Effect of Cold-rolling Deformation on Microstructure and Mechanical Properties of Fe-11Cr-5Al-2Mo Alloy

-

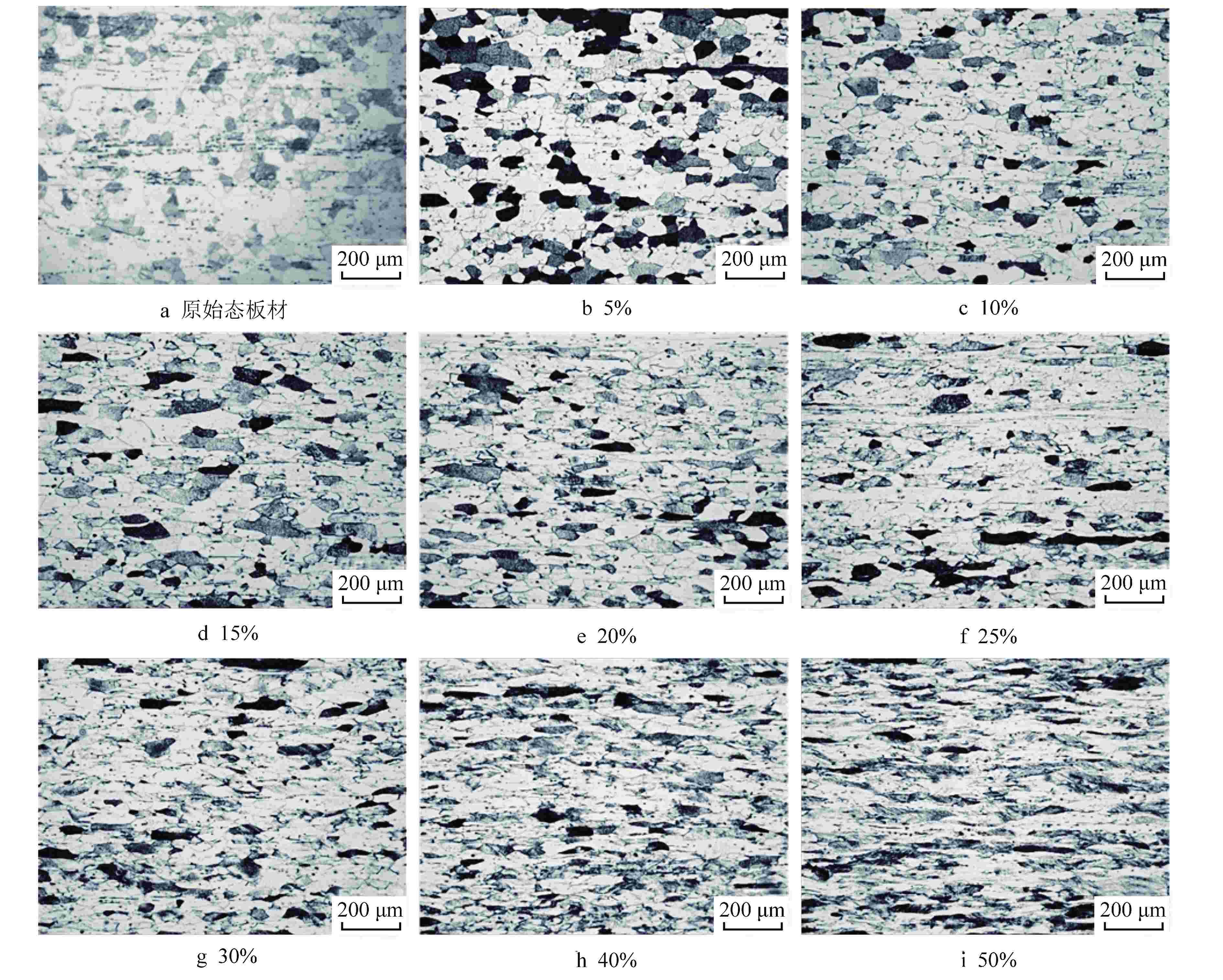

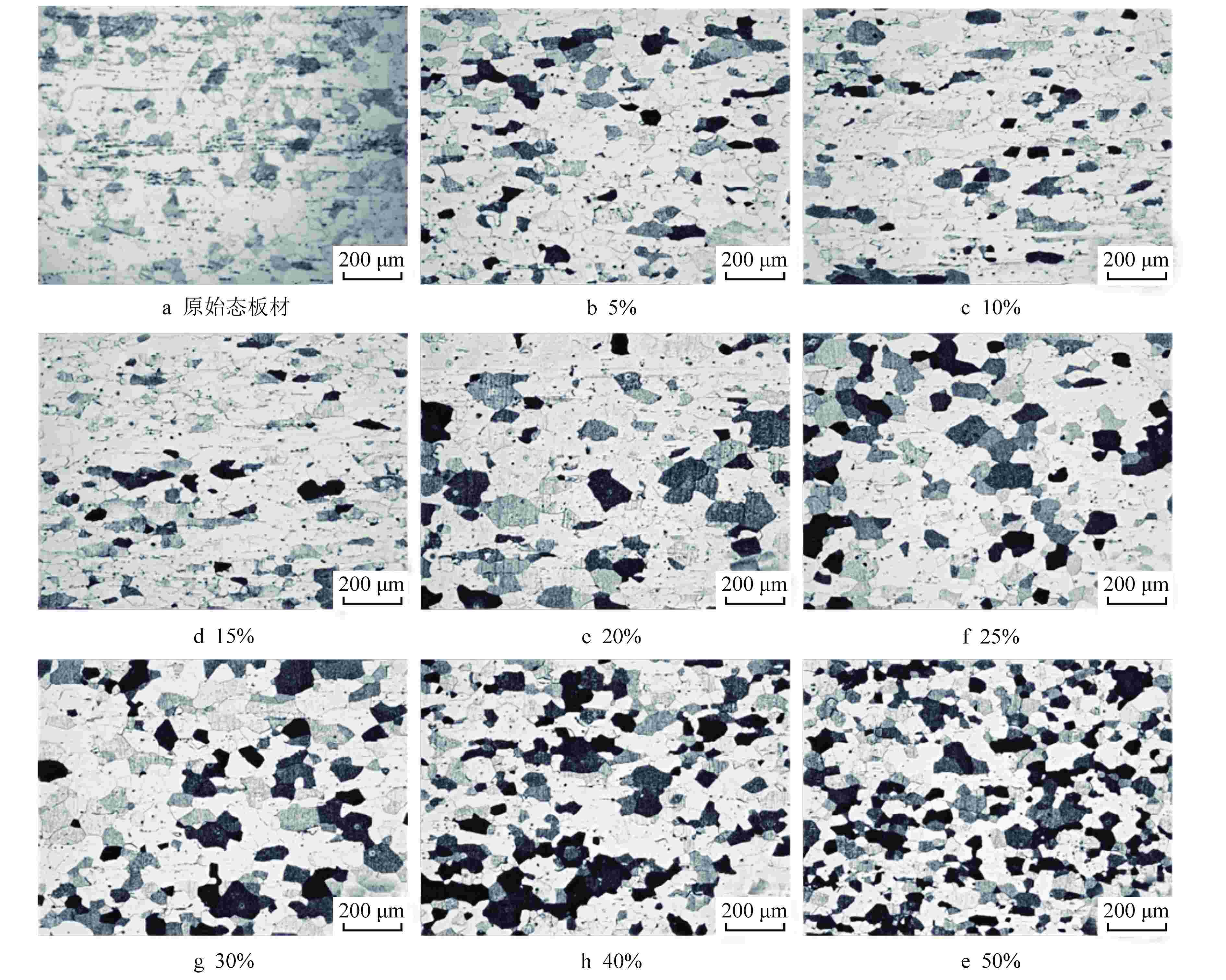

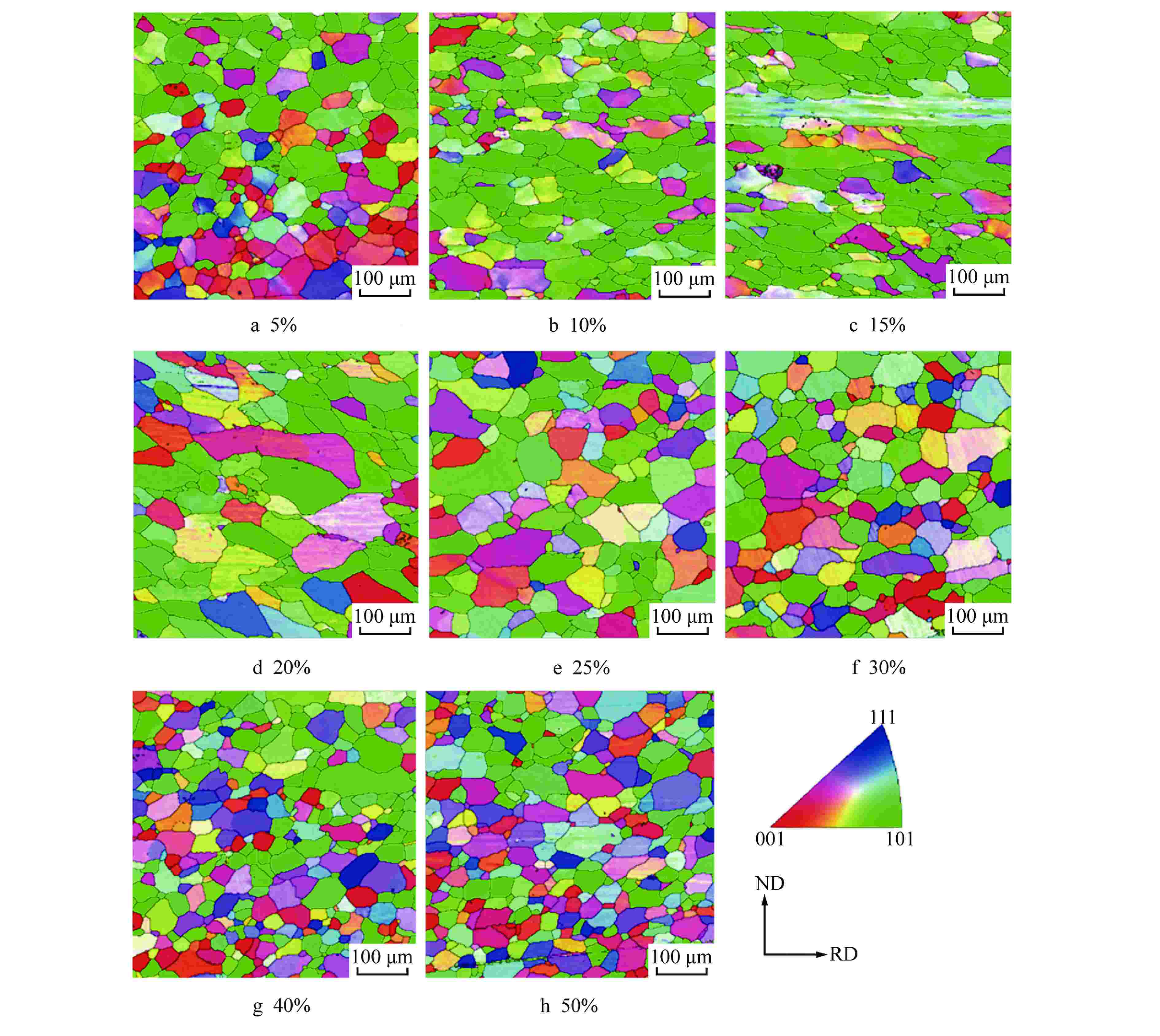

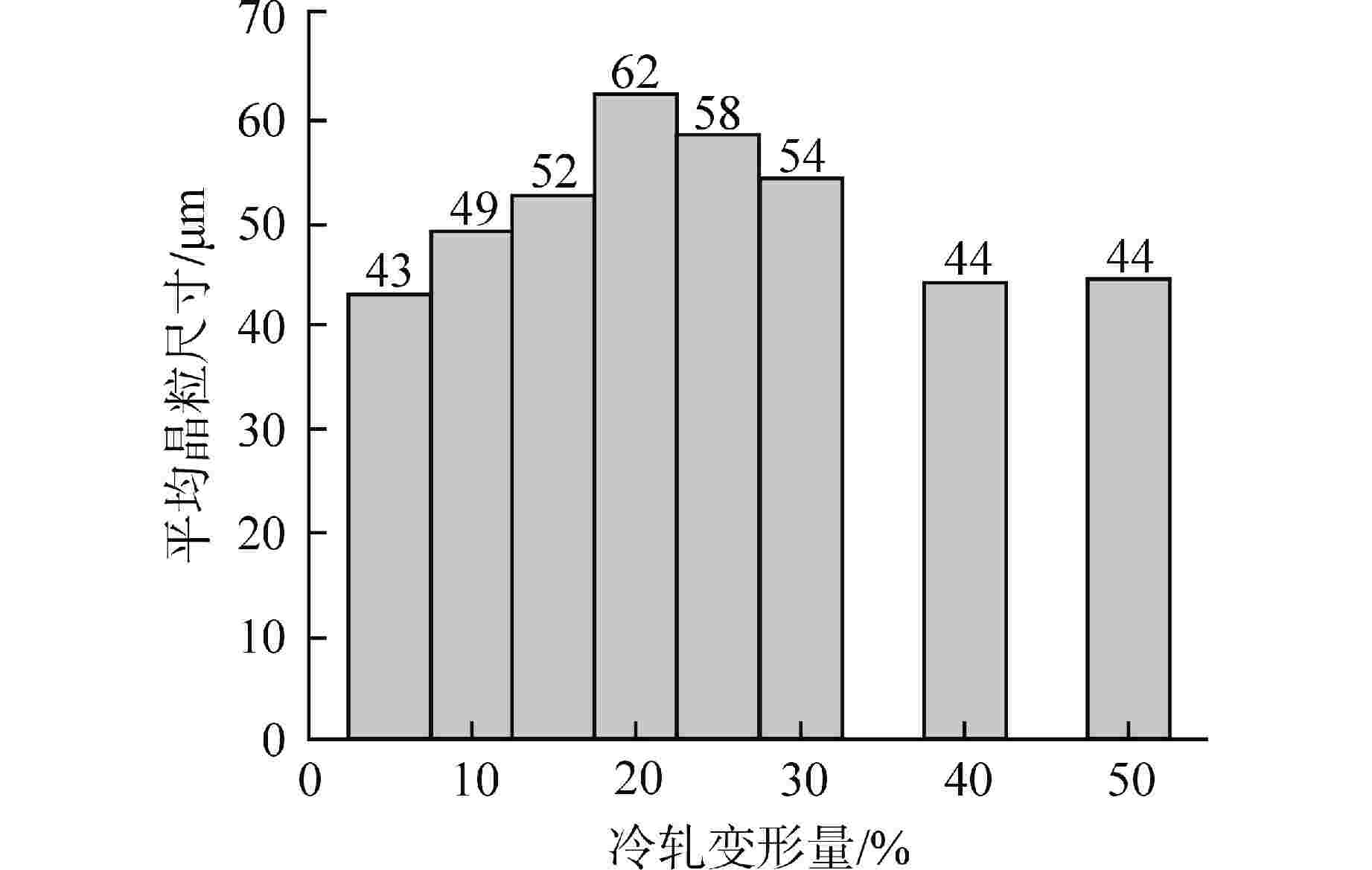

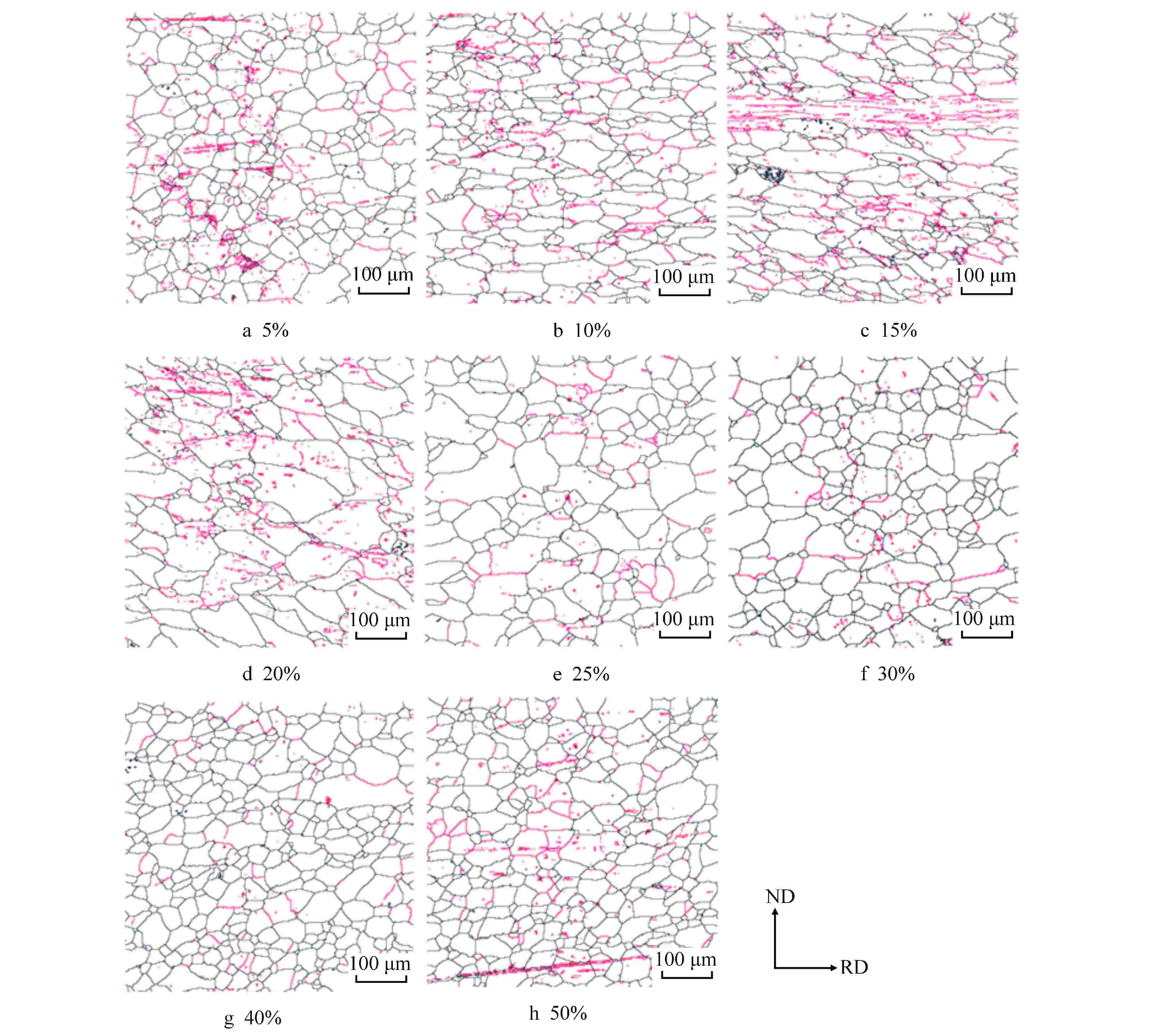

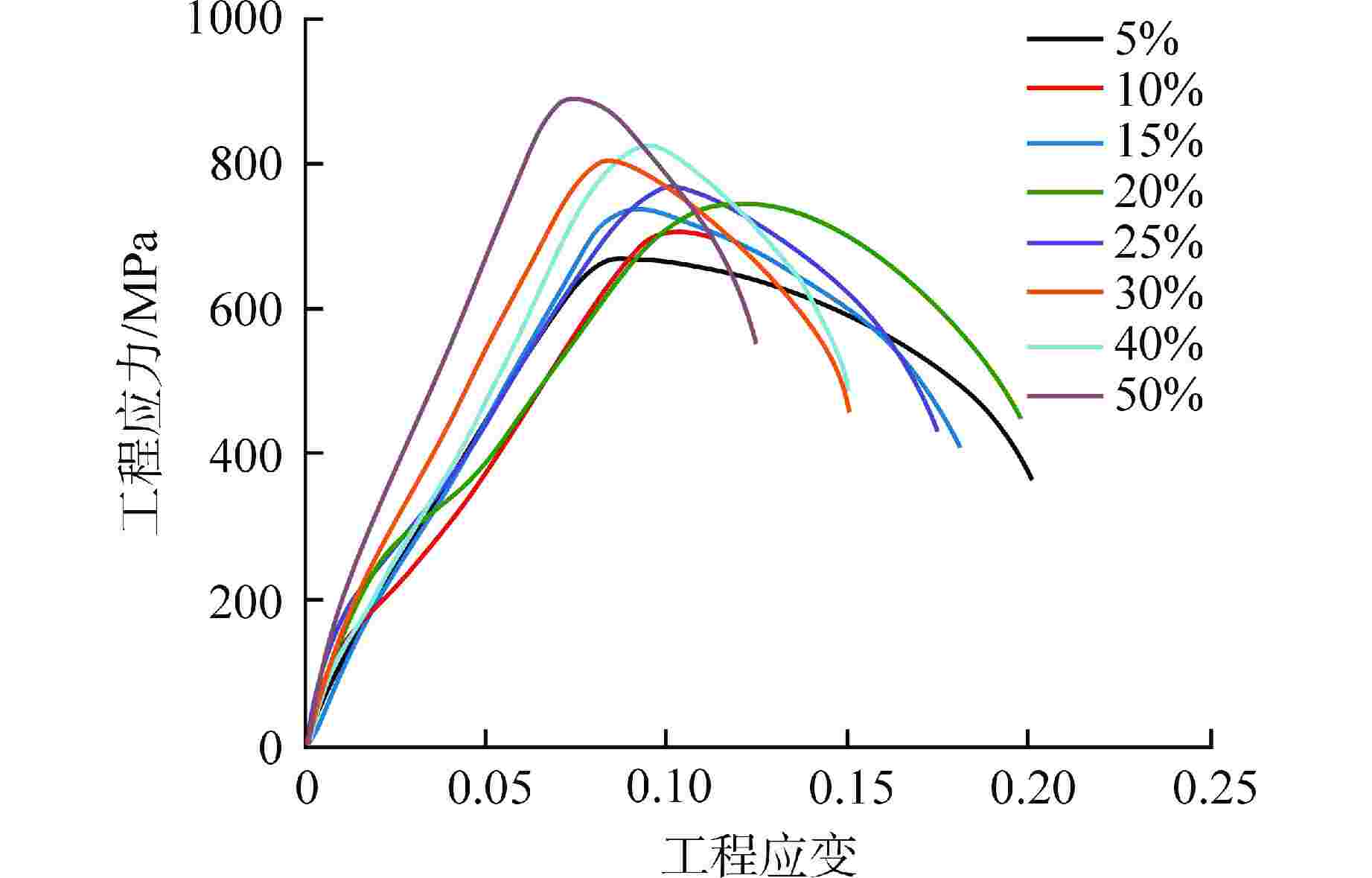

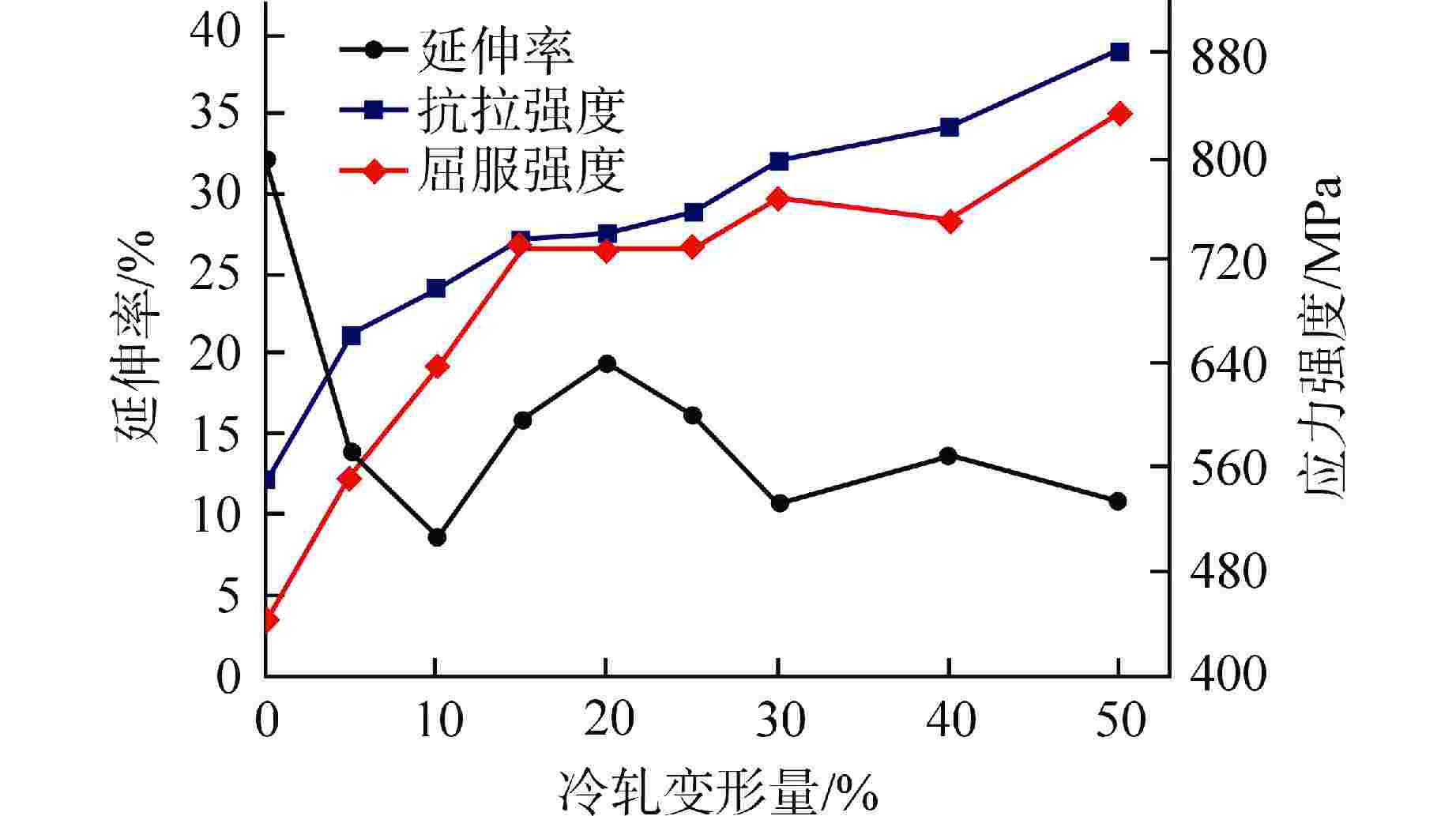

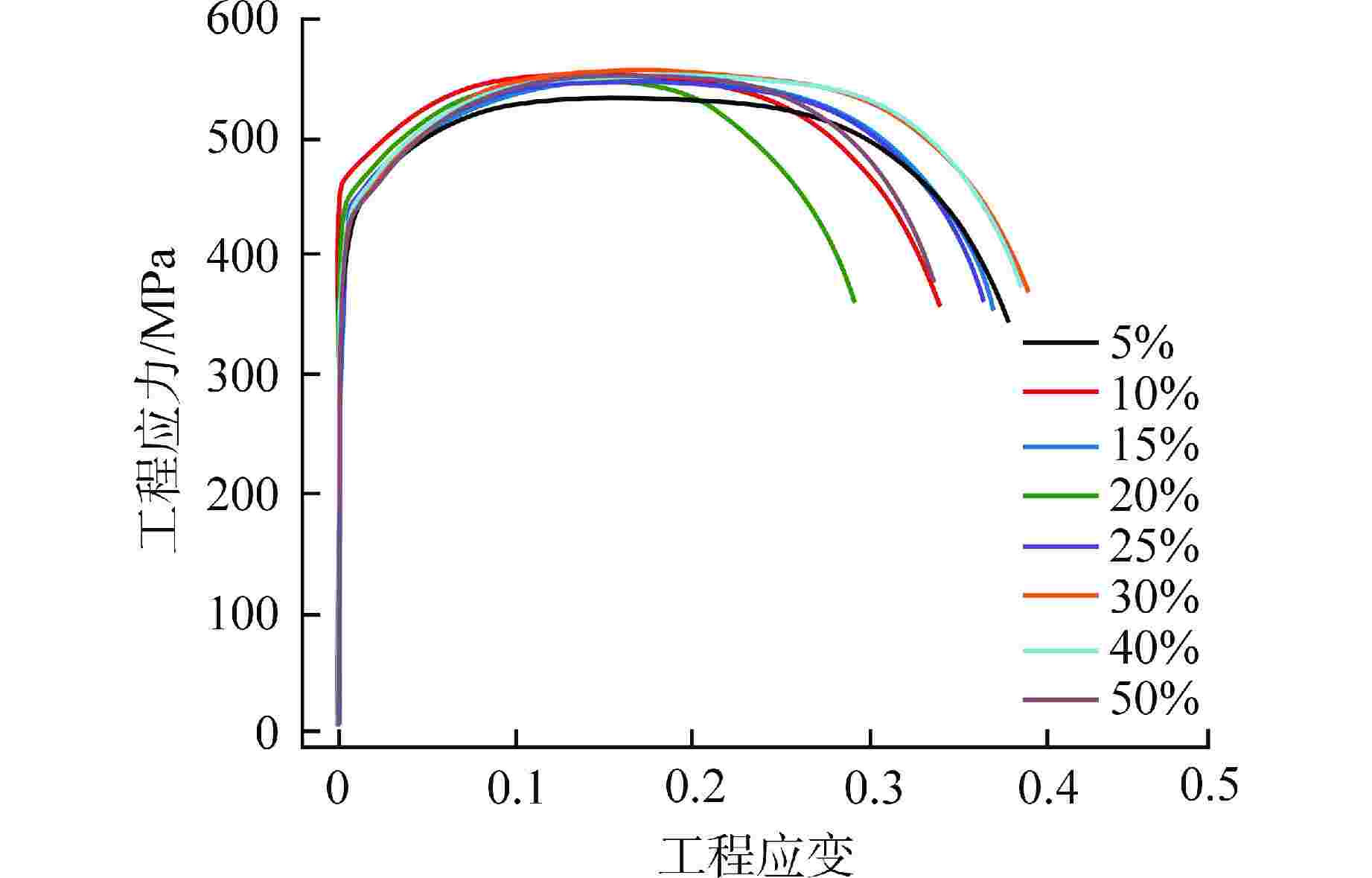

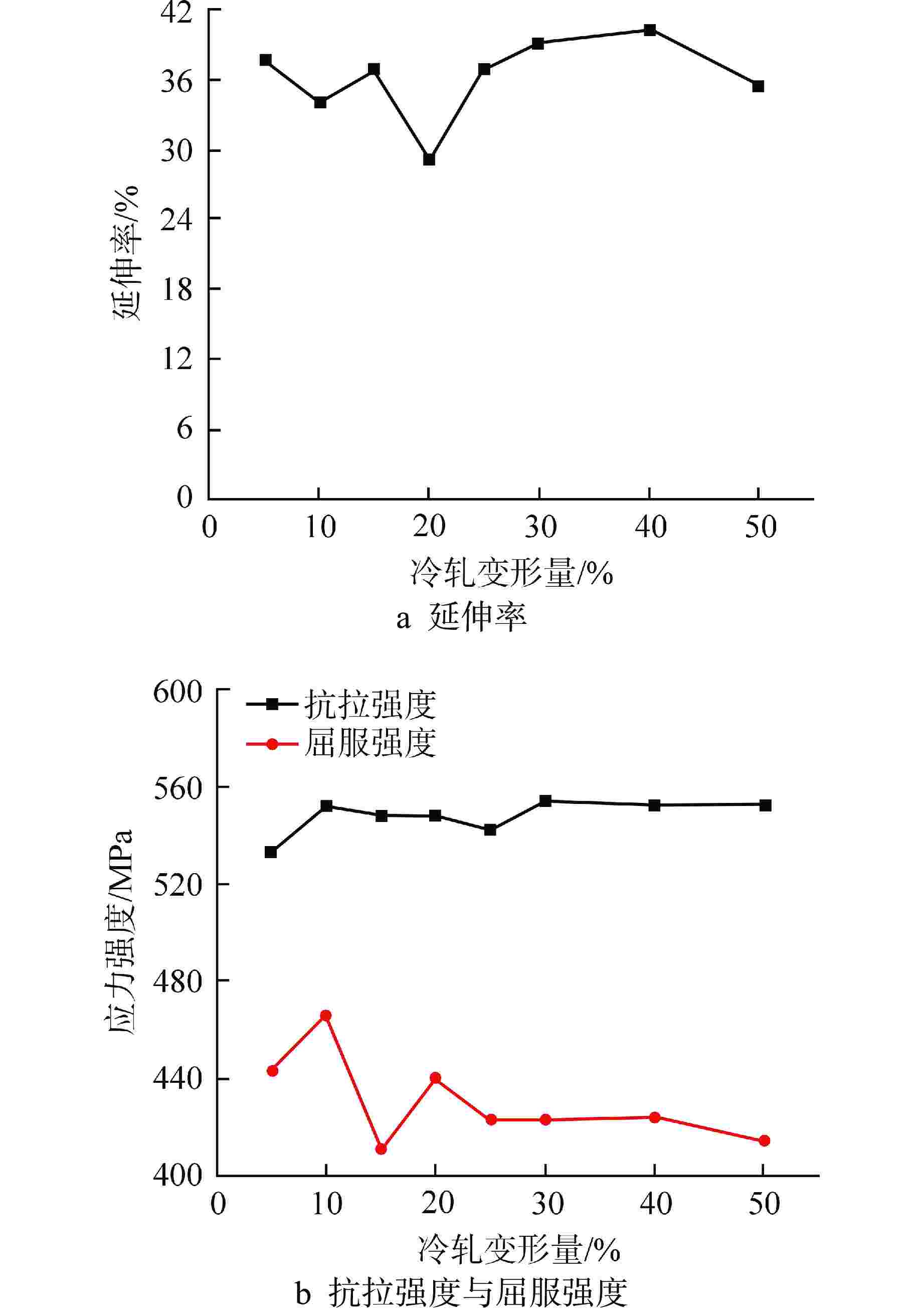

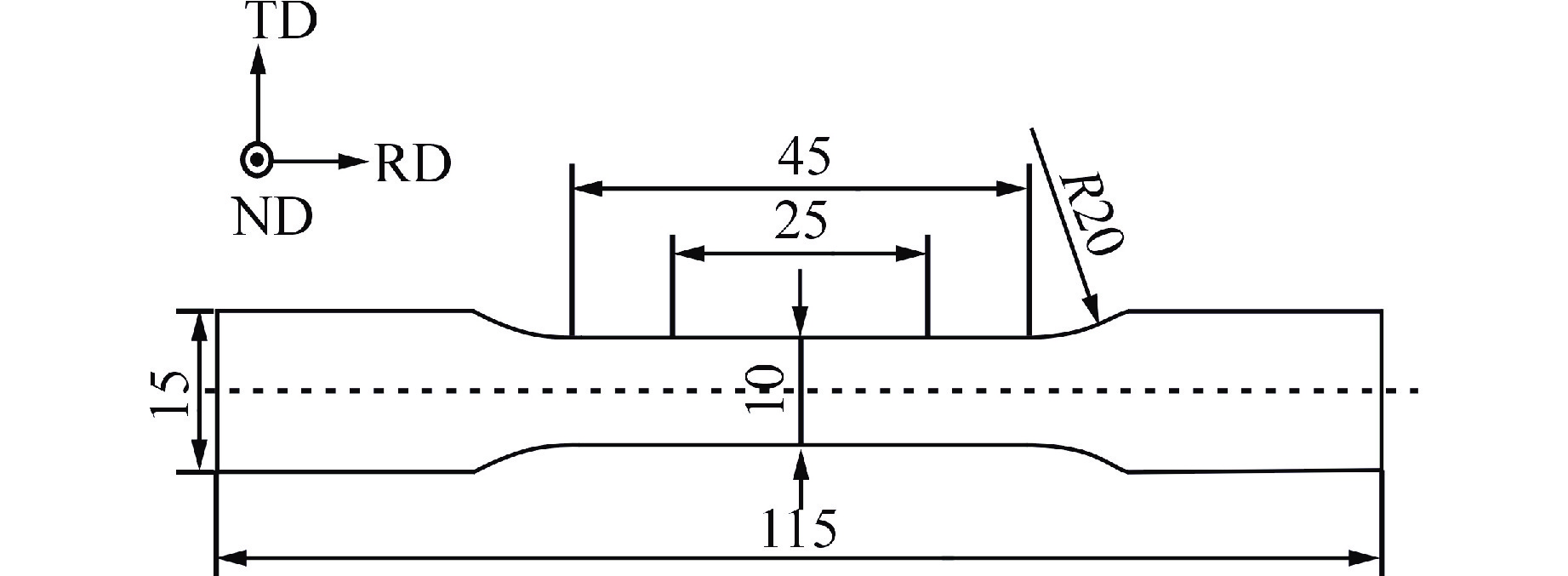

摘要: 为掌握 Fe-11Cr-5Al-2Mo合金冷变形规律,并为其包壳管材研制提供基础数据和理论依据。开展了不同冷轧变形量的Fe-11Cr-5Al-2Mo合金板材轧制实验,对冷轧后的板材在800℃下进行了1 h退火,并对冷轧板材及退火板材的显微组织演变进行了表征,通过室温拉伸试验评价了Fe-11Cr-5Al-2Mo合金的强度和塑性。Fe-11Cr-5Al-2Mo合金板材的变形态组织随着冷轧变形量的增大而拉长,板材的强度随着冷轧变形量的增大而增大。800℃退火1 h后,50%冷轧变形量的板材获得了最细小、均匀的再结晶组织,并且具有良好的韧塑性配合。本文阐明了合金冷轧变形量-组织-性能之间的关系,为Fe-11Cr-5Al-2Mo合金管材冷轧变形量设计和退火工艺研究提供了参考。

-

关键词:

- Fe-11Cr-5Al-2Mo合金 /

- 冷轧变形 /

- 力学性能 /

- 显微组织

Abstract: The purpose of the study is to understand the cold deformation rule of Fe-11Cr-5Al-2Mo alloy, so as to provide data and theoretical basis for the cladding tube manufacturing. The rolling experiments of Fe-11Cr-5Al-2Mo alloy plates with different cold-rolled deformation were carried out. The cold-rolled plates were annealed at 800℃ for 1 h, and the microstructure evolution of the cold-rolled plates and annealed plates was characterized. The strength and plasticity of Fe-11Cr-5Al-2Mo alloy were evaluated by the tensile test at room temperature. The deformed microstructure of Fe-11Cr-5Al-2Mo alloy plate is elongated with the increase of cold rolling deformation, and the strength of the plate increases with the increase of cold rolling deformation. After annealing at 800℃ for 1h, the plate with 50% cold rolling deformation showed the smallest and uniform recrystallization microstructure, and had a good ductile-plastic fit. In this paper, the relationship between cold rolling deformation, microstructure and properties of the alloy is expounded, which provides a reference for the design of cold rolling deformation and the study of annealing process of Fe-11Cr-5Al-2Mo alloy tube.-

Key words:

- Fe-11Cr-5Al-2Mo alloy /

- Cold-rolling deformation /

- Mechanical properties /

- Microstructure

-

表 1 Fe-11Cr-5Al-2Mo合金化学成分实测值

Table 1. Actual Composition of Fe-11Cr-5Al-2Mo Alloy

元素 Cr Al Mo Si Y Fe 质量分数/% 10.7 5.0 1.8 0.19 0.04 余量 -

[1] YAMAMOTO Y. Development and quality assessments of commercial heat production of ATF FeCrAl tubes: ORNL/TM-2015/478[R]. U.S.: Oak Ridge National Laboratory (ORNL), 2015. [2] YAMAMOTO Y, SUN Z Q, PINT B A, et al. Optimized Gen-II FeCrAl cladding production in large quantity for campaign testing: ORNL/TM-2016/227[R]. U.S.: Oak Ridge National Laboratory (ORNL), 2016. [3] 梁小龙,潘钱付,王辉,等. 温轧FeCrAl钢退火组织演变对力学性能的影响[J]. 钢铁研究学报,2019, 31(11): 1012-1022. [4] 郑继云,王辉,曹萍,等. FeCrAl合金包壳的冷轧退火织构及力学性能[J]. 金属热处理,2019, 44(4): 175-179. [5] HUANG X F, WANG H, QIU S Y, et al. Cold-rolling & annealing process for nuclear grade wrought FeCrAl cladding alloy to enhance the strength and ductility[J]. Journal of Materials Processing Technology, 2020, 277: 116434. doi: 10.1016/j.jmatprotec.2019.116434 [6] 刘胜,米振莉,唐荻,等. Fe-Cr-Al合金退火过程中组织和性能的演变[J]. 材料热处理学报,2013, 34(7): 53-57. [7] 武雪婷. 核燃料包壳用FeCrAl合金的制备工艺及组织性能研究[D]. 沈阳: 东北大学,2019. -

下载:

下载: