Study on Non-classical PCMI Behavior Based on FUPAC3D

-

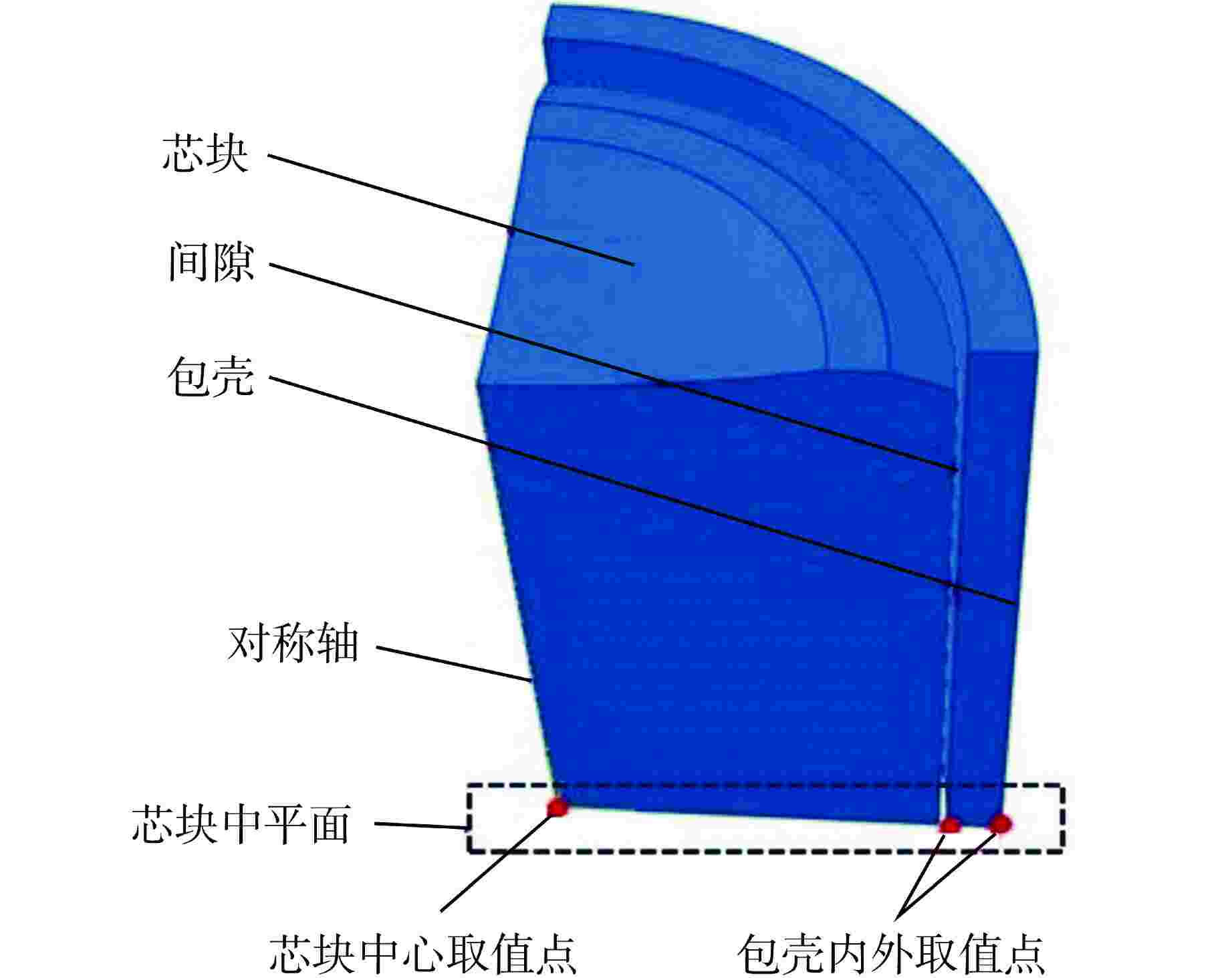

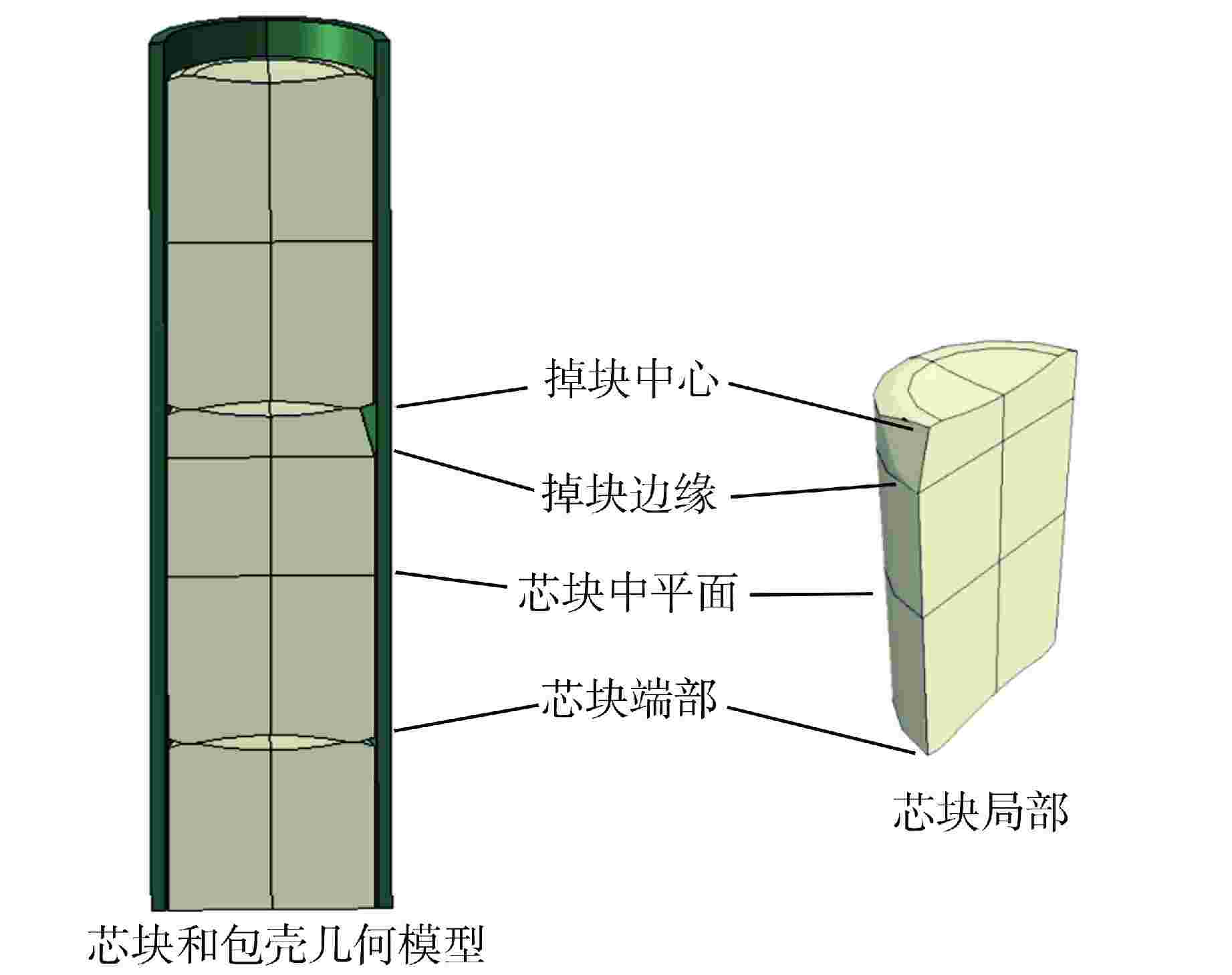

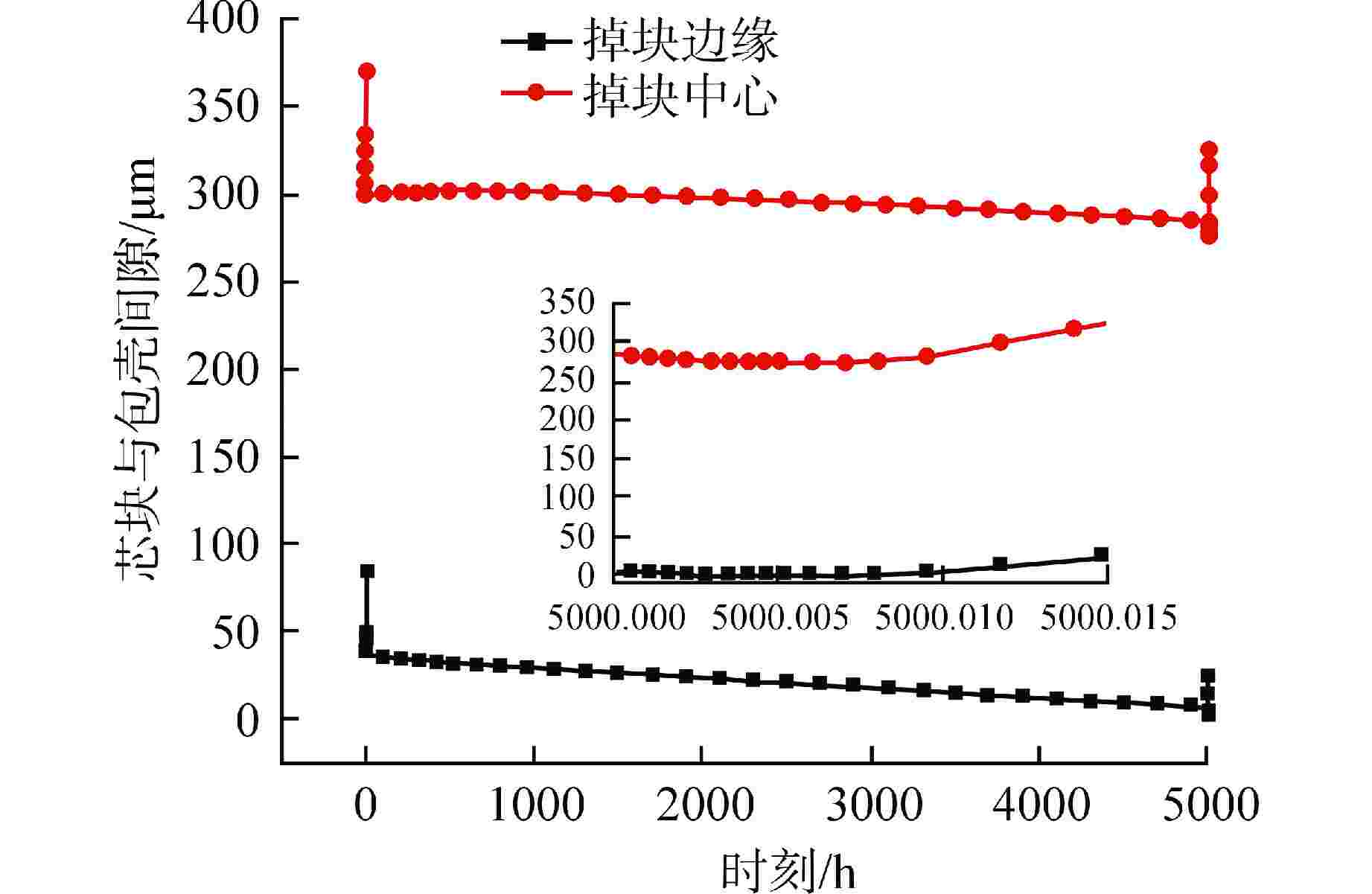

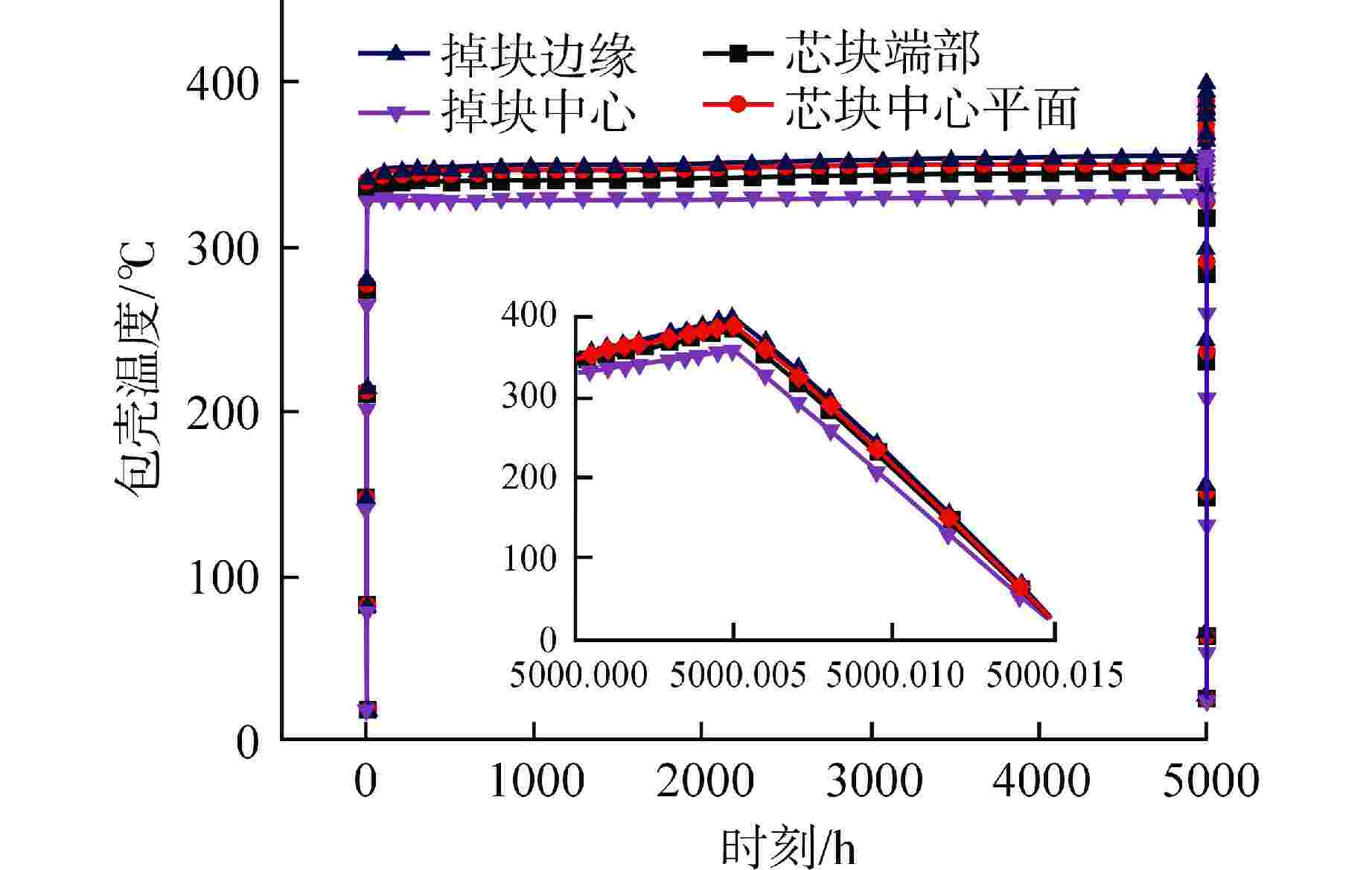

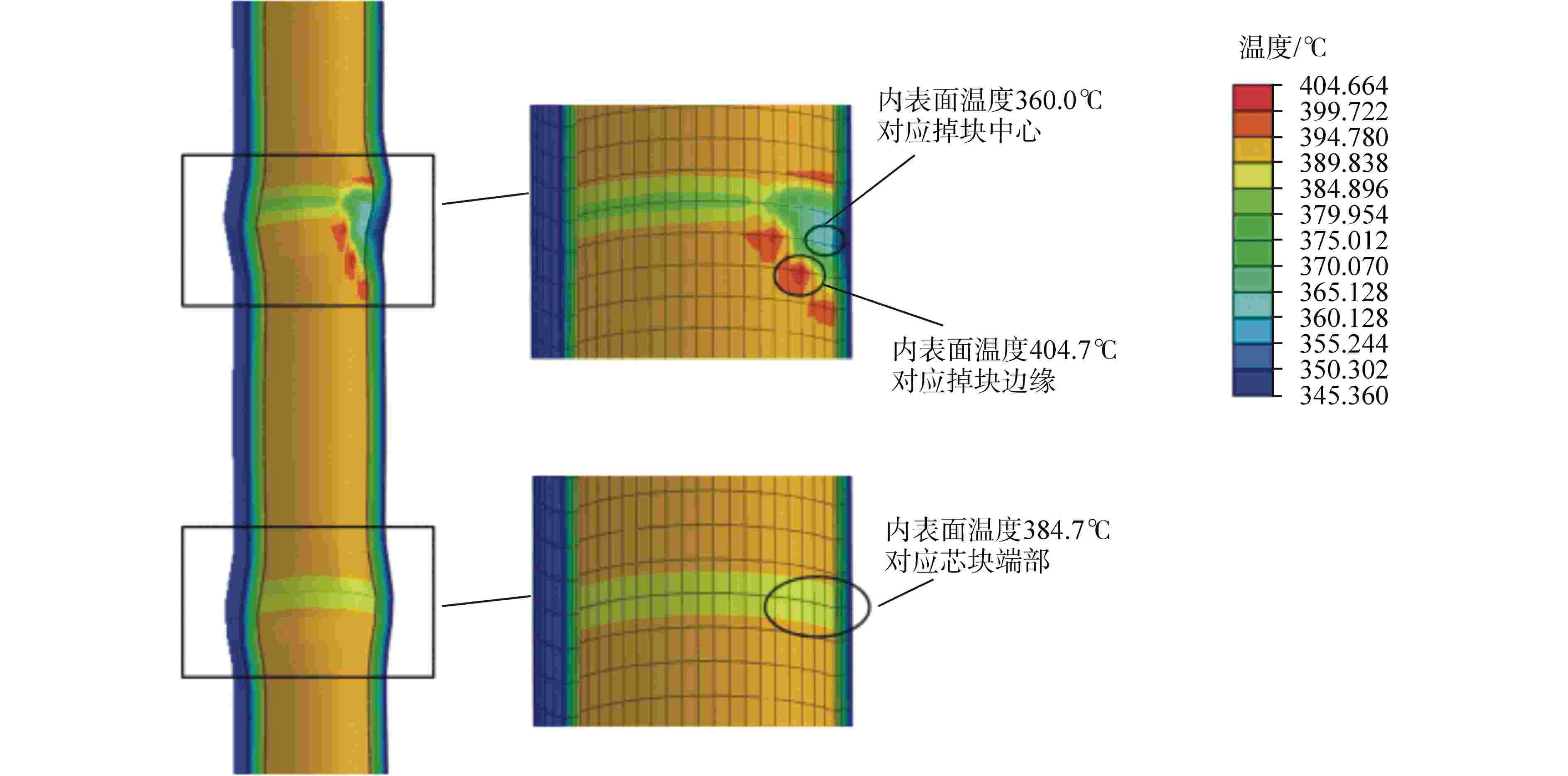

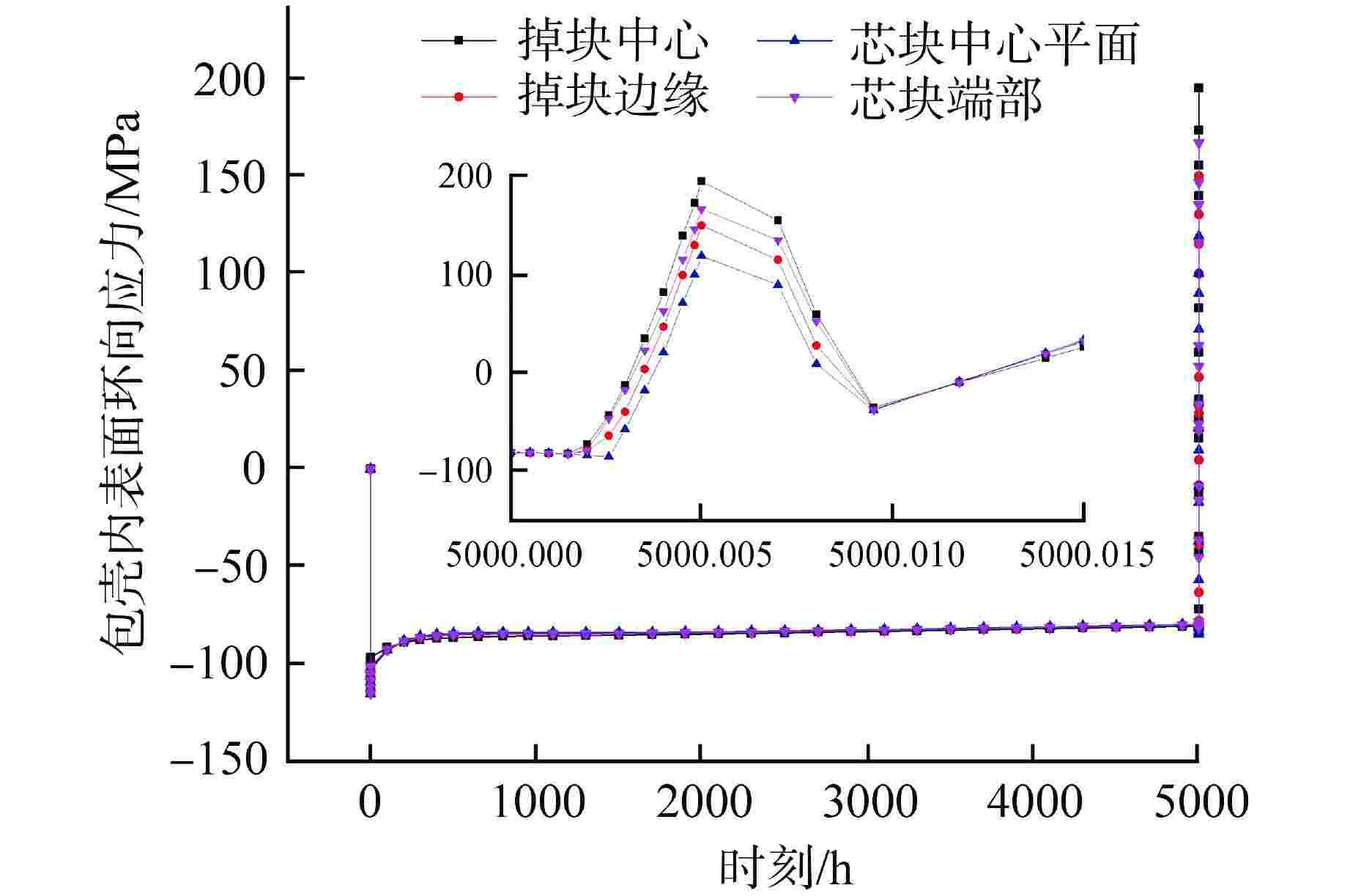

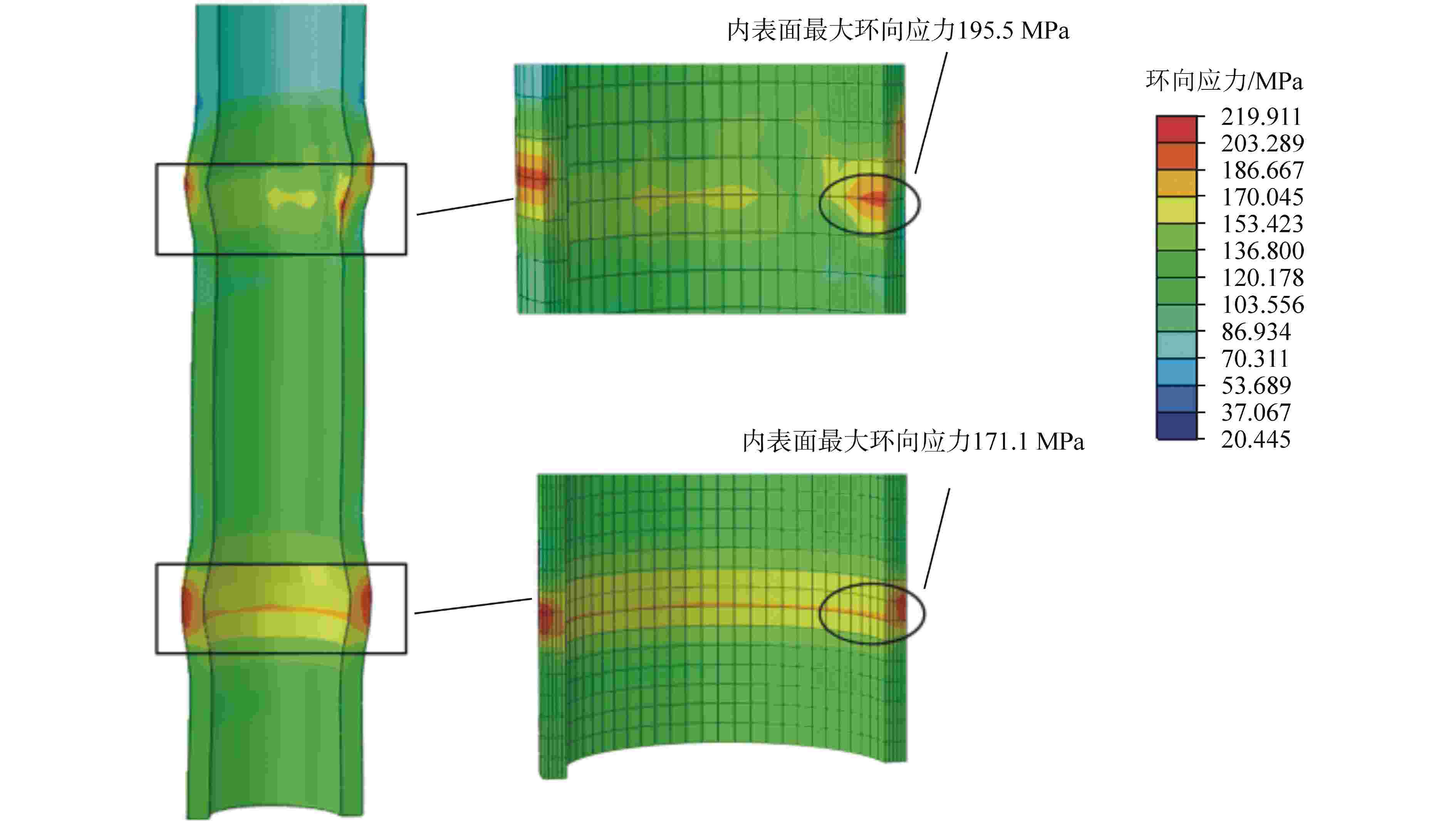

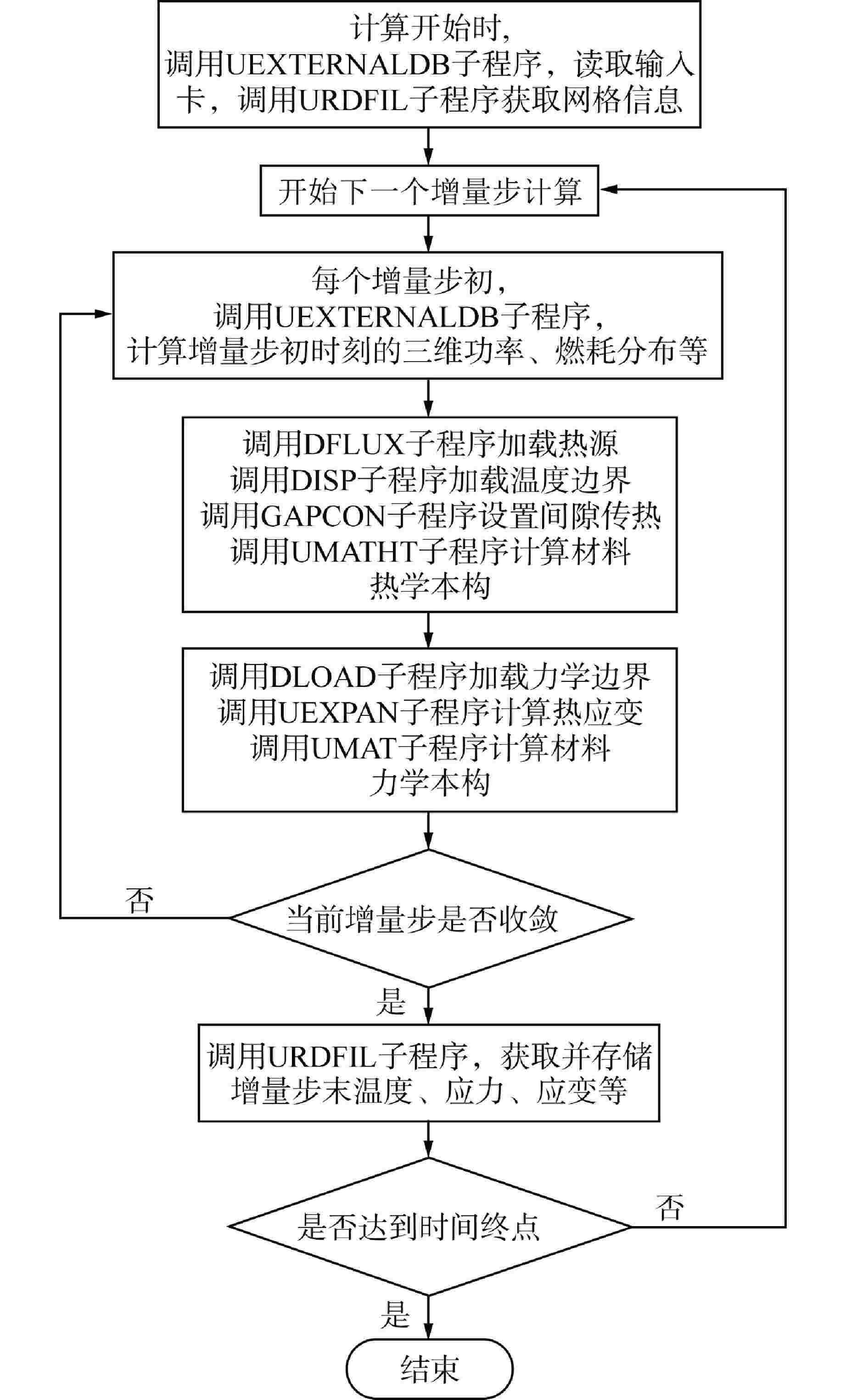

摘要: 压水堆核燃料棒在Ⅱ类瞬态下芯块与包壳会发生强烈的机械相互作用(PCMI),当芯块存在掉块缺陷时,PCMI会进一步加强。针对这类非典型的PCMI现象,传统1.5维燃料性能分析程序无法分析。基于自主开发的3维燃料性能分析程序FUPAC3D进行了模拟计算,以芯块制造过程中常见的芯块掉块缺陷为例,分析了瞬态过程中芯块掉块对燃料棒传热和力学性能的影响。结果表明,芯块掉块附近的包壳温度分布不均匀,芯块掉块边缘处的温度升高,芯块掉块中心处的温度降低;芯块掉块附近的包壳向内凹陷,导致芯块掉块中心附近的包壳环向应力增加,相比完整芯块对应的“竹节”处(芯块端部)增加约14.3%,相比芯块中平面处增加约62.9%。Abstract: For the fuel rods of pressurized water reactor, strong mechanical interaction between the fuel pellet and cladding (PCMI) occurs under Class Ⅱ transient. When the pellet exhibits missing surface defects, the interaction are further intensified. Traditional 1.5D fuel performance analysis codes cannot analyze this non-classical PCMI phenomenon. In this paper, the developed 3D fuel performance analysis code FUPAC3D is used for simulation. Taking the common pellet end missing surface defect in manufacturing as an example, the impact of defect on the heat transfer and mechanical behavior of the fuel rod during transient is analyzed. The results show that the temperature distribution around the cladding near the pellet defect is uneven, with increased temperature at the edge of the defect and decreased temperature in the center. The cladding near the defect is indented inwards, causing an increase in the hoop stress of the cladding near the center of the defect. Compared to the corresponding "bamboo joint" part (the pellet end) of a complete pellet, it increases by about 14.3%, and compared to the middle plane of the pellet, it increases by about 62.9%.

-

Key words:

- 3D fuel rod performance analysis /

- FEM /

- Missing pellet surface defect /

- Fuel behavior

-

表 1 3维模拟的主要输入参数

Table 1. Main Input Parameters of 3D Simulation

运行时刻/h 局部线功率密度/

(kW·m−1)燃料棒

内压/MPa包壳外表面

温度/℃0 0 2.1 20.0 0.01 20 5.7 319.3 5000 20 6.6 323.3 5000.005 40 6.5 345.6 5000.015 0 2.6 20.0 -

[1] STEPHANIE S. The consortium for advanced simulation of light water reactors[EB/OL].(2020-09-30) [2022-01-20]. https://www.casl.gov/wp-content/uploads/2020/11/CASL_FINAL_REPORT_09.30.2020-002.pdf. [2] Idaho National Lab. The nuclear energy advanced modeling and simulation (NEAMS) program[EB/OL]. (2021-10-19)[2022-01-20]. http://neams.inl.gov. [3] WILLIAMSON R L, HALES J D, NOVASCONE S R, et al. BISON: a flexible code for advanced simulation of the performance of multiple nuclear fuel forms[J]. Nuclear Technology, 2021, 207(7): 954-980. doi: 10.1080/00295450.2020.1836940 [4] TONKS M R, SCHWEN D, ZHANG Y, et al. Assessment of MARMOT. A mesoscale fuel performance code: INL/EXT-15-35108[R]. Idaho Falls, ID: INL, 2015. [5] 邢硕,张坤,陈平,等. 燃料棒性能分析程序FUPAC V2.0的研发与验证[J]. 原子能科学技术,2021, 55(11): 2048-2053. doi: 10.7538/yzk.2020.youxian.0925 [6] BERNARD L C, JACOUD J L, VESCO P. An efficient model for the analysis of fission gas release[J]. Journal of Nuclear Materials, 2002, 302(2-3): 125-134. doi: 10.1016/S0022-3115(02)00793-6 [7] ROSS A M, STOUTE R L. Heat transfer coefficient between UO2 and zircaloy-2: AECL-1552[R]. Chalk River, Ont: Atomic Energy of Canada Technical Report, 1962. [8] OLANDER D R. Fundamental aspects of nuclear reactor fuel elements: TID-26711-P1, TRN: 08-019392[R]. Berkeley: University of California, Berkeley, 1976: 137-138. [9] DUNNE F, PETRINIC N. Introduction to computational plasticity[M]. New York: Oxford University Press Inc. , 2005: 146-153. [10] 刘振海,陈平,周毅,等. 三维模拟芯块掉块对燃料性能的影响[J]. 核动力工程,2018, 39(2): 180-184. -

下载:

下载: