Research Progress and Development Trend of Accident Tolerant Fuel UN Pellets

-

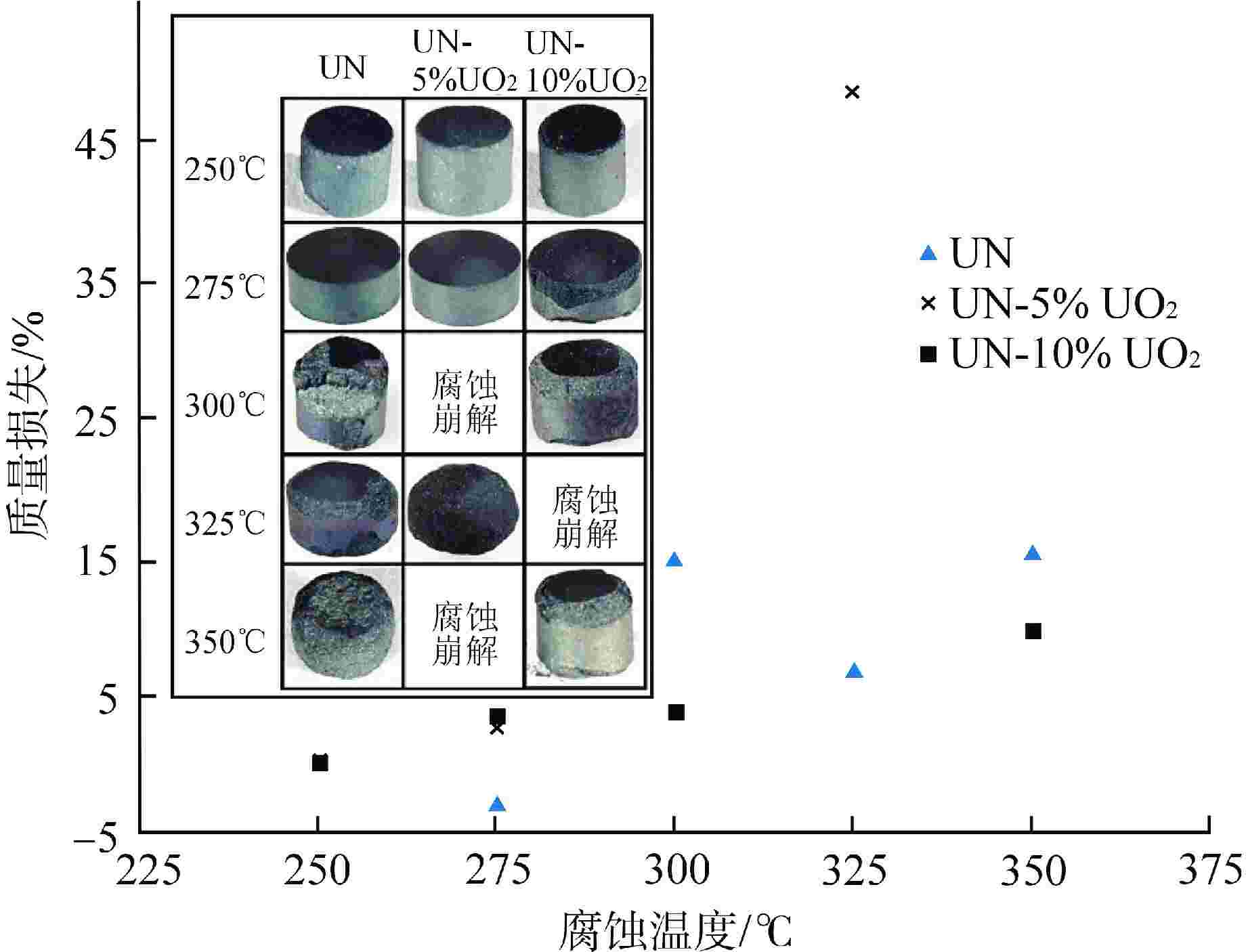

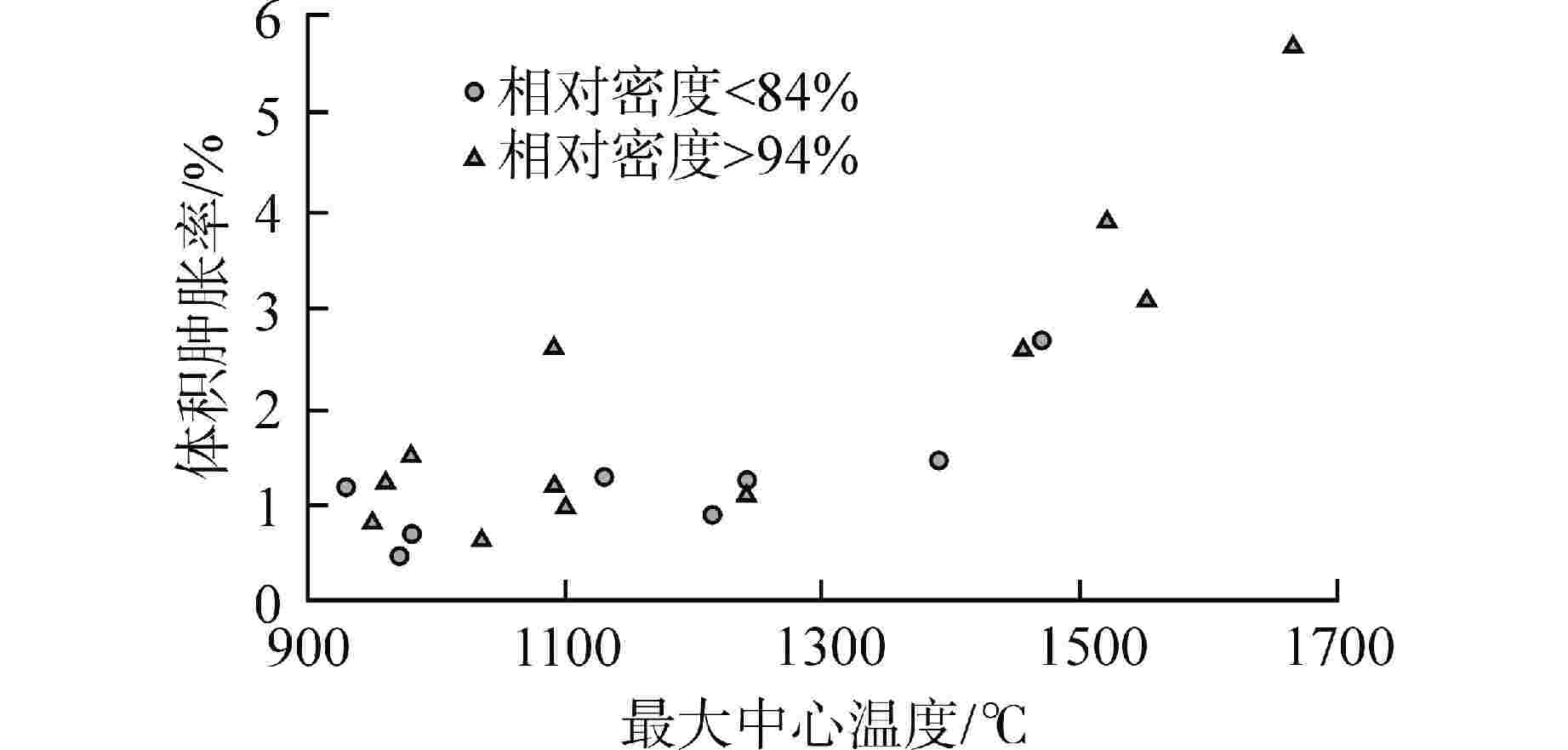

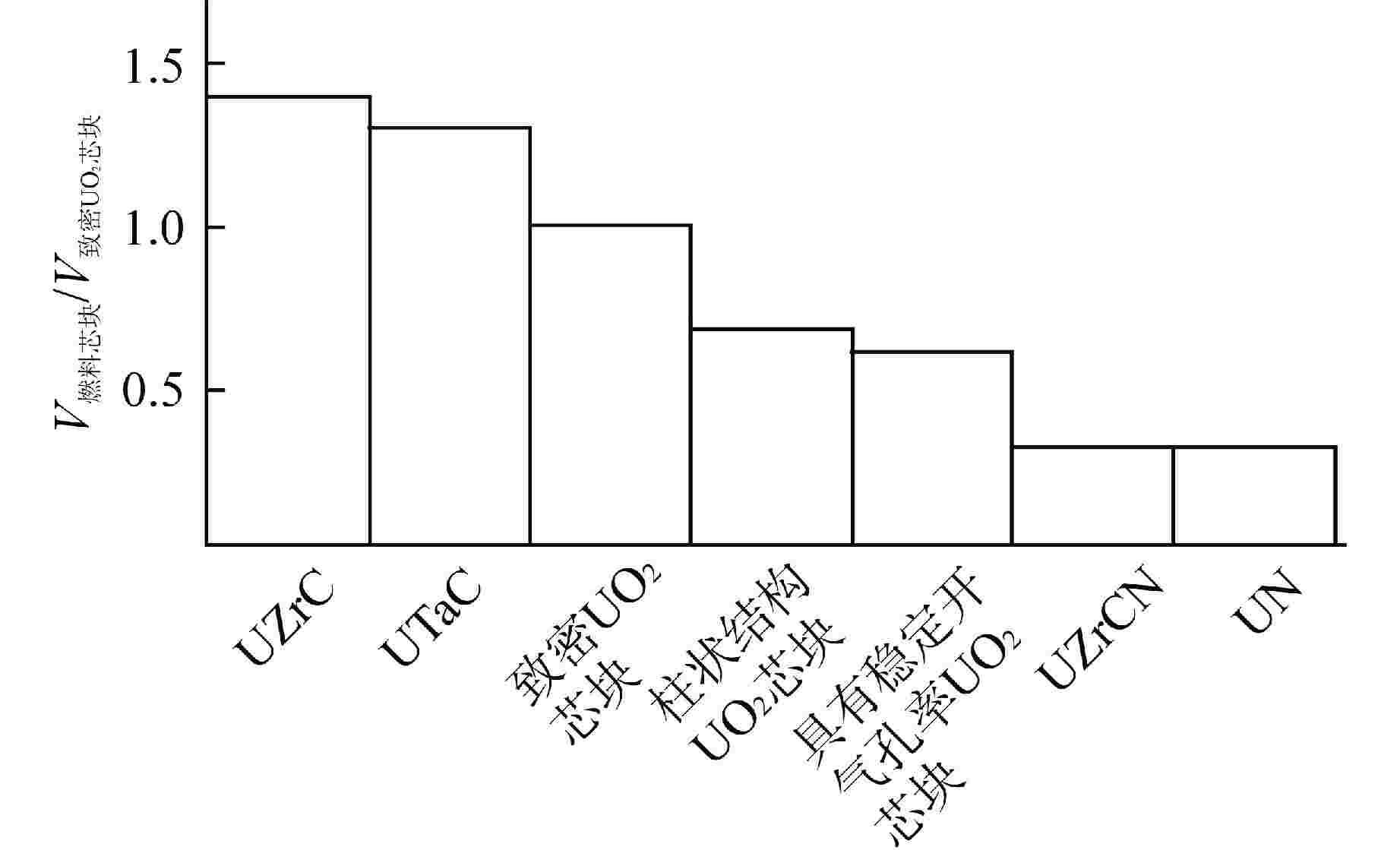

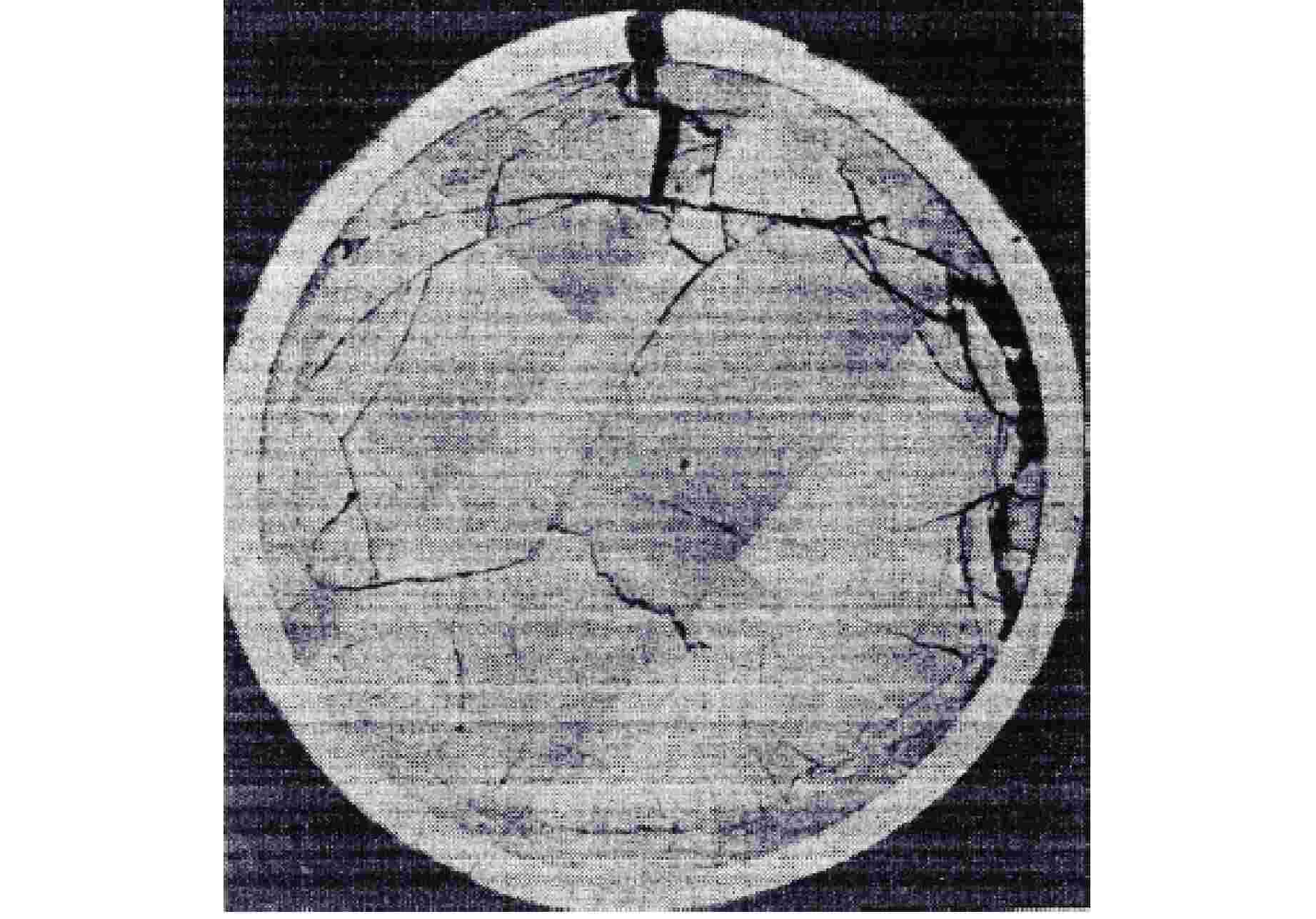

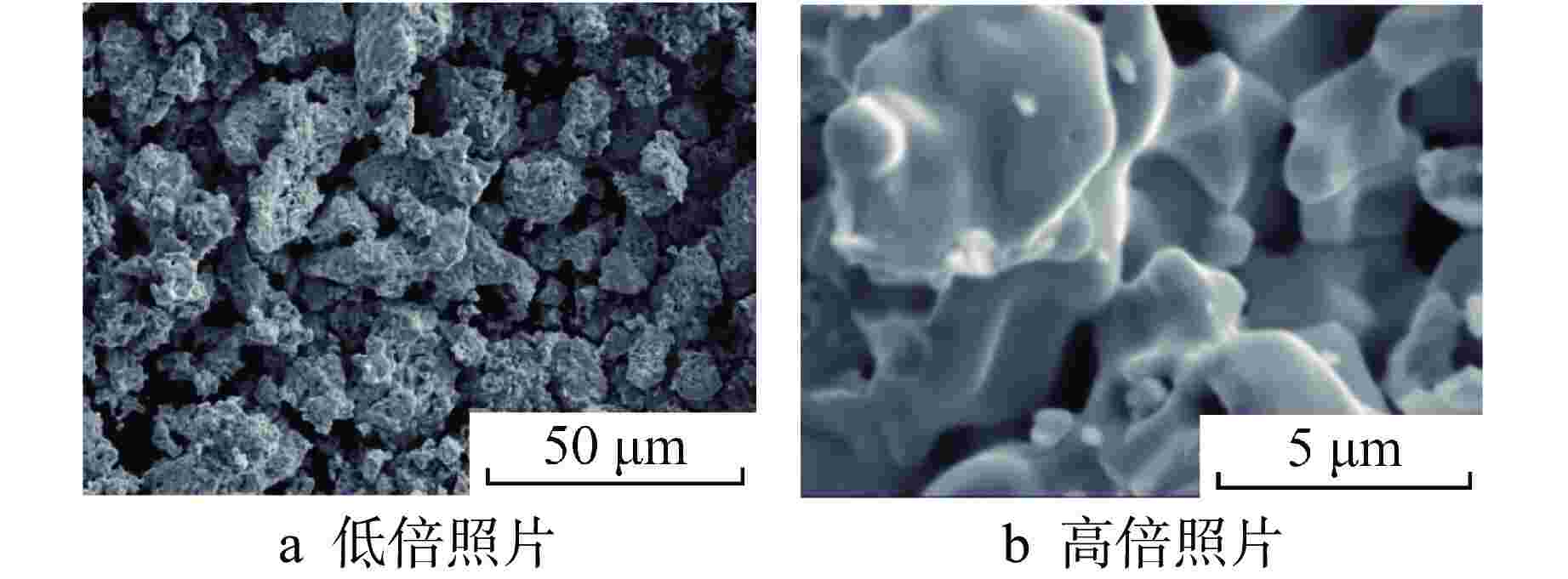

摘要: UN芯块是一种高铀密度、高热导芯块,是一种潜在耐事故燃料芯块。本文从制备工艺和物理性能、环境相容性、辐照性能、芯块-包壳相互作用以及经济性和安全性5个方面对UN芯块研究进展进行了总结。研究结果表明在压水堆中使用UN芯块对提升反应堆安全性利大于弊,总体上有利于促进堆芯事故工况下的安全性,具有降低芯块运行温度、减少事故下储能释放的显著特点,需要解决的主要问题是抗水腐蚀性能差和15N富集成本高,对于提升抗水腐蚀和抗氧化性能的可能解决方案包括掺杂或添加抗氧化成分,高成本问题需要降低15N富集成本。本综述较为全面地总结了UN芯块整体研究进展和发展趋势,对于理解其作为抗耐事故燃料芯块的可行性和存在问题提供参考。Abstract: UN pellet has high uranium density and high thermal conductivity, and is a kind of potential accident tolerant fuel pellet. In this paper, the research progress of UN pellets is summarized from five aspects: preparation process and physical properties, environmental compatibility, irradiation properties, pellet-cladding interaction, economy and safety. The research results show that the advantages of using UN pellets in PWR outweigh the disadvantages, and it is generally beneficial to promote the safety of the reactor under accident conditions. It has the remarkable characteristics of reducing the operating temperature of pellets and reducing the release of energy storage in accidents. The main problems to be solved are poor water corrosion resistance and high cost of 15N enrichment. The possible solutions to improve water corrosion resistance and oxidation resistance include doping or adding antioxidant components, and the high cost problem needs to reduce the cost of 15N enrichment. This review comprehensively summarizes the overall research progress and development trend of UN pellets, and provides reference for understanding its feasibility and existing problems as accident tolerant fuel pellets.

-

Key words:

- NU /

- Accident tolerant fuel /

- Research progress

-

表 1 UN芯块基本物理性能

Table 1. Basic Physical Properties of UN Pellet

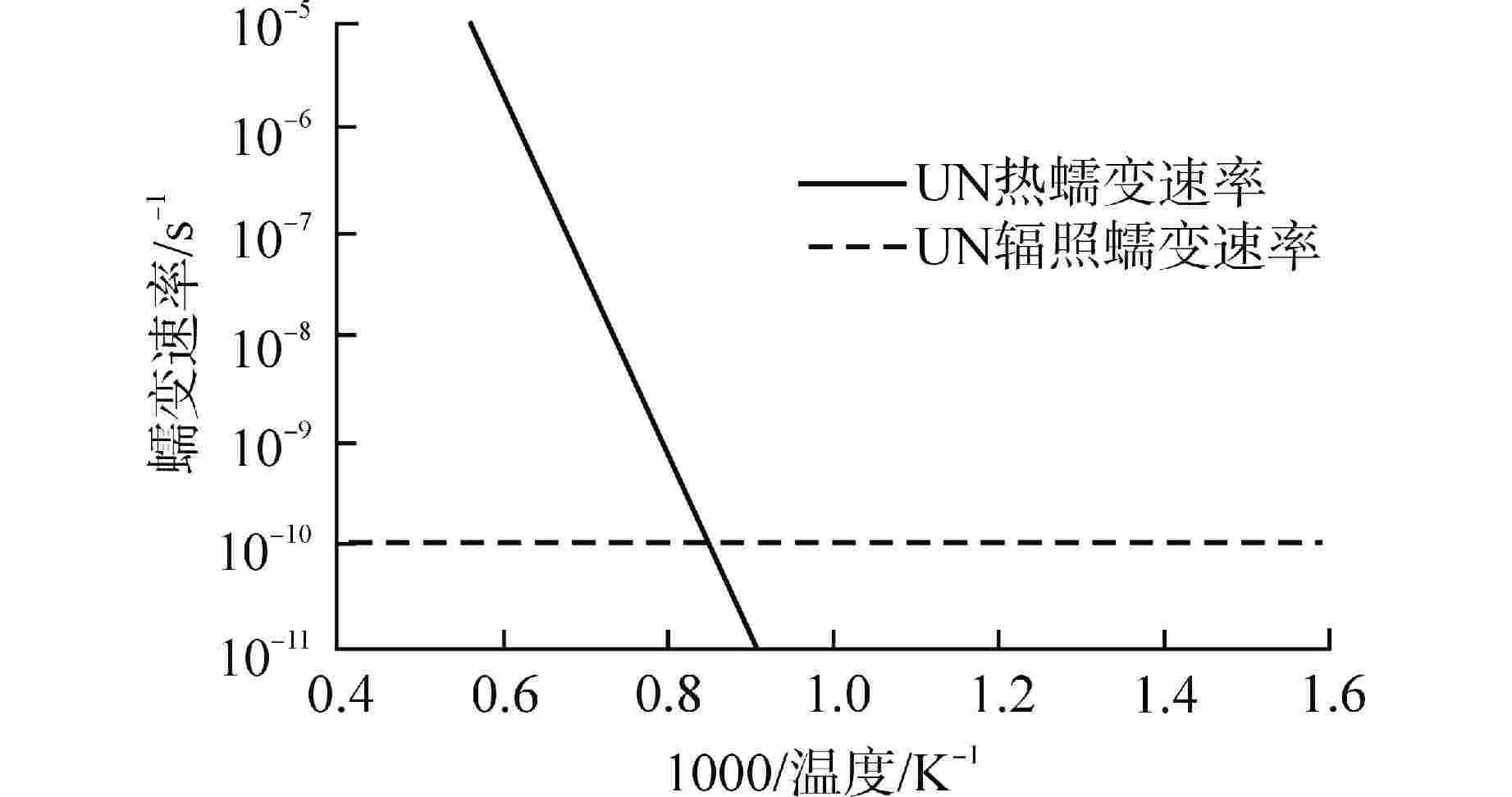

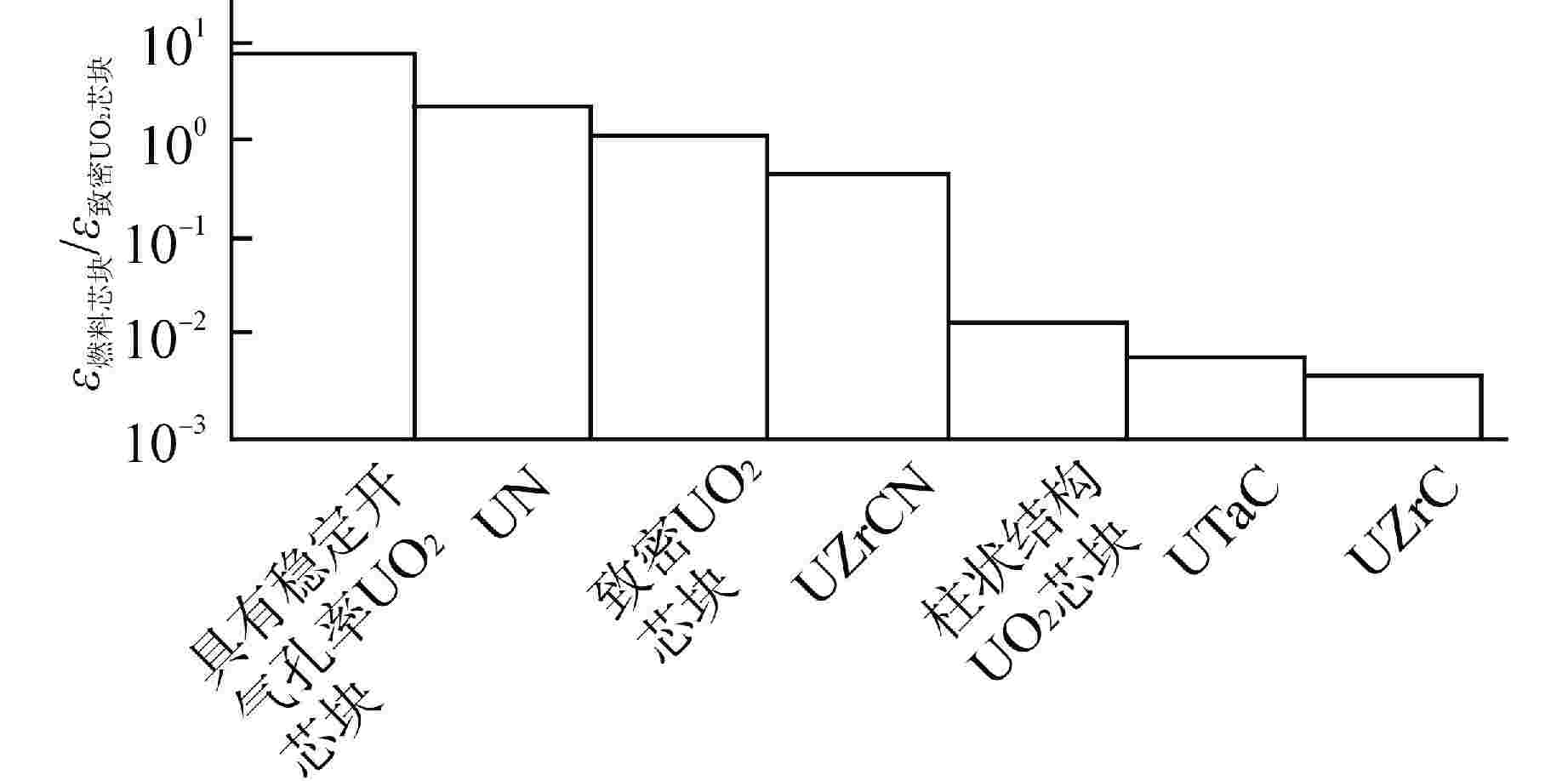

参数 属性 热导率/[W·(m·K)−1] $ k = 1.864{e^{ - 2.14P}}{T^{0.361}} $;P的适用范围0~0.2,T的适用范围298~1923 K 热膨胀系数/K−1 $ \alpha = 7.096 \times {10^{ - 6}} + 1.409 \times {10^{ - 9}}T $,T的适用范围298~2523 K 杨氏模量/MPa $ E = 0.258{D^{3.002}}(1 - 2.375 \times {10^{ - 5}}T) $;D的适用范围70~100,T的适用范围298~1473 K 泊松比 $ \upsilon = 1.26 \times {10^{ - 3}}{D^{1.174}} $,D的适用范围70~100 分解温度/K >1800(真空); >2100(Ar) 熔点/K 3120 比热容/[J·(kg·K)−1] 190(298 K);260(2000 K) 拉伸强度/MPa 148(测试温度不详) 弯曲强度/MPa 74(293 K);136(1473 K) 注:k—热导率;P—气孔率;T—温度;α—热膨胀系数;E—杨氏模量;D—理论密度百分数;$ \upsilon $—泊松比 表 2 轻水堆燃料芯块与包壳在正常运行、功率跃升、冷却剂丧失事故、全厂断电事故和反应性引入事故时芯块的理想属性

Table 2. Desirable Properties of LWR Fuel Pellets under Normal Operation, Power Ramps, Loss-of-coolant Accident, Station Blackout and Reactivity Insertion Accident

芯块性能 对不同运行工况的影响 正常运行 功率跃升 冷却剂丧失事故 全厂断电事故 反应性引入事故 熔点 ↑ ↑ ↑ ↑ ↑ 热导率 ↑ ↑ ↑ — — 比热容 — — ↑ ↑ ↓ 热膨胀系数 — ↓ — — ↓ 蠕变速率 — ↑ — — — 强度 — ↓ — — ↓ 辐照肿胀 ↓ ↓ ↓ ↓ ↓ 注: ↑表示需要提高的性能;↓表示该性能需要降低;—表示该项性能对该事故工况下不敏感 -

[1] OTT L J, ROBB K R, WANG D. Preliminary assessment of accident-tolerant fuels on LWR performance during normal operation and under DB and BDB accident conditions[J]. Journal of Nuclear Materials, 2014, 448(1-3): 520 [2] 潘昕怿,兰兵,贾斌,等. 事故容错燃料包壳和芯块材料中子学分析[J]. 核电子学与探测技术,2016, 36(9): 958-961,965. doi: 10.3969/j.issn.0258-0934.2016.09.018 [3] United States Nuclear Regulatory Commission. Longer term accident tolerant fuel technologies[EB/OL]. (2021-01-12)[2022-04-15]. https://www.nrc.gov/reactors/power/atf/technologies/longer-term.html. [4] 尹邦跃,屈哲昊. 热压烧结UN陶瓷芯块的性能[J]. 原子能科学技术,2014, 48(10): 1850-1856. doi: 10.7538/yzk.2014.48.10.1850 [5] BLANCHARD J, BUTT D, MEYER M, et al. Development of advanced high uranium density fuels for light water reactors: project no. 11-3041[R]. USA: U. S. Department of Energy, 2016. [6] JAQUES B J, WATKINS J, CROTEAU J R, et al. Synthesis and sintering of UN-UO2 fuel composites[J]. Journal of Nuclear Materials, 2015, 466: 745-754. doi: 10.1016/j.jnucmat.2015.06.029 [7] ALEXANDER C A. Metal-actinide nitride nuclear fuel: US, 4624828[P]. 1986-11-25. [8] 尹邦跃,屈哲昊. 氮化铀燃料粉末和芯块的制备方法: 中国,201310403675.6[P]. 2013-12-25. [9] MUTA H, KUROSAKI K, UNO M, et al. Thermal and mechanical properties of uranium nitride prepared by SPS technique[J]. Journal of Materials Science, 2008, 43(19): 6429-6434. doi: 10.1007/s10853-008-2731-x [10] HAYES S L, THOMAS J K, PEDDICORD K L. Material property correlations for uranium mononitride: I. Physical properties[J]. Journal of Nuclear Materials, 1990, 171(2-3): 262-270. doi: 10.1016/0022-3115(90)90374-V [11] HAYES S L, THOMAS J K, PEDDICORD K L. Material property correlations for uranium mononitride: II. Mechanical properties[J]. Journal of Nuclear Materials, 1990, 171(2-3): 271-288. doi: 10.1016/0022-3115(90)90375-W [12] 苏著亭,杨继材,柯国土. 空间核动力[M]. 上海: 上海交通大学出版社,2016: 211. [13] KEMPTER C P, ELLIOTT R O. Thermal expansion of 〈UN〉, 〈UO2〉, 〈UO2·ThO2〉, and〈ThO2〉[J]. The Journal of Chemical Physics, 1959, 30(6): 1524-1526. doi: 10.1063/1.1730230 [14] YOUINOU G J, SEN R S. Impact of accident-tolerant fuels and claddings on the overall fuel cycle: a preliminary systems analysis[J]. Nuclear Technology, 2014, 188(2): 123-138. doi: 10.13182/NT14-22 [15] JAQUES B J, WATKINS J, BUTT D P, et al. Hydrothermal corrosion studies on nitride fuels[C]//Top Fuel 2016: LWR Fuels with Enhanced Safety and Performance. Boise: American Nuclear Society, 2016. [16] LESSING P A. Oxidation protection of uranium nitride fuel using liquid phase sintering: INL/EXT-12-24974[R]. Idaho Falls: Idaho National Laboratory, 2012. [17] FENG B, KARAHAN A, KAZIMI M S. Steady-state fuel behavior modeling of nitride fuels in FRAPCON-EP[J]. Journal of Nuclear Materials, 2012, 427(1-3): 30-38. doi: 10.1016/j.jnucmat.2012.04.011 [18] BAUER A A, BROWN J B, FROMM E O, et al. Mixed-nitride fuel irradiation performance[C]//Proceedings of ANS Conference on Fast Reactor Fuel Element Technology. New Orleans: Battelle Memorial Inst. , 1971: 785-818. [19] ROUTBORT J L, SINGH R N. Elastic, diffusional, and mechanical properties of carbide and nitride nuclear fuels-a review[J]. Journal of Nuclear Materials, 1975, 58(1): 78-114. doi: 10.1016/0022-3115(75)90169-5 [20] TANAKA K, MAEDA K, KATSUYAMA K, et al. Fission gas release and swelling in uranium–plutonium mixed nitride fuels[J]. Journal of Nuclear Materials, 2004, 327(2-3): 77-87. doi: 10.1016/j.jnucmat.2004.01.002 [21] ROGOZKIN B D, STEPENNOVA N M, PROSHKIN A A. Mononitride fuel for fast reactors[J]. Atomic Energy, 2003, 95(3): 624-636. doi: 10.1023/B:ATEN.0000007886.86817.32 [22] ARAI Y, MAEDA A, SHIOZAWA K I, et al. Chemical forms of solid fission products in the irradiated uranium-plutonium mixed nitride fuel[J]. Journal of Nuclear Materials, 1994, 210(1-2): 161-166. doi: 10.1016/0022-3115(94)90233-X [23] ALEKSEEV S V, VYBYVANETS V I, GONTAR’ A S, et al. Promising fuel materials for thermionic nuclear power installations[J]. Atomic Energy, 2014, 115(6): 391-401. doi: 10.1007/s10512-014-9801-8 [24] RICHTER K, SARI C. Investigation of the operational limits of uranium-plutonium nitride fuels[J]. Journal of Nuclear Materials, 1991, 184(3): 167-176. doi: 10.1016/0022-3115(91)90537-H [25] POPLAVSKII V M, TSIBULYA A M, KHOMYAKOV Y S, et al. Core and fuel cycle for an advanced sodium-cooled fast reactor[J]. Atomic Energy, 2010, 108(4): 260-266. doi: 10.1007/s10512-010-9287-y [26] KAZIMI M S, DOBISESKY J, CARPENTER D M, et al. PWR cores with silicon carbide cladding: MIT-NFC;PR-124[R]. California: Electric Power Research Institute, 2011. [27] TERRANI K A. Accident tolerant fuel cladding development: promise, status, and challenges[J]. Journal of Nuclear Materials, 2018, 501: 13-30. doi: 10.1016/j.jnucmat.2017.12.043 [28] YANG K, KARDOULAKI E, ZHAO D, et al. Cr-incorporated uranium nitride composite fuels with enhanced mechanical performance and oxidation resistance[J]. Journal of Nuclear Materials, 2022, 559: 153486. doi: 10.1016/j.jnucmat.2021.153486 -

下载:

下载: