Analysis of Laser-TIG Hybrid Welding Performance on 15-15Ti Stainless Steel Lock Bottom Structure

-

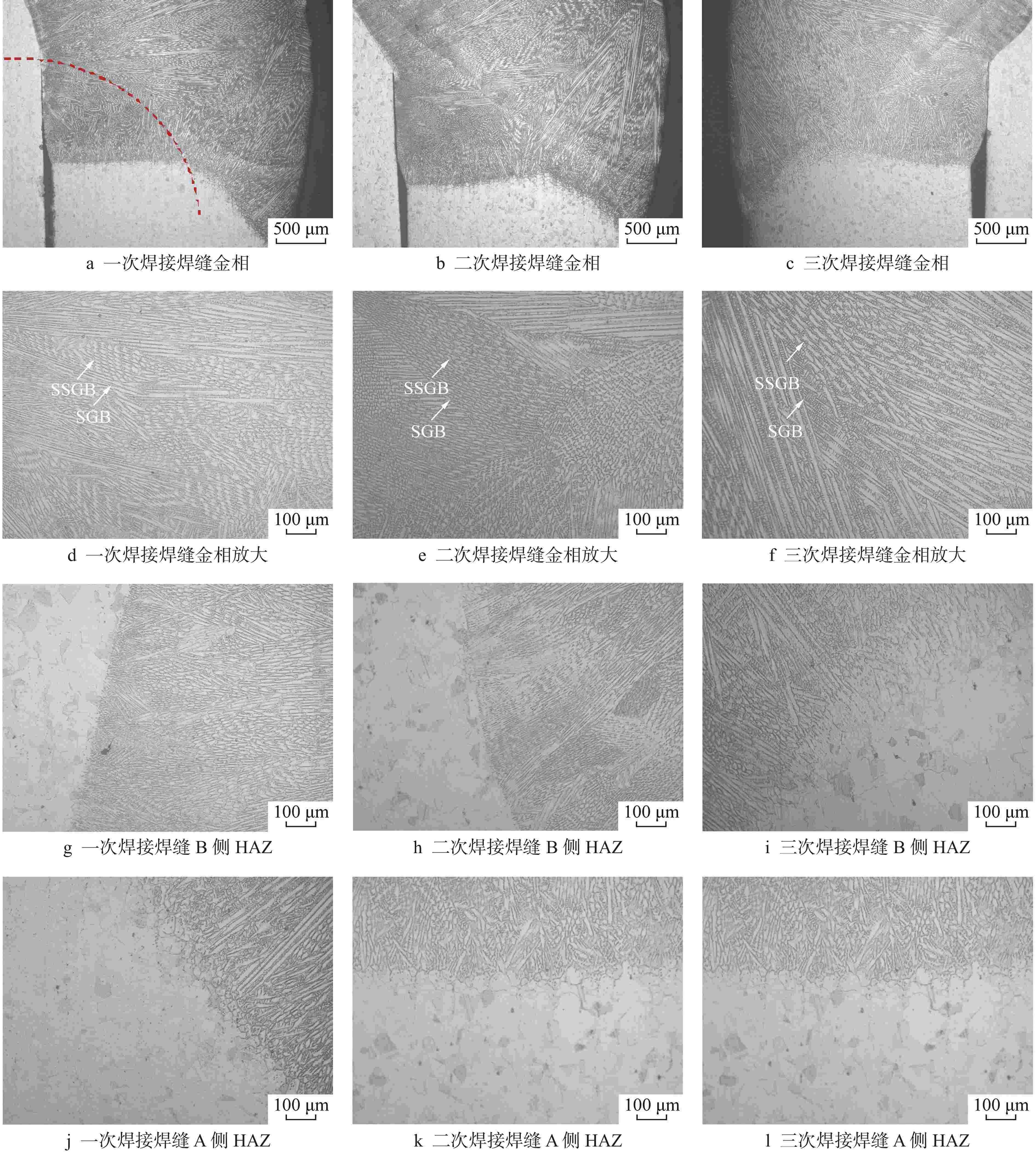

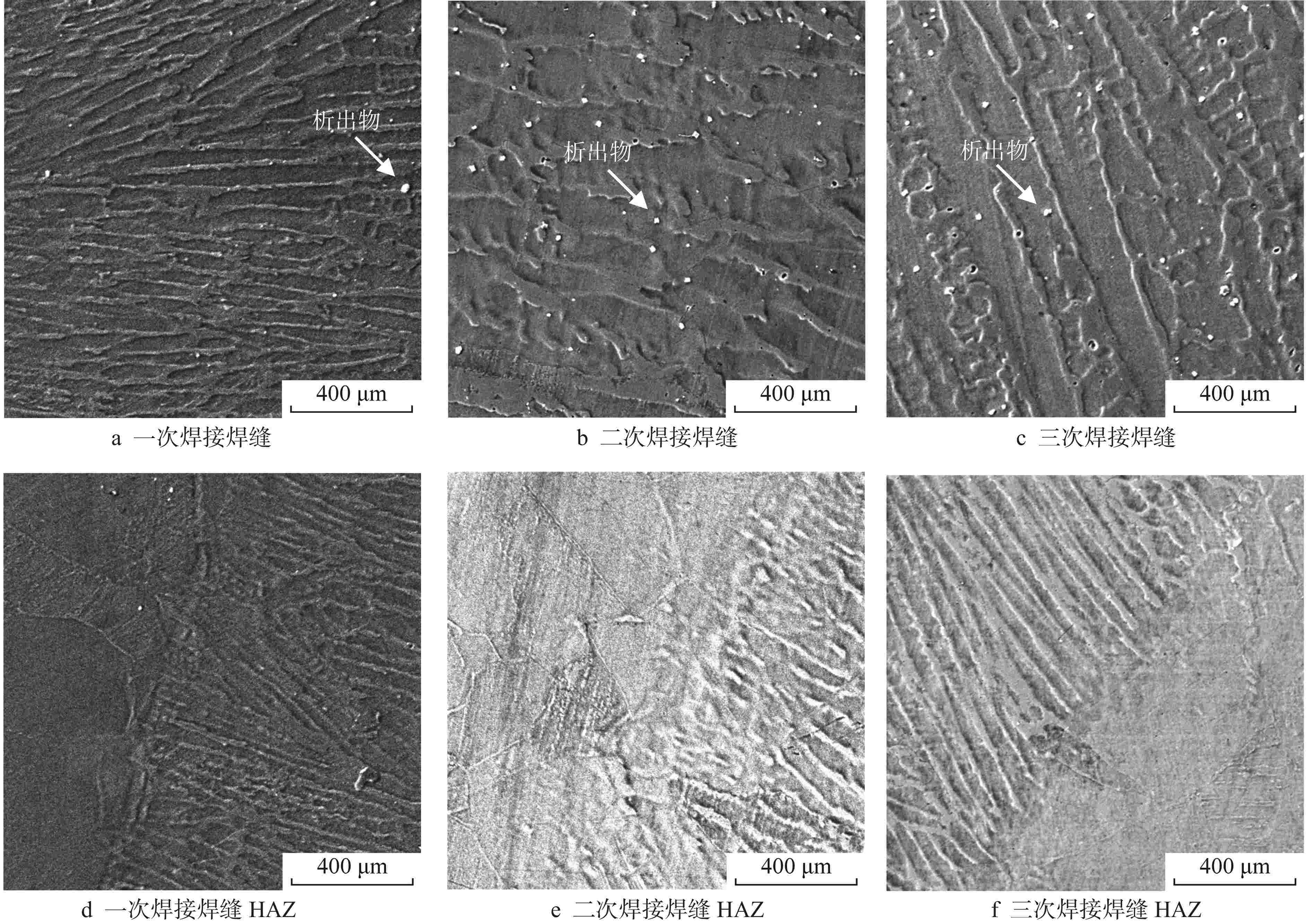

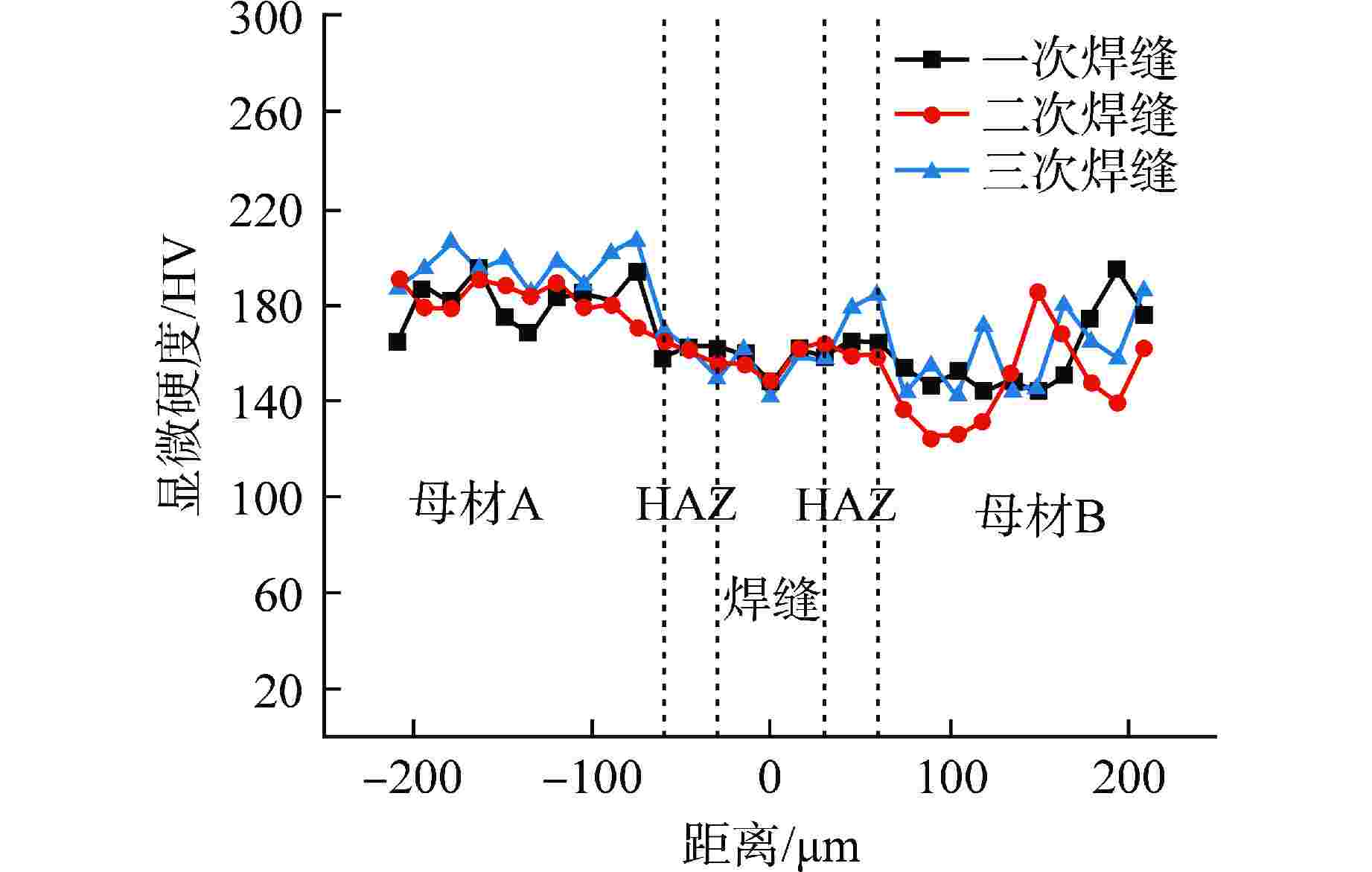

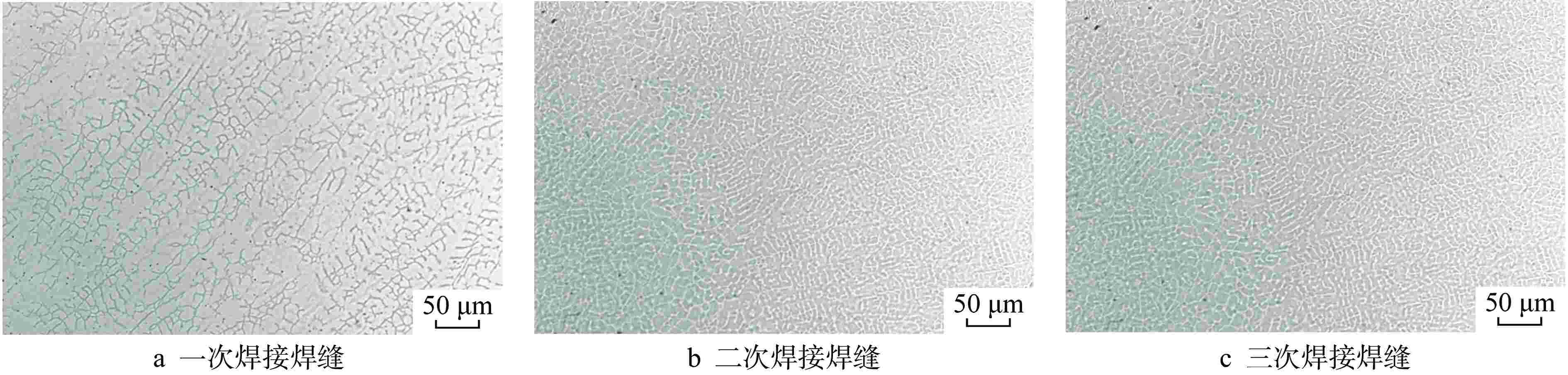

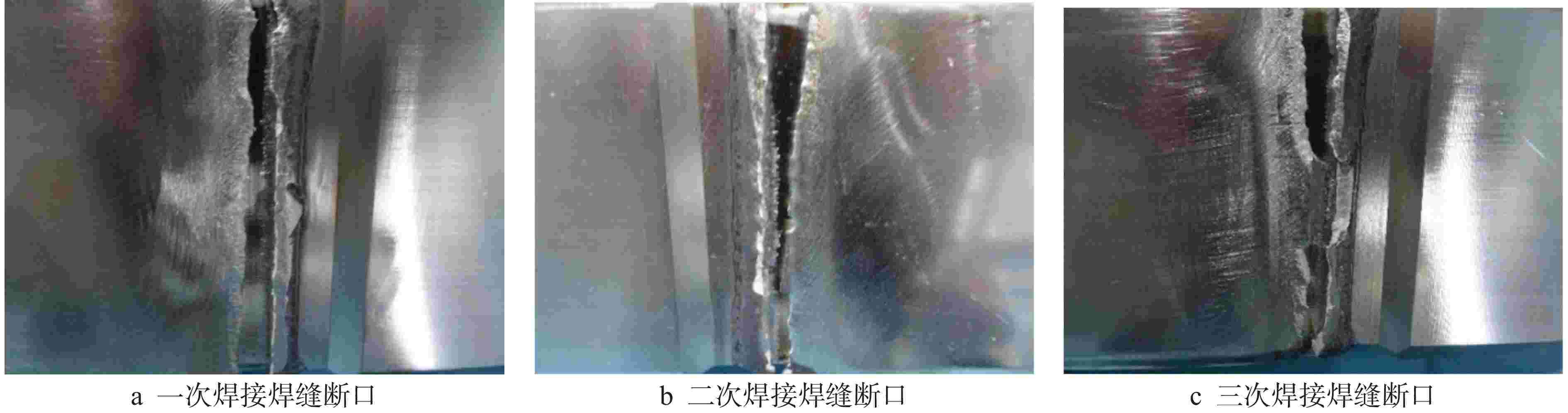

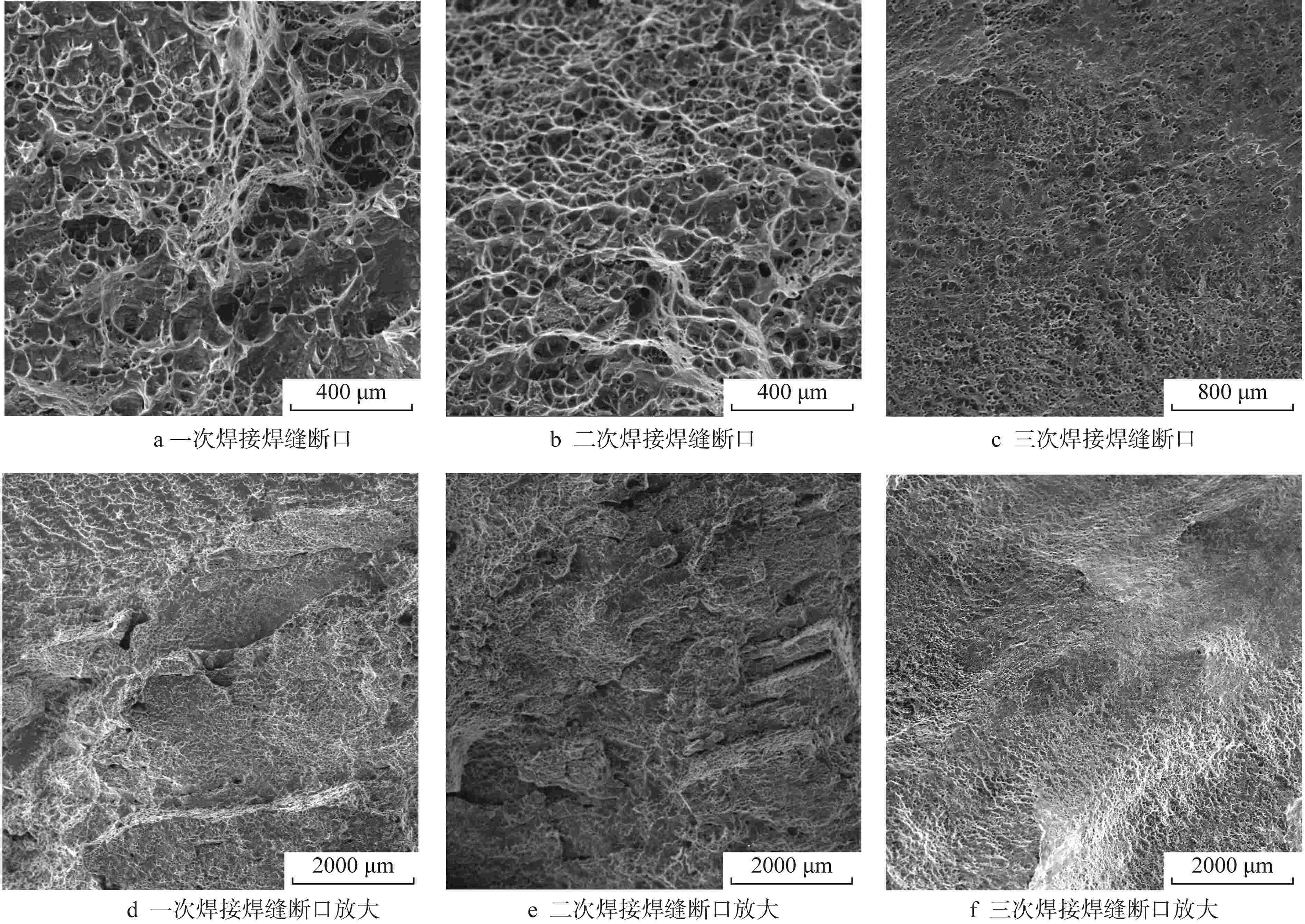

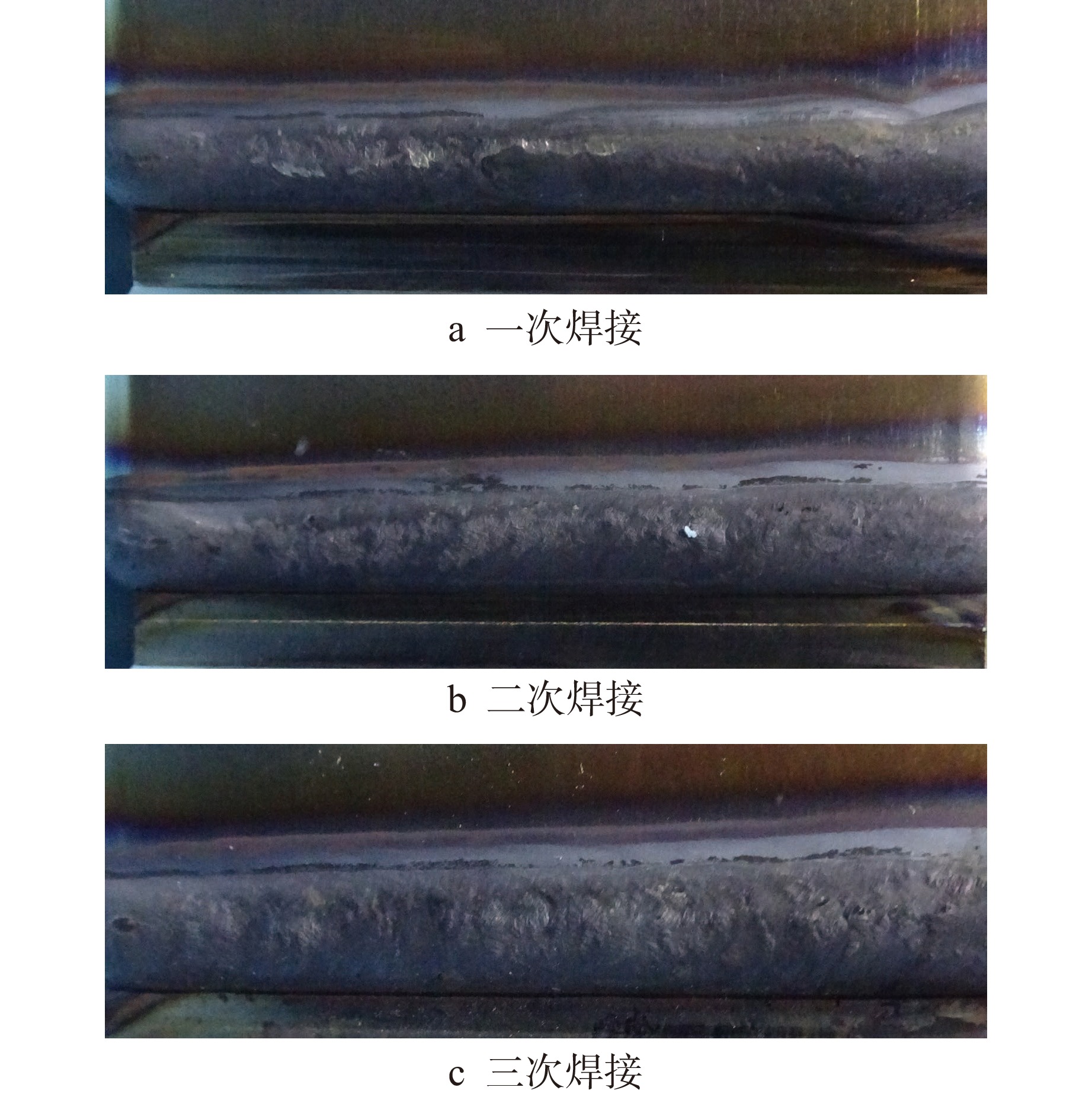

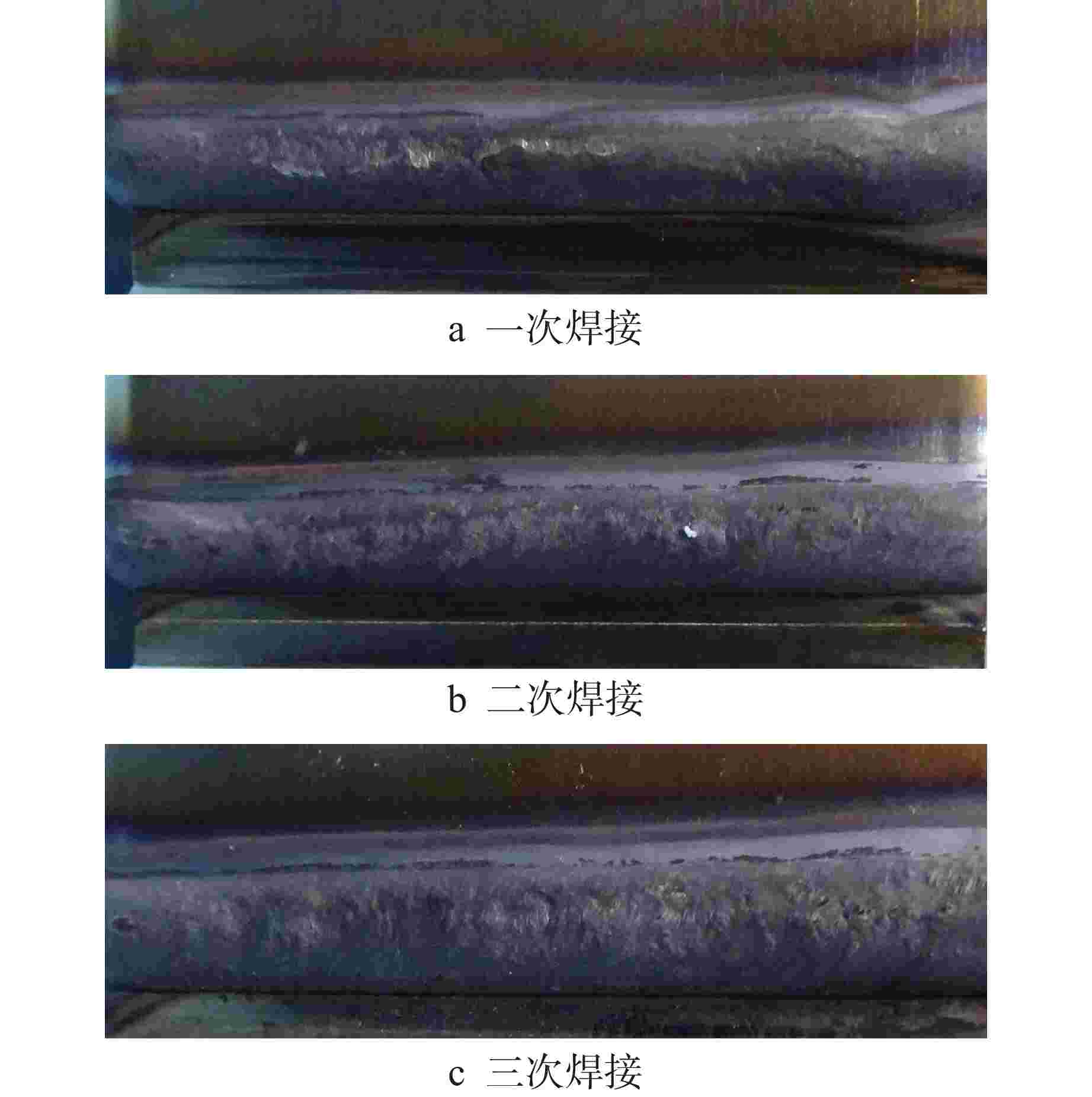

摘要: 为研究一种钠冷快堆用15-15Ti不锈钢材料的焊接工艺,探究一种能够适应锁底结构,进行多次焊接后,该材料仍能保持良好性能的方法。本文采用激光-氩弧复合焊接工艺,对国产15-15Ti材料的一种典型锁底结构开展了焊接工艺探索,通过金相显微镜、扫描电镜、硬度计和拉伸试验机对焊缝的组织特征、显微硬度、晶间腐蚀和力学性能进行了测试,对多次焊接后的焊缝形貌与性能进行了对比。研究发现,激光-氩弧复合焊接能够实现锁底型结构的焊接,并获得较好的焊缝组织和力学性能;并且经过多次焊接后,焊缝凝固模式、焊缝组织、力学性能未发生变化,焊缝组织和力学性能具有较好的一致性,具有广泛的工程应用范围和应用场景。Abstract: To investigate a kind of welding process of 15-15Ti stainless steel material for Sodium-cooled fast reactors, a method that can accommodate to the bottom lock structure while maintaining good welding performance after multiple welding cycles is explored. In this paper, laser-TIG hybrid welding process is adopted to a bottom lock structure made of domestically produced 15-15Ti stainless steel. The microstructural characteristics, microhardness, intergranular corrosion resistance, and mechanical properties of the weld seam were tested using metallurgical microscope, scanning electron microscope, hardness tester, and tensile testing machine. Comparisons were made between the weld morphology and properties after multiple welding cycles. The research shows that laser-TIG hybrid welding can realize the welding of lock bottom structure and obtain superior welding microstructure and mechanical properties. After multiple welding cycles, the weld seam solidification mode, microstructure, and mechanical properties remain unchanged, and the microstructure and mechanical properties of the weld have good consistency. This welding method of 15-15Ti material has broad engineering application potential and scenarios.

-

Key words:

- 15-15Ti /

- Laser-TIG hybrid welding /

- Microscopic structure /

- Welding performance

-

表 1 母材化学成分 %

Table 1. Chemical Composition of Base Metal

材料 元素 C Si P S Mn Ni Cr Mo Ti 15-15Ti(冷轧) 0.05 0.46 <0.01 <0.01 1.71 14.96 16.21 2.07 0.34 15-15Ti(固溶) 0.06 0.53 <0.01 <0.01 1.64 15.06 16.97 2.07 0.37 表 2 试样对照表

Table 2. Sample Information

焊接次数 微观试样 晶间腐蚀试验 硬度试样 拉伸试样 1 1-A-1 1-A-2 1-A-3 1-B 2 2-A-1 2-A-2 2-A-3 2-B 3 3-A-1 3-A-2 3-A-3 3-B 表 3 焊接接头弥散物EDS分析结果

Table 3. EDS Results of the Welding Diffuse Objects

元素 原子序数 质量分数/% 原子分数/% Ti 22 48.43 31.34 Fe 26 17.29 9.59 Cr 24 7.80 4.65 N 7 20.72 45.84 Al 13 2.03 2.33 Ni 28 1.64 0.87 C 6 2.08 5.38 表 4 15-15Ti激光-氩弧复合焊接接头焊缝拉伸性能

Table 4. Tensile Property of 15-15Ti Laser-TIG Hybrid Welding

焊接

次数试样

编号拉断力/

kN抗拉

强度/MPa母材A

强度/MPa母材B

强度/MPa1 1-B 666.6 588.4 677 582 2 2-B 690.6 609.6 677 582 3 3-B 689.1 608.3 677 582 -

[1] 刘健. 国产快堆包壳材料15-15Ti不锈钢的拉伸行为研究[J]. 产业与科技论坛,2018, 17(10): 45-46. doi: 10.3969/j.issn.1673-5641.2018.10.022 [2] MAHRLE A, BEYER E. Hybrid laser beam welding-classification, characteristics, and applications[J]. Journal of Laser Applications, 2006, 18(3): 169-180. doi: 10.2351/1.2227012 [3] 肖荣诗,吴世凯. 激光-电弧复合焊接的研究进展[J]. 中国激光,2008, 35(11): 1680-1685. doi: 10.3321/j.issn:0258-7025.2008.11.004 [4] ONO M, SHINBO Y, YOSHITAKE A, et al. Development of laser-arc hybrid welding[J]. NKK Technical Review, 2002(86): 8-12. [5] RIBIC B, PALMER T A, DEBROY T. Problems and issues in laser-arc hybrid welding[J]. International Materials Reviews, 2009, 54(4): 223-244. doi: 10.1179/174328009X411163 [6] LIPPOLD J C, KOTECKI D J. Welding metallurgy and weldability of stainless steels[M]. Hoboken: Wiley-VCH, 2005, 140-143. [7] 孙咸. 不锈钢焊缝金属的组织演变及其影响[J]. 机械制造文摘-焊接分册,2012(6): 6-10. -

下载:

下载: