Experimental Study on the Influence of Thermal Parameter Deviation on Steady-state Characteristic of Once-through Steam Generator

-

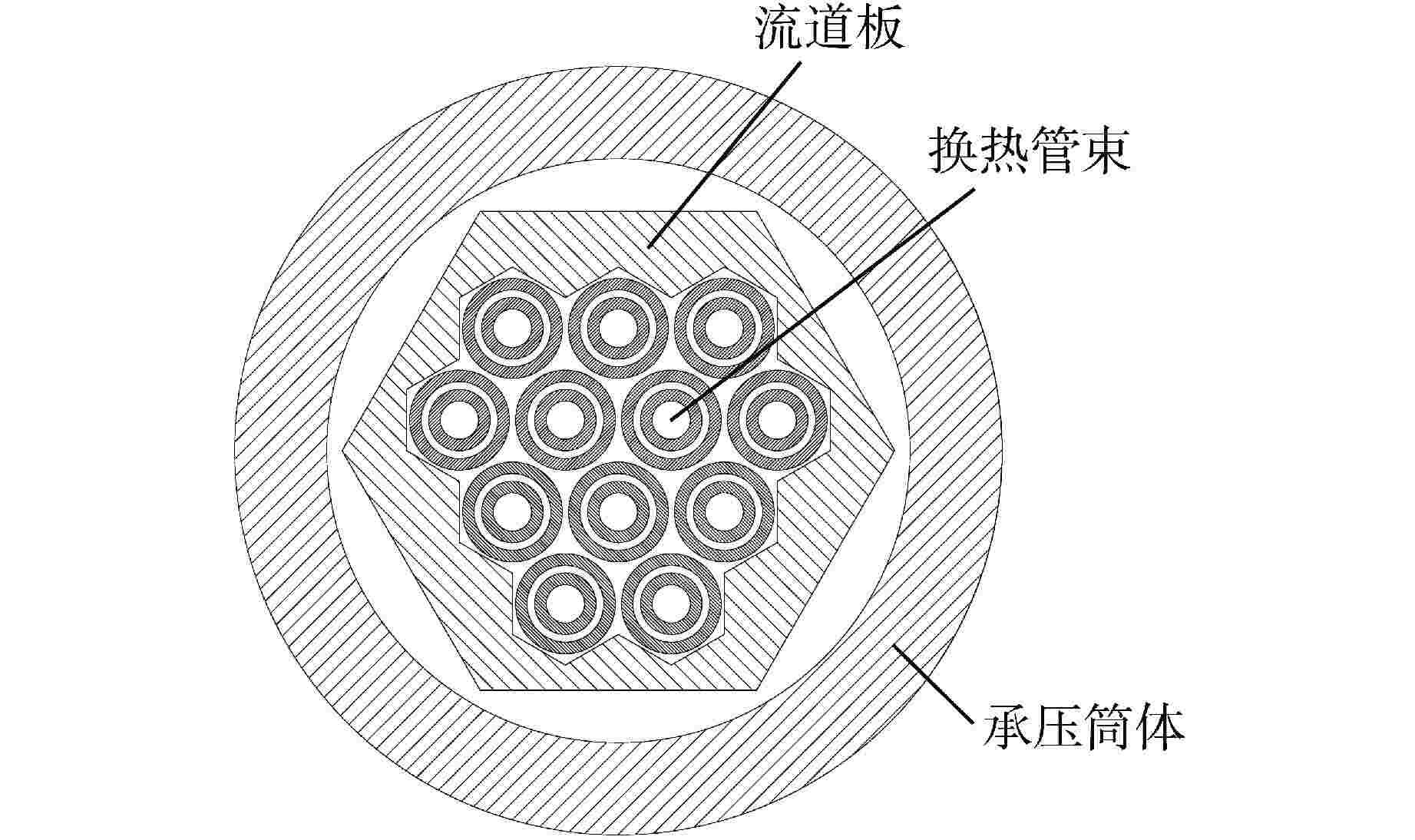

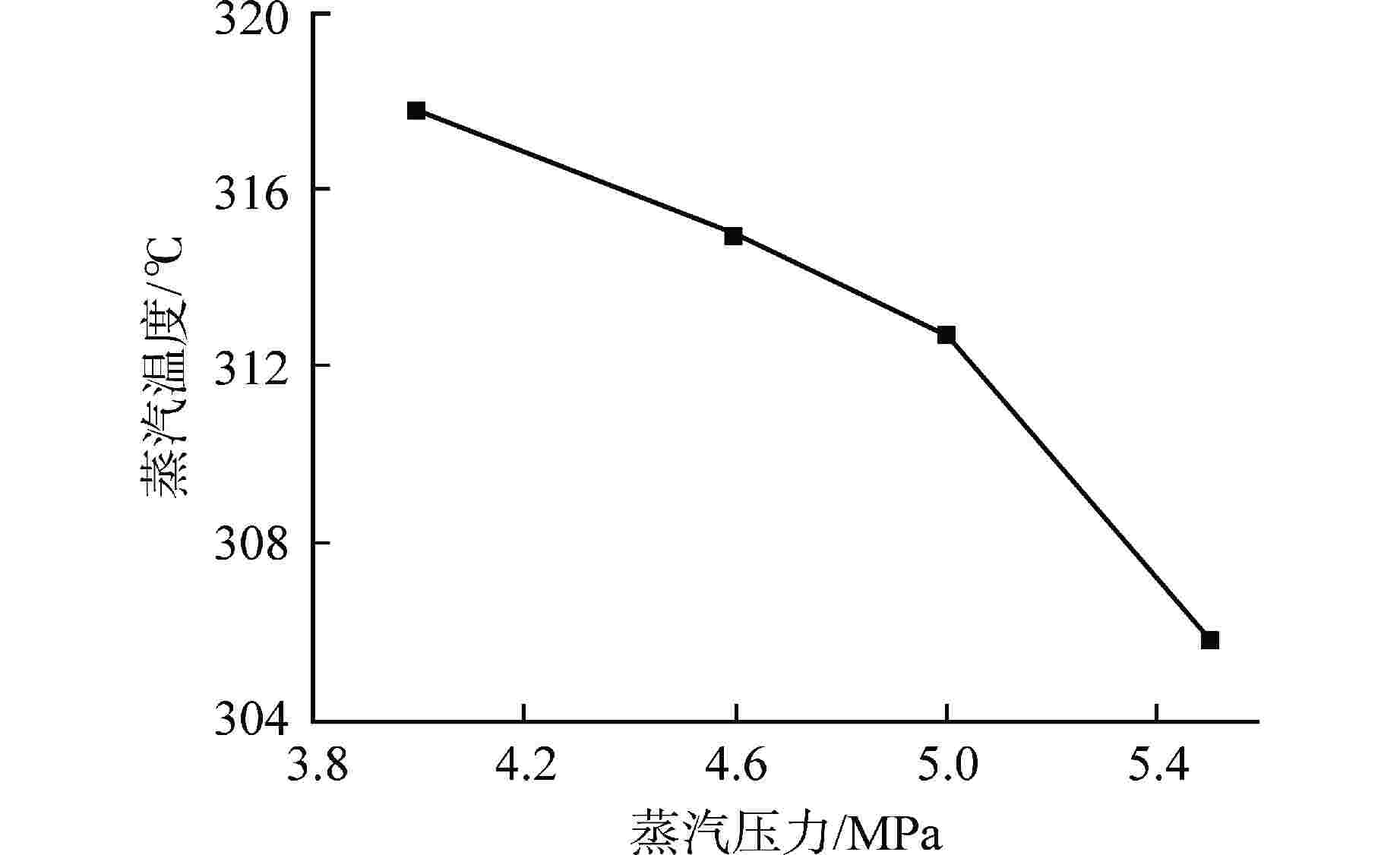

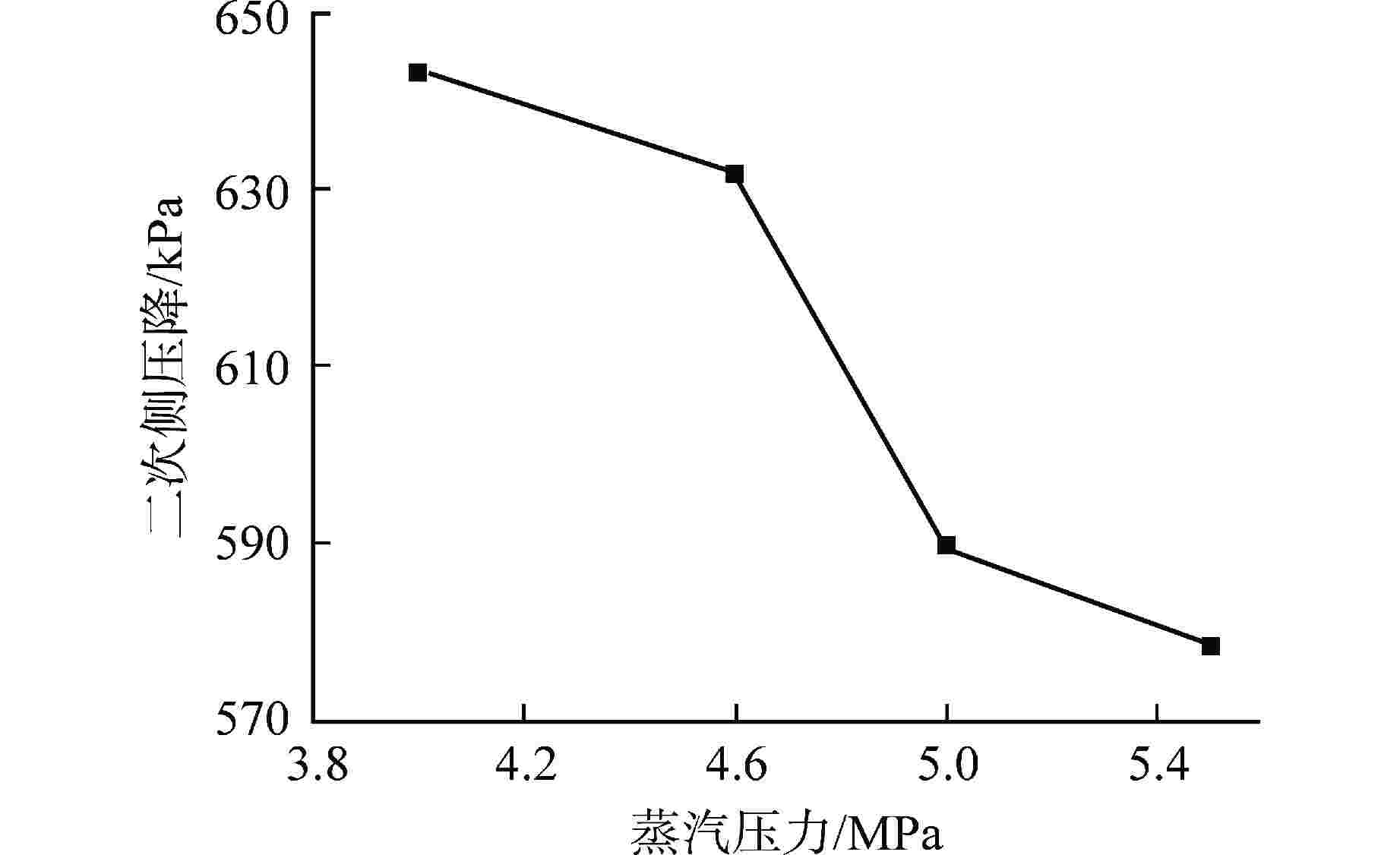

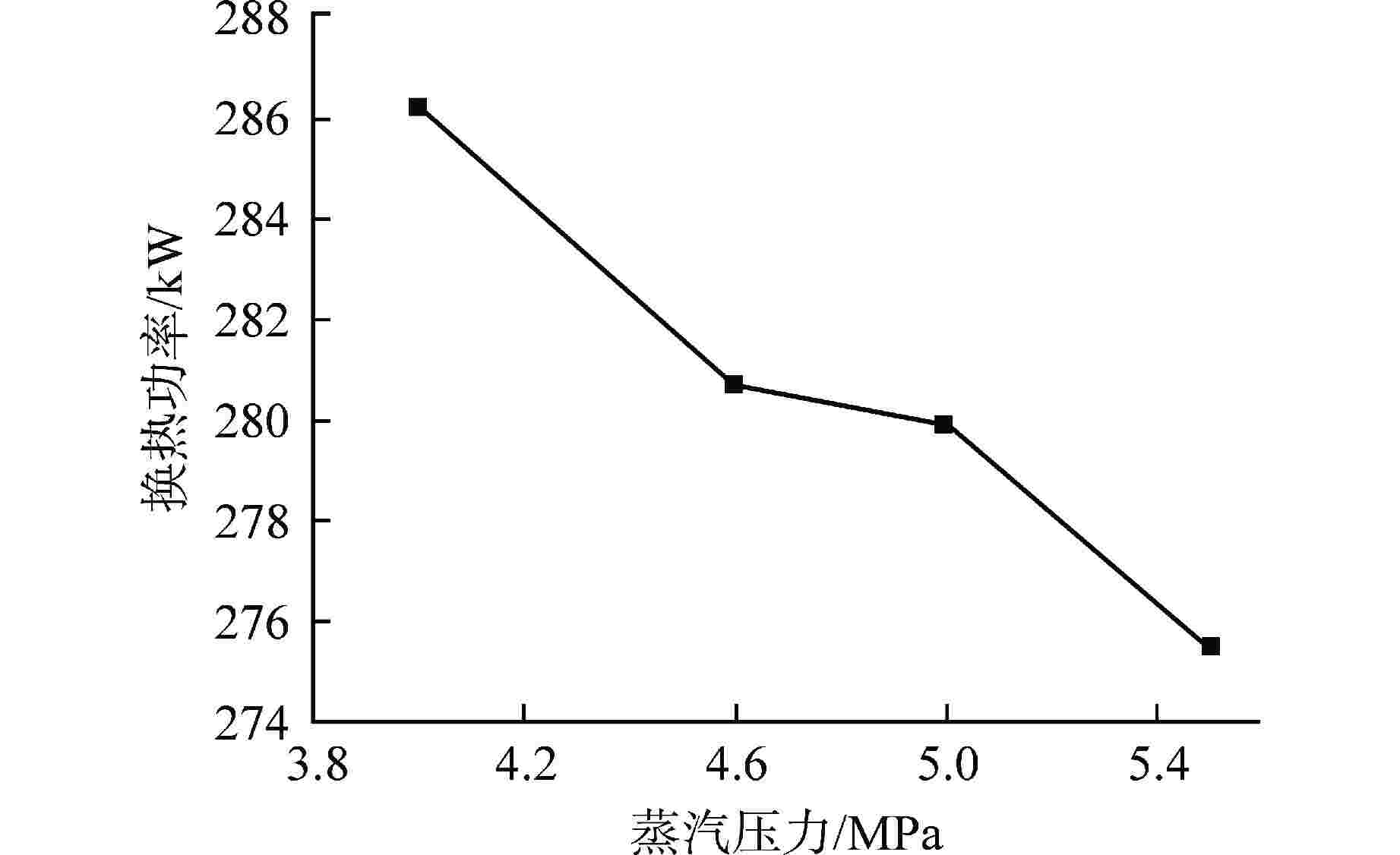

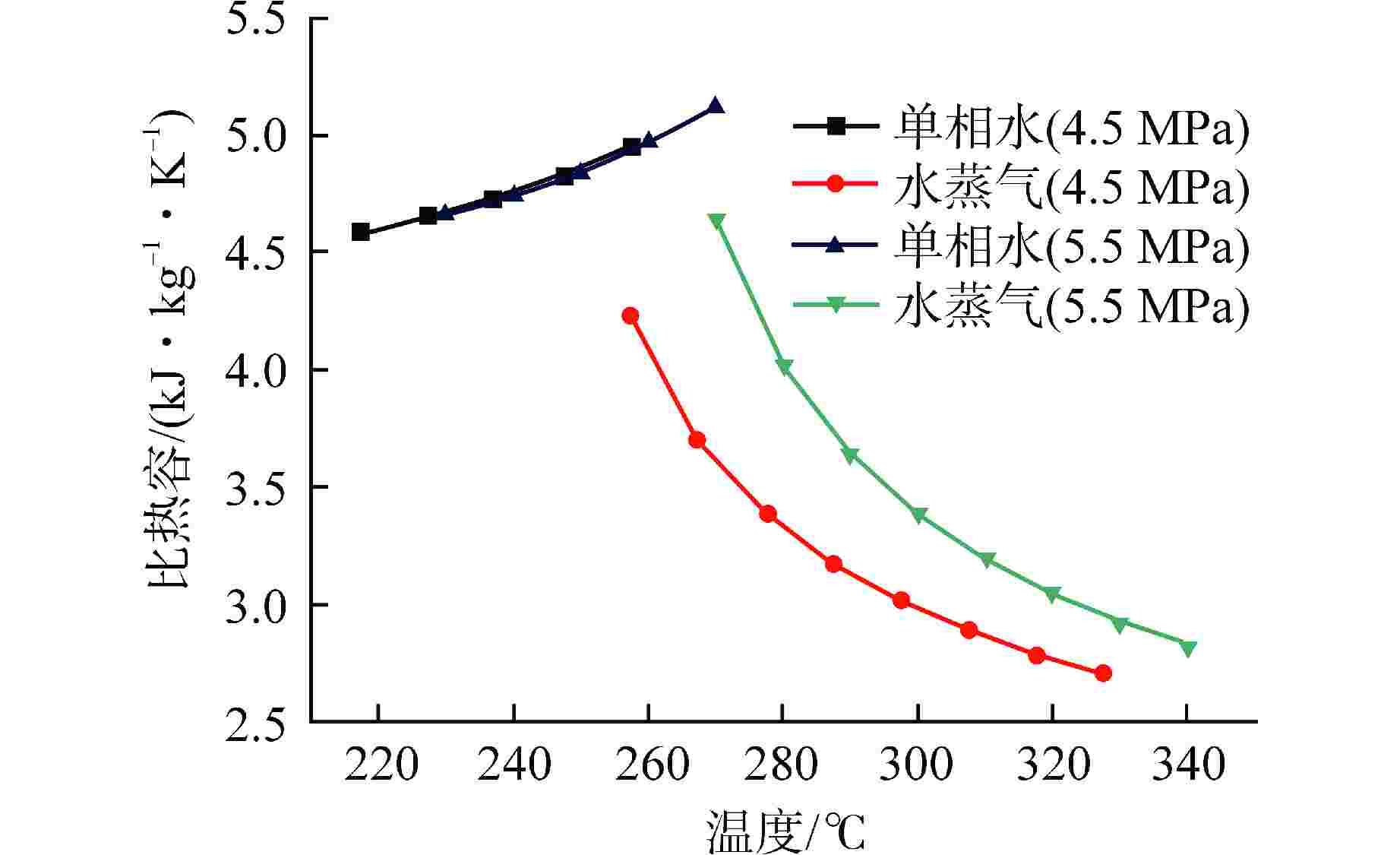

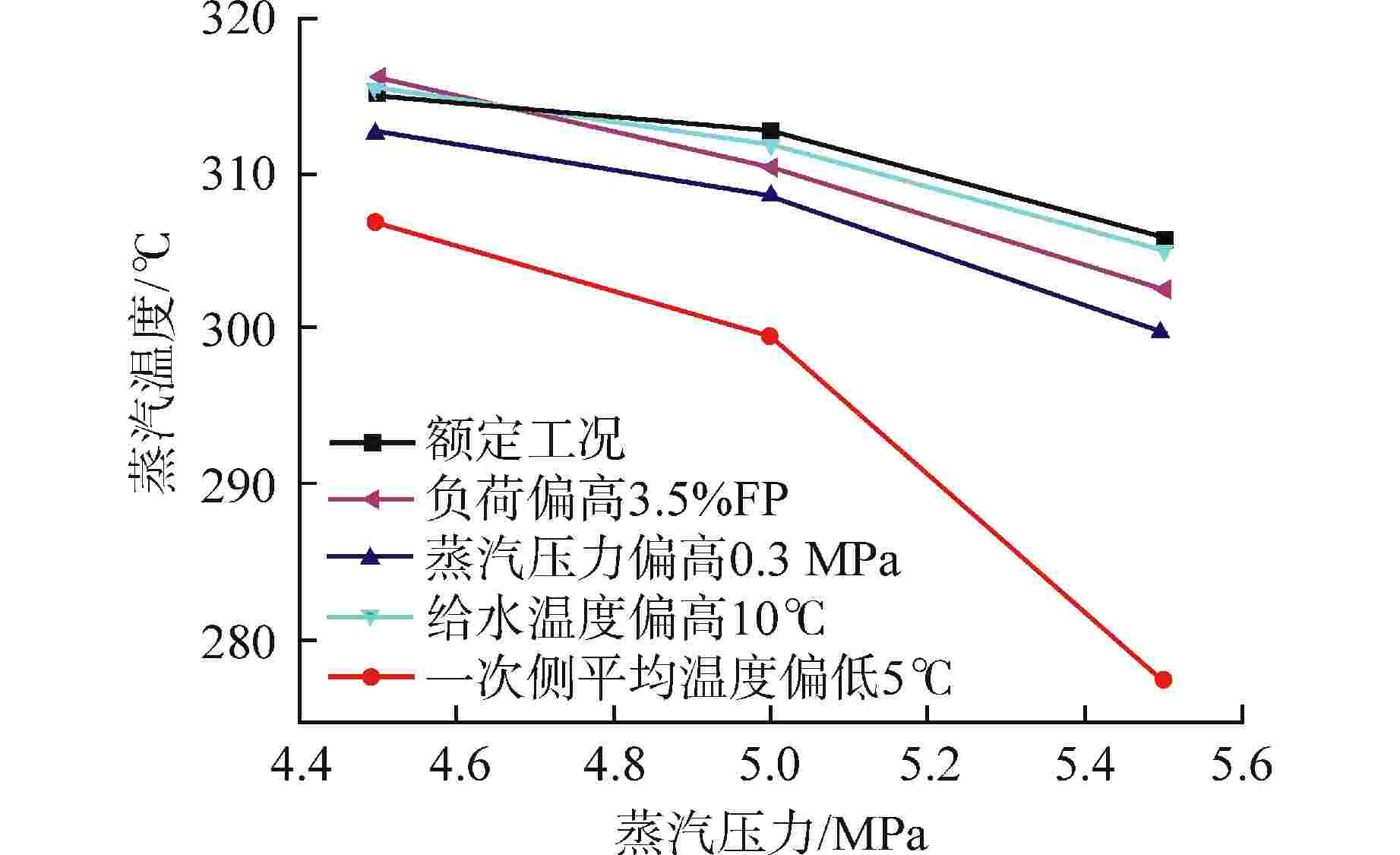

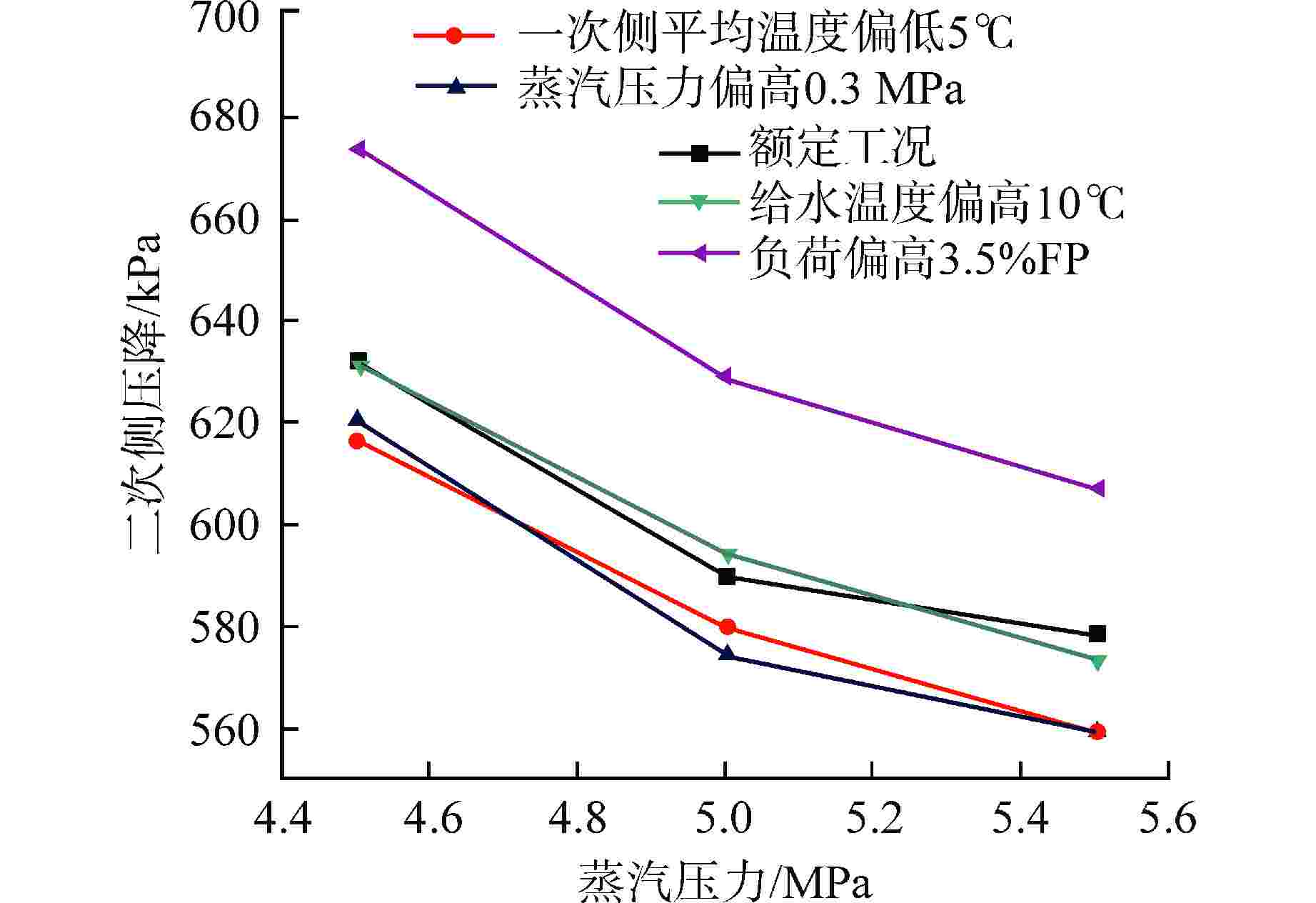

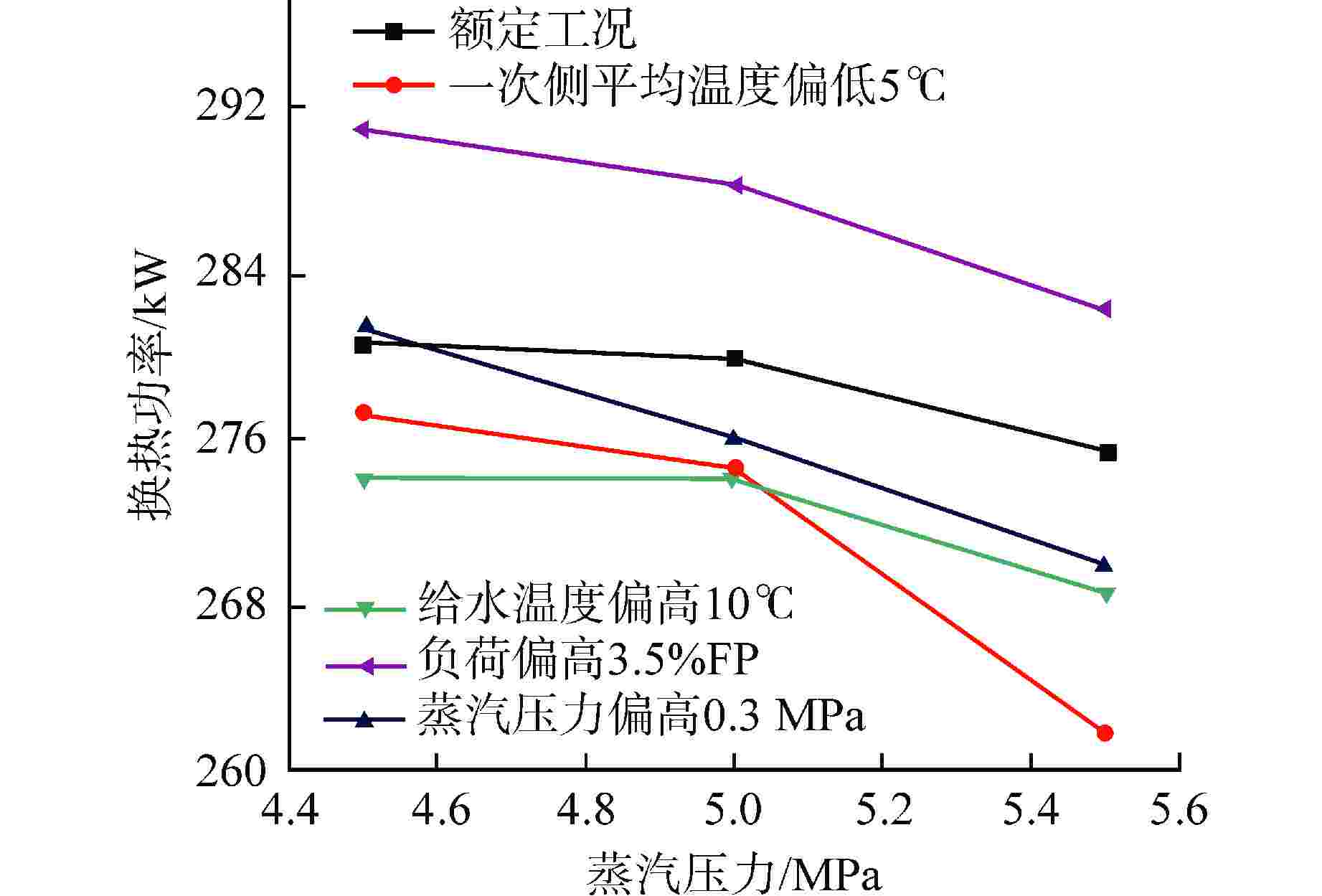

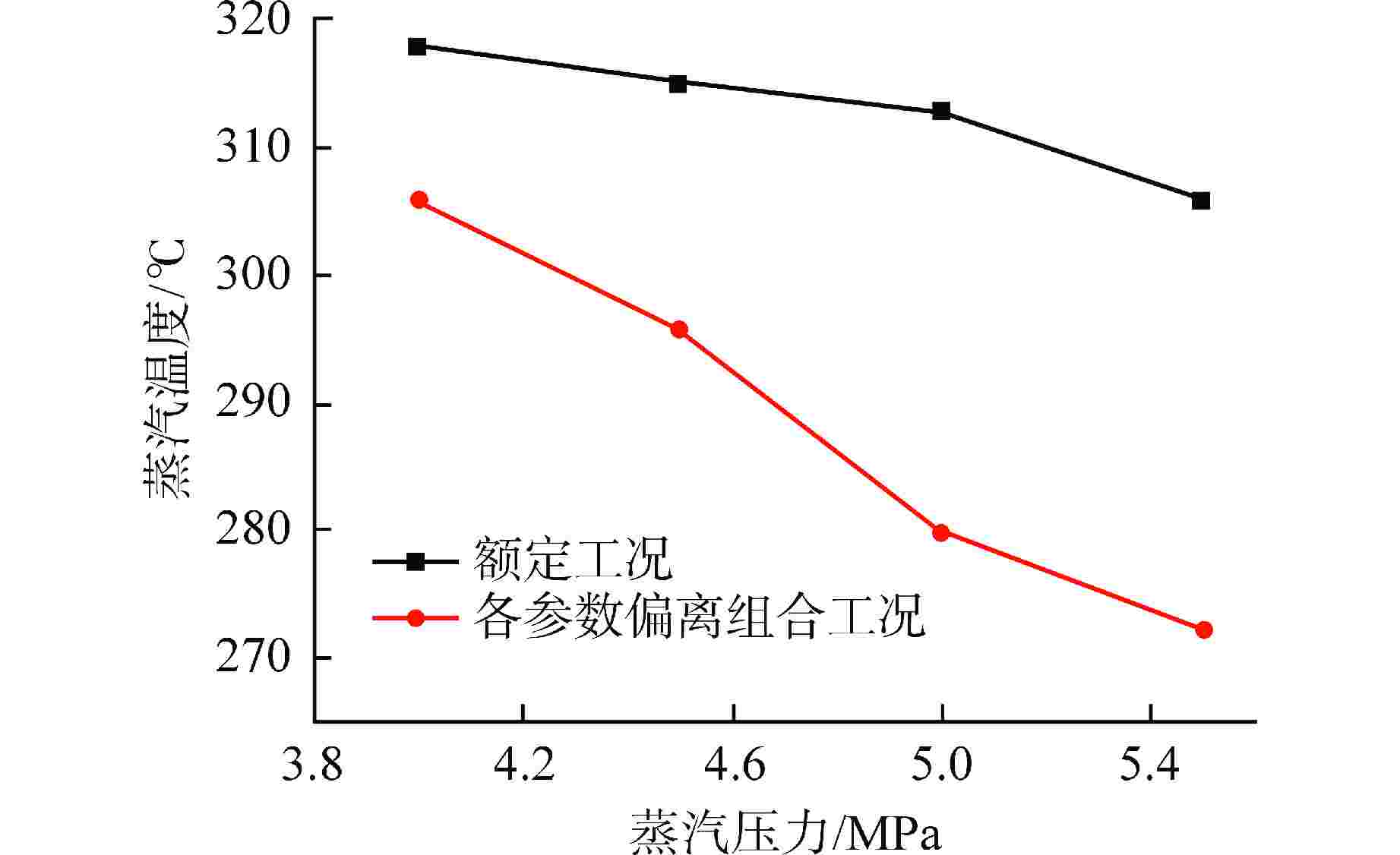

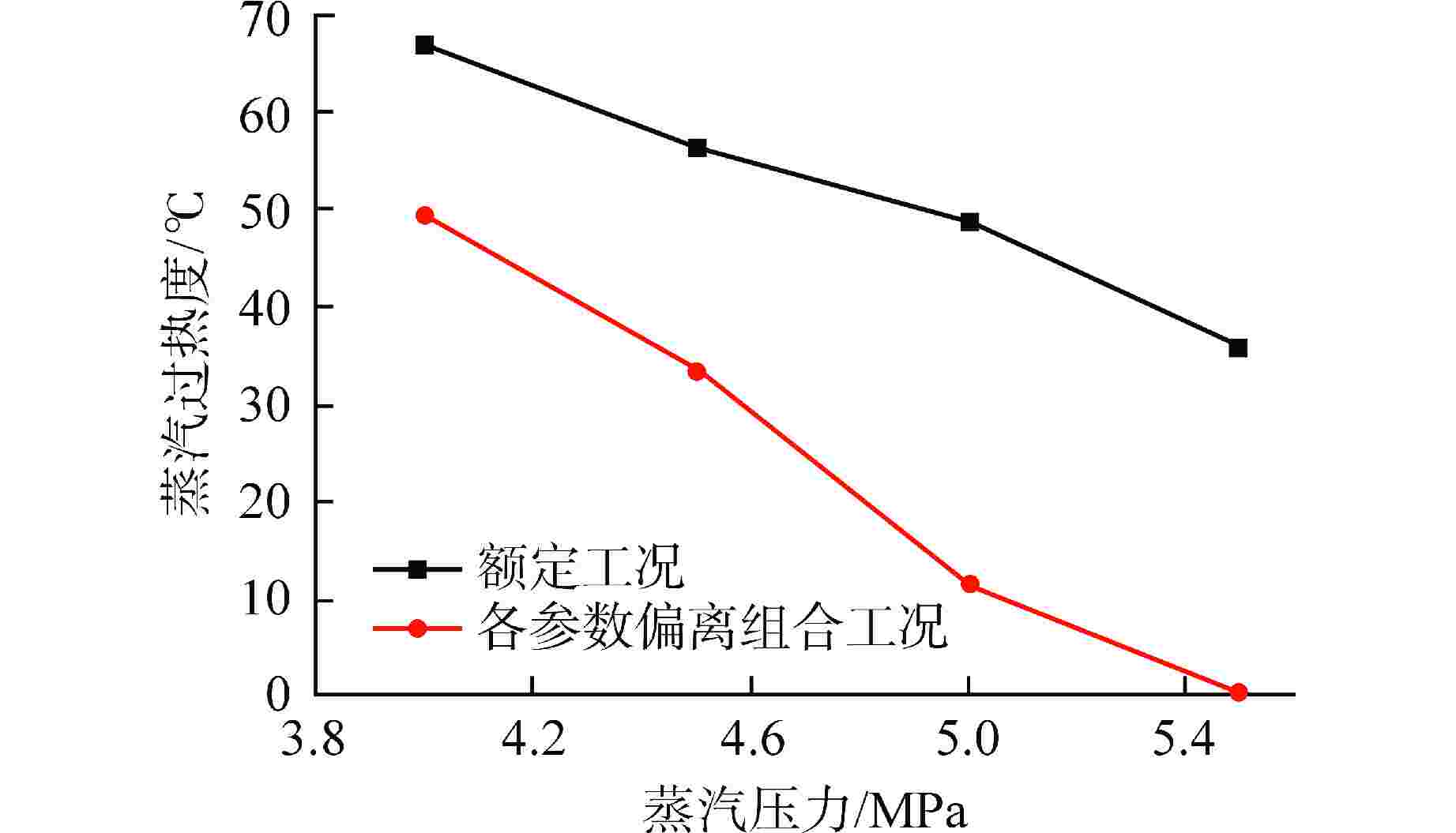

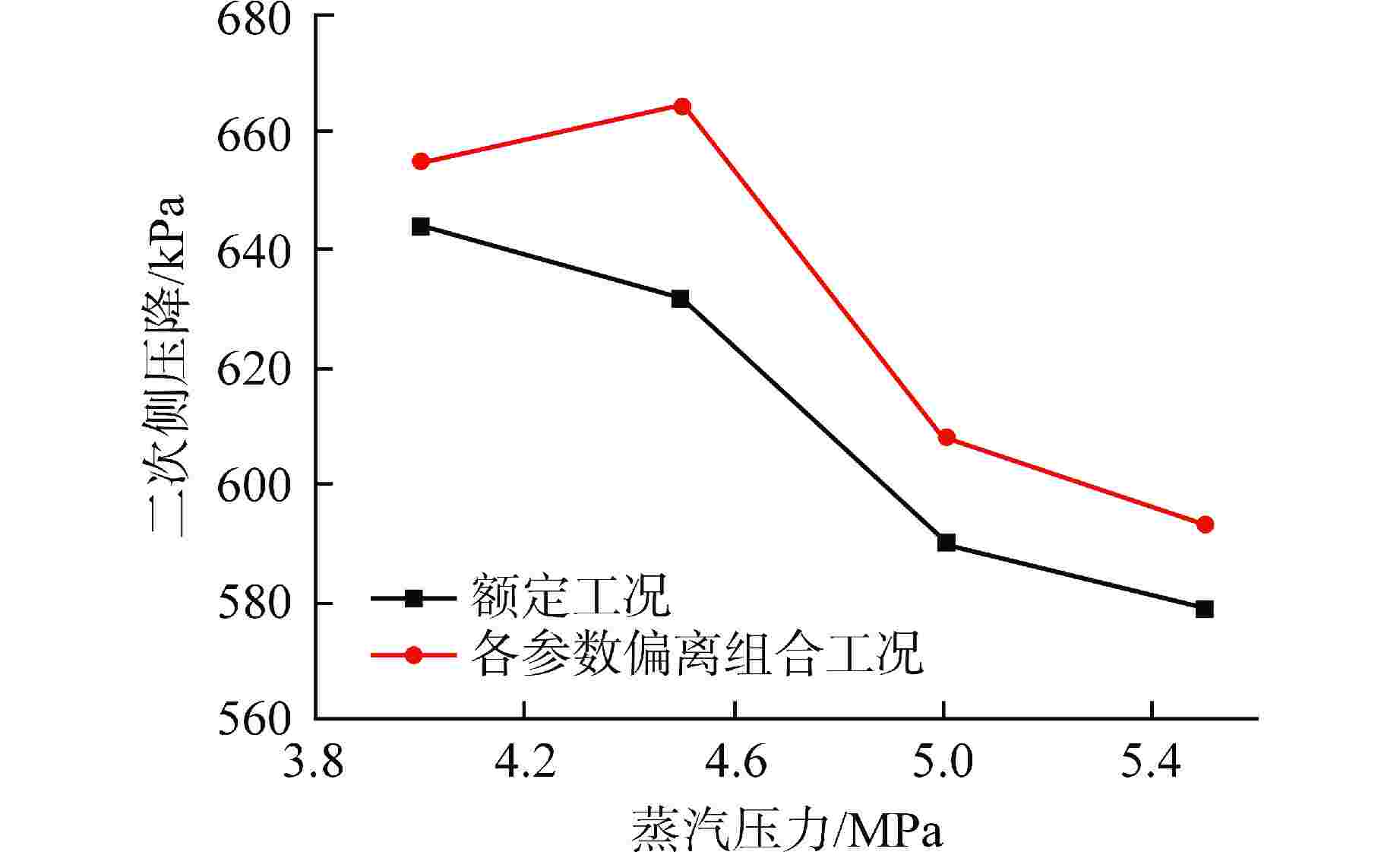

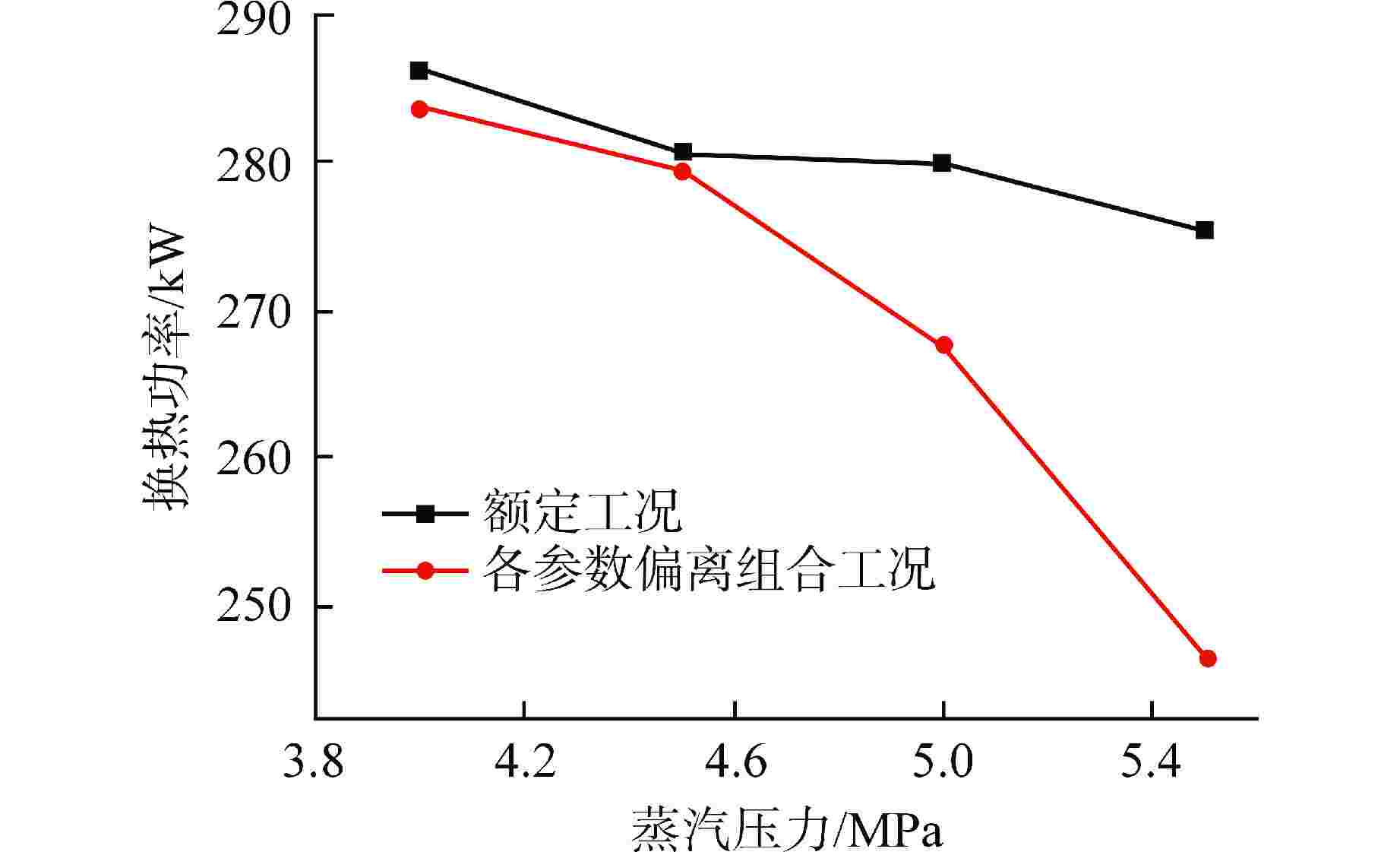

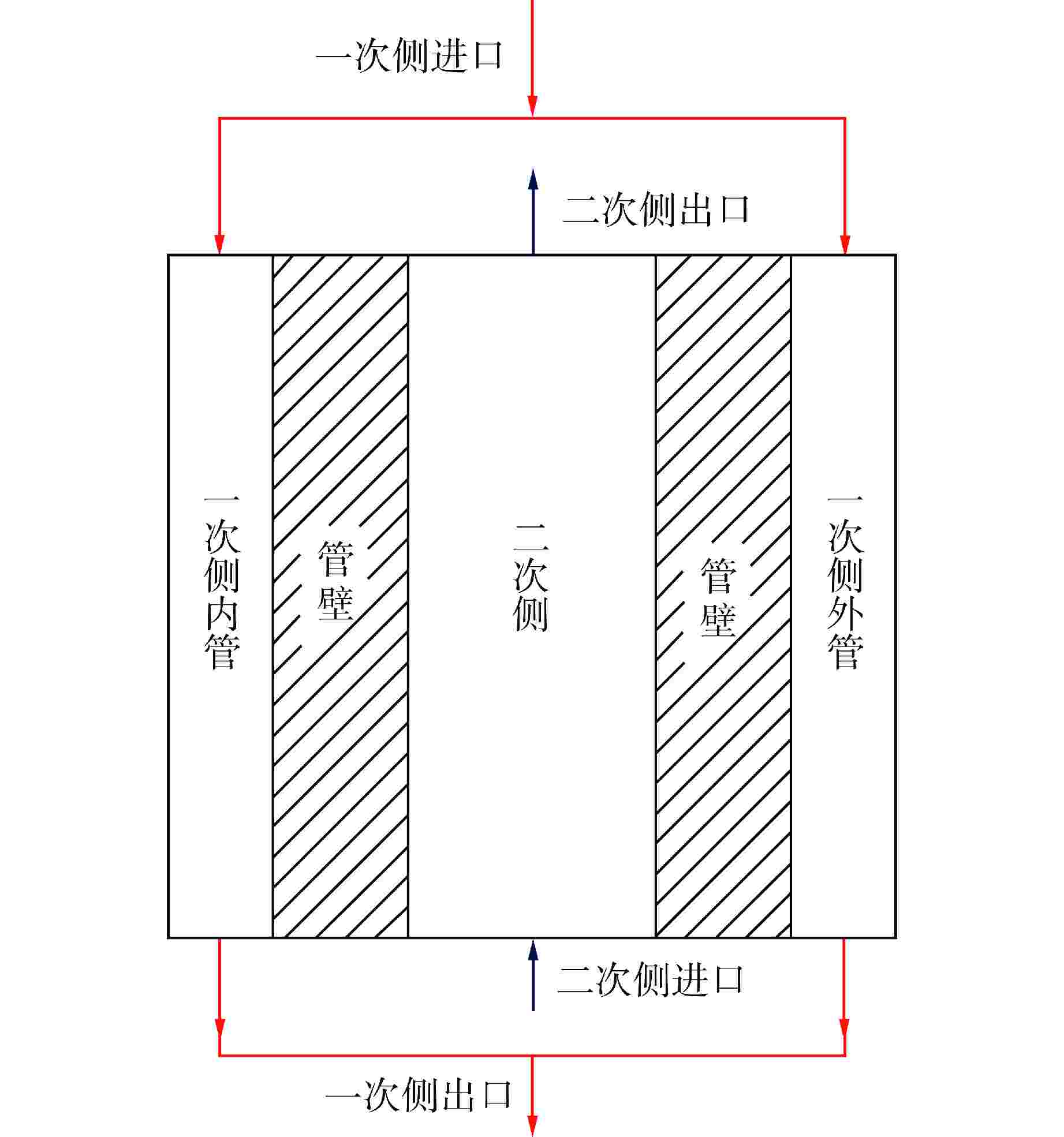

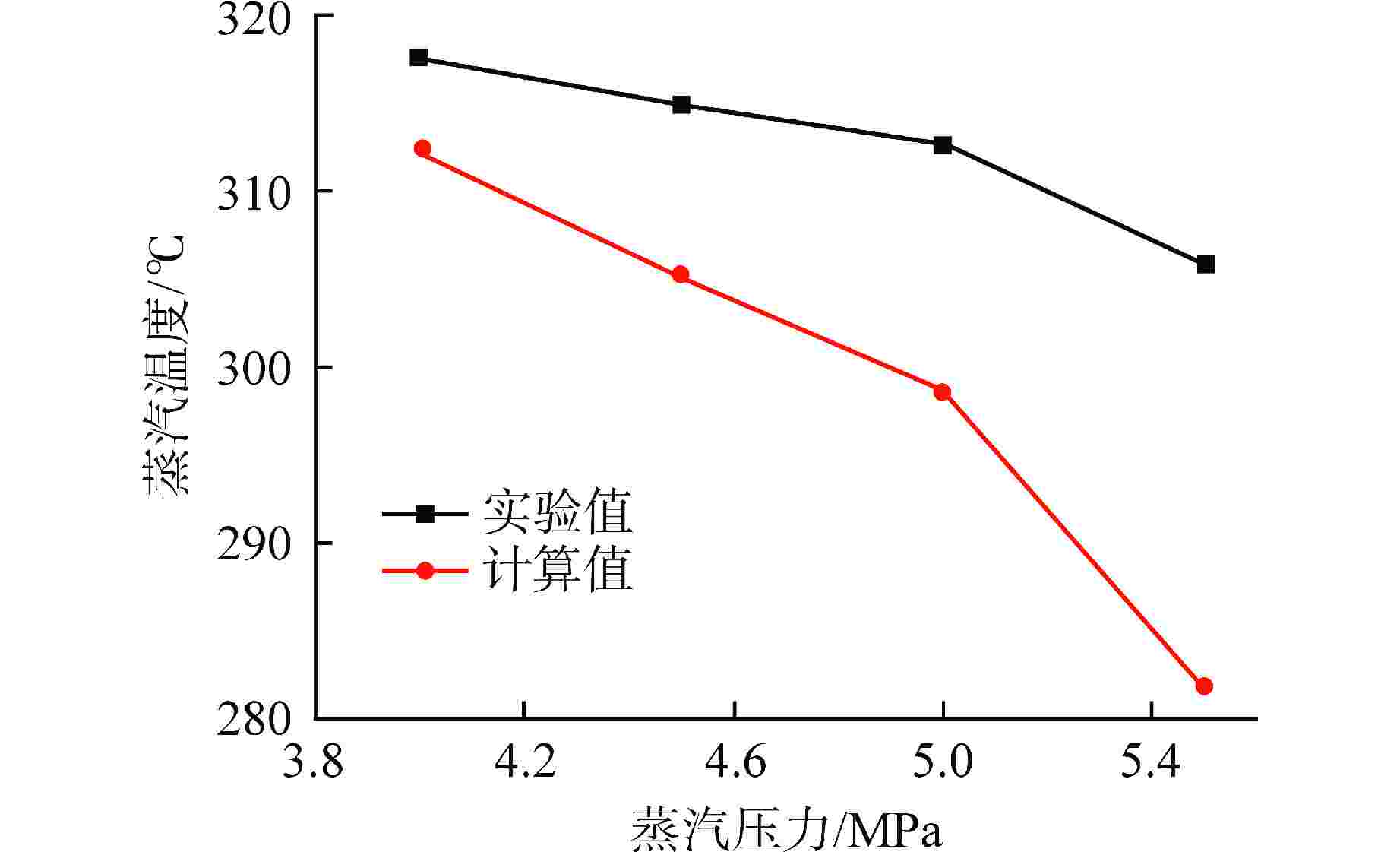

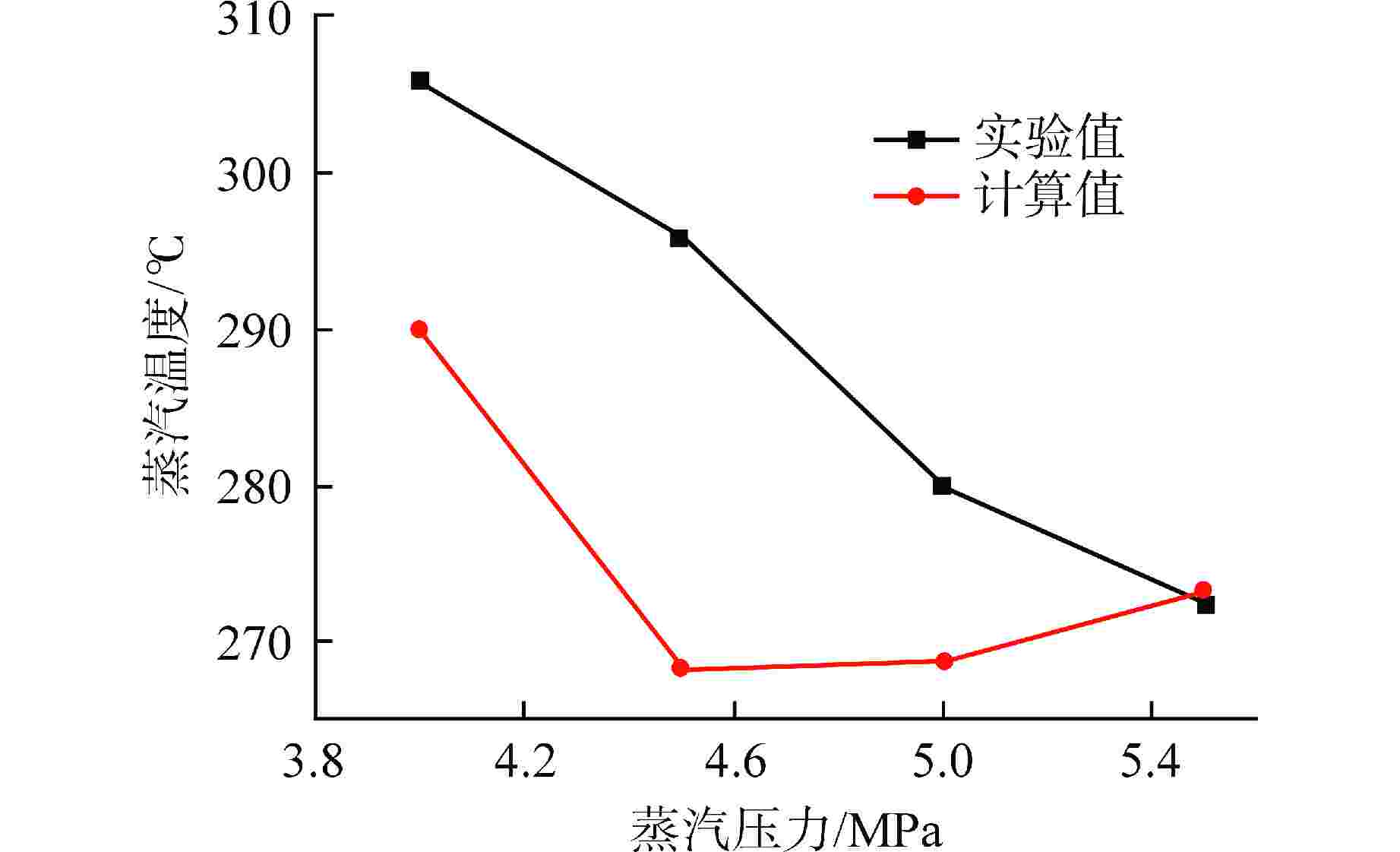

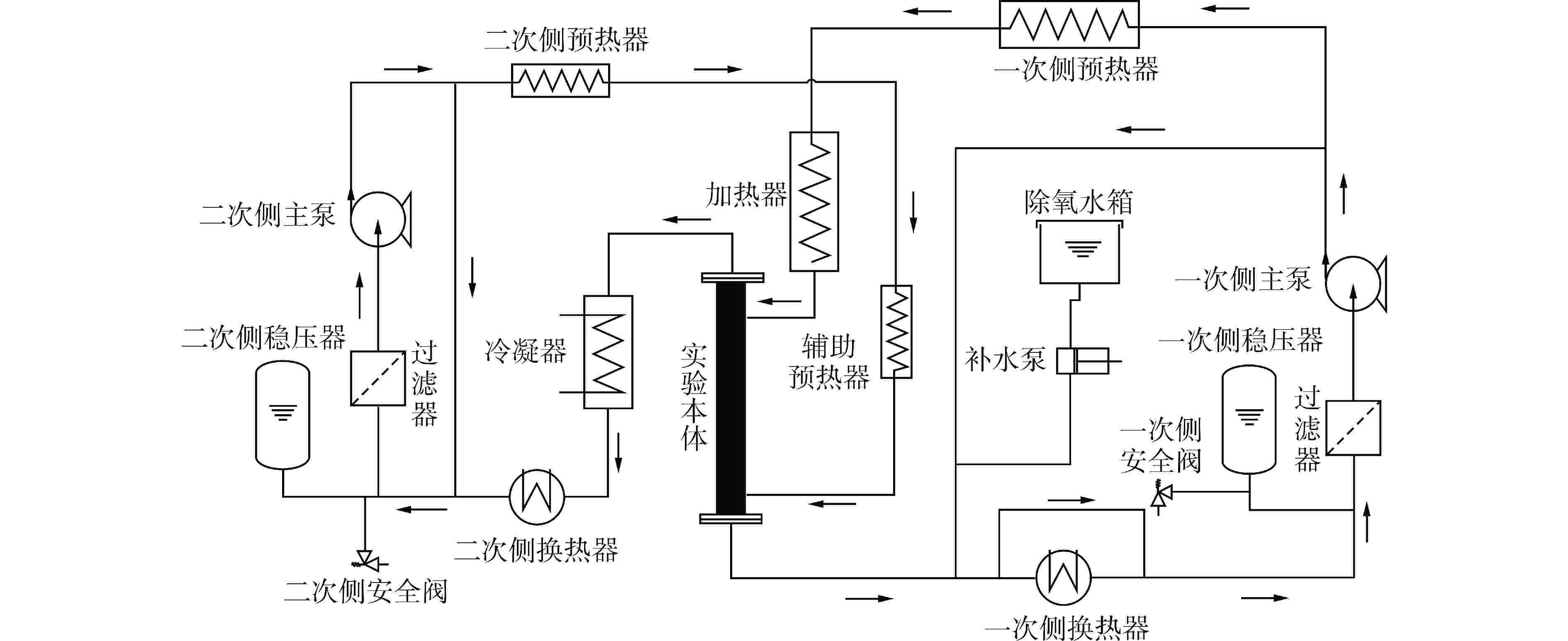

摘要: 为研究额定工况条件下直流蒸汽发生器各热工参数(一次侧平均温度、给水温度、负荷和蒸汽压力)发生设计偏离对其稳态特性的影响,开展了针对直流蒸汽发生器原型设计典型栅元的热工水力实验。实验工况范围:一次侧平均温度297~304℃,负荷100%FP~104%FP(FP表示满功率),蒸汽压力4.0~5.8 MPa,给水温度138~152℃。实验结果表明,各热工参数偏离主要影响蒸汽发生器出口蒸汽温度、换热功率和二次侧压降;一次侧平均温度发生设计偏离对蒸汽温度的影响最大;在各热工参数同时发生设计偏离条件下,出口蒸汽温度随蒸汽压力增加而减小。Abstract: In order to study the influence of design deviation of thermal parameters (average temperature of primary side, feed water temperature, load and steam pressure) on the steady-state characteristics of once-through steam generator (OTSG) under rated conditions, the thermal-hydraulic experiment of typical cells for prototype design of OTSG is carried out. The experimental conditions are as follows: the average temperature of primary side is 297-304℃, the load is 100%FP-104%FP (full power), the steam pressure is 4.0-5.8 MPa, and the feed water temperature is 138-152℃. The experimental results show that the deviation of thermal parameters mainly affects the outlet steam temperature, heat transfer power and secondary side pressure drop of OTSG. The design deviation of the average temperature of primary side has the greatest influence on the steam temperature. The outlet steam temperature decreases with the increase of steam pressure under the condition that the design deviation of each thermal parameter occurs at the same time.

-

表 1 额定工况实验参数

Table 1. Experimental Parameters of Rated Condition

参数 数值 一次侧压力/MPa 15.0 一次侧流量(单根管)/(kg·h−1) 426.1 一次侧平均温度/℃ 303 蒸汽压力/MPa 4.0、4.5、5.0、5.5 给水温度/℃ 140 负荷/%FP 100 表 2 偏离工况实验参数

Table 2. Experimental Parameters of Deviation Condition

参数名 设计偏离值 偏离后数值 一次侧压力/MPa 15.0 一次侧流量(单根管)/(kg·h−1) 426.1 一次侧平均温度/℃ −5 298 蒸汽压力/MPa +0.3 4.3、4.8、5.3、5.8 给水温度/℃ +10 150 负荷/%FP 3.5 103.5 -

[1] 宋丹戎,李庆,秦冬,等. “玲龙一号”反应堆研发关键技术——堆芯设计与安全设计[J]. 核动力工程,2021, 42(4): 1-5. [2] 孙中宁,阎昌琪,谈和平,等. 窄环隙流道强迫对流换热实验研究[J]. 核动力工程,2003, 24(4): 350-353. [3] 毛宇飞,朱天宇,曹飞,等. 螺旋管内气液两相流摩擦压降计算方法新探[J]. 工程热物理学报,2016, 37(3): 556-561. [4] 王明路. 螺旋管直流蒸汽发生器管内气液两相流动传热特性研究[D]. 上海: 上海交通大学,2019: 175. [5] 刘茂龙,刘利民,巢孟科,等. 小型压水堆螺旋管式直流蒸汽发生器热工水力特性试验及数值模拟研究[J]. 原子能科学技术,2022, 56(11): 2327-2333. [6] 张廷,杜代全,张文豪,等. 直流蒸汽发生器稳态热工水力实验参数敏感性研究[J]. 原子能科学技术,2022, 56(11): 2365-2374. [7] CHUNG Y J, BAE K H, KIM K K, et al. Boiling heat transfer and dryout in helically coiled tubes under different pressure conditions[J]. Annals of Nuclear Energy, 2014, 71: 298-303. doi: 10.1016/j.anucene.2014.04.015 [8] VINOD V, SIVAKUMAR L S, KUMAR V A S, et al. Experimental evaluation of the heat transfer performance of sodium heated once through steam generator[J]. Nuclear Engineering and Design, 2014, 273: 412-420. doi: 10.1016/j.nucengdes.2014.03.034 [9] HWANG K W, KIM D E, YANG K H, et al. Experimental study of flow boiling heat transfer and dryout characteristics at low mass flux in helically-coiled tubes[J]. Nuclear Engineering and Design, 2014, 273: 529-541. doi: 10.1016/j.nucengdes.2014.03.046 [10] YANG S H, KIM S H, CHUNG Y J, et al. Experimental validation of the helical steam generator model in the TASS/SMR code[J]. Annals of Nuclear Energy, 2008, 35(1): 49-59. doi: 10.1016/j.anucene.2007.06.004 [11] 宋丹戎,刘承敏. 多用途模块式小型核反应堆[M]. 北京: 中国原子能出版社,2021: 365. -

下载:

下载: