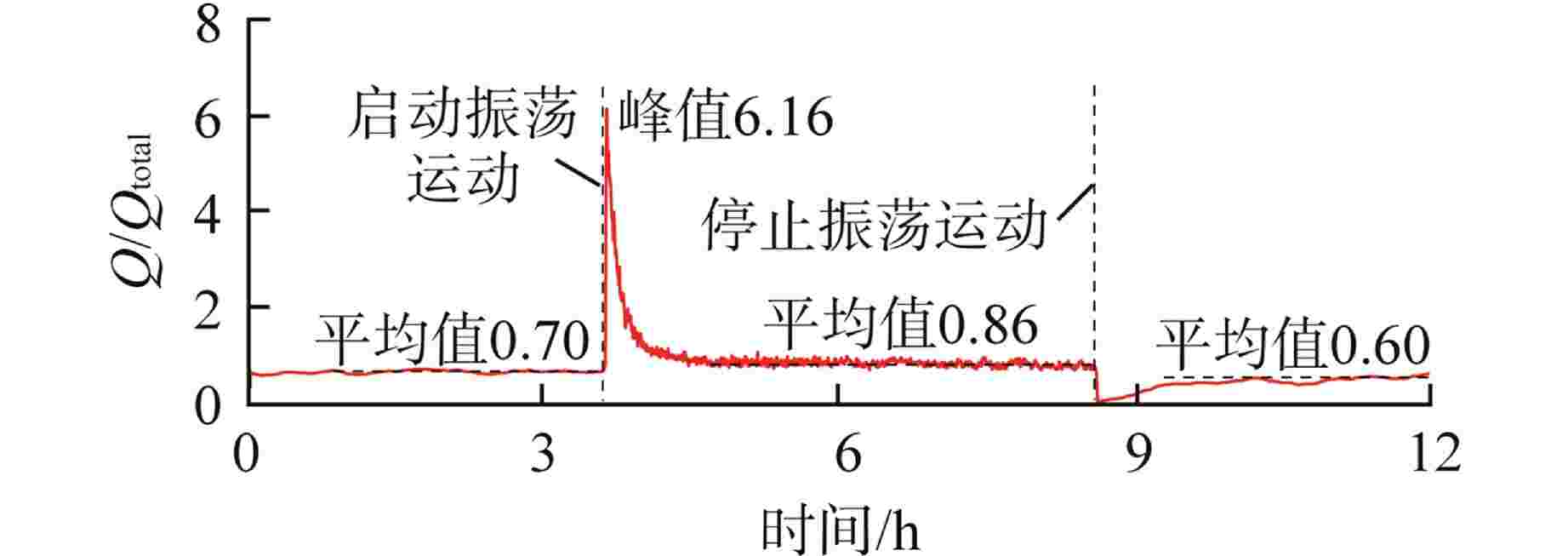

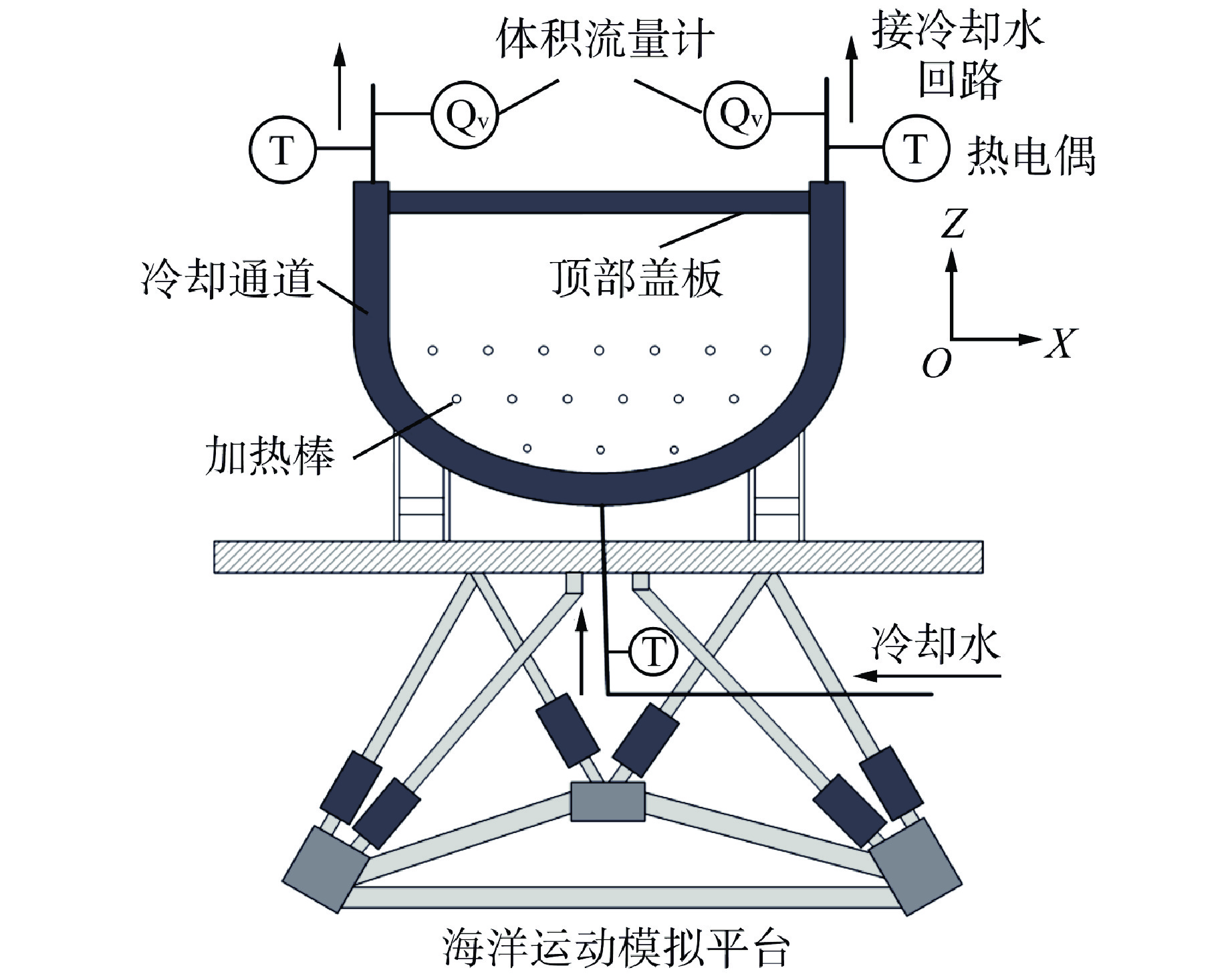

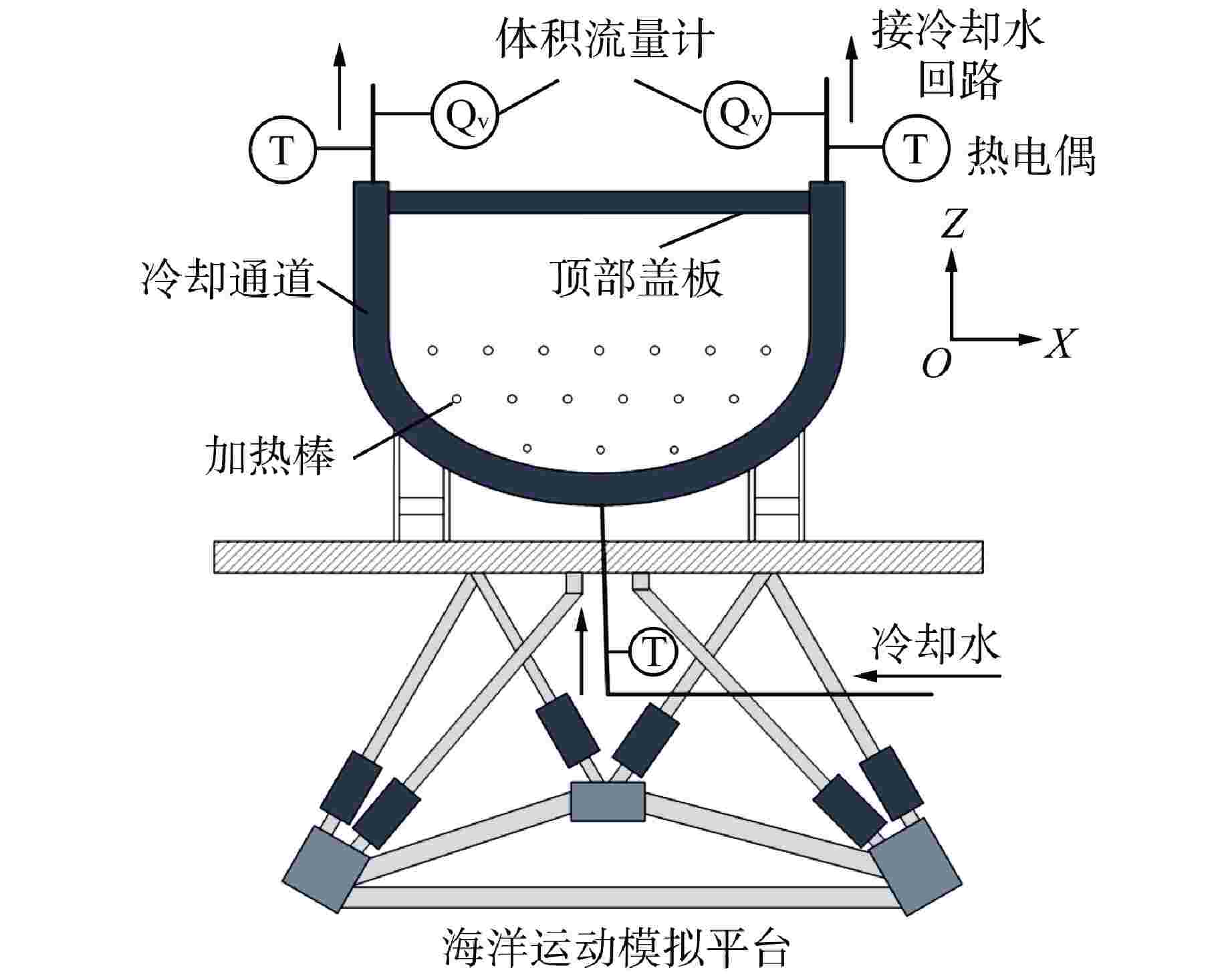

摘要: 为获得振荡条件下熔融池的传热特性,本研究以海洋小型反应堆(简称海洋小堆)双层熔融池为对象开展实验研究。实验采用氟化液FC-40和水分别模拟熔融池的氧化层和金属层,获得了不同振荡条件下熔融池的温度场以及传热量的瞬态变化情况。实验结果显示,振荡条件在运动初始阶段对熔融池的影响最为剧烈,随着振荡运动的持续,熔融池会达到热平衡准稳态。一般情况下,振荡条件下熔融池的温度分层减弱,整体温度较静止条件下的温度低,且向冷却壁面的传热量增大。在相同的高强度振荡条件下,纵向振荡的影响比横向振荡更为剧烈,而在低强度振荡条件下,纵向振荡的影响可以忽略。此外,本研究提出了一个新的无量纲参数Lo来表征振荡影响强度,该参数表示在振荡条件下,特征振荡附加力与流体的特征剪切力之比,可用于量化在相同振荡方向条件下不同振荡强度的影响。本研究成果可为海洋小堆的熔融物堆内滞留(IVR)分析和安全系统的设计提供有价值的参考。Abstract: In order to obtain the heat transfer characteristics of corium pool under oscillating conditions, an experimental study was carried out on the two-layer corium pool of small marine reactors. Fluorinert liquid FC-40 and water were used respectively to simulate the oxide layer and metal layer of corium pool in the experiment, and the transient variations of temperature field and heat transfer capacity under different oscillating conditions were obtained. The experimental results show that the oscillating conditions exert the most intense influences in the early stage of movements, and as the oscillating motion continues, the corium pool will reach a quasi-steady state of thermal equilibrium. In general, the temperature stratification of corium pool is weakened under the condition of oscillation, and the overall temperature is lower than that under the static condition, together with the increased heat transfer capacity to the cooling wall. Under the same high-intensity oscillating conditions, the effect of oscillations in vertical direction is more intense than that of oscillations in lateral direction. However, under the condition of low-intensity oscillation, the effect of oscillations in vertical direction can be ignored. Additionally, a new dimensionless parameter Lo was proposed to characterize the oscillatory influence strength, which represents the ratio of the characteristic oscillatory force to the characteristic shear force of fluid under oscillating conditions. It can be used to quantify the influence of different oscillation intensities under the same oscillation direction. This research is supposed to offer valuable reference to the in-vessel retention (IVR) analysis and safety system design for small marine reactors.

-

Key words:

- Small marine reactor /

- Corium pool /

- Oscillating condition

-

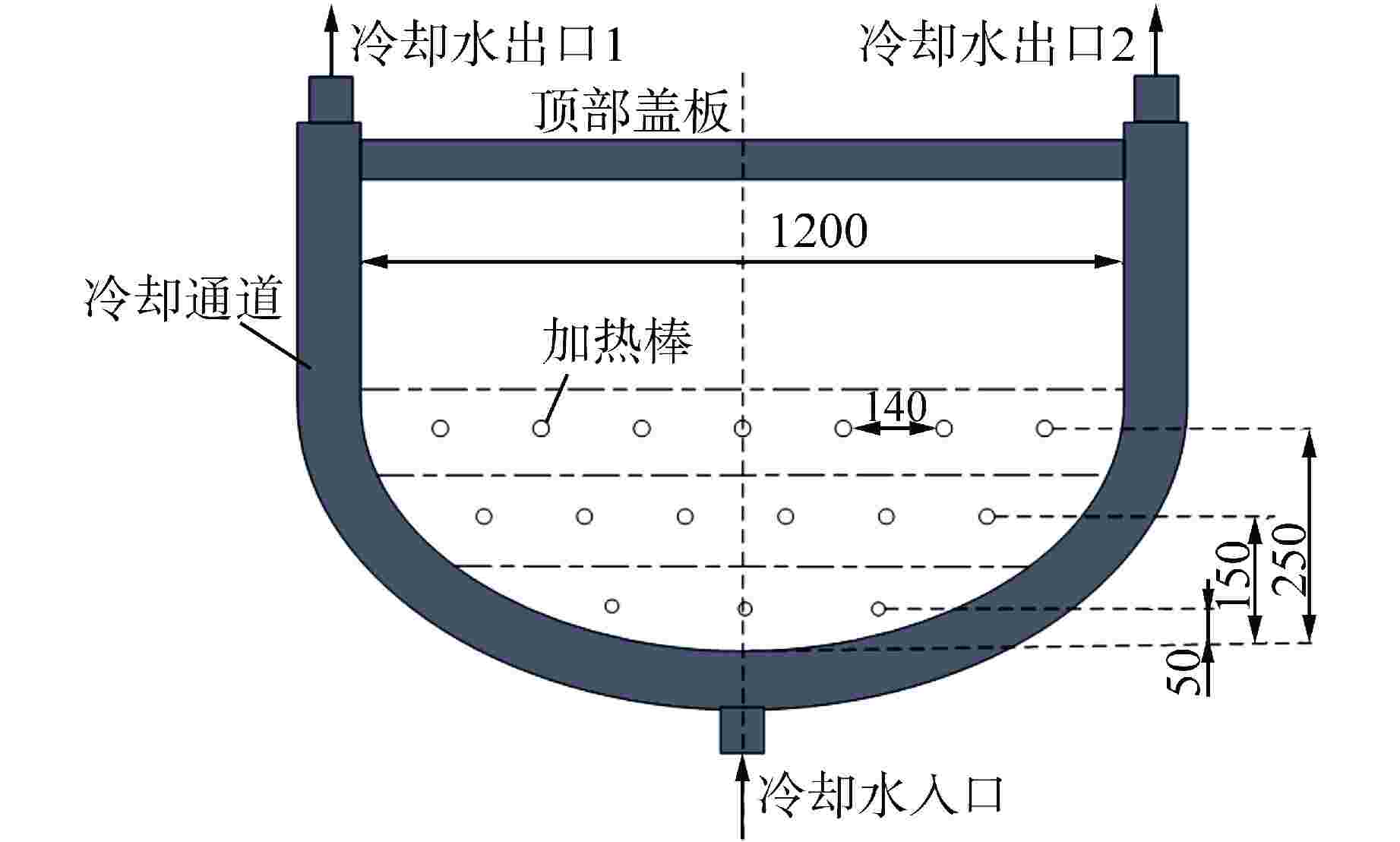

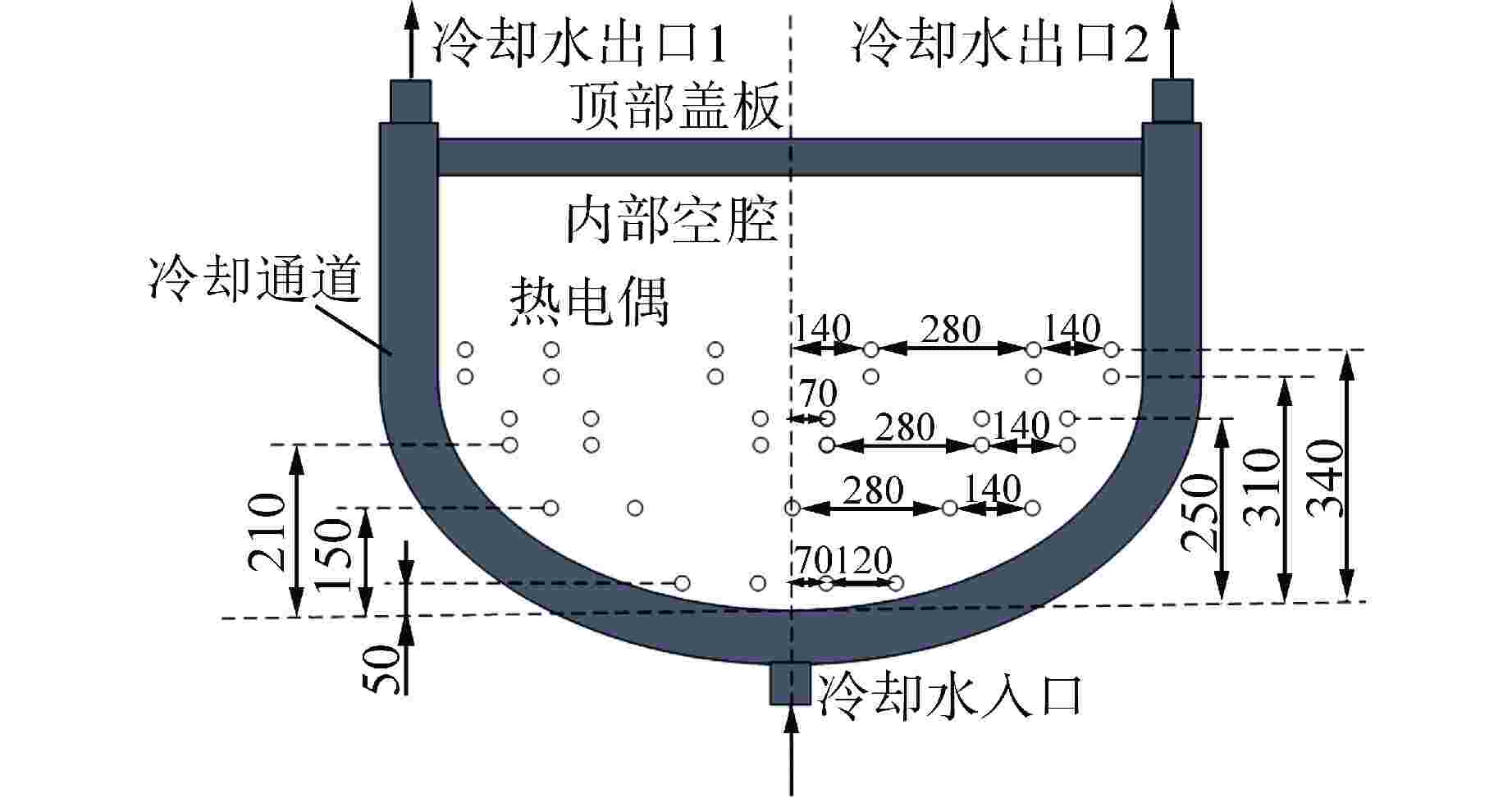

表 1 热电偶位置与编号

Table 1. Thermocouples’ Locations and Numbers

编号 距底部

高度/mm距中轴线

距离d①/mm编号 距底部

高度/mm距中轴线

距离d/mmPT1-1 50 −190 PT2-5 150 420 PT1-2 50 −70 PT3-1 210 −490 PT1-3 50 70 PT3-2 210 −350 PT1-4 50 190 PT3-3 210 −70 PT2-1 150 −420 PT3-4 210 70 PT2-2 150 −280 PT3-5 210 350 PT2-3 150 0 PT3-6 210 490 PT2-4 150 280 注:①负值表示在实验段中轴线左侧,正值表示在中轴线右侧,零则表示在中轴线上,如图3所示 表 2 模拟物与熔融物的物性对比

Table 2. Comparison of Properties between the Simulants and the Corium

模拟物物性参数(25℃) FC-40

(模拟氧化层)水(模拟金属层) 物性比① 密度ρ/(kg·m−3) 1855 997 0.54 动力粘度μ/(Pa·s) 4.10×10−3 9.03×10−4 0.22 定压比热容cp/(J·kg−1·K−1) 1100 4178 3.80 导热系数λ/(W·m−1·K−1) 0.065 0.609 9.37 热膨胀系数β/K−1 1.2×10−3 2.57×10−4 0.21 熔融物物性参数[14] 氧化层 金属层 物性比 密度ρ /(kg·m−3) 8196.41 6818.50 0.83 动力粘度μ/(Pa·s) 8.12×10−3 3.01×10−3 0.37 定压比热容cp(J·kg−1·K−1) 532.67 758.27 1.42 导热系数λ/(W·m−1·K−1) 4.89 25.13 5.14 热膨胀系数β/K−1 1.05×10−4 1.05×10−4 1.00 注:①物性比表示模拟物或熔融物中的金属层与氧化层的物性之比 表 3 实验工况设置

Table 3. Experimental Conditions

工况编号 振荡方向 加速度幅值amax/(m·s−2) 频率f/Hz 工况1 横向(X轴) 5.00 2.04 工况2 横向(X轴) 0.55 0.20 工况3 纵向(Z轴) 5.00 2.04 工况4 纵向(Z轴) 0.55 0.20 注:表中的X轴与Z轴表示的方向与图1一致 表 4 实验工况对应的无量纲参数Lo

Table 4. Dimensionless Parameter Lo for Experimental Conditions

工况编号 Lo 工况1 22768.6 工况2 245.5 工况3 22768.6 工况4 245.5 表 5 不同振荡条件下的熔融池传热特性

Table 5. Heat Transfer Characteristics of Corium Pool under Different Oscillating Conditions

工况编号 Lo 最高温度比

(Tosc/Tstatic)峰值传热比

(Qp/Qstatic)稳态传热比

(Qosc/Qstatic)工况1 22768.6 0.547 3.76 1.26 工况2 245.5 0.798 1.56 1.23 工况3 22768.6 0.403 8.80 1.23 工况4 245.5 ≈1 ≈1 ≈1 -

[1] ZHANG Y P, SU G H, QIU S Z, et al. A simple novel and fast computational model for the LIVE-L4[J]. Progress in Nuclear Energy, 2013, 68: 20-30. doi: 10.1016/j.pnucene.2013.04.009 [2] KYMÄLÄINEN O, TUOMISTO H, HONGISTO O, et al. Heat flux distribution from a volumetrically heated pool with high Rayleigh number[J]. Nuclear Engineering and Design, 1994, 149(1-3): 401-408. doi: 10.1016/0029-5493(94)90305-0 [3] BONNET J M, SEILER J M. Thermal hydraulic phenomena in corium pools: the BALI experiment[C]//7th International Conference on Nuclear Engineering. Tokyo: Japan Society of Mechanical Engineers, 1999. [4] Gubaidullin AA, Sehgal BR. SIMECO tests in a melt stratified pool[C]. The 10th International Conference on Nuclear Engineering (ICONE-10), Arlington, USA, 2002: 935-945. [5] FLUHRER B, MIASSOEDOV A, CRON T, et al. The LIVE-L1 and LIVE-L3 experiments on melt behaviour in RPV lower head: FZKA 7419[R]. Karlsruhe: Forschungszentrum Karlsruhe GmbH, 2008. [6] MIASSOEDOV A, CRON T, FOIT J, et al. Results of the LIVE-L1 experiment on melt behaviour in RPV lower head performed within the LACOMERA project at the Forschungszentrum Karlsruhe[C]//15th International Conference on Nuclear Engineering (ICONE-15). Tokyo: Japan Society of Mechanical Engineers, 2007: 22-26. [7] GAUS-LIU X, MIASSOEDOV A, CRON T, et al. Test and simulation results of LIVE-L4 + LIVE-L5L: KIT-SR-7593[R]. Germany: Karlsruhe Institute of Technology, 2011. [8] ZHANG L T, ZHANG Y P, ZHOU Y K, et al. COPRA experiments on natural convection heat transfer in a volumetrically heated slice pool with high Rayleigh numbers[J]. Annals of Nuclear Energy, 2016, 87: 81-88. doi: 10.1016/j.anucene.2015.08.021 [9] ZHANG Y P, ZHANG L T, ZHOU Y K, et al. Natural convection heat transfer test for in-vessel retention at prototypic Rayleigh numbers–results of COPRA experiments[J]. Progress in Nuclear Energy, 2016, 86: 80-86. doi: 10.1016/j.pnucene.2015.10.014 [10] LUO S M, ZHANG Y P, ZHOU Y K, et al. COPRA experiment and numerical research on the behavior of internally-heated melt pool with eutectic salt[J]. Applied Thermal Engineering, 2018, 140: 313-324. doi: 10.1016/j.applthermaleng.2018.05.041 [11] ZHOU Y K, ZHANG Y P, LUO S M, et al. Results of simulant effect on large corium pool behavior based on COPRA facility[J]. Progress in Nuclear Energy, 2018, 108: 398-408. doi: 10.1016/j.pnucene.2018.06.018 [12] ZHANG L T, LUO S M, ZHANG Y P, et al. Large eddy simulation on turbulent heat transfer in reactor vessel lower head corium pools[J]. Annals of Nuclear Energy, 2018, 111: 293-302. doi: 10.1016/j.anucene.2017.08.055 [13] LUO S M, ZHANG Y P, ZHANG D L, et al. Numerical analysis of simulant effect on natural convection characteristics in corium pools[J]. Applied Thermal Engineering, 2019, 156: 730-740. doi: 10.1016/j.applthermaleng.2019.04.101 [14] ZHANG L T, ZHOU Y K, LUO S M, et al. Large eddy simulation for the thermal behavior of one-layer and two-layer corium pool configurations in HPR1000 reactor[J]. Applied Thermal Engineering, 2018, 145: 38-47. doi: 10.1016/j.applthermaleng.2018.09.019 [15] LUO S M, ZHANG Y P, ZHANG D L, et al. Convection of internal-heated two-layer fluids with deformable interface under swinging motion conditions[J]. Applied Thermal Engineering, 2020, 167: 114755. doi: 10.1016/j.applthermaleng.2019.114755 [16] LUO S M, CHEN P, BAI J Y, et al. Experimental research on the influence of rolling motions on the convection behaviors inside two-layer corium pools[J]. Progress in Nuclear Energy, 2020, 128: 103466. doi: 10.1016/j.pnucene.2020.103466 [17] LUO S M, WANG X A, ZHANG Y P, et al. Numerical research on melt pool flow characteristics under rolling condition[C]//Proceedings of the 26th International Conference on Nuclear Engineering. London: ASME, 2018. -

下载:

下载: