Study on Bubble Behavior Mechanism of Saturated Pool Boiling on SiC Cladding Material Surface under Atmospheric Pressure

-

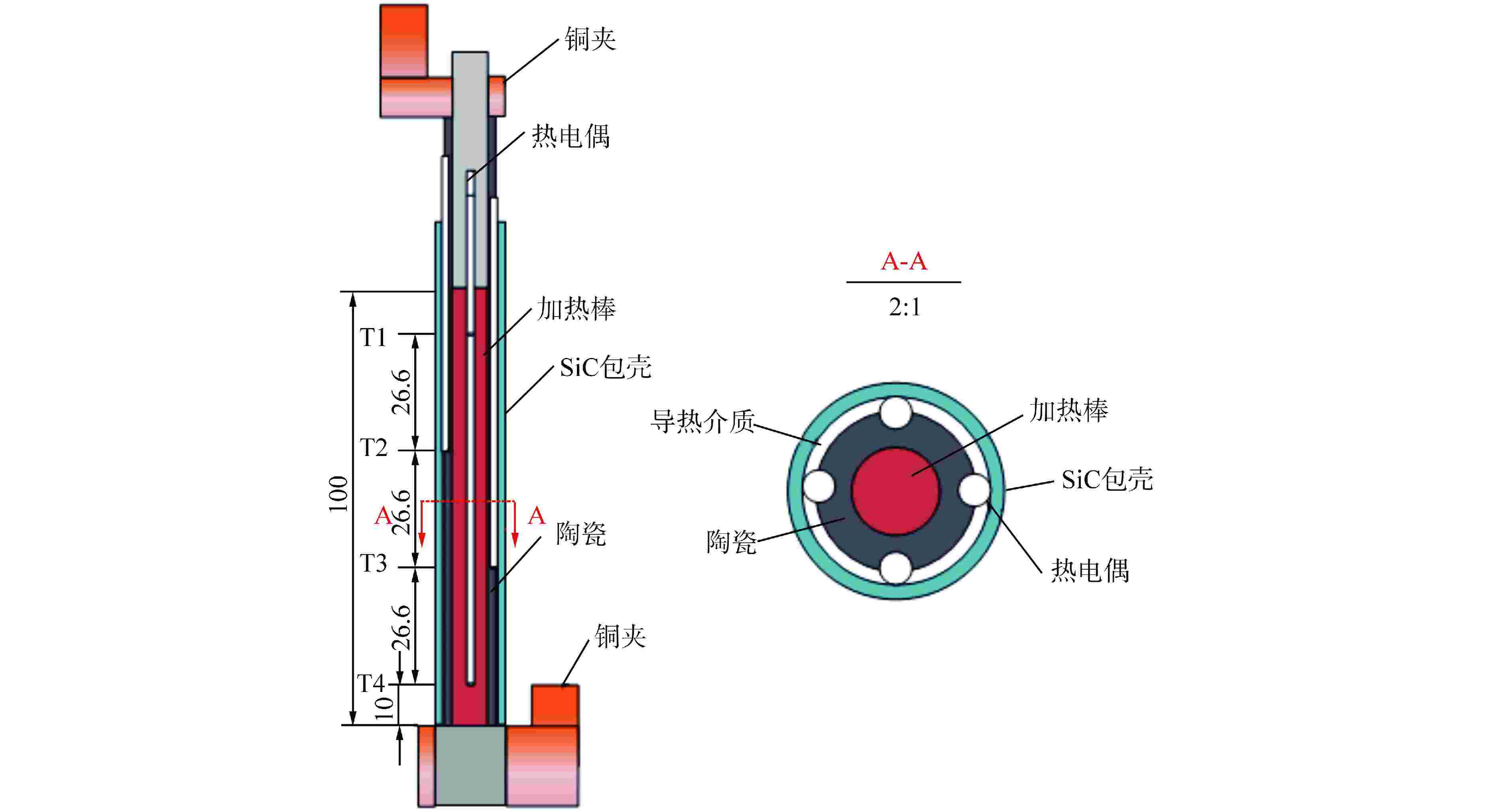

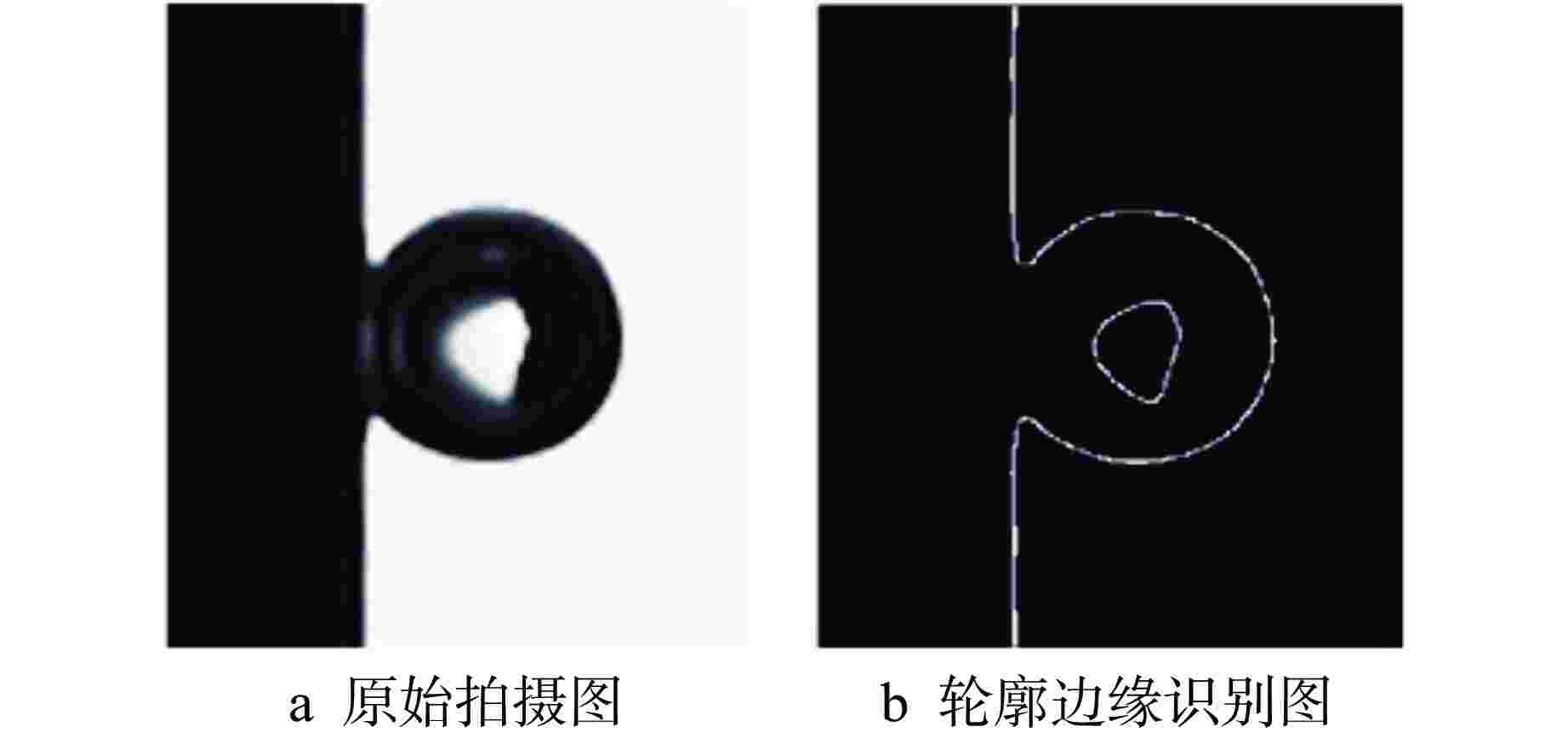

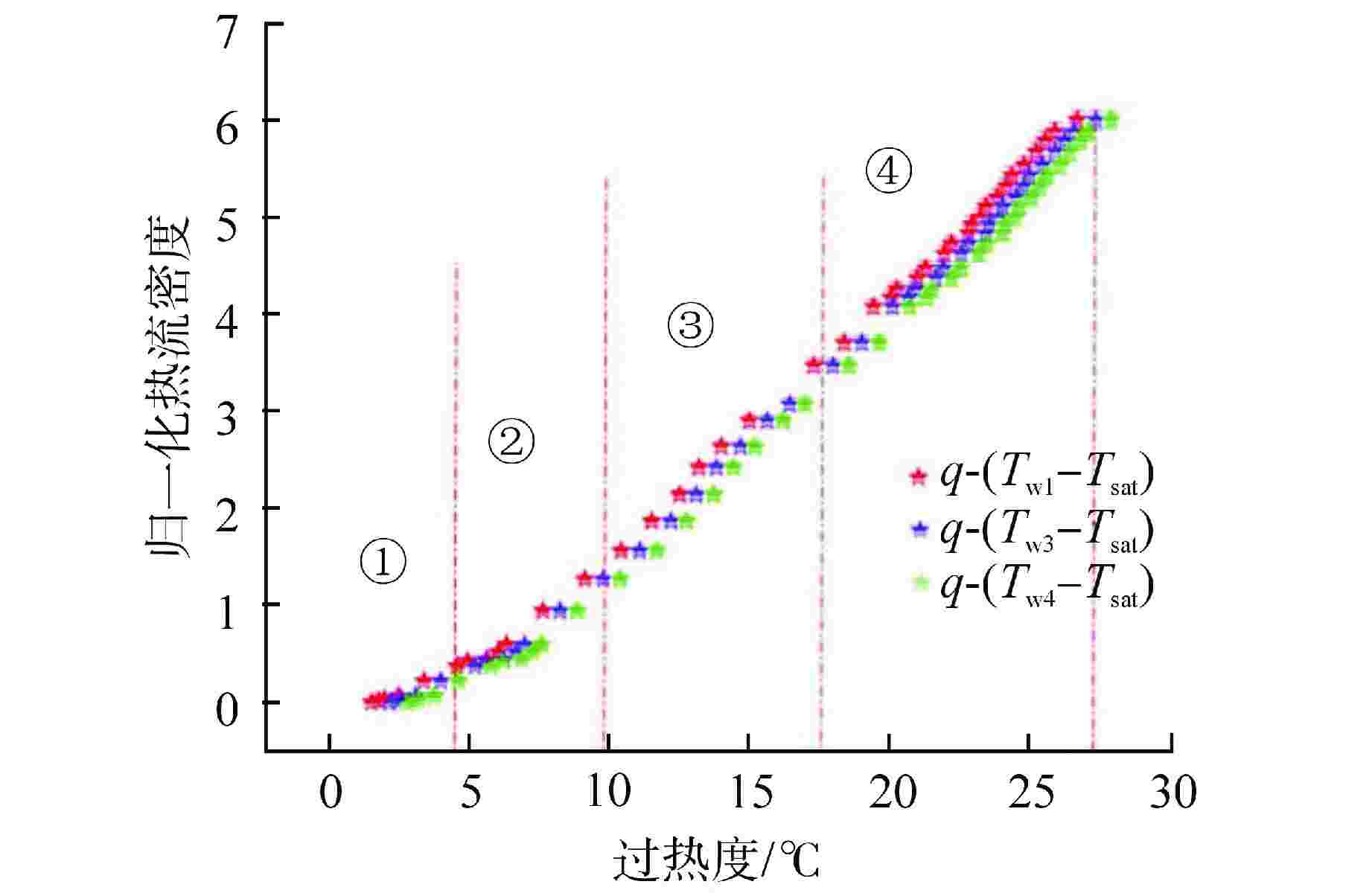

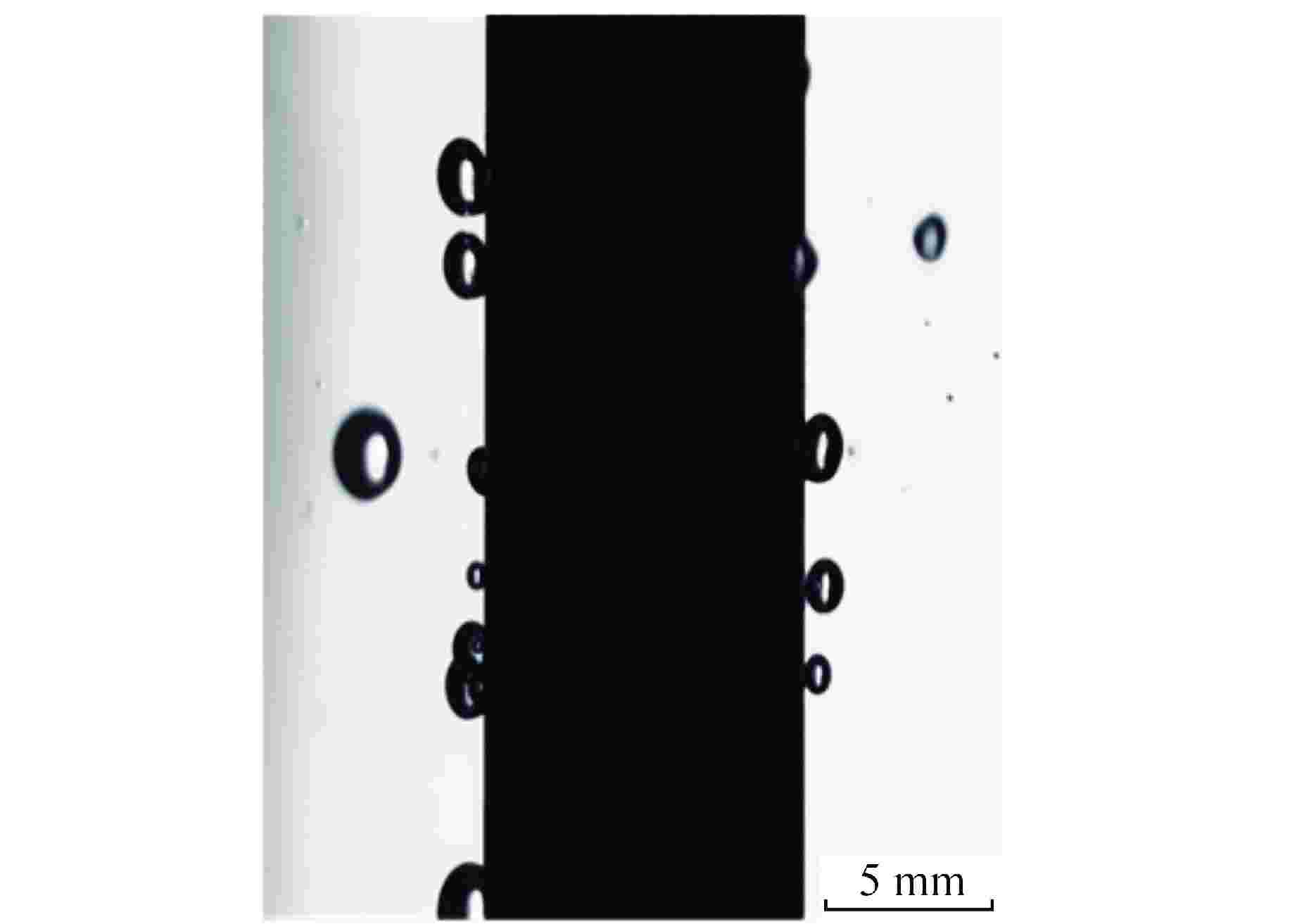

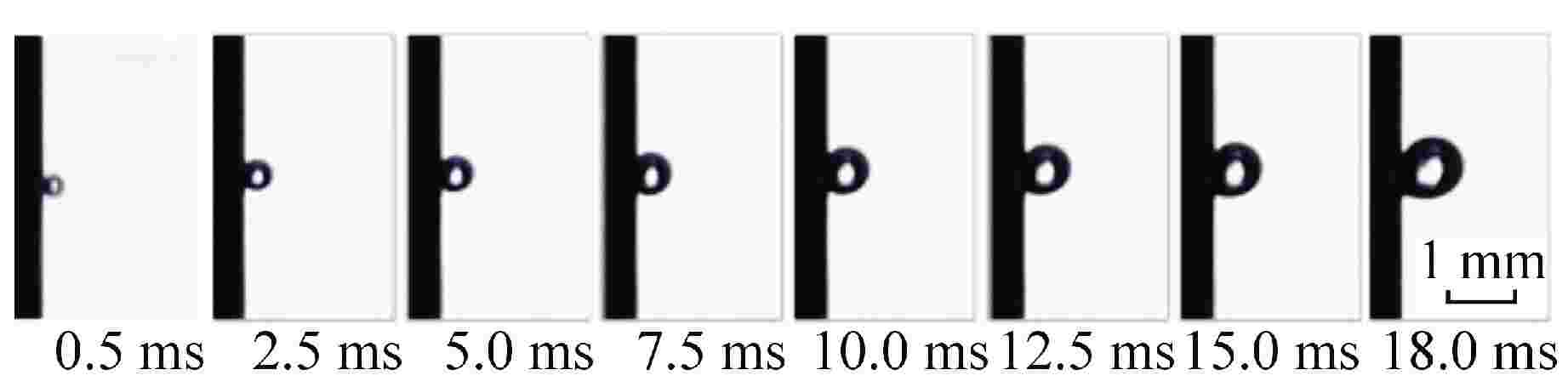

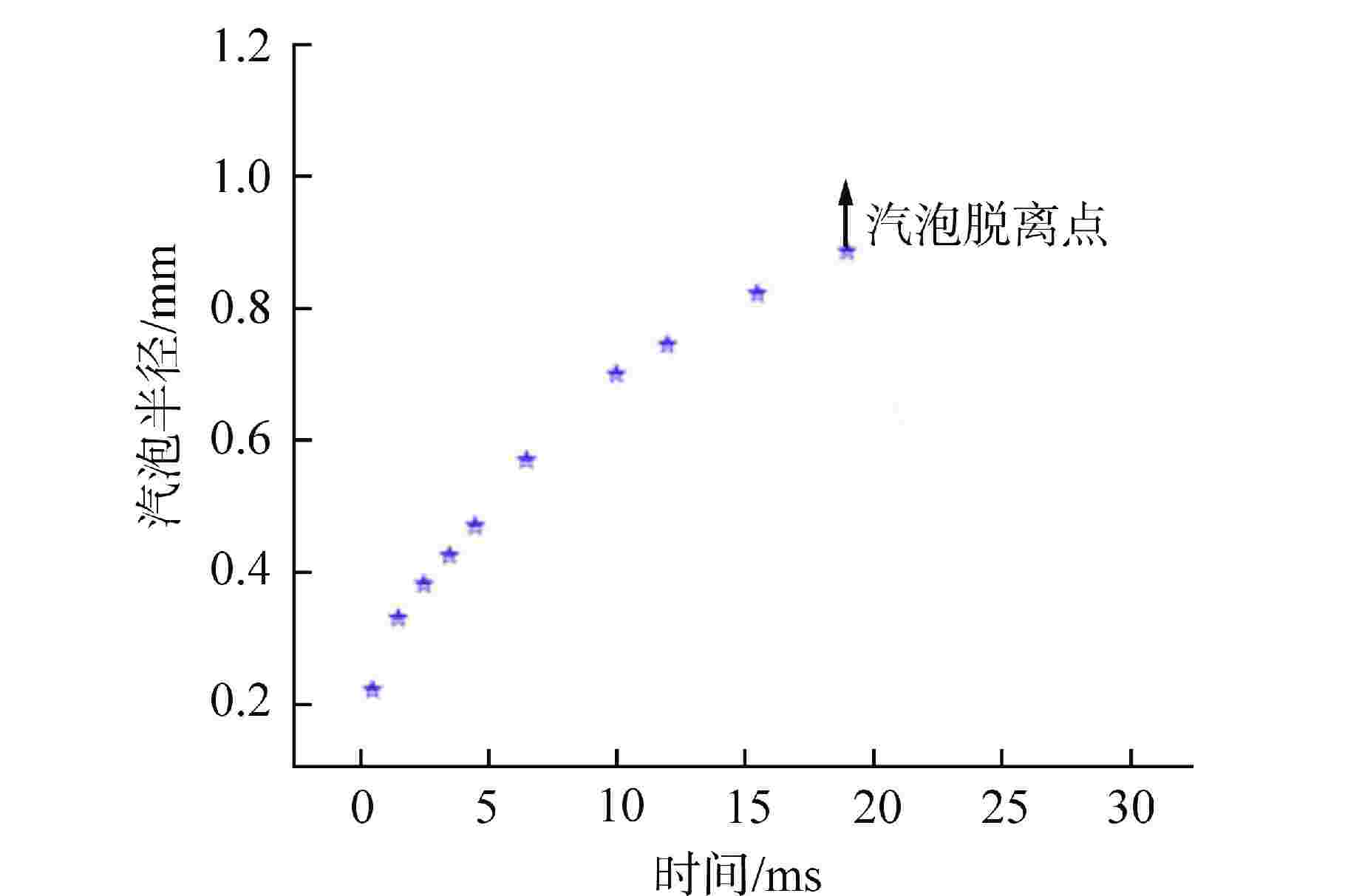

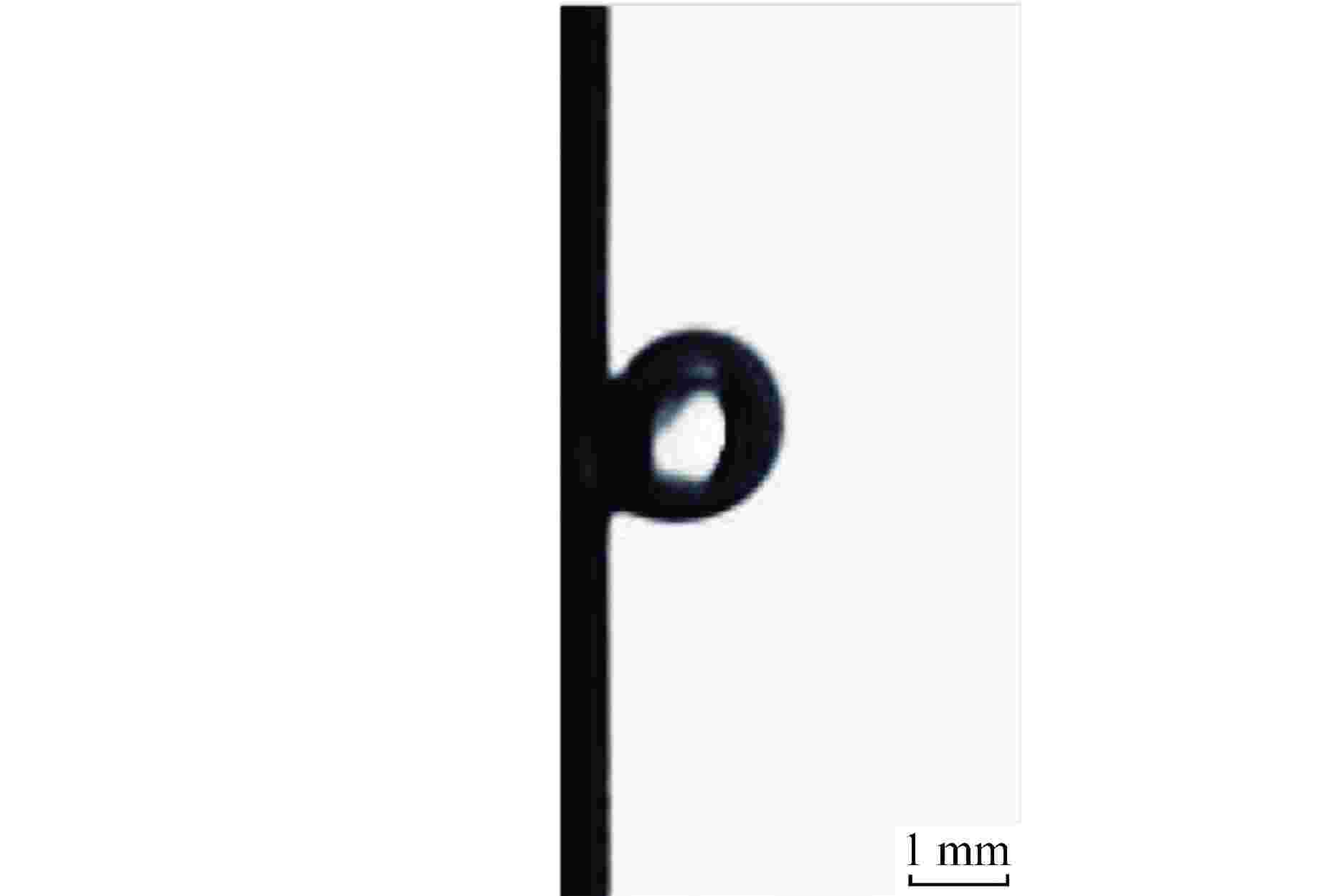

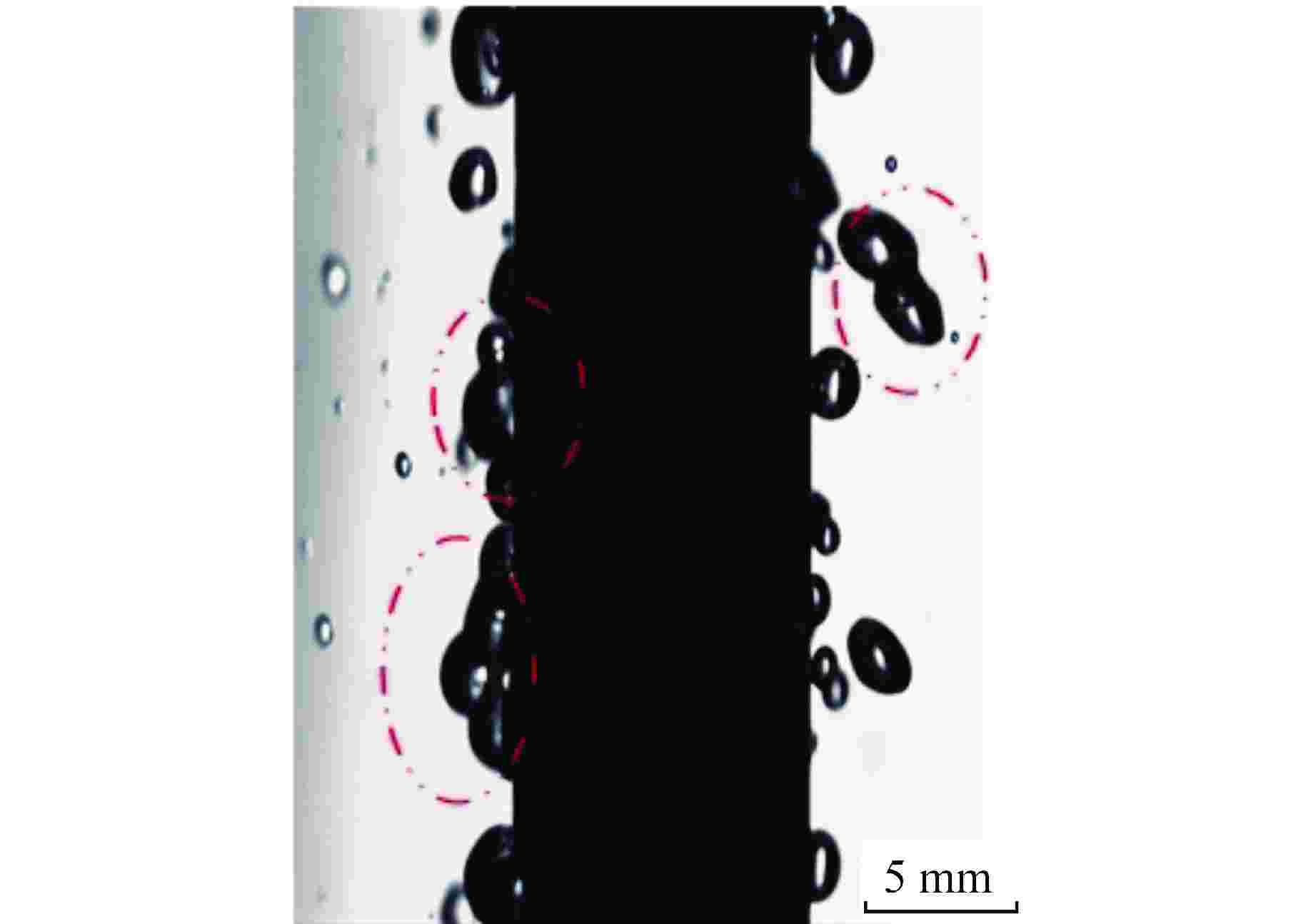

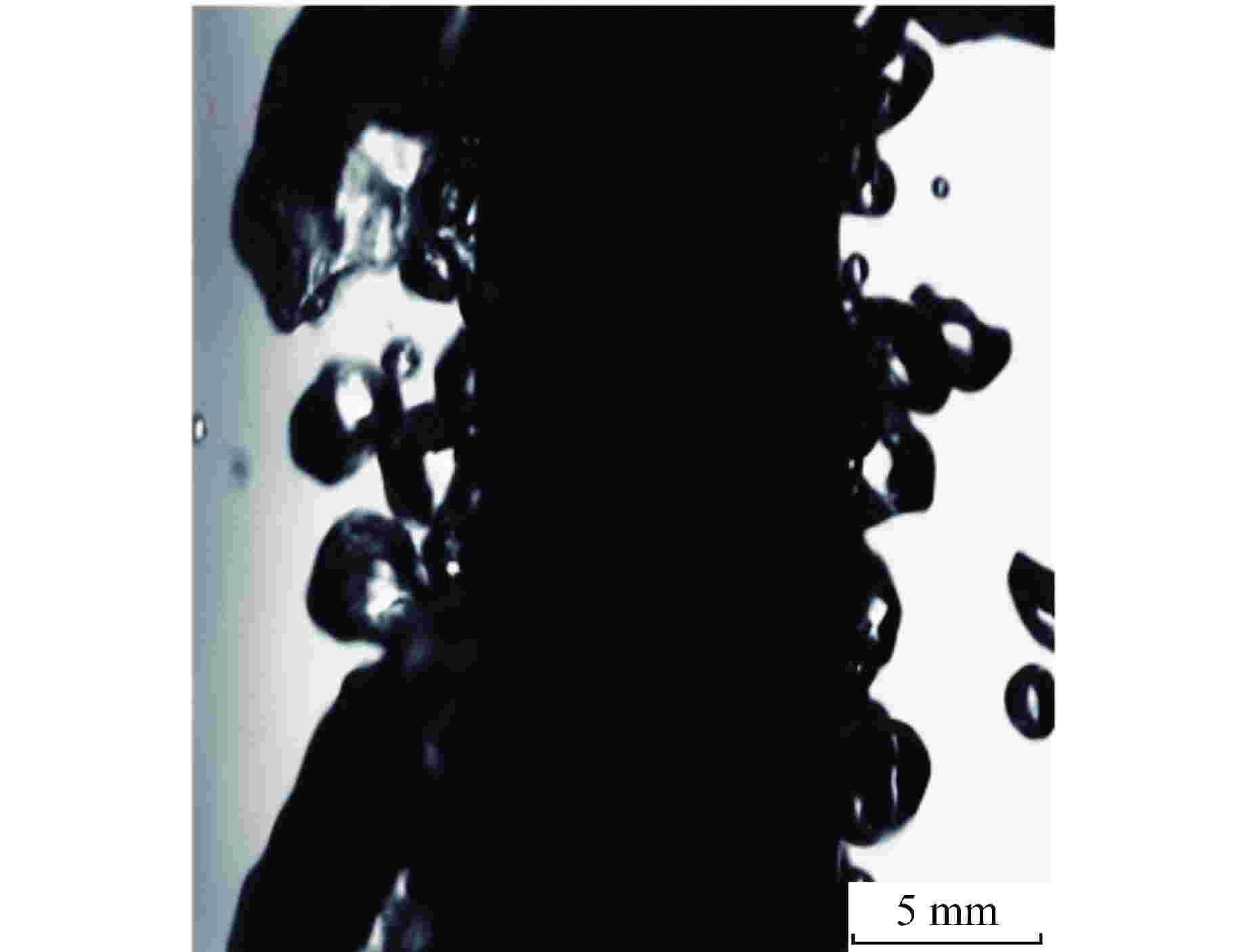

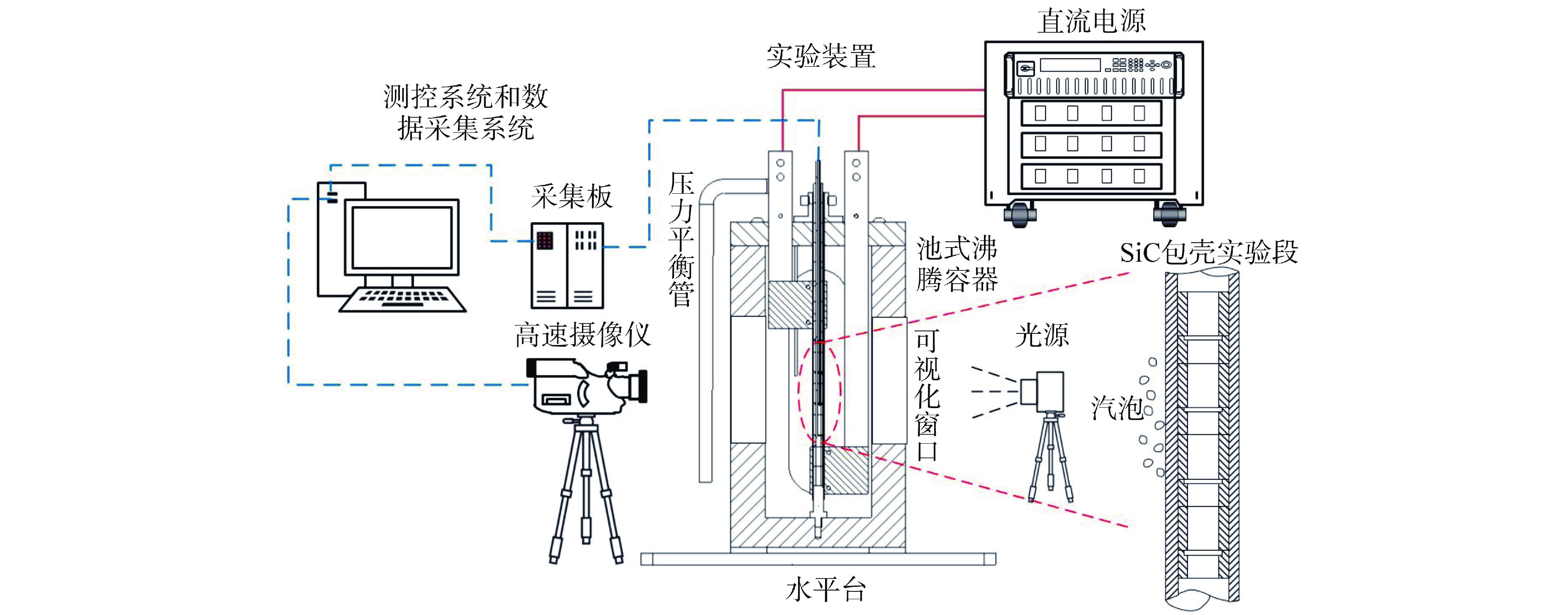

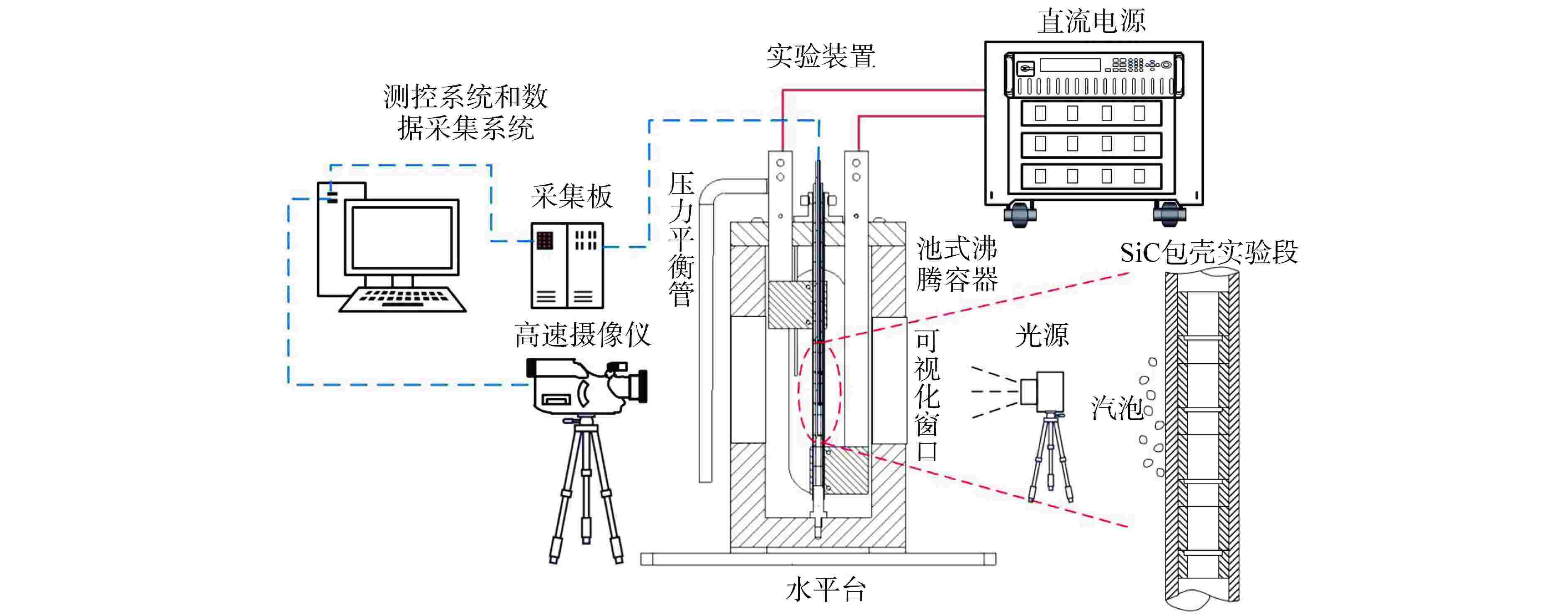

摘要: SiC材料是一种耐高温、抗氧化性好的耐事故燃料(ATF)类型,其传热及临界热流密度(CHF)性能是评估材料性能的重要指标,汽泡行为机理研究有助于评估其传热性能。采用常压池式沸腾可视化实验装置对SiC包壳材料汽泡行为机理进行研究,分析了其池式沸腾曲线不同区段中汽泡生长、脱离过程。根据观察到的SiC包壳表面池式沸腾汽泡图像,将整个池式沸腾传热过程分为自然对流区段、孤立汽泡核态沸腾区段、弹状汽泡核态沸腾区段和膜状汽泡核态沸腾区段4个区段。在孤立汽泡核态沸腾区段,SiC包壳表面汽泡生长时间较短、汽泡脱离频率高;在弹状汽泡核态沸腾区段,SiC表面产生大量汽泡,汽泡之间的相互作用剧烈,SiC表面传热较强。建立的接触角与脱离直径关系式可为后续传热模型的建立提供重要支撑。Abstract: SiC material is a kind of accident tolerant fuel (ATF) with high temperature resistance and good oxidation resistance. Its heat transfer and critical heat flux (CHF) are important indexes to evaluate the material performance, and the study of bubble behavior mechanism is helpful to evaluate its heat transfer performance. In this paper, the bubble behavior mechanism of SiC cladding material was studied by using the visualization experimental device of pool boiling at atmospheric pressure, and the bubble growth and detachment process in different sections of pool boiling curve were analyzed. According to the observed images of pool boiling bubbles on the surface of SiC cladding, the whole pool boiling heat transfer process can be divided into four sections: natural convection section, isolated bubble nucleate boiling section, slug bubble nucleate boiling section and film bubble nucleate boiling section. In the nucleate boiling zone of isolated bubbles, the growth time of bubbles on the surface of SiC cladding is short and the detachment frequency of bubbles is high. In the nucleate boiling zone of slug bubbles, a large number of bubbles are produced on the surface of SiC, and the interaction between bubbles is intense, resulting in strong heat transfer on the surface of SiC. The relationship between contact angle and detachment diameter is established, which can provide important support for the establishment of subsequent heat transfer model.

-

Key words:

- SiC /

- Pool boiling /

- Bubble behavior /

- Detachment diameter /

- Detachment frequency

-

表 1 SiC包壳实验段主要参数

Table 1. Main Parameters of Experimental Section

参数 数值 实验段总长/mm 352 实验加热段长度/mm 100 热电偶固定陶瓷外径/mm 7.2 镍铬棒直径/mm 4.0 下钼棒最大直径/mm 9.5 上钼棒直径/mm 4.0 铜排截面积/mm2 400 表 2 直接测量参数不确定度

Table 2. Uncertainties of the Directly Measured Parameters

测量参数 仪表名称 仪表精度 不确定度/% 温度 T型热电偶 0.3℃ 0.5 电流 霍尔电流传感器 0.2级 0.3 电压 直流电压传感器 0.0015 V 0.2 管外径 游标卡尺 0.02 mm 0.2 管长度 米尺 1 mm 0.3 表 3 间接测量参数不确定度

Table 3. Uncertainties of the Indirectly Measured Parameters

测量参数 不确定度/% SiC管传热面积/m2 0.98 SiC管加热功率/kW 0.42 SiC管热流密度/(kW·m−2) 0.52 SiC管表面传热系数/(kW·m−2·K−1) 2.80 -

[1] CHEN H, WANG X M, ZHANG R Q. Application and development progress of Cr-based surface coatings in nuclear fuel element: I. Selection, preparation, and characteristics of coating materials[J]. Coatings, 2020, 10(9): 808. doi: 10.3390/coatings10090808 [2] KIM H G, YANG J H, KIM W J, et al. Development status of accident-tolerant fuel for light water reactors in Korea[J]. Nuclear Engineering and Technology, 2016, 48(1): 1-15. doi: 10.1016/j.net.2015.11.011 [3] REBAK R B, TERRANI K A, FAWCETT R M. FeCrAl alloys for accident tolerant fuel cladding in light water reactors[C]//Proceedings of ASME 2016 Pressure Vessels and Piping Conference. Vancouver: American Society of Mechanical Engineers, 2016. [4] TERRANI K A. Accident tolerant fuel cladding development: promise, status, and challenges[J]. Journal of Nuclear Materials, 2018, 501: 13-30. doi: 10.1016/j.jnucmat.2017.12.043 [5] COLETTI C, JAROSZESKI M J, PALLAORO A, et al. Biocompatibility and wettability of crystalline SiC and Si surfaces[C]//Proceedings of the 2007 29th Annual International Conference of the IEEE Engineering in Medicine and Biology Society. Lyon: IEEE, 2007: 5849-5852. [6] KAM D H, JEONG Y H, LEE J H. Experiment on pool and flow boiling CHF for the SiC surfaces under atmospheric condition[C]//Proceedings of KNS Fall Meeting. Daejeon: Korean Nuclear Society, 2013. [7] SEO H, CHU J H, KWON S Y, et al. Pool boiling CHF of reduced graphene oxide, graphene, and SiC-coated surfaces under highly wettable FC-72[J]. International Journal of Heat and Mass Transfer, 2015, 82: 490-502. doi: 10.1016/j.ijheatmasstransfer.2014.11.019 [8] SEO G H, JEUN G, KIM S J. Pool boiling heat transfer characteristics of zircaloy and SiC claddings in deionized water at low pressure[J]. Experimental Thermal and Fluid Science, 2015, 64: 42-53. doi: 10.1016/j.expthermflusci.2015.01.017 [9] KAM D H, LEE J H, LEE T, et al. Critical heat flux for SiC- and Cr-coated plates under atmospheric condition[J]. Annals of Nuclear Energy, 2015, 76: 335-342. doi: 10.1016/j.anucene.2014.09.046 [10] 文青龙,曾谢虎,杜强,等. 常压下ATF锆合金包壳Cr涂层表面饱和池式沸腾气泡行为实验研究[J]. 核动力工程,2022, 43(5): 34-42. [11] 曾谢虎,陈志强,文青龙,等. Cr涂层锆包壳池式沸腾传热实验研究[J]. 核动力工程,2023, 44(2): 91-97. [12] MURABAYASHI M, TANAKA S, TAKAHASHI Y. Thermal conductivity and heat capacity of zircaloy-2, −4 and unalloyed zirconium[J]. Journal of Nuclear Science and Technology, 1975, 12(10): 661-662. doi: 10.1080/18811248.1975.9733170 [13] FRITZ W. Maximum volume of vapor bubbles [J]. Physikalische Zeitschrift, 1935, 36: 379-384. -

下载:

下载: