Development of Segmented Air-gap Coupled Electric Heating Test Device for Material Irradiation

-

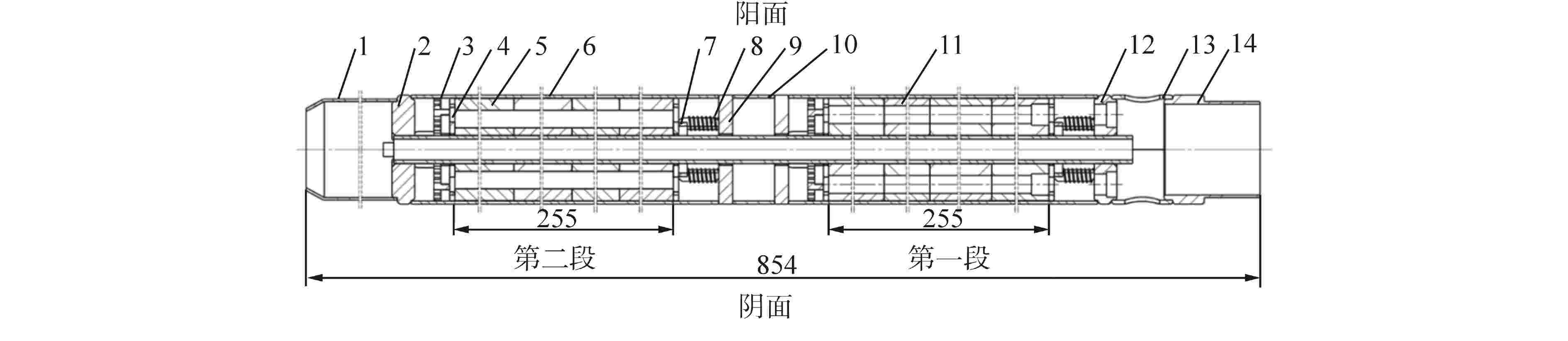

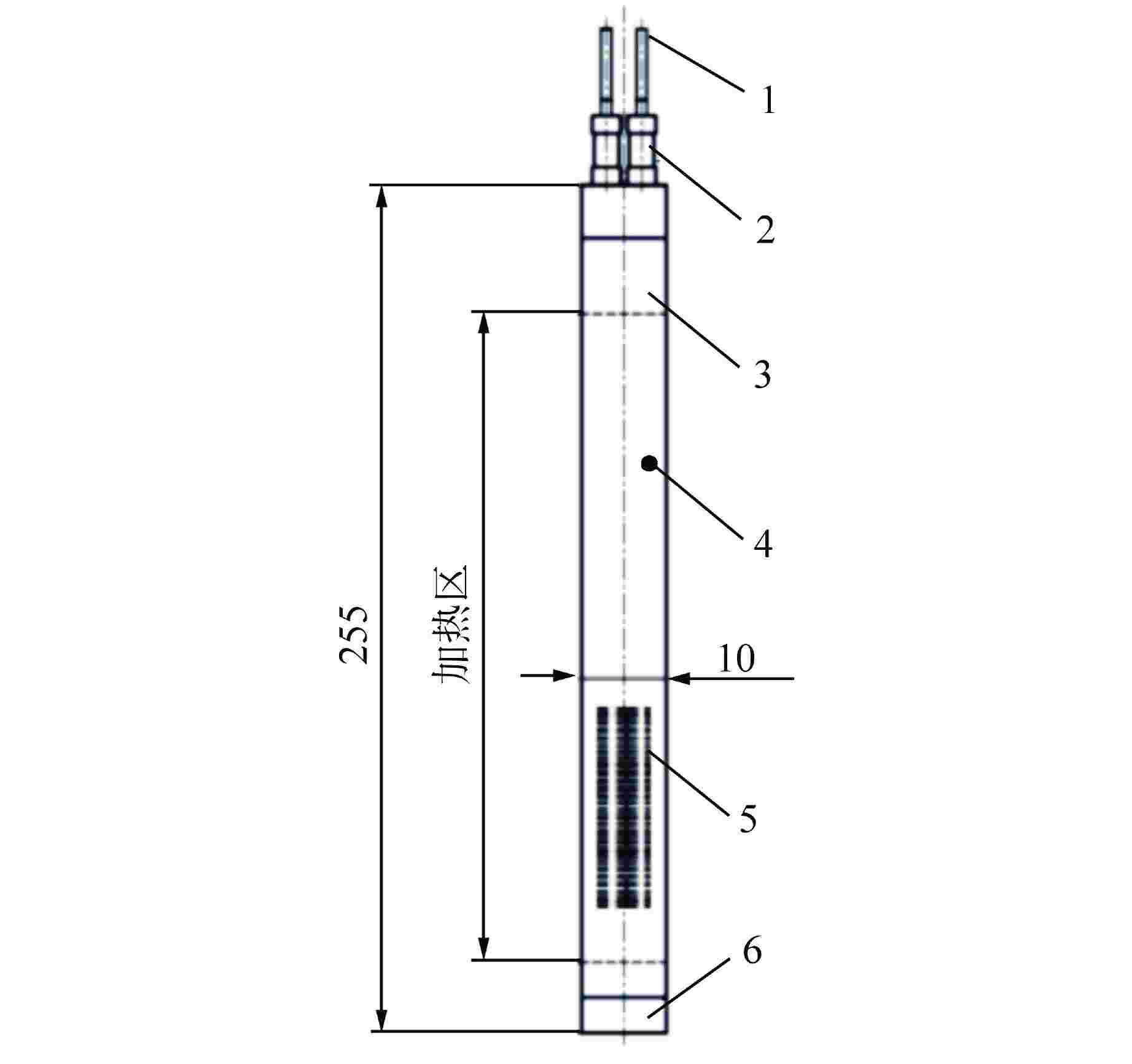

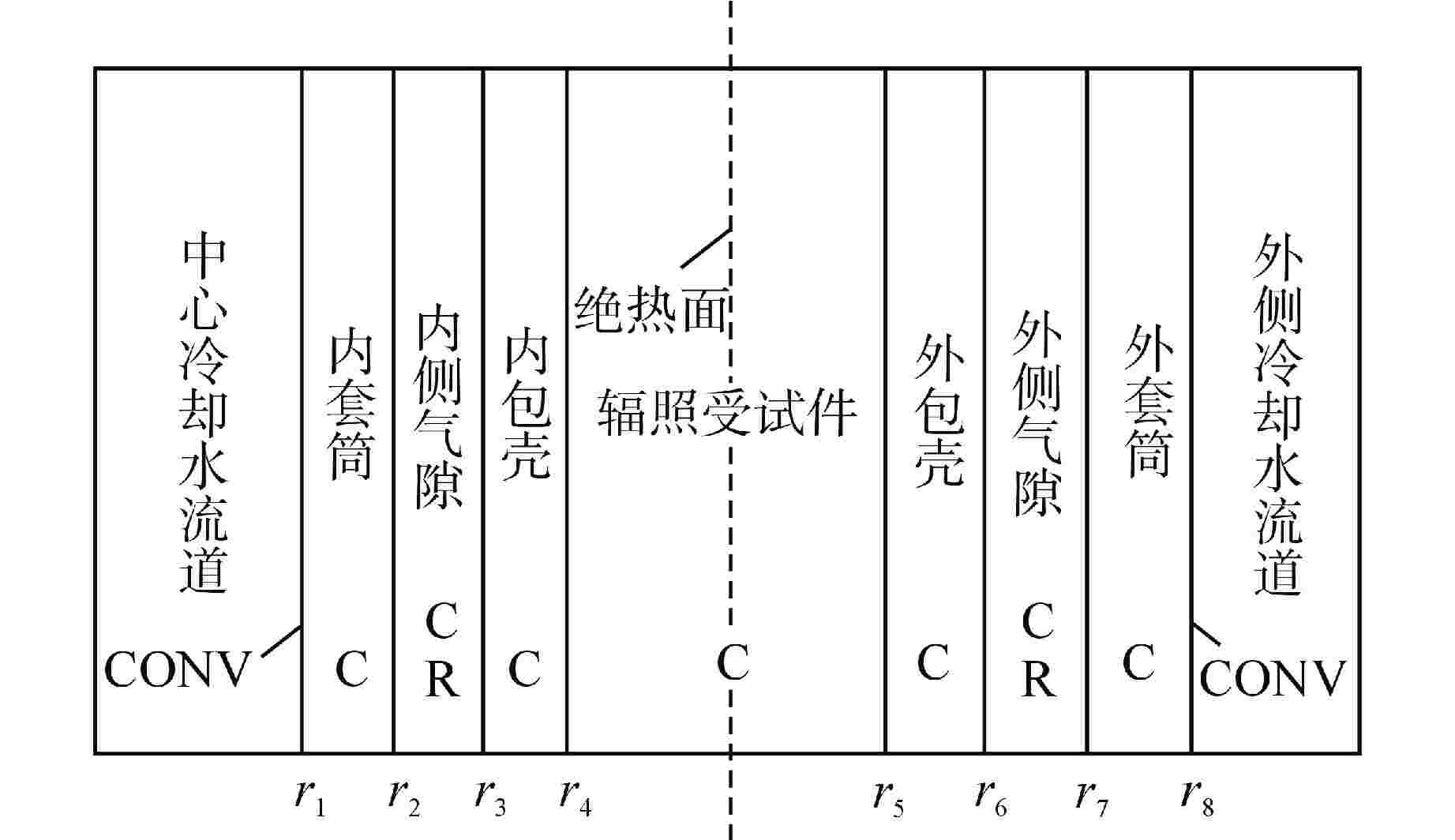

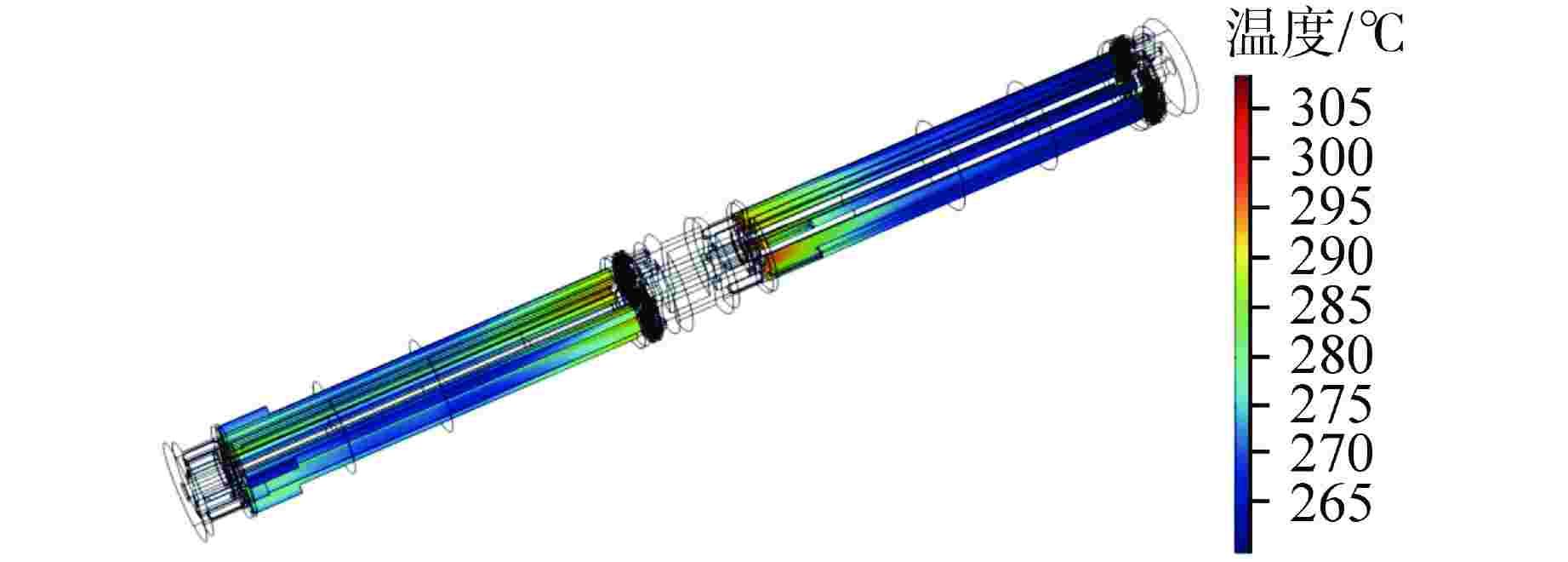

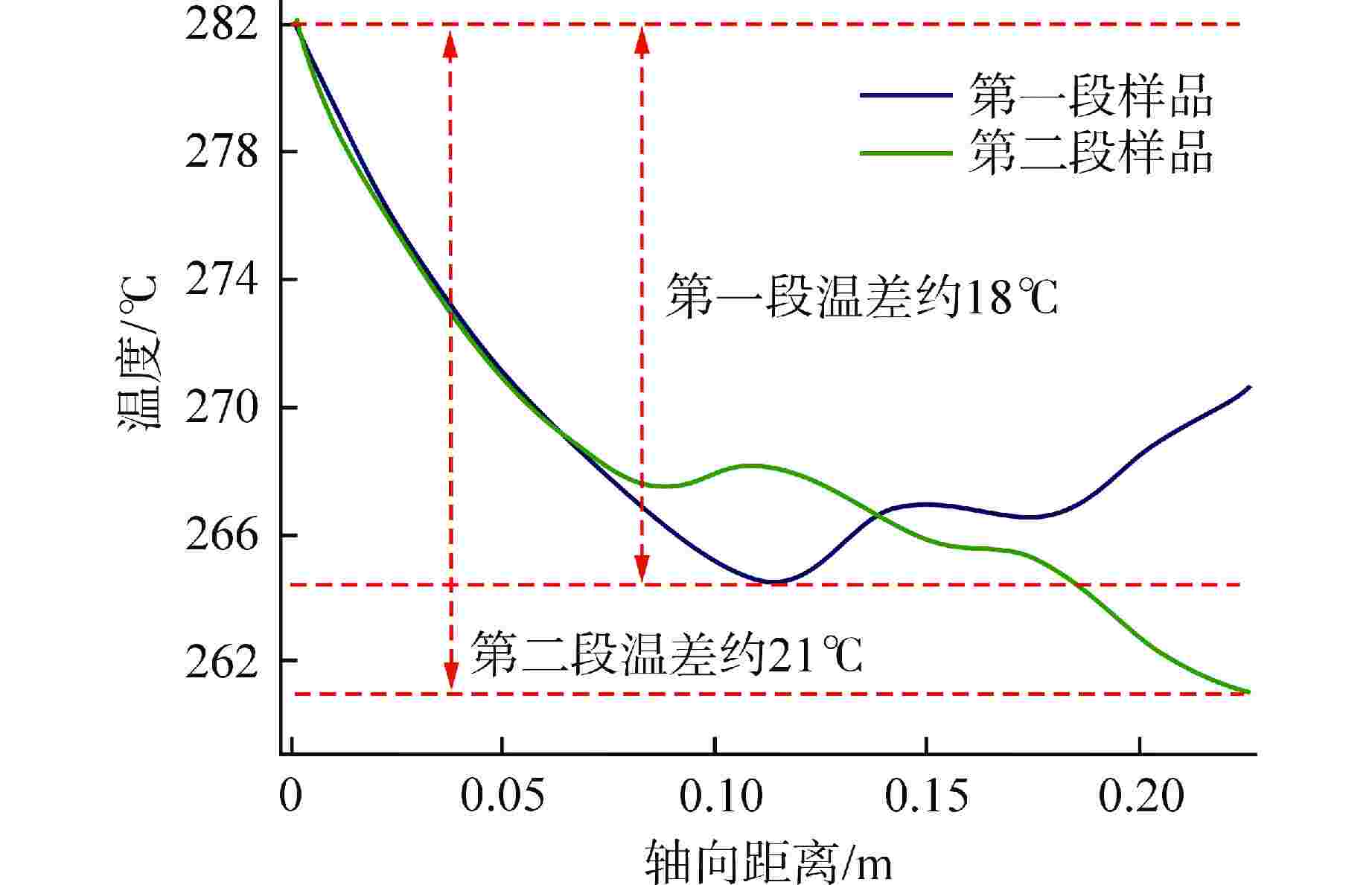

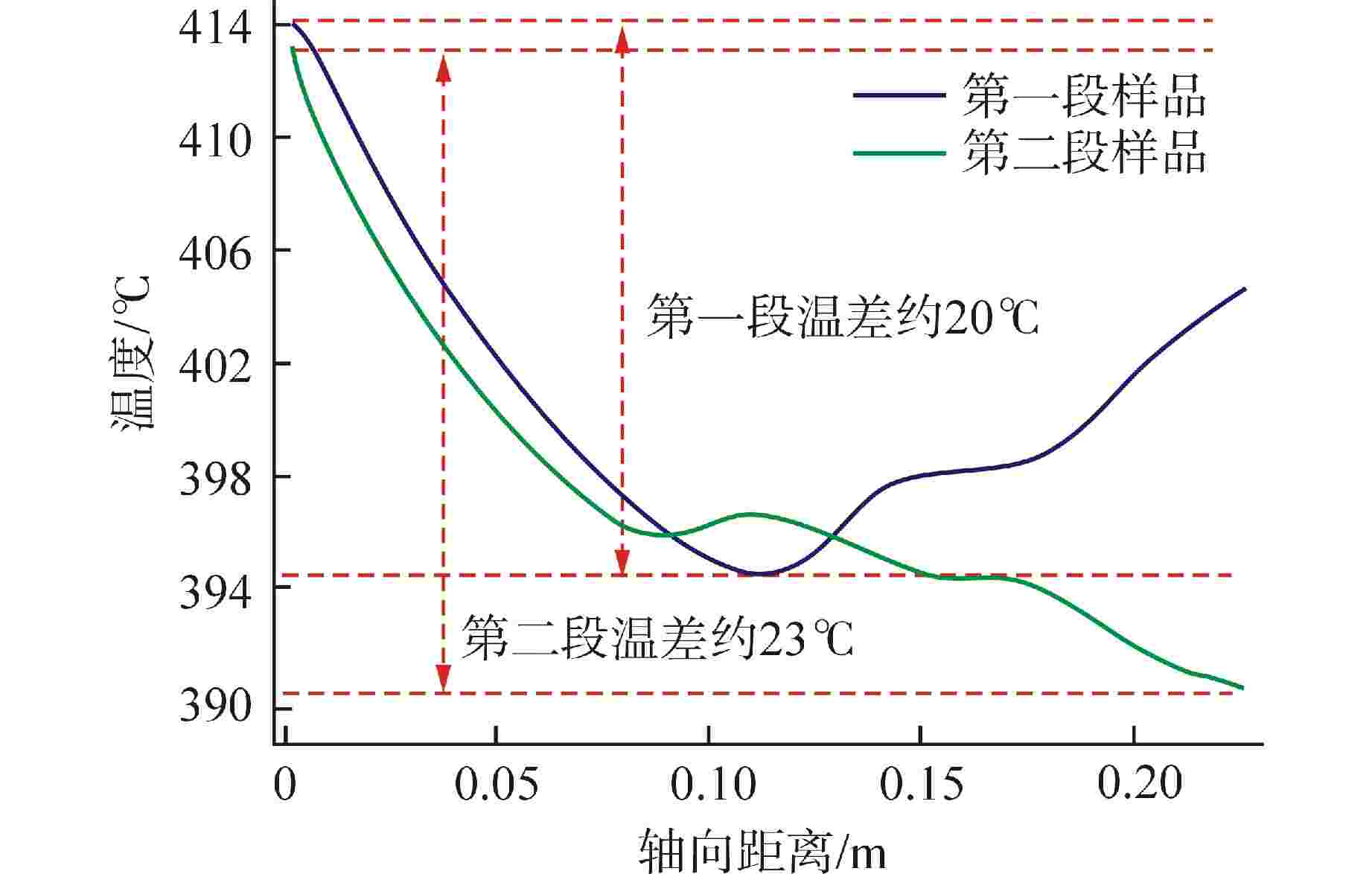

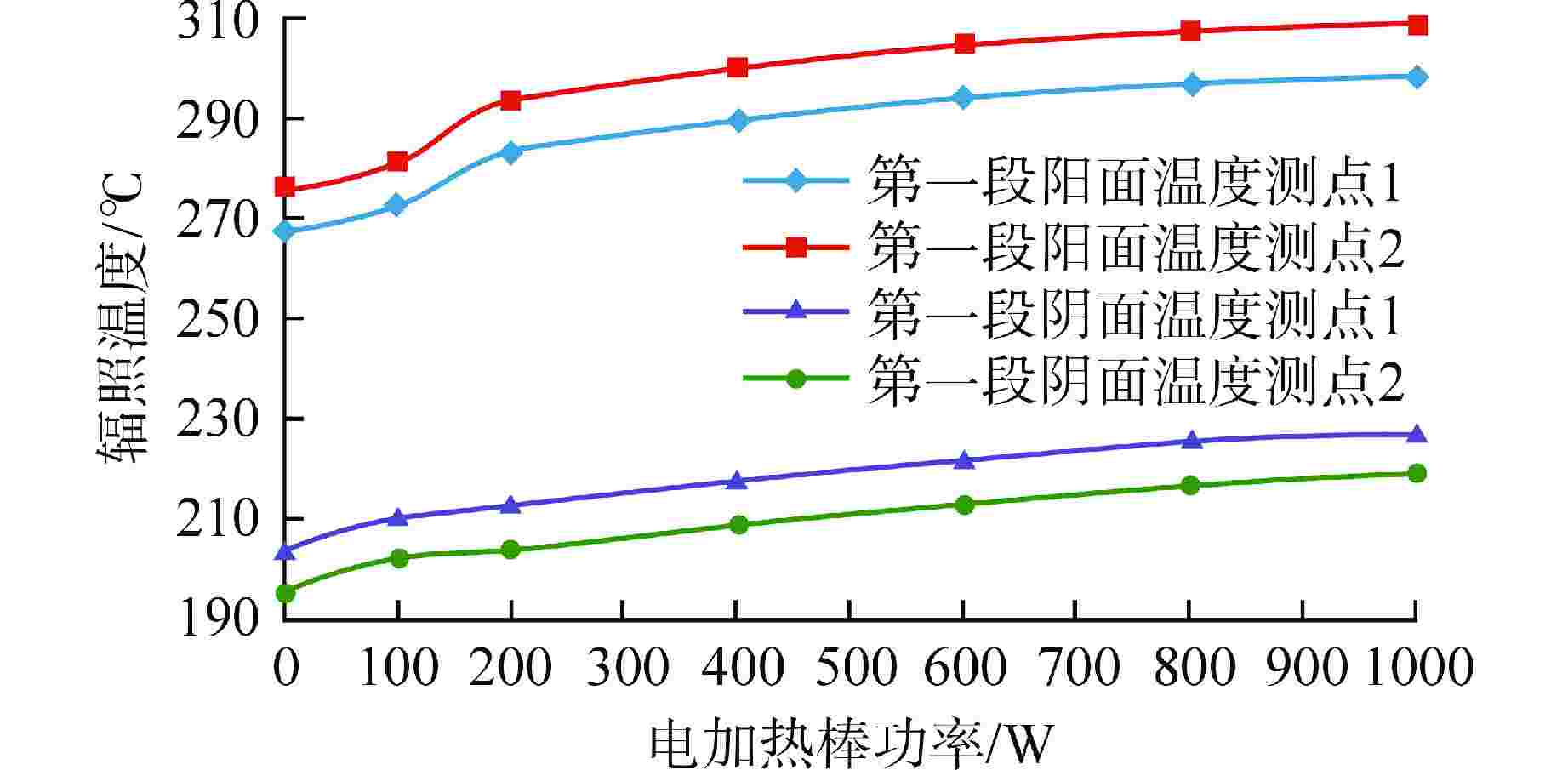

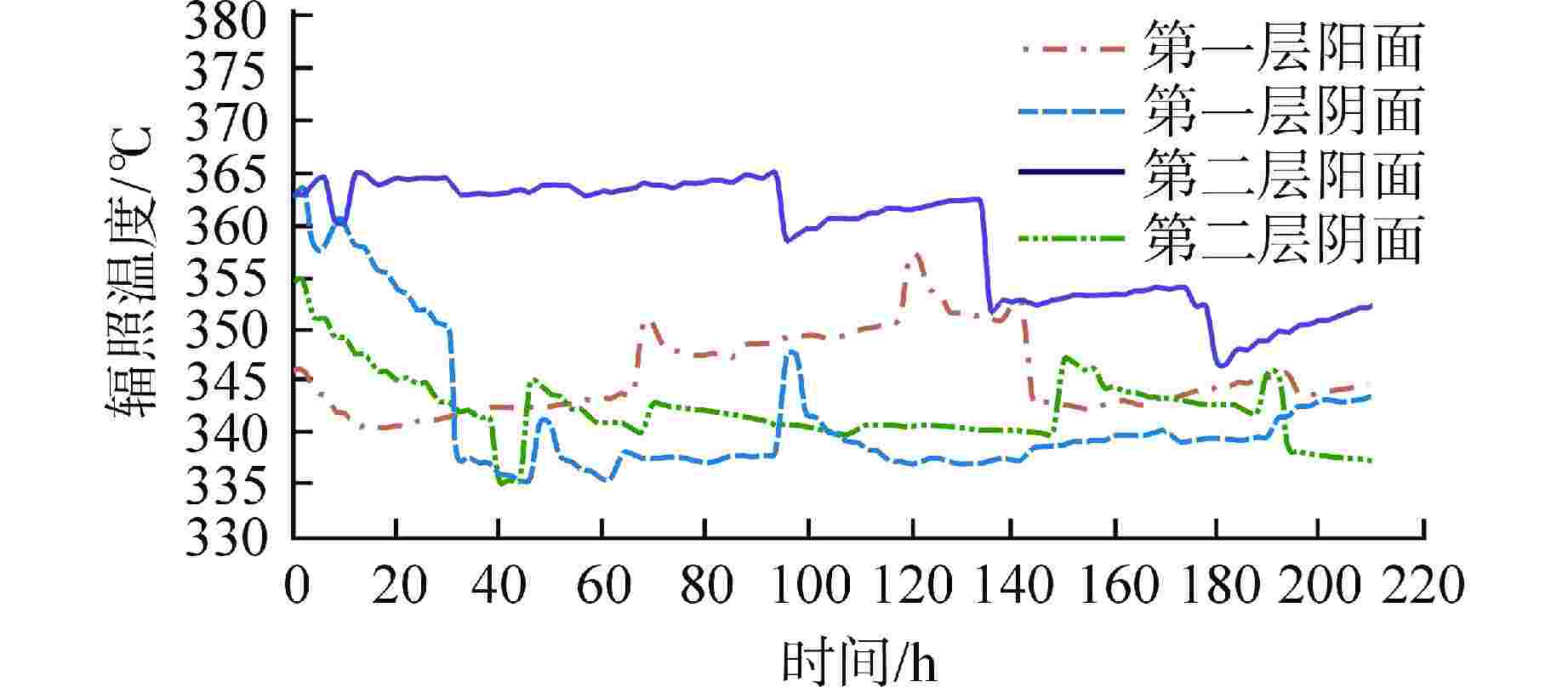

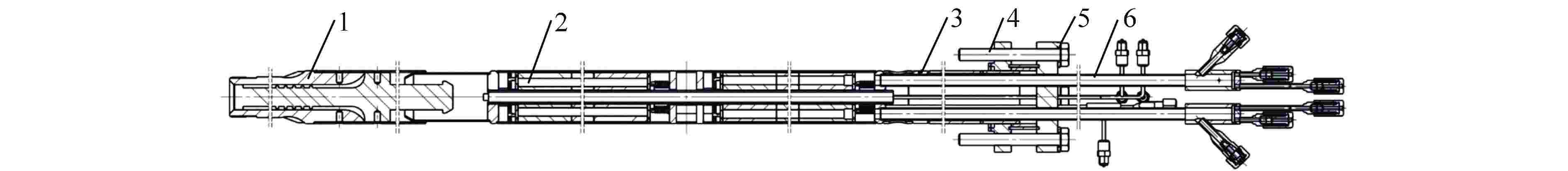

摘要: 为了解决研究堆高释热率区材料辐照温度精确控制技术难题,研制了材料辐照用分段式气隙耦合电加热试验装置。试验装置采用轴向分段式气隙耦合电加热的辐照温度控制方法,使其具有较大的温度调节能力。装载材料样品的辐照试验段采用轴向分段式阴阳面独立分区的结构,由两段4个独立腔室组成,每个腔室设置独立的惰性气体调节回路,并且在第一段两个腔室内设置电加热棒辅助气隙进行辐照温度调节。利用该装置进行的堆内辐照试验结果表明:试验装置在反应堆高注量率区能够将材料辐照温度有效控制在335~365℃,电加热棒独立控温能力达30℃。研制的装置大幅提高了辐照温度控制精度,实现了辐照温度在线精确调节与控制,达到了材料辐照精细化控温的目的。Abstract: In order to solve the technical problem of precise control for the material irradiation temperature in high heat release rate region of the research reactor, the segmented air-gap coupled electric heating test device for the material irradiation was developed. The irradiation temperature control method of axial segmented air gap coupling electric heating was adopted to enable the irradiation device to have a large temperature regulation ability. The structure of axial segmented yin-yang plane independent partition was adopted in the test device. The irradiation test section loaded with material samples was composed of four independent chambers, each of which was equipped with an independent inert gas regulating circuit, and the two chambers on the first segment were equipped with the electric heating rod auxiliary air gap for the irradiation temperature regulation. This device was used to carry out irradiation test in the research reactor, and the results show that the material irradiation temperature for the test device can be effectively controlled at 335~365℃ in high flux rate region of the research reactor, and the independent temperature control ability of the electric heating rod can reach 30℃. The developed device greatly improves the accuracy of irradiation temperature control, realizes on-line accurate adjustment and control of irradiation temperature, and achieves the purpose of fine temperature control for material irradiation.

-

表 1 气隙厚度计算结果

Table 1. Calculation Results of Air Gap Thickness

段数 第一段(由上至下) 第二段(由上至下) 序号 1 2 3 4 5 6 7 8 内侧气隙厚度/mm 0.17 0.14 0.14 0.12 0.12 0.14 0.14 0.17 外侧气隙厚度/mm 0.24 0.20 0.16 0.16 0.16 0.16 0.20 0.24 -

[1] XU H L, HUANG L, ZHANG W, et al. Progress of irradiation-resistance materials[J]. Rare Metal Materials and Engineering, 2023, 52(5): 1661-1672. [2] 邓才玉,邱立青,王振东,等. HFETR堆芯及φ63辐照孔道γ释热研究[J]. 核动力工程,2007, 28(6): 97-100. [3] 刘洋,张亮,杨文华. HFETR材料高温辐照试验温度控制技术研究[J]. 核动力工程,2016, 37(S1): 23-25. [4] REMPE J L, MEYER M K, KNUDSON D L, et al. ATR NSUF instrumentation enhancement efforts[J]. Nuclear Technology, 2011, 173: 66-77. doi: 10.13182/NT11-A11485 [5] NARUI M, KURISHITA H, KAYANO H, et al. Development of controlled temperature-cycle irradiation technique in JMTR[J]. Journal of Nuclear Materials, 1994, 212-215: 1665-1670. doi: 10.1016/0022-3115(94)91110-X [6] HOWARD R H, MCDUFFEE J L, KATOH Y. Graphite compressive creep capsule design for irradiation in the HFIR[C]//2013 ANS Annual Meeting. Atlanta: WFO, 2013: 108. [7] BYUN T S, LI M M, SNEAD L L, et al. Principles and practice of a bellows-loaded compact irradiation vehicle[J]. Journal of Nuclear Materials, 2013, 439(1-3): 108-116. doi: 10.1016/j.jnucmat.2013.03.096 [8] KOHSE G E, R G B, HEZJLAR P, et al. Demonstration of a high temperature irradiation capability in the MITR-II research reactor[J].Transactions of the American Nuclear Society, 2006, 95(12/16): 420-421. [9] 孙胜,杨文华,童明炎,等. HFETR高注量率区辐照装置研制与应用[J]. 核动力工程,2016, 37(3): 99-102. [10] 聂良兵,杨文华,童明炎,等. 独立温度补偿型高温材料辐照考验装置设计研究[J]. 核动力工程,2017, 38(S1): 160-163. -

下载:

下载: