Study on Limitation Size of Fretting Wear of Inconel 690 Steam Generator Tube

-

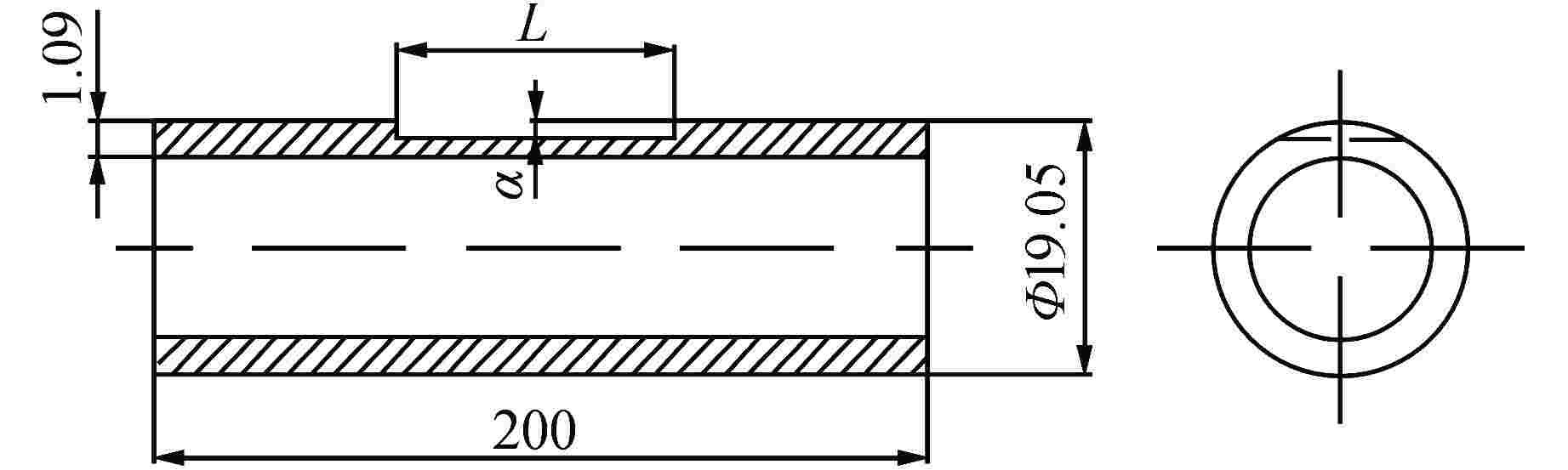

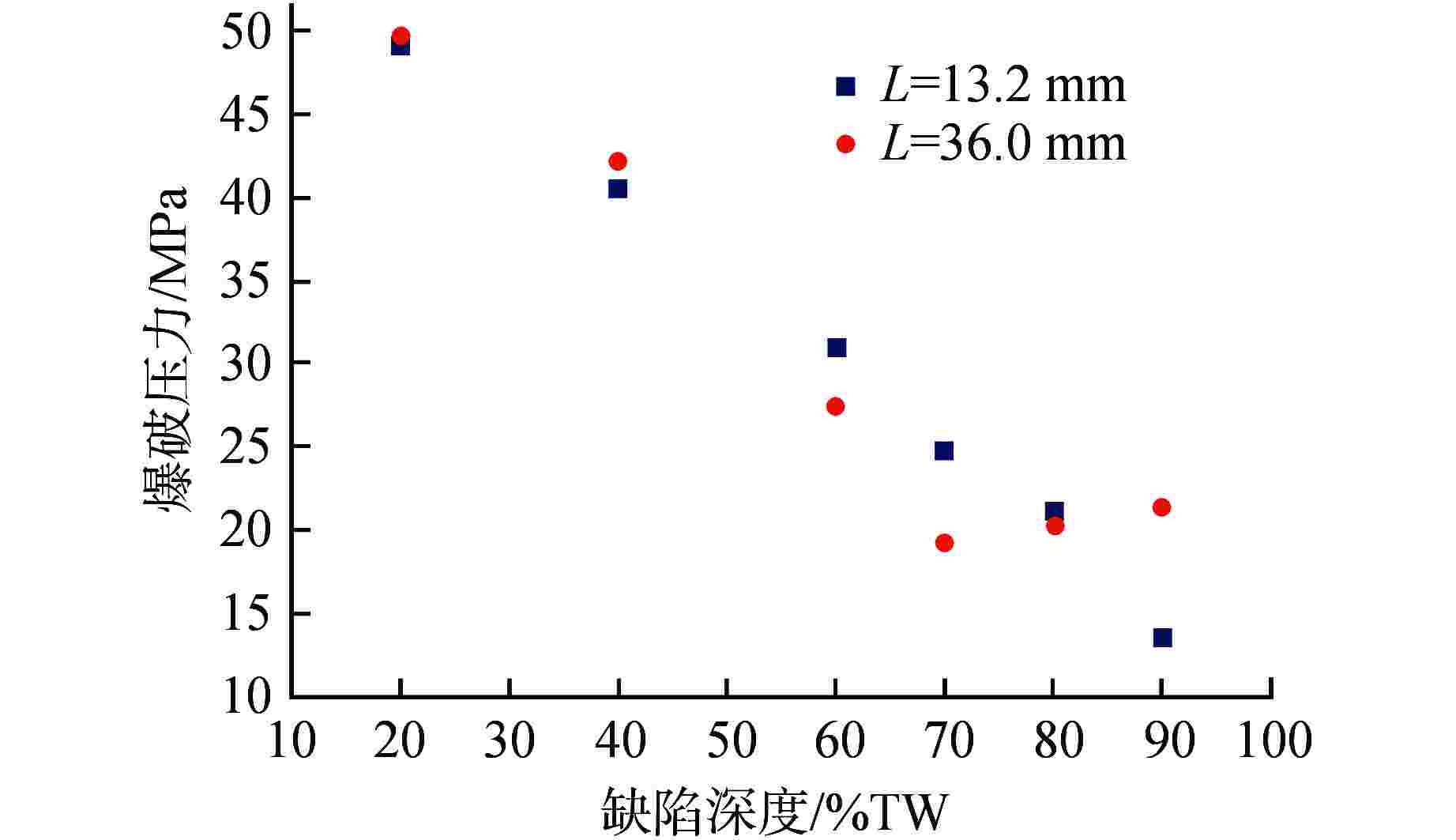

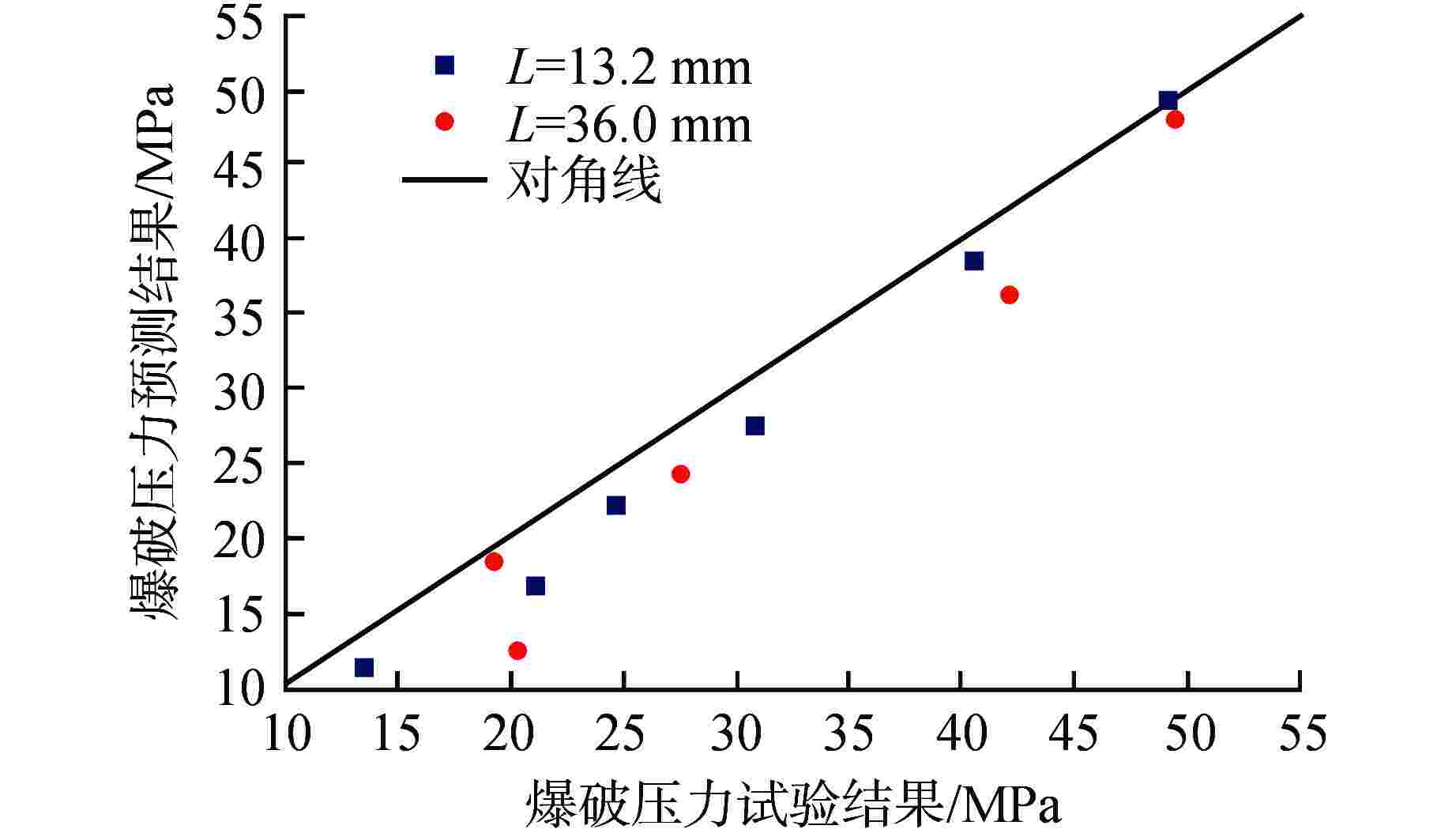

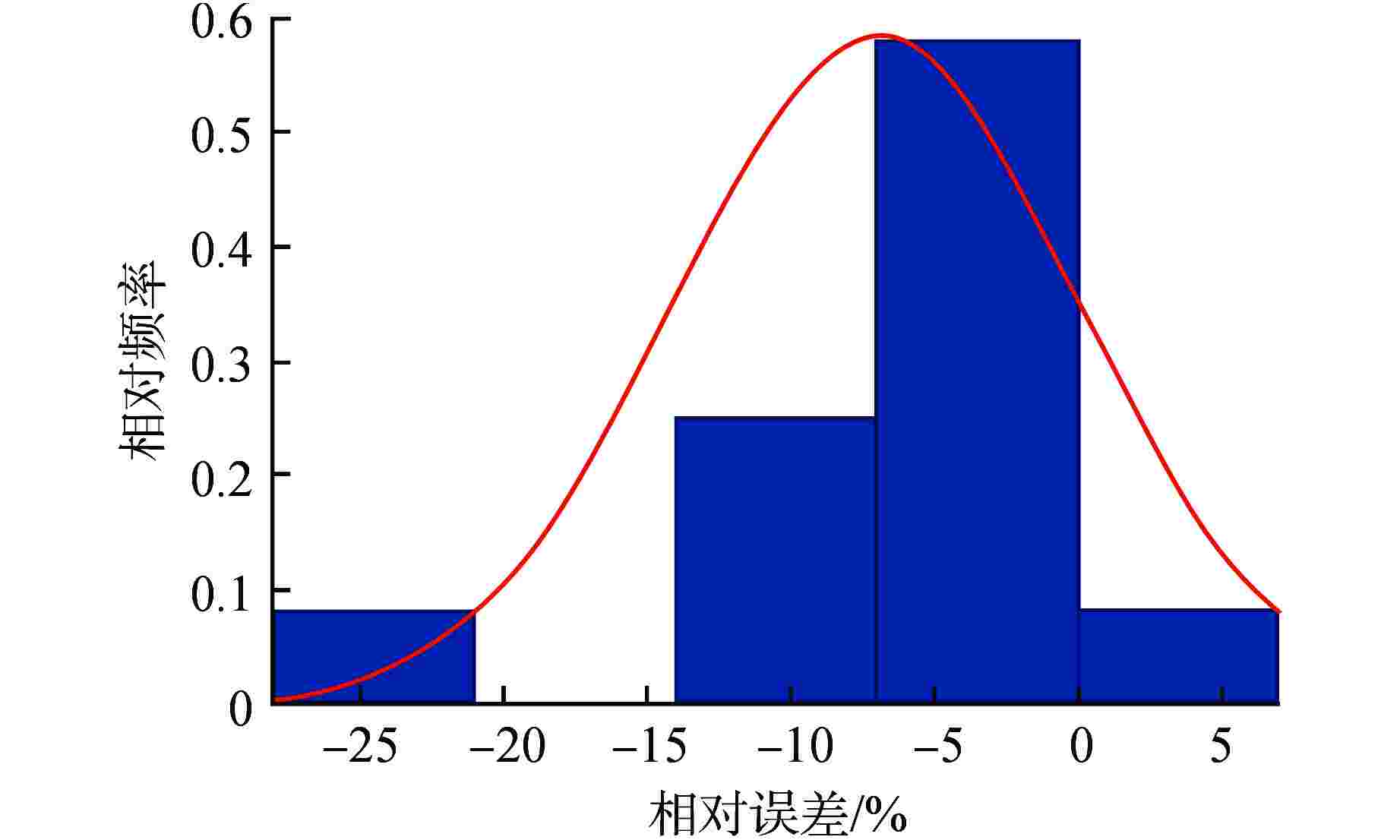

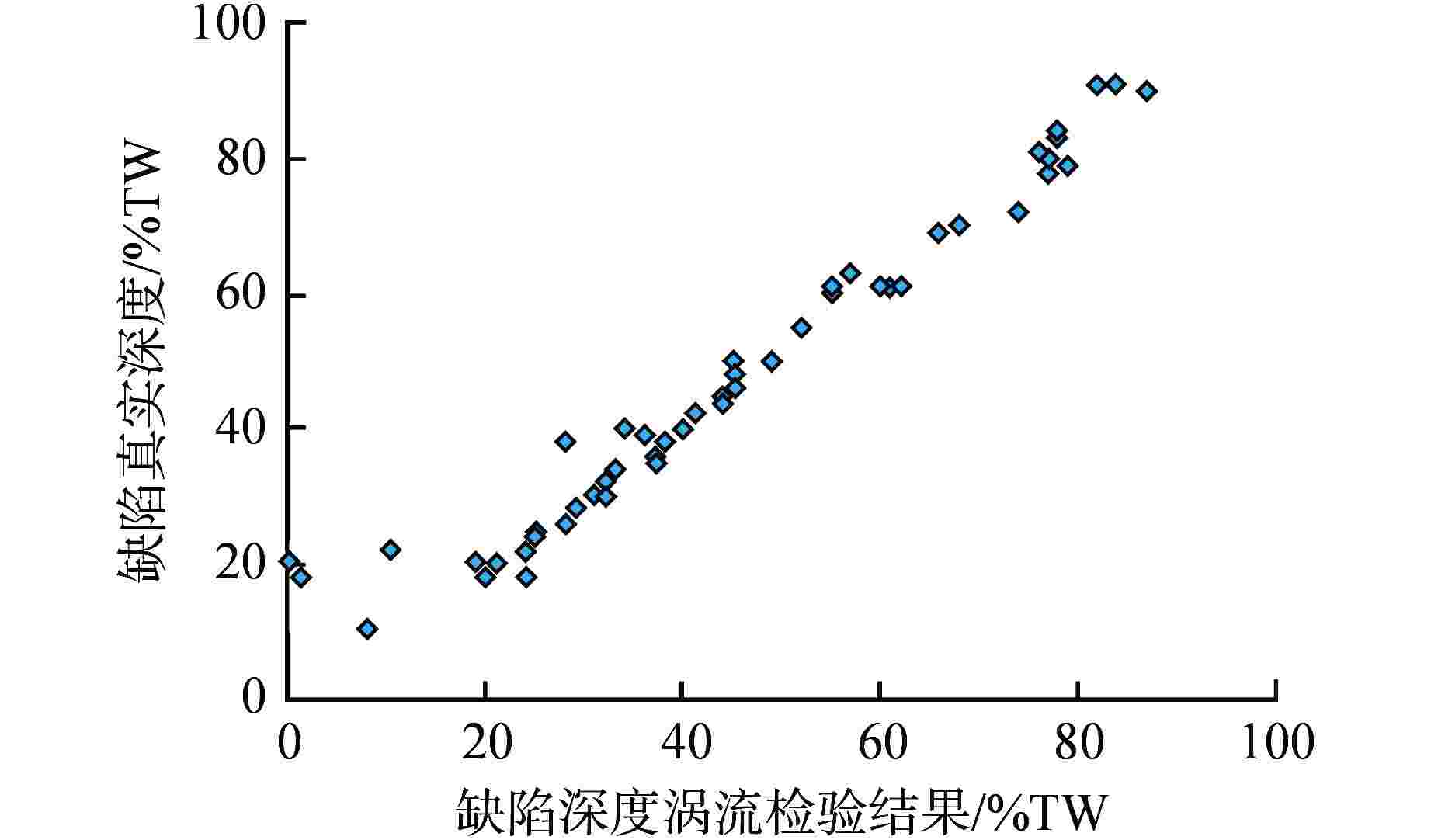

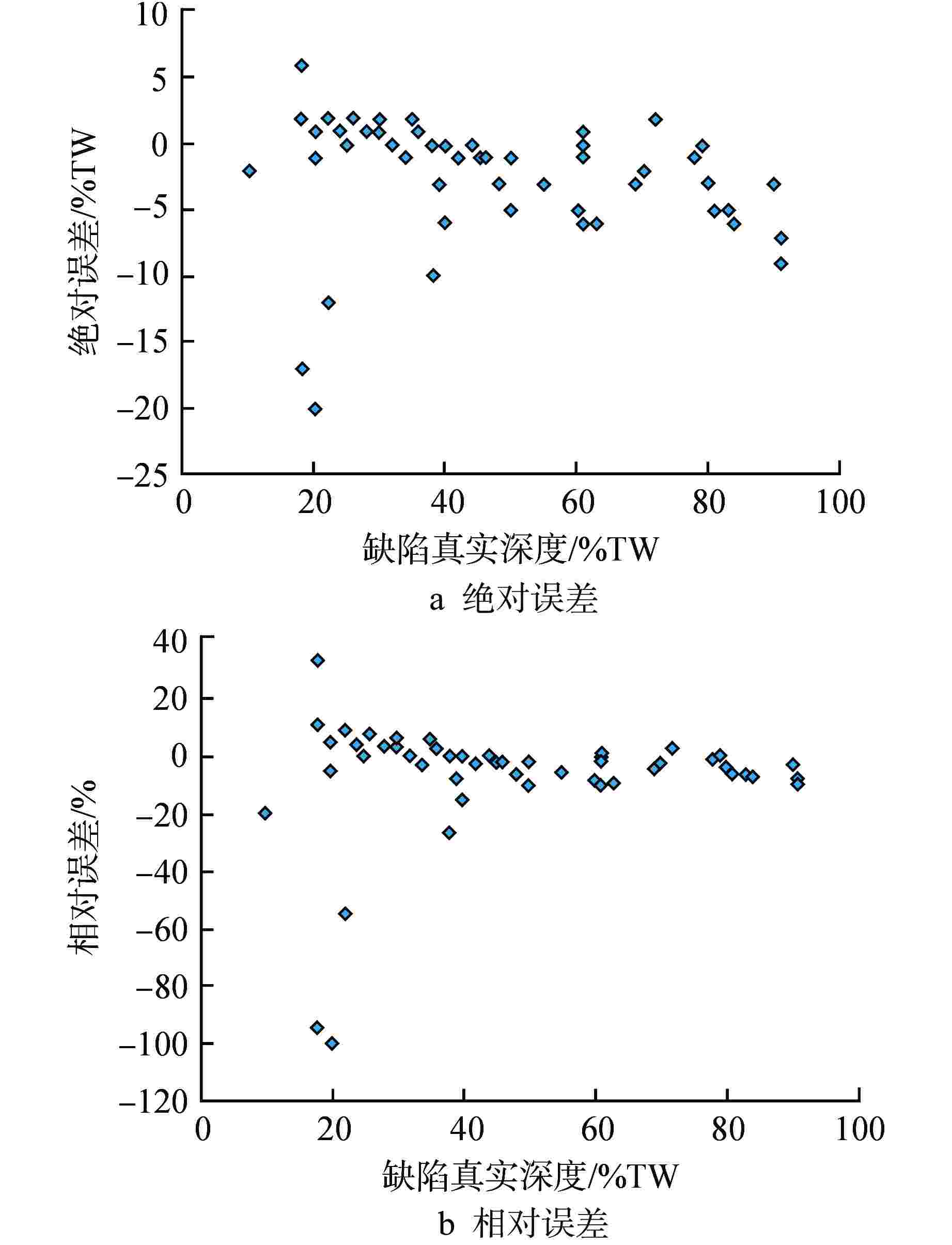

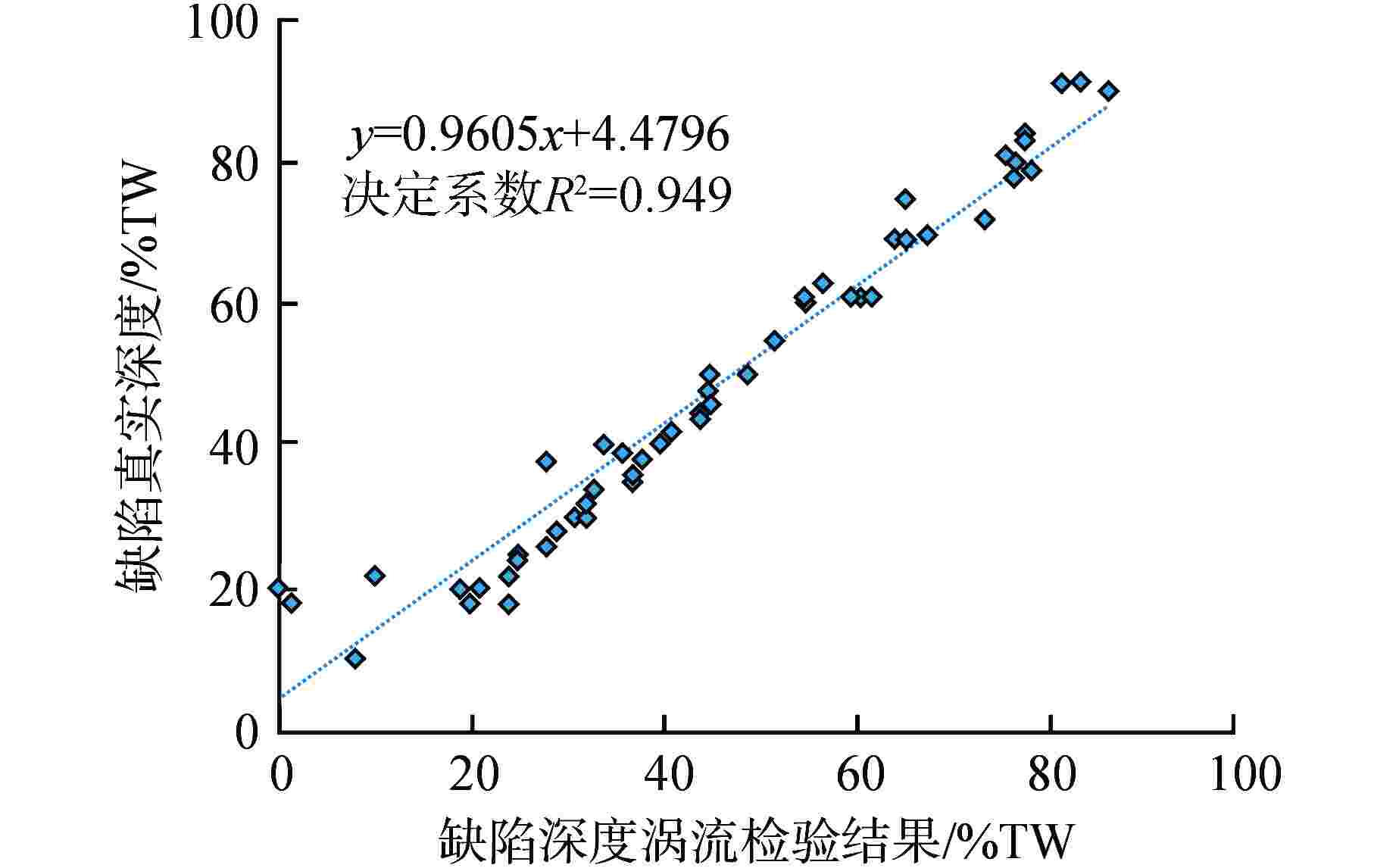

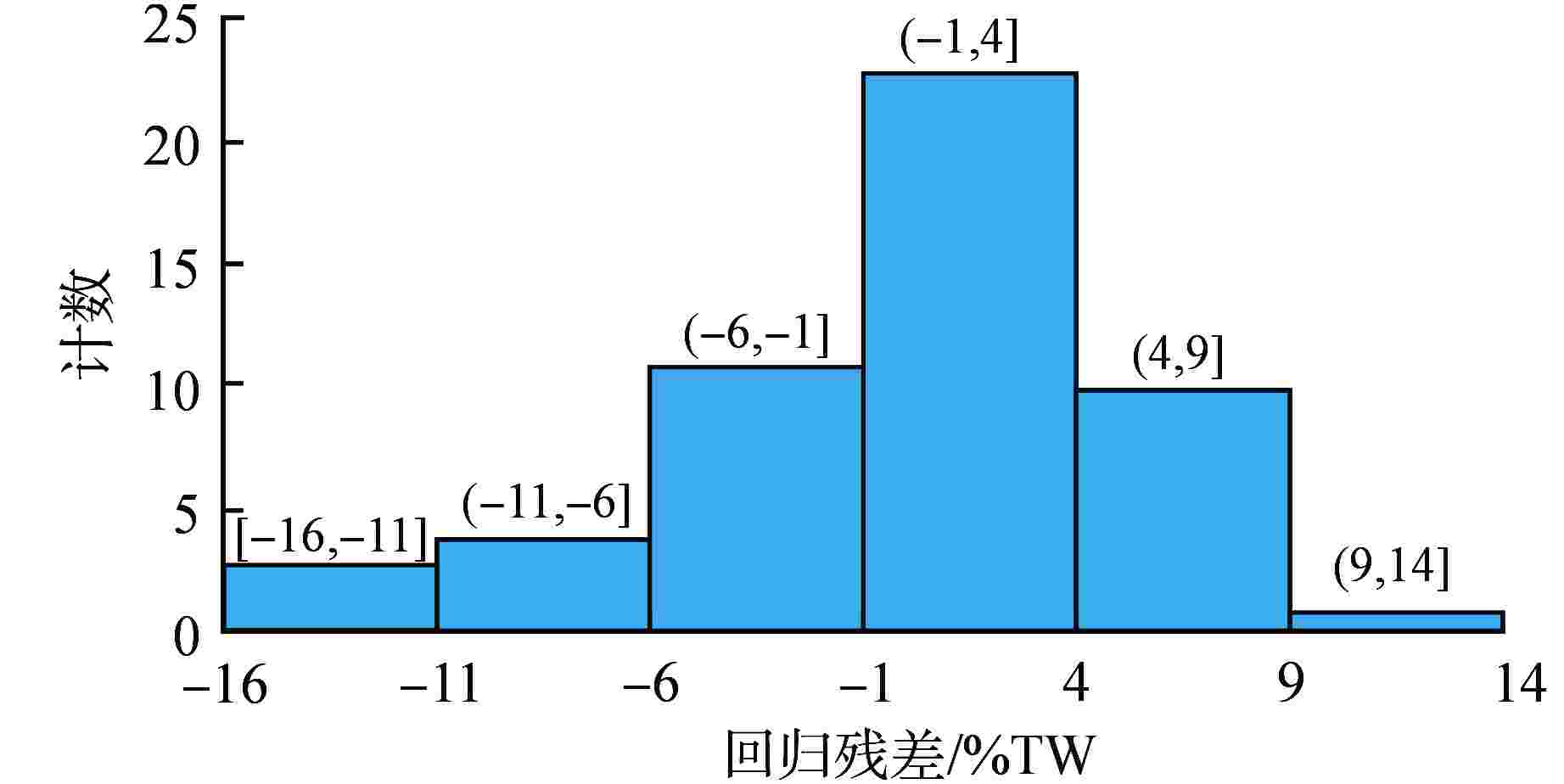

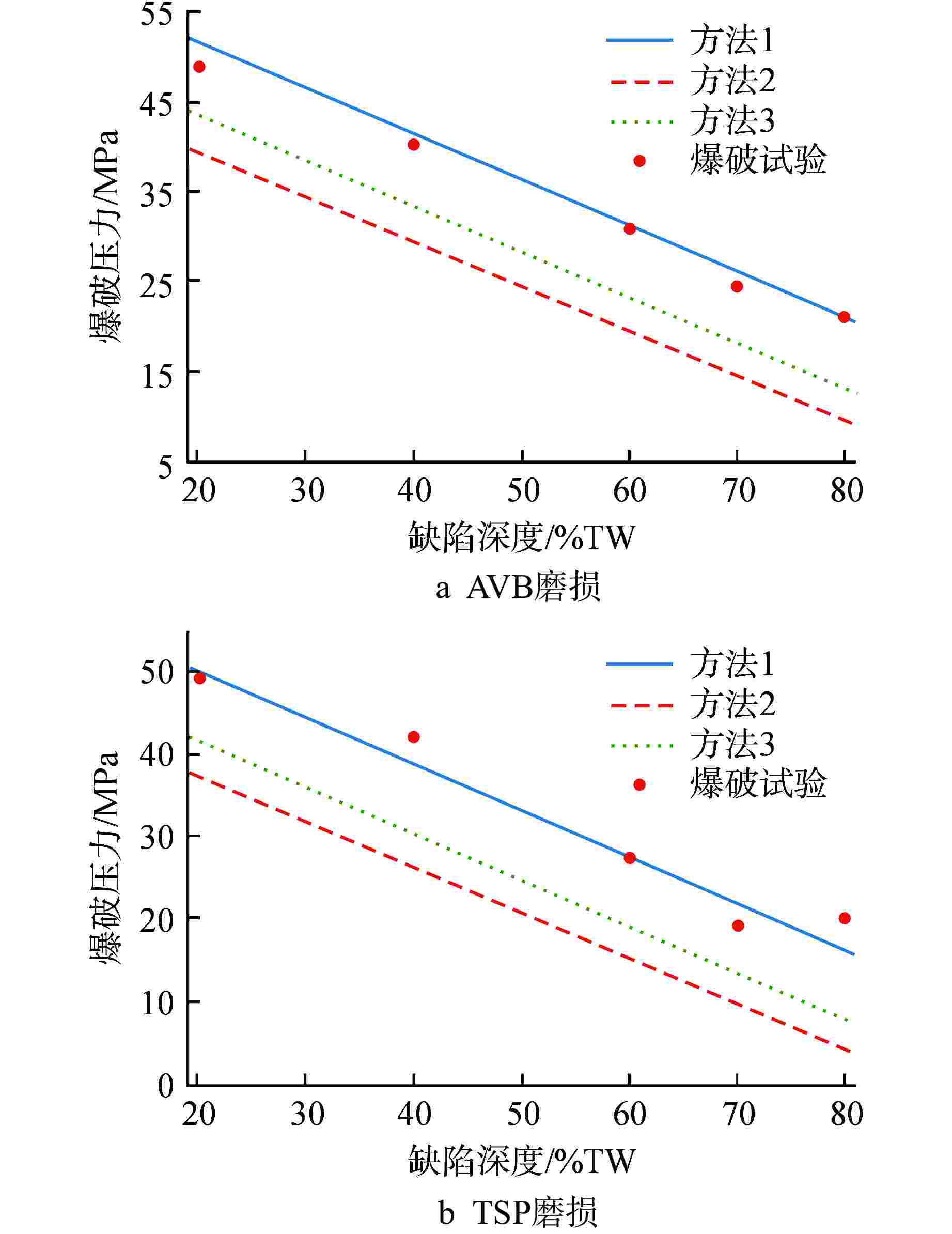

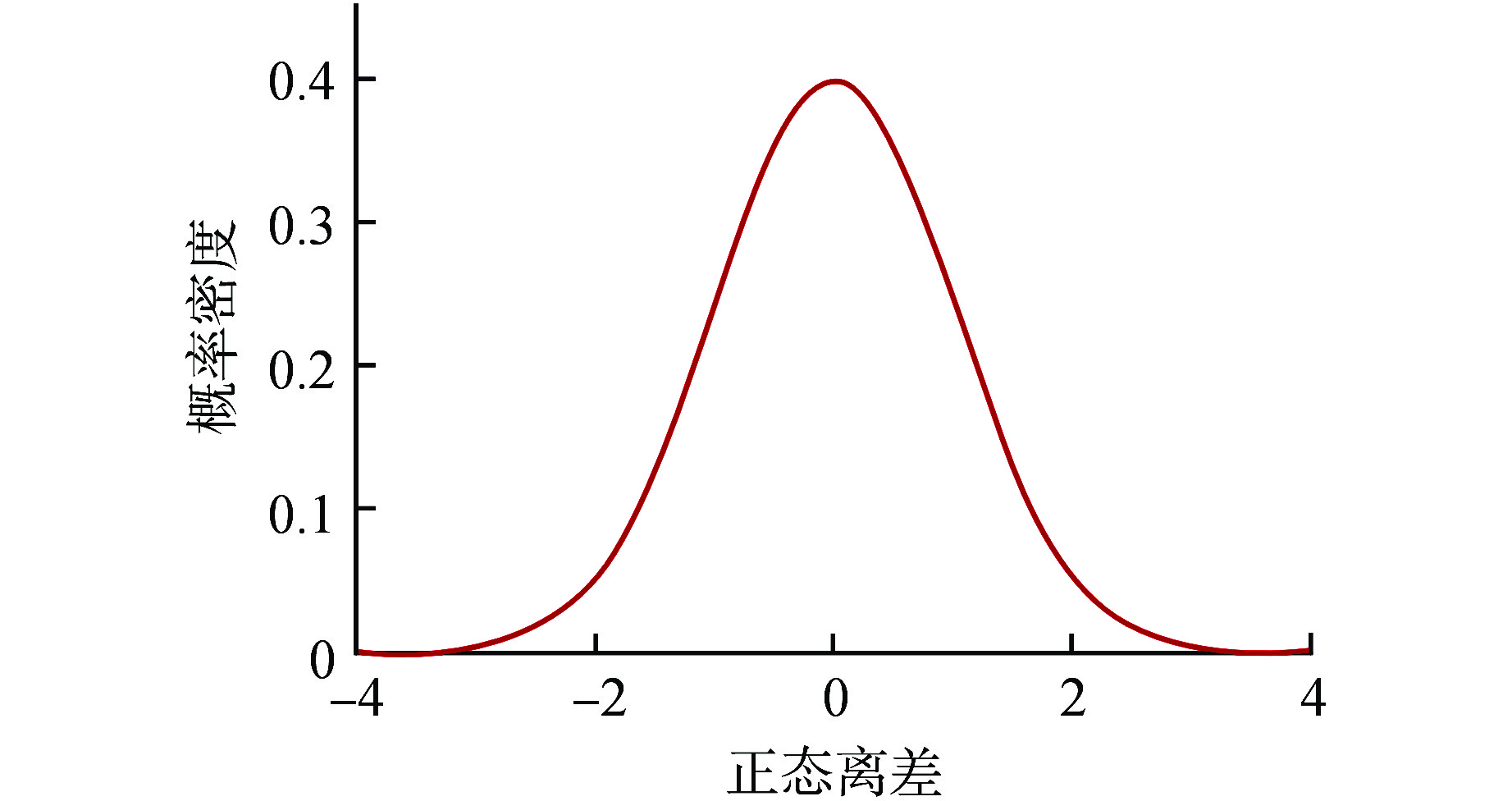

摘要: 以含微振磨损缺陷的Inconel 690传热管爆破压力为研究对象,开展了含缺陷传热管的高温爆破试验和传热管缺陷尺寸的涡流检验试验,基于正态分布建立了包含不确定度的传热管爆破压力预测模型以及缺陷深度预测模型,并采用直接累加和简化统计方法计算了包含不确定性的传热管爆破压力。结果显示,采用直接累积法同时计入材料性能、爆破压力预测模型、涡流检验的第95百分位最坏情况,可得到较保守的传热管爆破压力预测值。采用简化统计法计入材料性能、爆破压力预测模型、涡流检验的不确定性,可有效降低直接累积误差带来的过保守问题。Abstract: This paper focuses on the burst pressure of Inconel 690 tubes with fretting wear defects. High-temperature burst test and eddy current testing on the defect size of tubes were conducted. Based on the normal distribution, a burst pressure prediction model and a defect depth prediction model with uncertainty are established. The direct cumulative and simplified statistical methods are used to calculate the burst pressure of the tubes with uncertainty. The results show that a more conservative prediction value of the burst pressure can be obtained by using the direct accumulation method to include the material properties, the burst pressure prediction model, and the 95th percentile worst-case scenario of eddy current testing. And, the simplified statistical method is used to take into account the material properties, the burst pressure prediction model and the uncertainty of eddy current detection, which can effectively reduce the over-conservative problem caused by direct accumulation error.

-

Key words:

- Heat transfer tube /

- Plugging criteria /

- Fretting wear /

- Limitation size /

- Burst pressure /

- Eddy current testing

-

[1] 陈斯琪,张振兴. 蒸汽发生器传热管微振磨损理论研究[C]//中国核科学技术进展报告(第五卷)——中国核学会2017年学术年会论文集第7册(计算物理分卷、核物理分卷、粒子加速器分卷、核聚变与等离子体物理分卷、脉冲功率技术及其应用分卷、核工程力学分卷). 威海: 中国核学会,2017: 362-366. [2] 丁训慎. 蒸汽发生器传热管的降质及对其完整性的评估[J]. 核安全,2009(2): 37-42. doi: 10.3969/j.issn.1672-5360.2009.02.008 [3] AYODEJI A, LIU Y K. PWR heat exchanger tube defects: trends, signatures and diagnostic techniques[J]. Progress in Nuclear Energy, 2019, 112: 171-184. doi: 10.1016/j.pnucene.2018.12.017 [4] 李志强. 核电站蒸发器传热管安全评定方法的研究[D]. 上海: 华东理工大学,2011. [5] 惠虎,李培宁,唐毅,等. 含缺陷Inconel 690蒸汽发生器传热管的强度及堵管准则研究[J]. 原子能科学技术,2008, 42(S2): 634-640. [6] HUANG S, HUI H, PENG Z Z. Probabilistic structural integrity assessment for Inconel690 alloy steam generator tube with volume defect[J]. Nuclear Engineering and Design, 2021, 371: 110949. doi: 10.1016/j.nucengdes.2020.110949 [7] SHUAI Y, SHUAI J, XU K. Probabilistic analysis of corroded pipelines based on a new failure pressure model[J]. Engineering Failure Analysis, 2017, 81: 216-233. doi: 10.1016/j.engfailanal.2017.06.050 [8] HOSEYNI S M, DI MAIO F, ZIO E. Condition-based probabilistic safety assessment for maintenance decision making regarding a nuclear power plant steam generator undergoing multiple degradation mechanisms[J]. Reliability Engineering & System Safety, 2019, 191: 106583. [9] PALENCIA O G, TEIXEIRA A P, GUEDES SOARES C. Safety of pipelines subjected to deterioration processes modeled through dynamic Bayesian networks[J]. Journal of Offshore Mechanics and Arctic Engineering, 2019, 141(1): 011602. doi: 10.1115/1.4040573 [10] KIM H, KIM J T, HEO G. Prognostics for integrity of steam generator tubes using the general path model[J]. Nuclear Engineering and Technology, 2018, 50(1): 88-96. doi: 10.1016/j.net.2017.10.006 [11] BHARDWAJ U, TEIXEIRA A P, GUEDES SOARES C. Uncertainty quantification of burst pressure models of corroded pipelines[J]. International Journal of Pressure Vessels and Piping, 2020, 188: 104208. doi: 10.1016/j.ijpvp.2020.104208 -

下载:

下载: