Extended Development and Application of CAD-based Transport in RMC

-

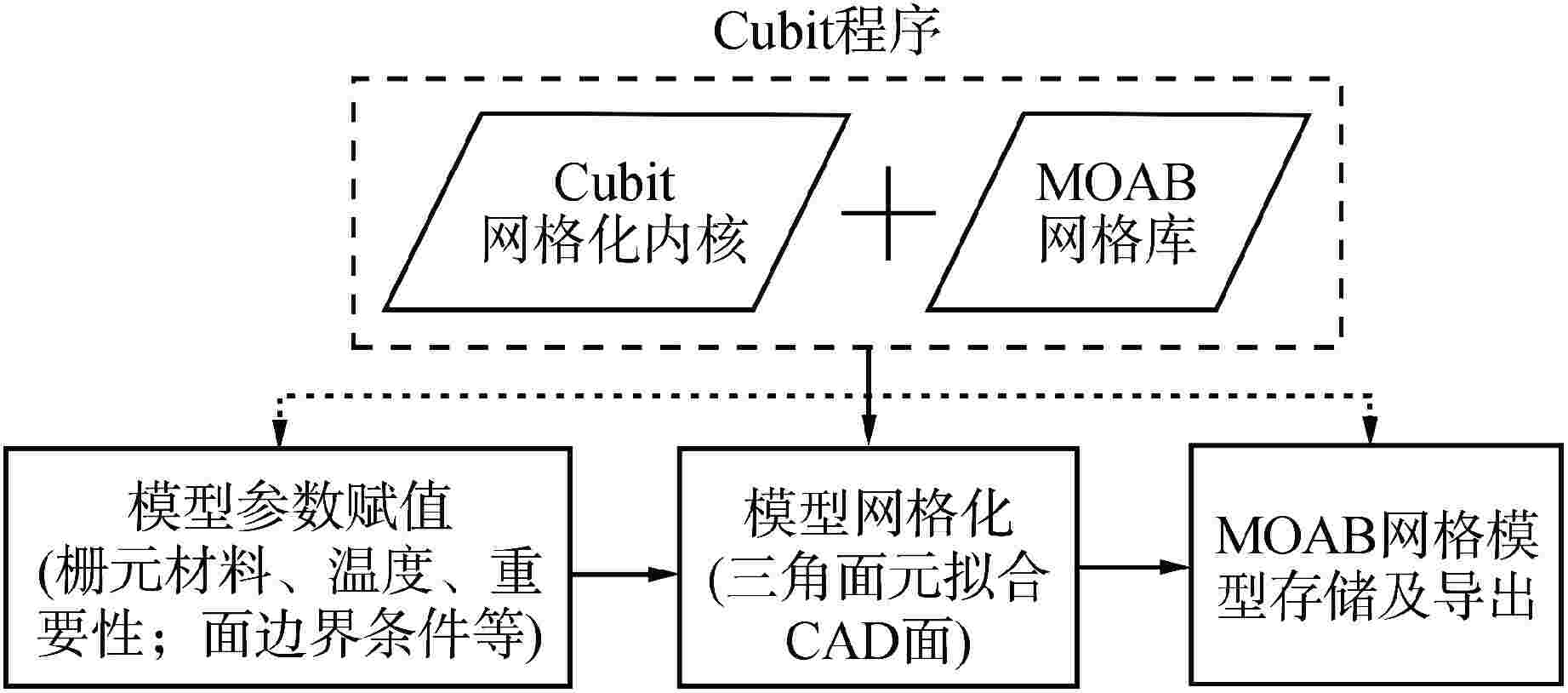

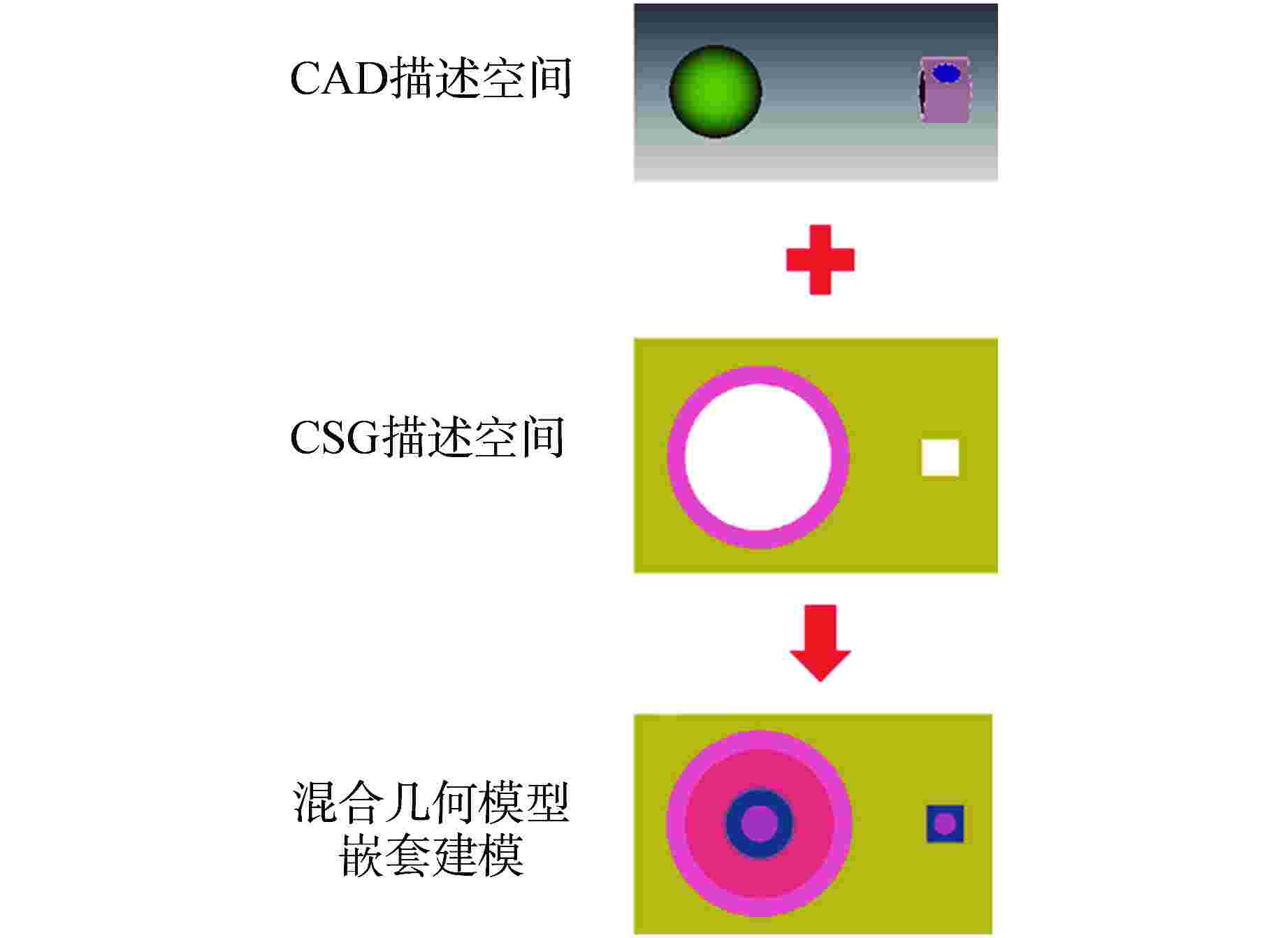

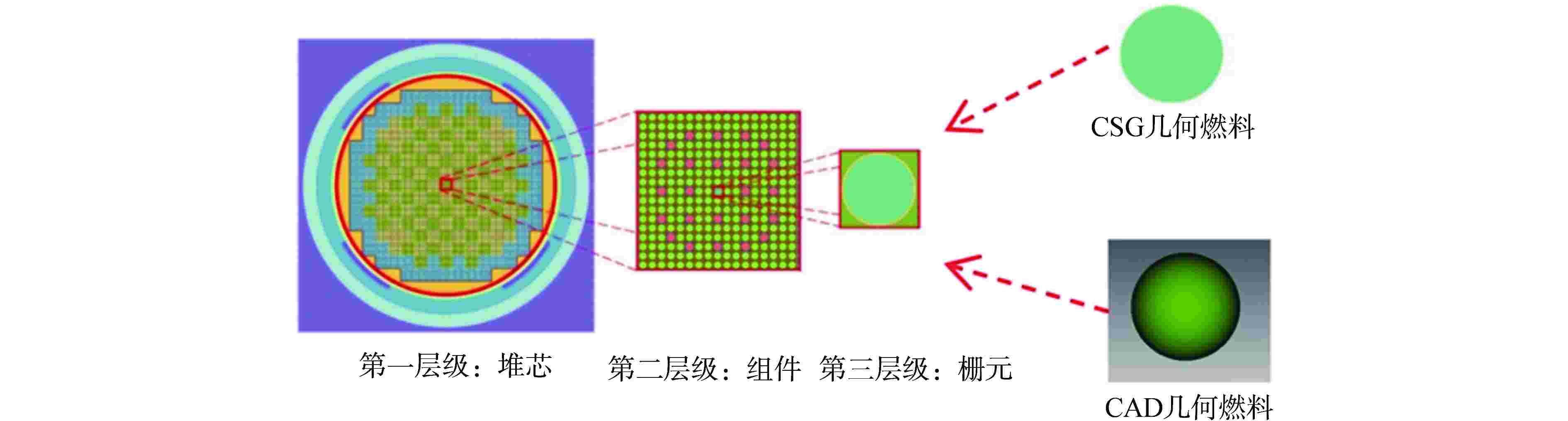

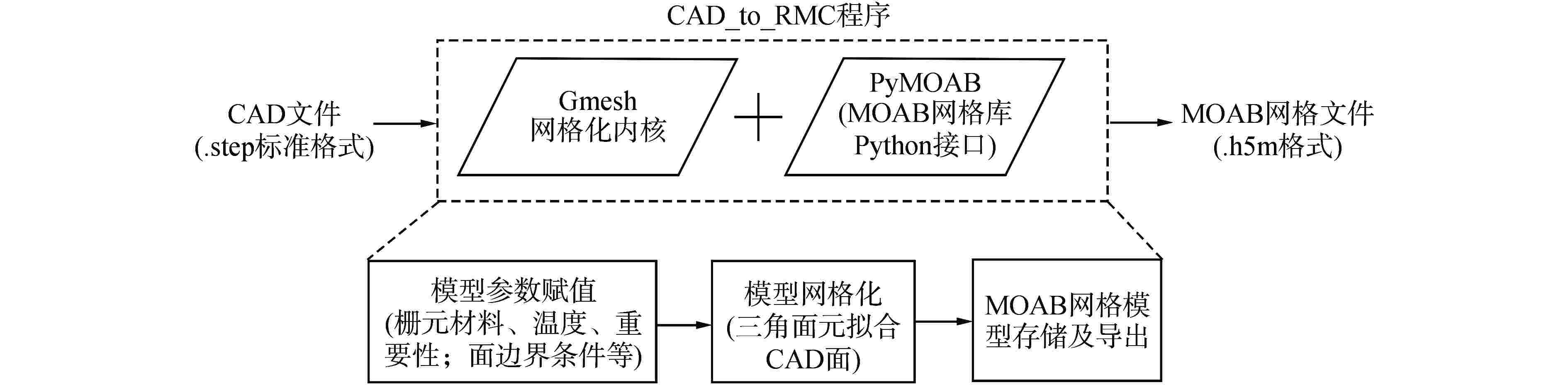

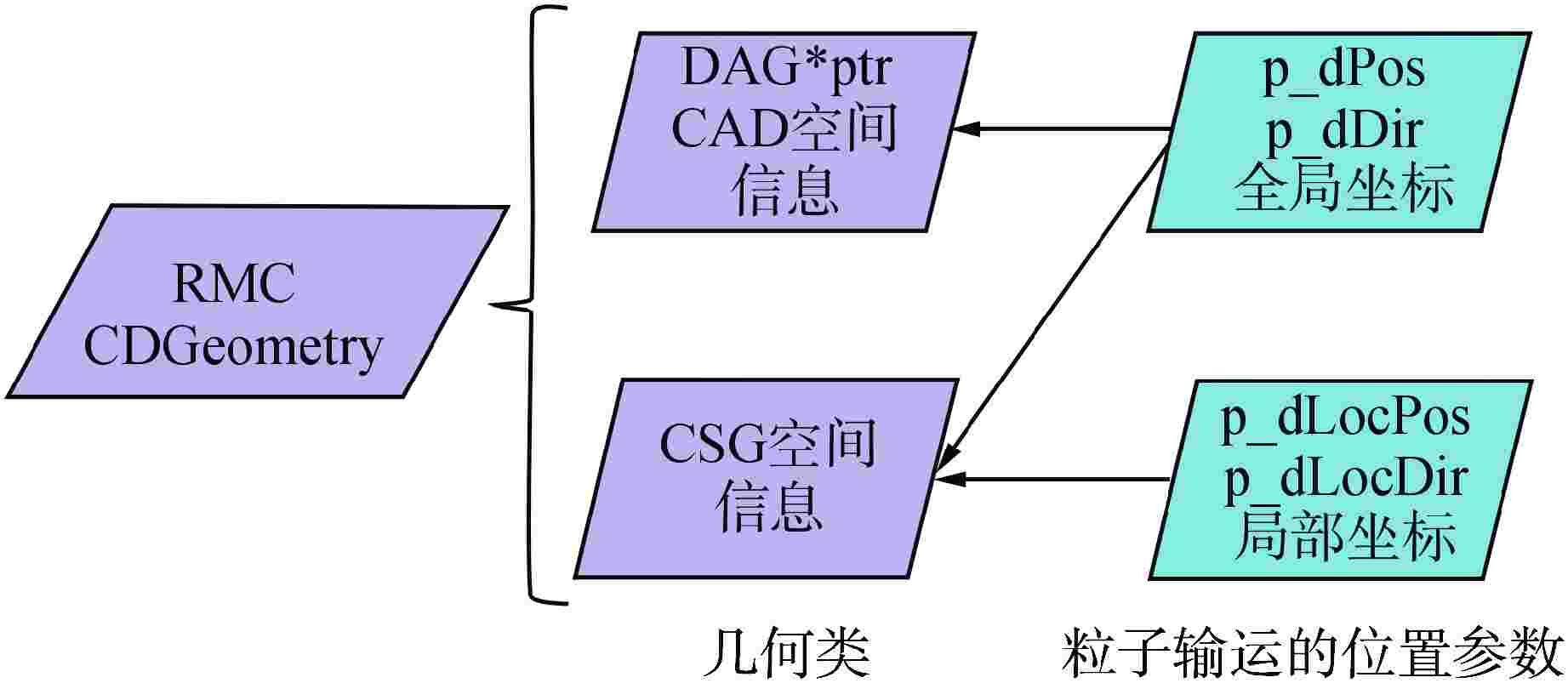

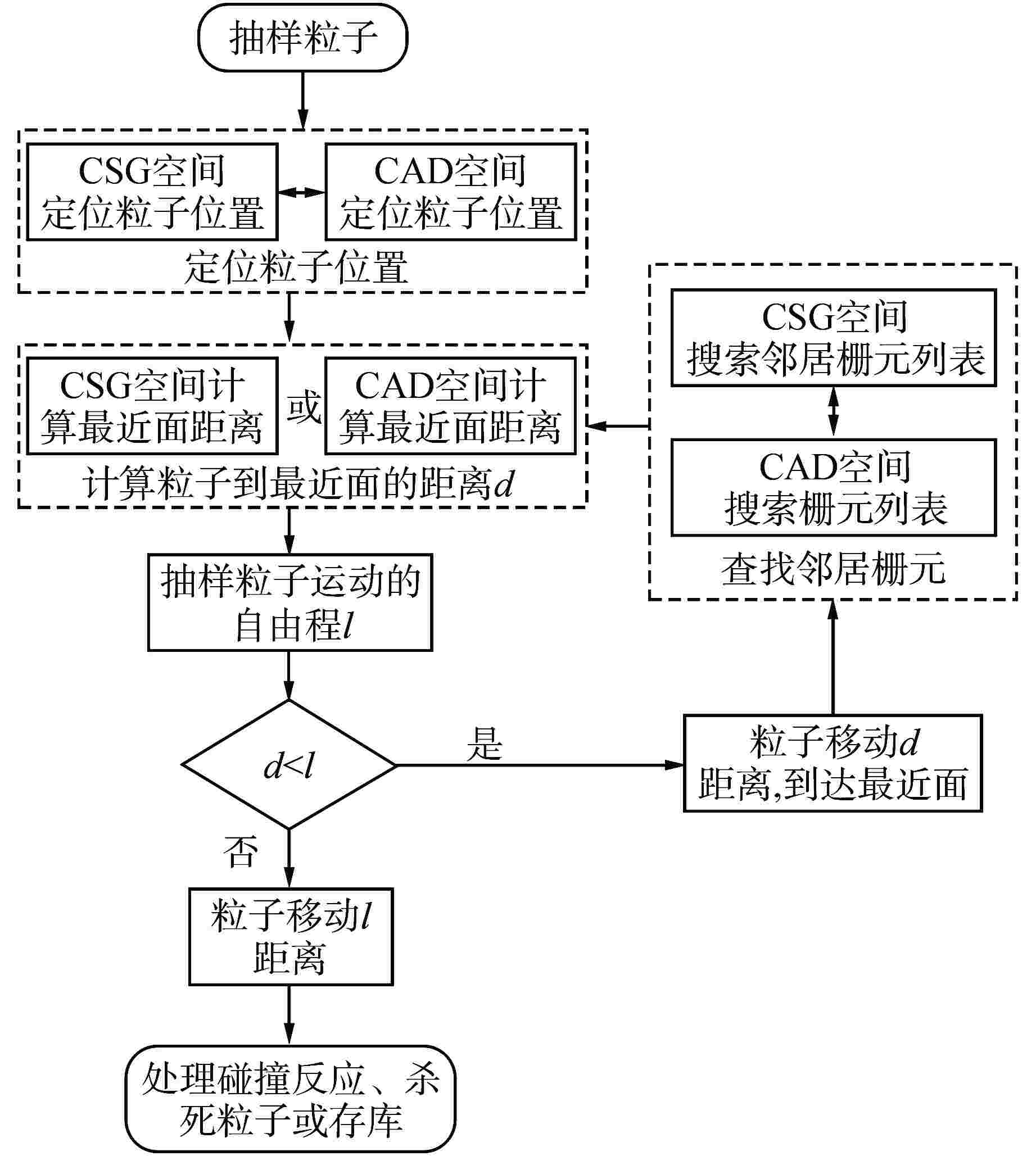

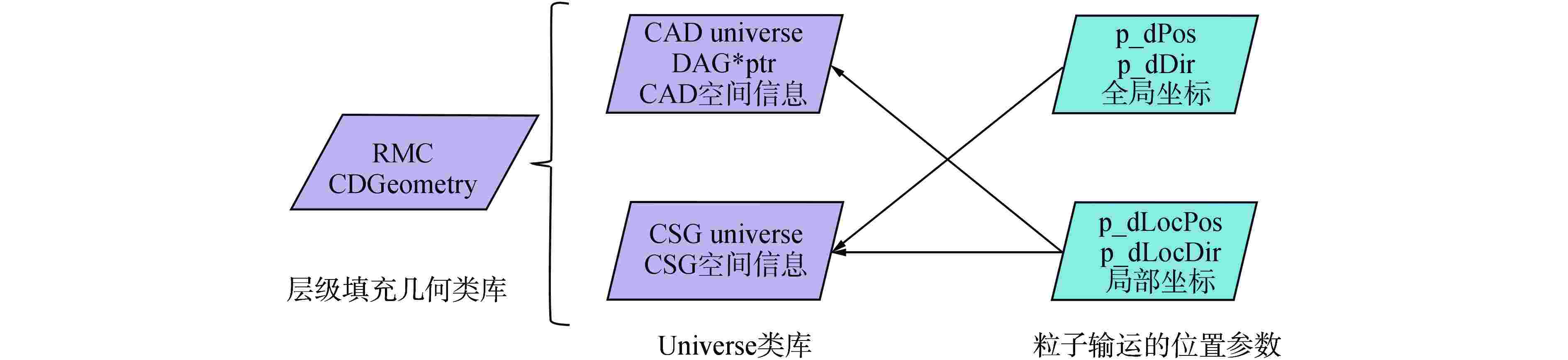

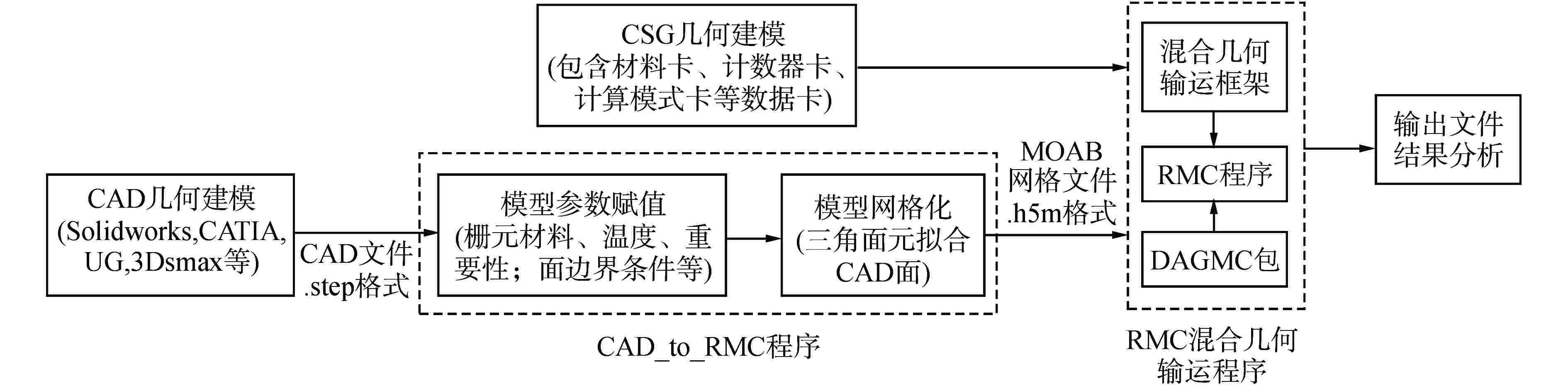

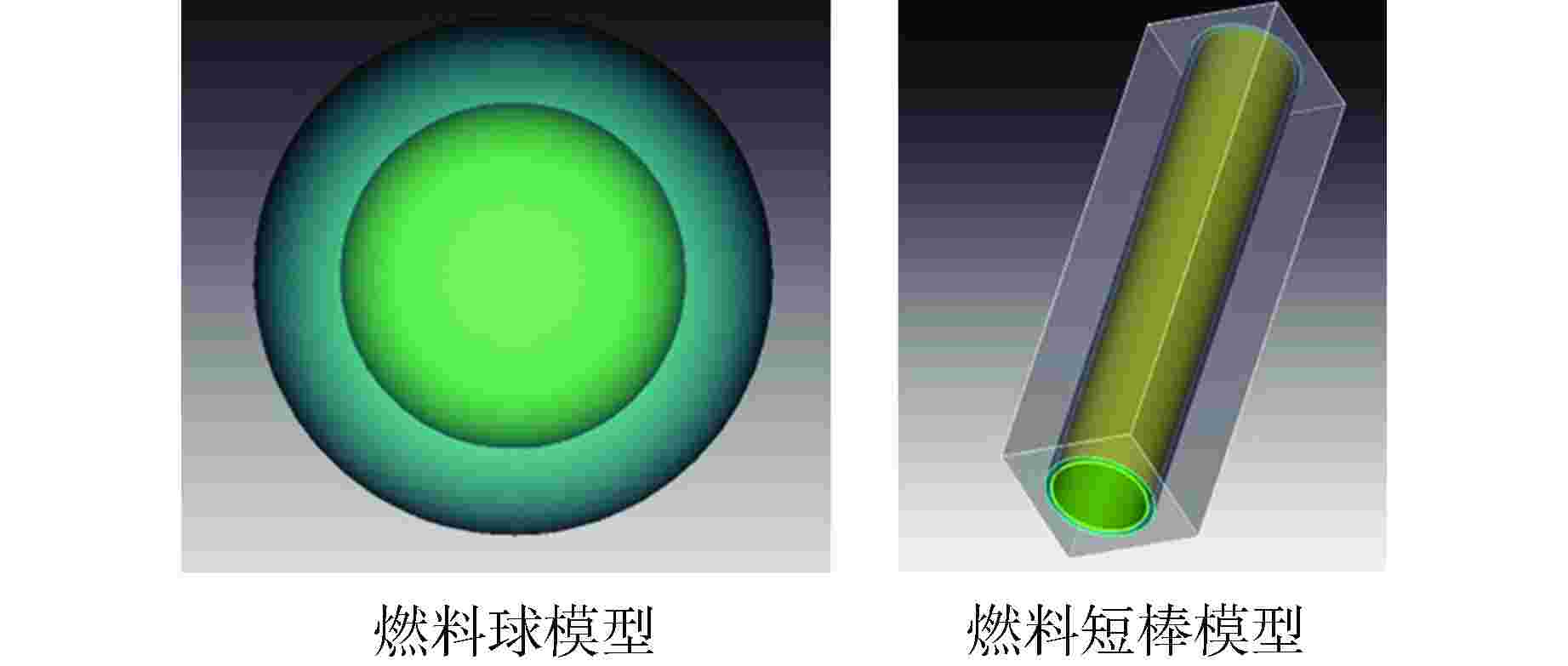

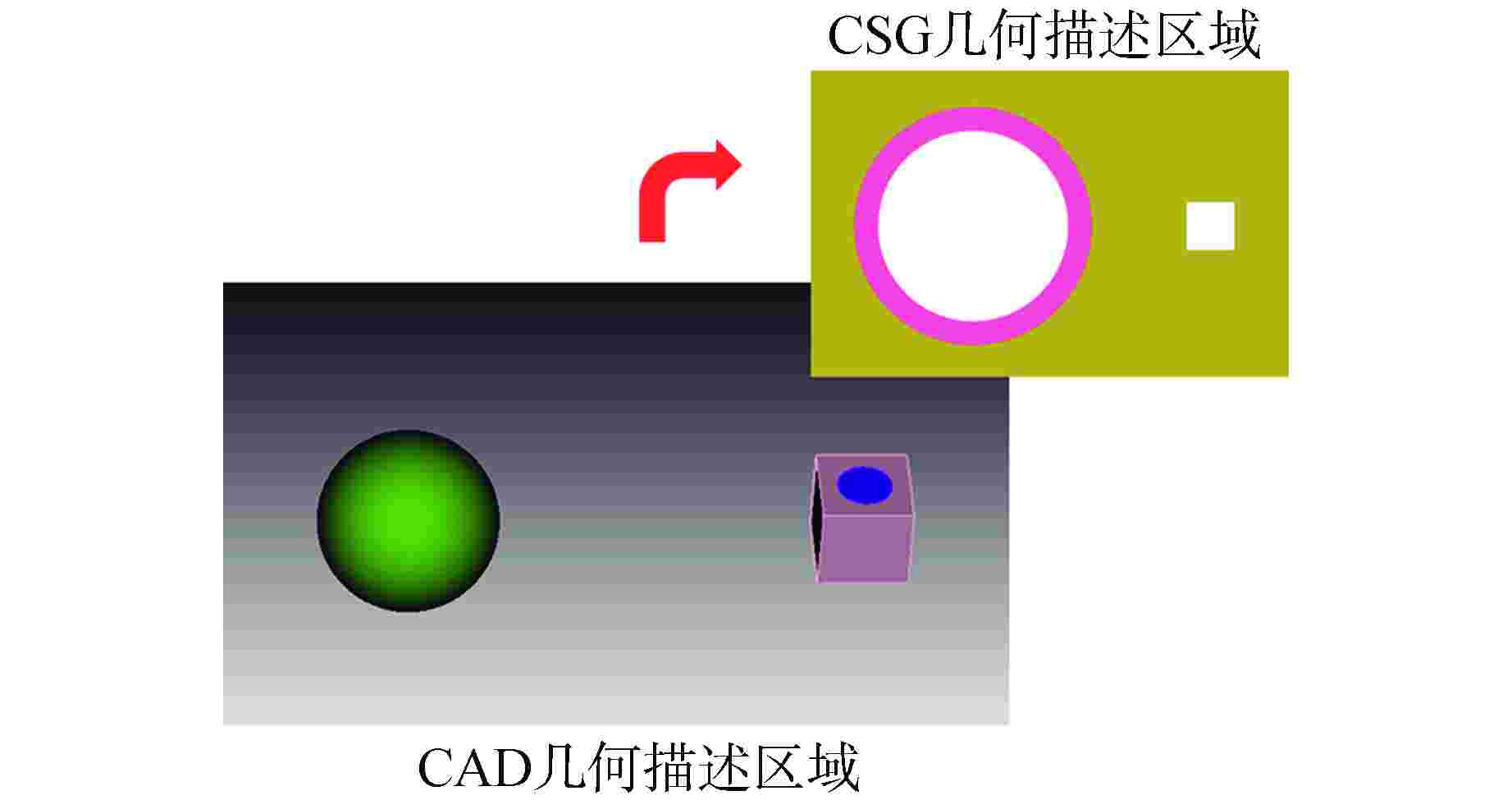

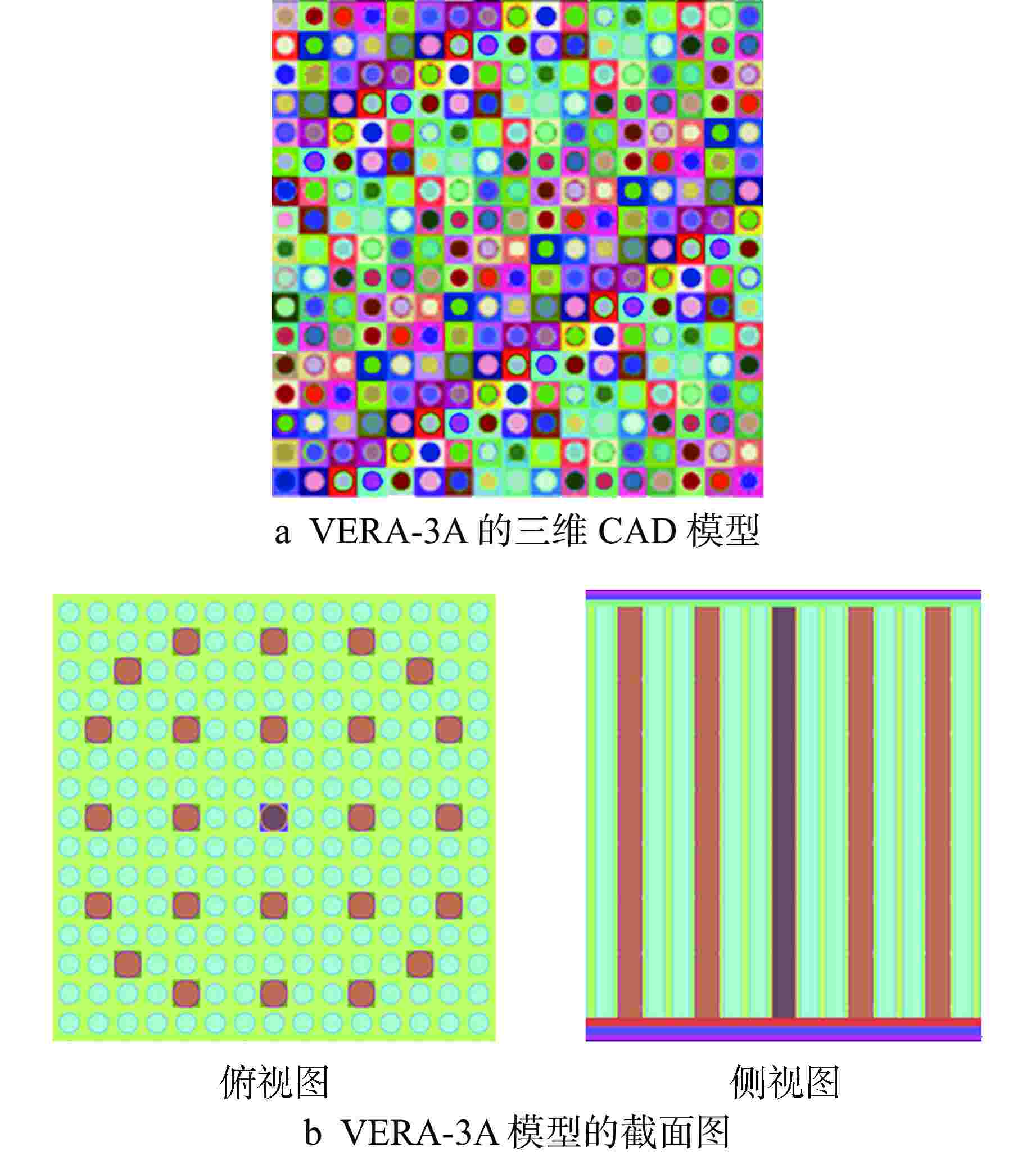

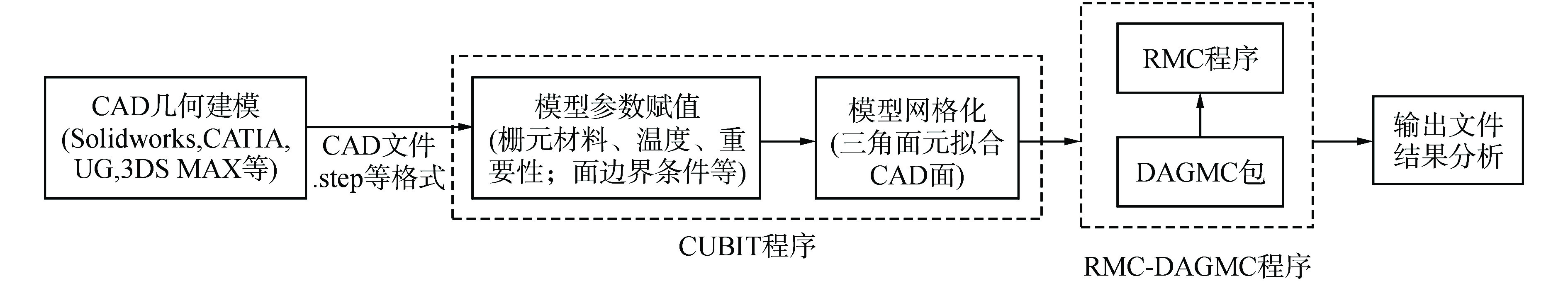

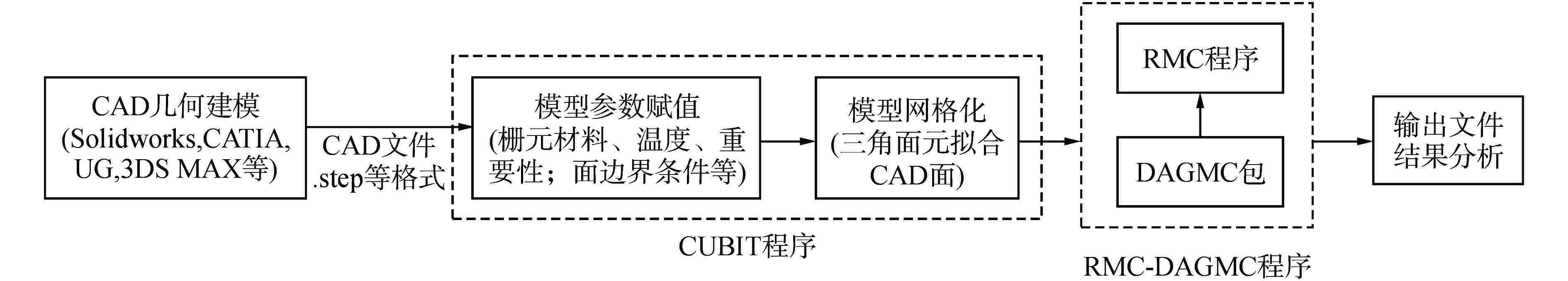

摘要: 为拓展蒙特卡罗程序RMC基于计算机辅助设计(CAD)几何输运能力,面向新型数值反应堆的RMC基于CAD几何建模输运提供新的计算手段。首先采用开源网格化内核处理CAD几何模型,实现全流程自主化的RMC基于CAD几何输运方法,其次开发了CAD与构造实体几何(CSG)的混合几何输运框架,提高几何处理效率和RMC输运效率。通过燃料球、VERA-3A燃料组件等模型的数值计算,验证了自主化CAD几何处理方法、混合几何建模输运方法的正确性;与现有CAD几何建模输运方法相比,混合几何建模输运方法在几何处理时间、计算效率等方面取得显著提升。因此,本研究开发的RMC基于CAD几何输运拓展功能可以用于新型数值反应堆的中子学分析计算。Abstract: To enhance the capability of CAD-based transport in RMC, and provide a new calculation method for the CAD-based geometry transport modeling in Monte Carlo (MC) for new numerical reactors, in this study, firstly, an open-source meshing kernel is employed to process CAD models, realizing an autonomous CAD-based transport method throughout the entire process in the Monte Carlo code RMC. Subsequently, a hybrid geometric transport framework combining CAD and CSG geometry is developed, which improves the efficiency of geometric processing and Monte Carlo transport. The correctness of the autonomous CAD geometric processing method and the hybrid geometric transport method is verified through numerical calculations of fuel spheres, VERA-3A fuel assembly and other models. Compared with the existing CAD geometric modeling transportation methods, the hybrid geometric modeling transportation method has significantly improved the geometric processing time and the efficiency of Monte Carlo calculation. Therefore, the enhanced CAD-based transport method in RMC developed in this study can be used for neutron transport analysis calculations of new numerical reactors.

-

Key words:

- Constructive solid geometry (CSG) /

- Hybrid geometry /

- CAD geometry /

- RMC /

- Geometry meshing /

- Monte Carlo

-

表 1 燃料球模型计算结果对比

Table 1. Calcultaion Results of Fuel Sphere Model

程序 建模方式 有效增殖系数(keff) σ 偏差/σ 粒子平均碰撞数 计算耗时/min RMC CSG几何 0.578047 0.000805 13.97 0.099 CAD几何(Cubit) 0.577595 0.000789 −0.69 14.07 15.35 CAD几何(Cad_to_RMC) 0.578417 0.000821 0.56 14.03 18.90 OpenMC CAD几何(Cubit) 0.57668 0.00081 −2.05 13.98 CAD几何(Cad_to_OpenMC) 0.57777 0.00081 −0.42 15.21 表 2 燃料短棒模型计算结果对比

Table 2. Calcultaion Results of Fuel Pin Model

参数 RMC

(CSG几何)RMC

[CAD几何(Cubit)]RMC

[CAD几何(Cad_to_RMC)]计算结果 σ 计算结果 σ 偏差/σ 计算结果 σ 偏差/σ 中子通量密度/(cm−2·s−1) 燃料芯块 5.27×10−1 2.73×10−3 5.22×10−1 2.58×10−3 −2.34 5.27×10−1 2.54×10−3 0.28 气隙 1.42×10−2 2.83×10−3 1.42×10−2 2.93×10−3 −0.38 1.42×10−2 2.68×10−3 0.83 包壳 9.29×10−2 2.64×10−3 9.26×10−2 2.73×10−3 −0.97 9.34×10−2 2.50×10−3 1.22 水层 3.25×10−1 1.77×10−3 3.24×10−1 1.82×10−3 −1.71 3.27×10−1 1.51×10−3 2.70 计算耗时/min 0.199 2.470 5.700 表 3 燃料球块模型计算结果对比

Table 3. Calcultaion Results of Fuel Sphere and Pin Model

参数 RMC(CSG几何模型) RMC(CAD几何模型) RMC(混合几何嵌套模型) 计算结果 σ 计算结果 σ 计算结果 σ keff 0.324823 0.000380 0.32466 0.000393 0.32466 0.000393 中子通量密度/(cm−2·s−1) 燃料球芯块 3.52×10−3 7.50×10−2 3.39×10−3 7.49×10−2 3.49×10−3 7.53×10−2 燃料球气隙 1.04×10−2 5.79×10−2 1.01×10−2 6.17×10−2 1.01×10−2 6.47×10−2 燃料球水层 2.93×10−3 5.28×10−2 2.77×10−3 5.47×10−2 2.67×10−3 5.77×10−2 燃料块内部 4.63×10−2 1.03×10−2 4.60×10−2 1.05×10−2 4.54×10−2 1.12×10−2 燃料块水层 1.05×103 5.91×10−4 1.06×103 5.90×10−4 1.06×103 5.93×10−4 粒子碰撞次数 1474.38 1474.59 1474.90 计算耗时/s 327 15430 7330 表 4 VERA-3A燃料组件模型计算结果对比

Table 4. Calcultaion Results of VERA-3A Assembly Model

参数 RMC

(CSG几何模型)RMC

(CAD几何模型)RMC

(混合几何层级

填充模型)计算

结果σ 计算

结果σ 计算

结果σ keff 1.177635 0.000822 1.176401 0.000852 1.175728 0.000834 粒子碰

撞次数34.12 34.11 34.11 计算

耗时/s1.38×102 1.70×104 7.36×103 表 5 VERA-3A燃料组件模型重点参数对比

Table 5. Key Parameters of VERA-3A Assembly Model

程序 建模方式 CAD几何

文件读入

耗时/s最大单核

内存占用/MBMOAB网格

文件导出时间/sRMC CAD几何模型 ~40 ~530 混合几

何模型~3 ~500 CAD_to_RMC CAD几何模型 ~1000 ~15 混合几

何模型~490 ~1 -

[1] WILSON P P H, TAUTGES T J, KRAFTCHECK J A, et al. Acceleration techniques for the direct use of CAD-based geometry in fusion neutronics analysis[J]. Fusion Engineering and Design, 2010, 85(10-12): 1759-1765. doi: 10.1016/j.fusengdes.2010.05.030 [2] DAVIS A, BARZILLA J, FERRARI A, et al. FluDAG: a CAD based tool for high energy physics[J]. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2019, 915: 65-74. [3] SHEN P F, LIANG J G, LIU S C, et al. Implementation and verification of the DAGMC module in Monte Carlo code RMC[C]//Proceedings of the 29th International Conference on Nuclear Engineering, Shenzhen: 2022. [4] SHRIWISE P C, ZHANG X K, DAVIS A. DAG-OpenMC: CAD-based geometry in OpenMC[J]. Transactions of the American Nuclear Society, 2020, 122(1): 395-398. [5] HAN M C, KIM C H, JEONG J H, et al. DagSolid: a new Geant4 solid class for fast simulation in polygon-mesh geometry[J]. Physics in Medicine & Biology, 2013, 58(13): 4595-4609. [6] MARTZ R L. The MCNP6 book on unstructured mesh geometry: user's guide for MCNP 6.2. 1: LA-UR-18-27630[R]. Los Alamos: Los Alamos National Laboratory, 2018. [7] SHU H L, CAO L Z, HE Q M, et al. Study on unstructured mesh-based Monte Carlo/deterministic coupled particle transport calculation method[J]. Nuclear Science and Engineering, 2024, 198(11): 2209-2229. doi: 10.1080/00295639.2023.2295065 [8] LEPPÄNEN J. CAD-based geometry type in serpent 2 - application in fusion neutronics[C]//Proceedings of the Mathematics and Computation, Supercomputing in Nuclear Applications and Monte Carlo International Conference. Nashville: Curran Associates Inc. , 2015: 19-23. [9] SHRIWISE P. DAGMC CAD-based geometry as universes[EB/OL]. (2021-04-28)[2024-07-10]. https://github.com/openmc-dev/openmc/pull/1825. [10] LEPPÄNEN J. Methodology, applications and performance of the CAD-based geometry type in the serpent 2 Monte Carlo code[J]. Annals of Nuclear Energy, 2022, 176: 109259. doi: 10.1016/j.anucene.2022.109259 [11] BIONDO E, DAVIDSON G, ADE B. Layered CAD/CSG geometry for spatially complex radiation transport scenarios[J]. Annals of Nuclear Energy, 2023, 181: 109569. doi: 10.1016/j.anucene.2022.109569 [12] WANG K, LI Z G, SHE D, et al. RMC – a Monte Carlo code for reactor core analysis[J]. Annals of Nuclear Energy, 2015, 82: 121-129. doi: 10.1016/j.anucene.2014.08.048 [13] TAUTGES T J, ERNST C, STIMPSON C, et al. MOAB: a mesh-oriented database[R]. Livermore, California, USA: Sandia National Laboratories, 2004. [14] GEUZAINE C, REMACLE J F. Gmsh: a 3-D finite element mesh generator with built-in pre- and post-processing facilities[J]. International Journal for Numerical Methods in Engineering, 2009, 79(11): 1309-1331. doi: 10.1002/nme.2579 [15] GODFREY A T. Vera core physics benchmark progression problem specifications, revision 4: CASL-U-2012-0131-004[R]. Pittsburgh, Pennsylvania, United States: Westinghouse Electric Corporation, 2014. -

下载:

下载: