Research on Disturbance Wave Characteristics of Annular Flow on Edge and Corner Rods of Rod Bundle Channel

-

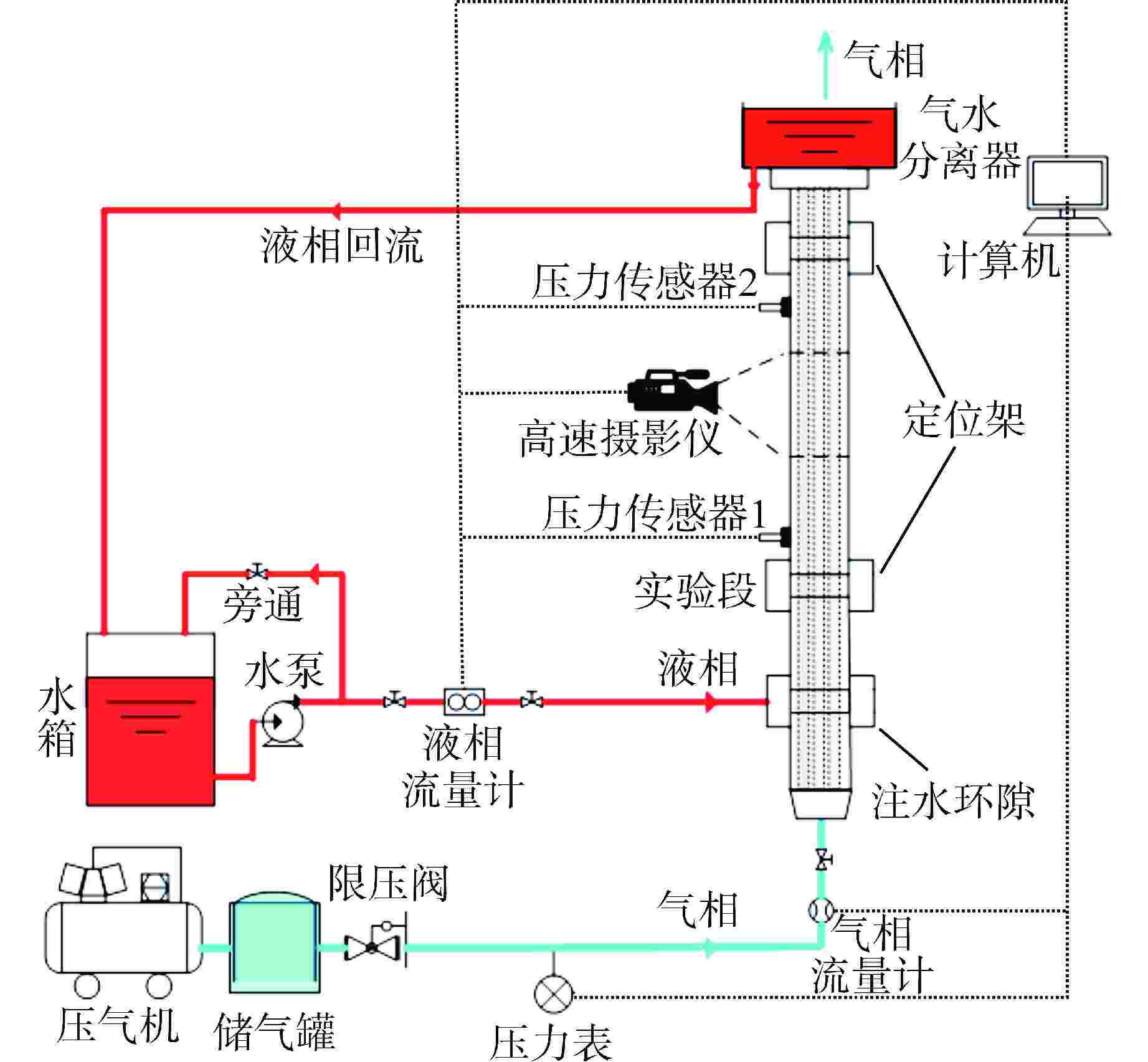

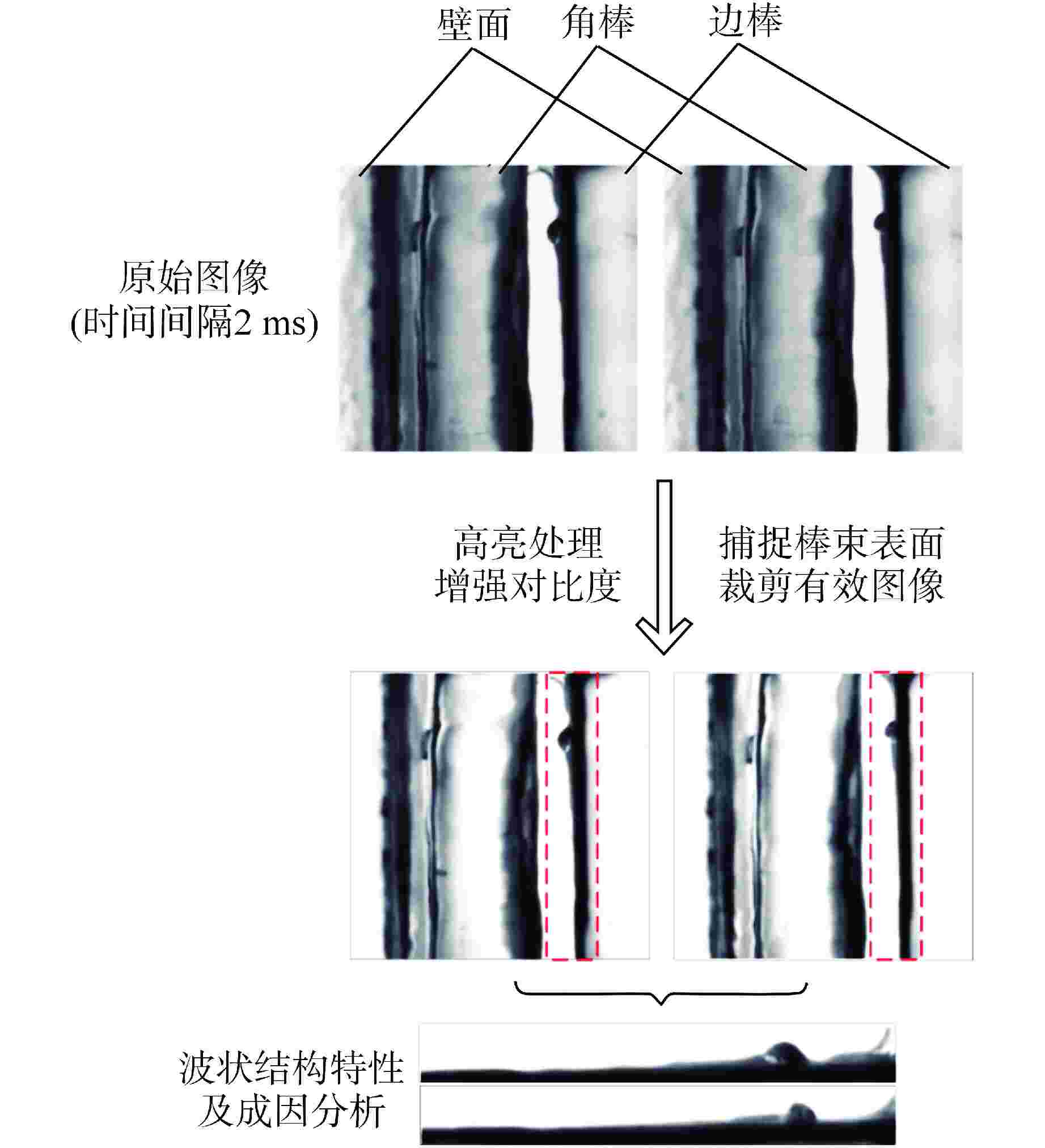

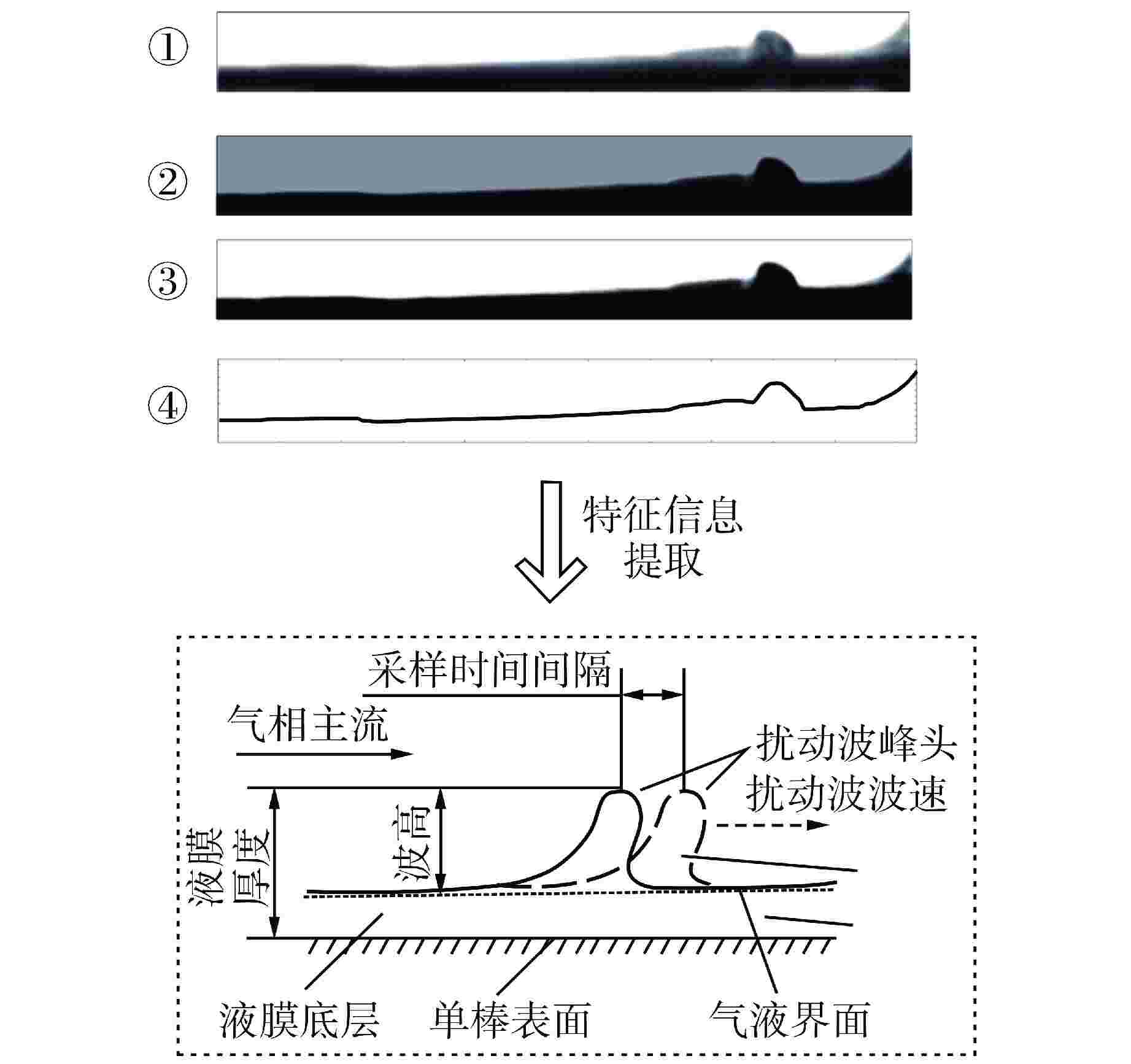

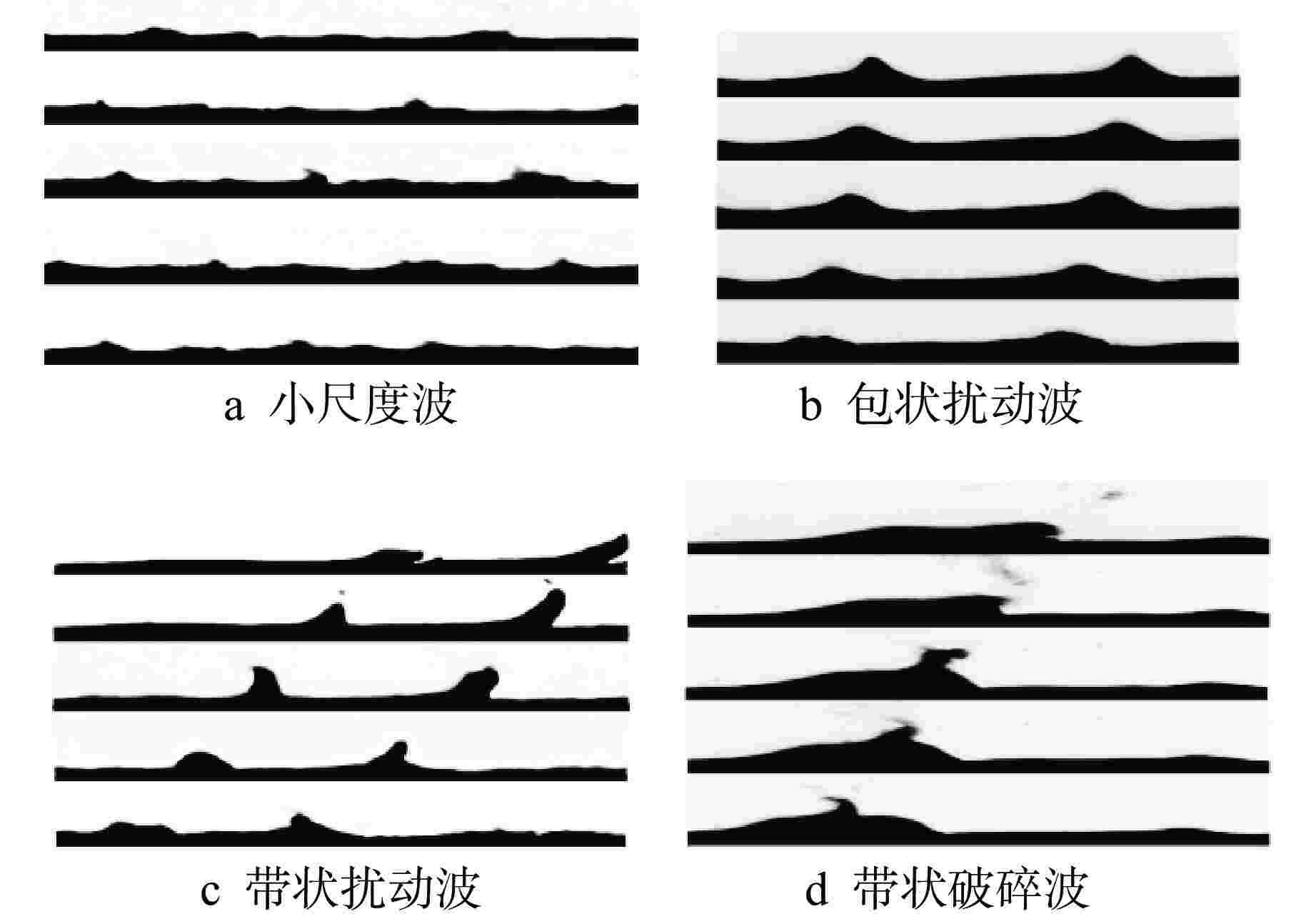

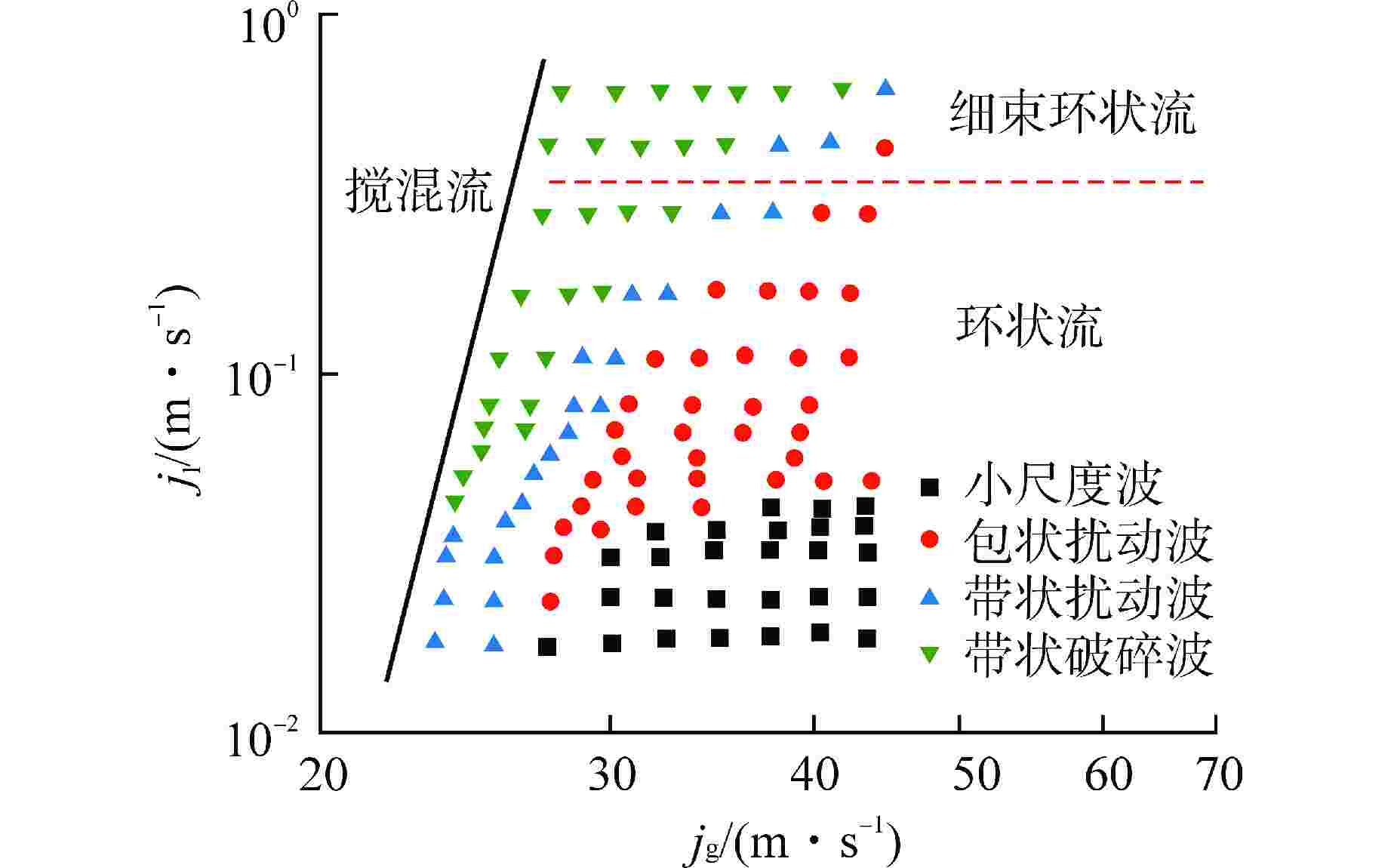

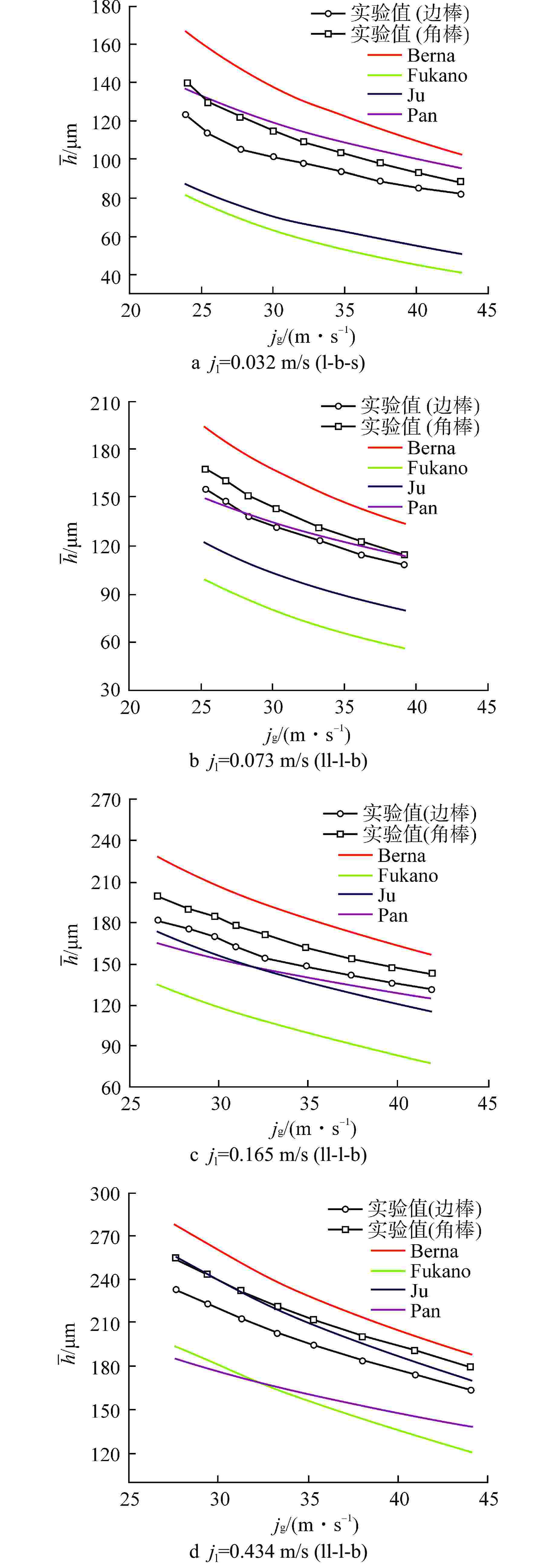

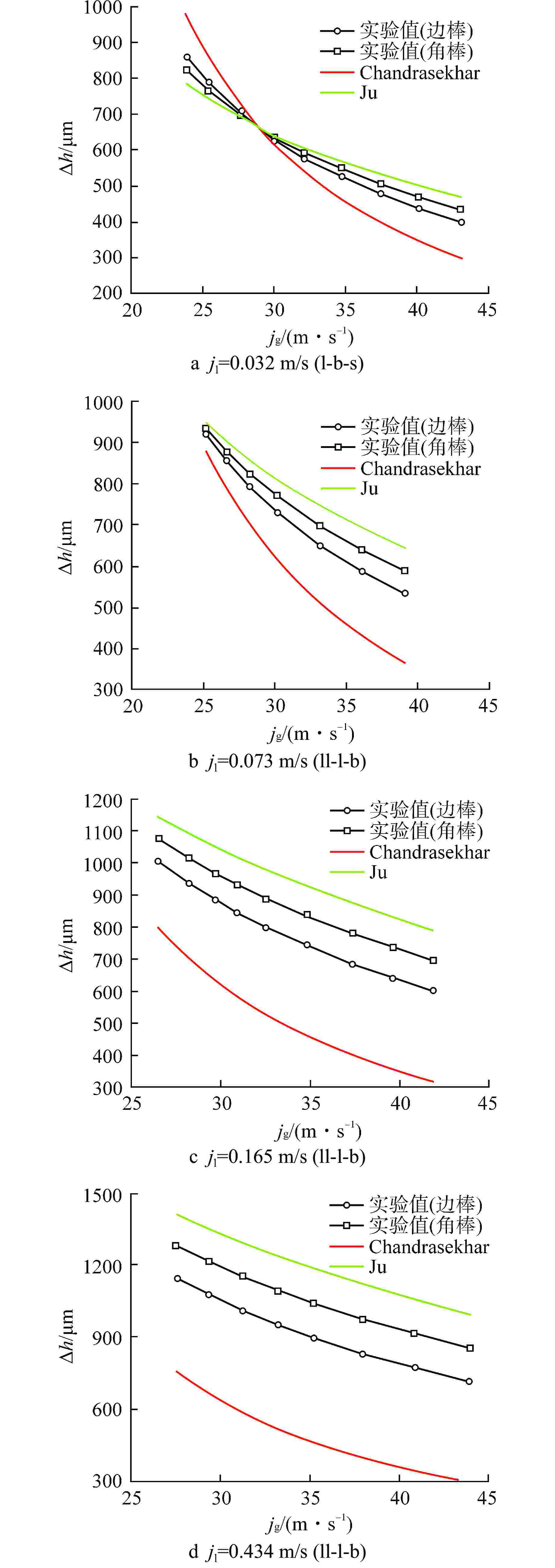

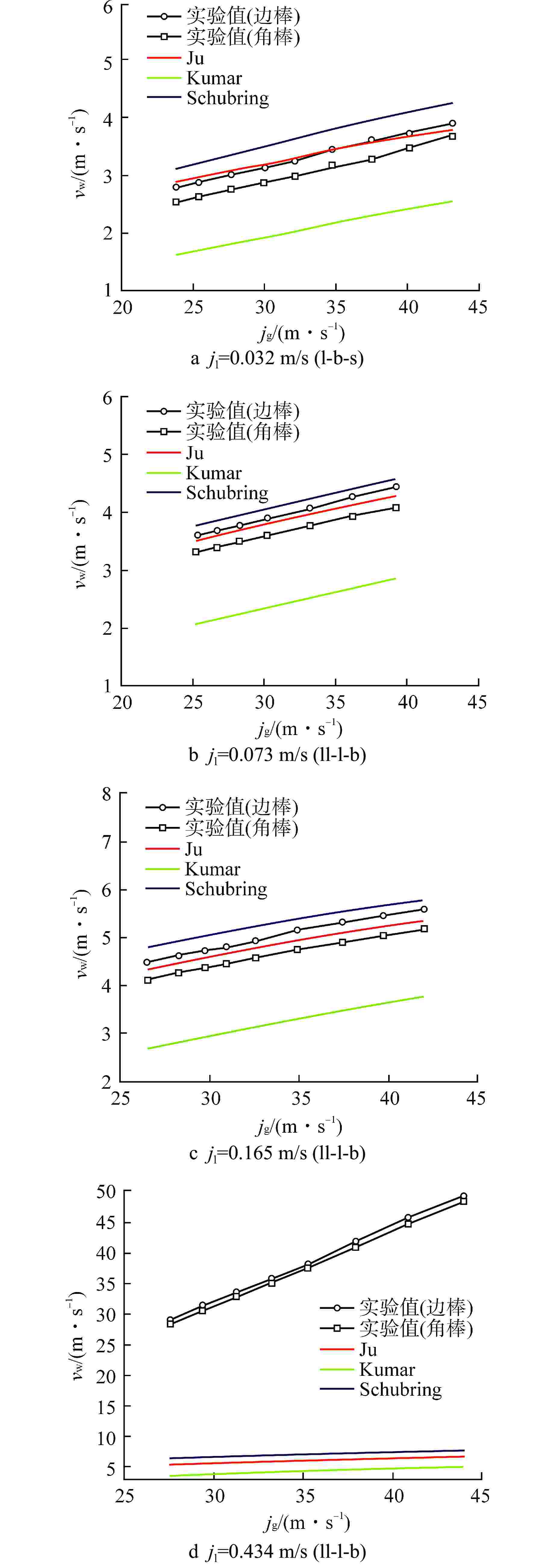

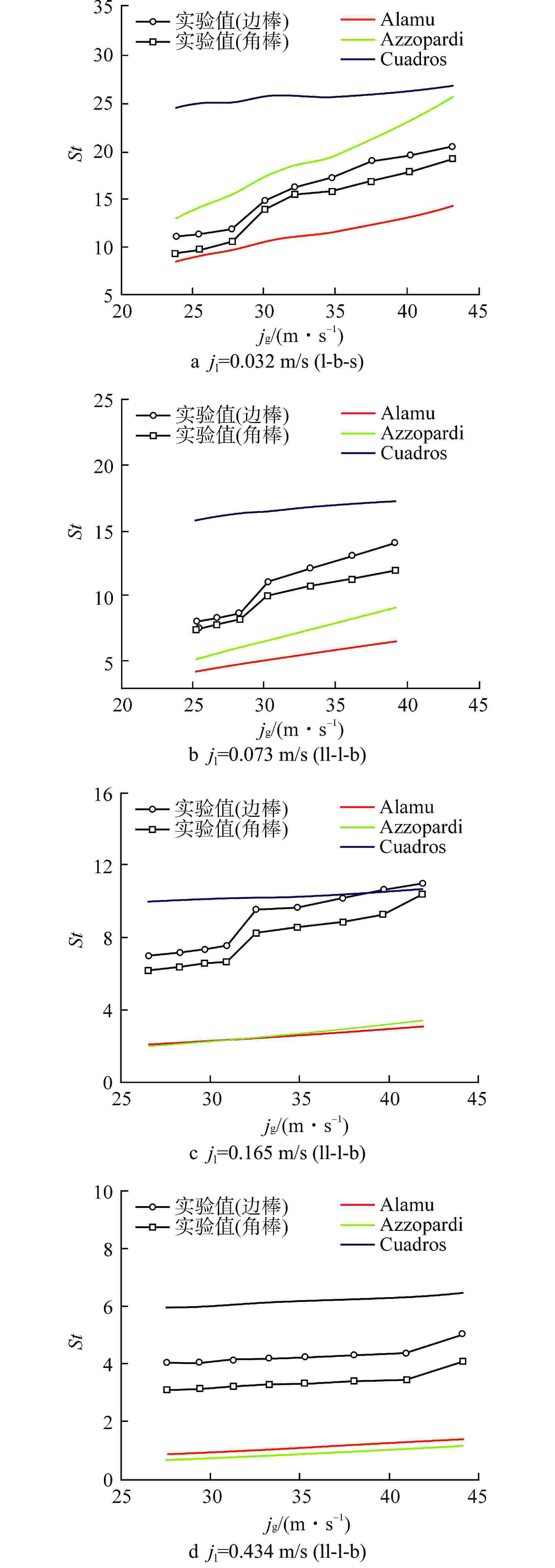

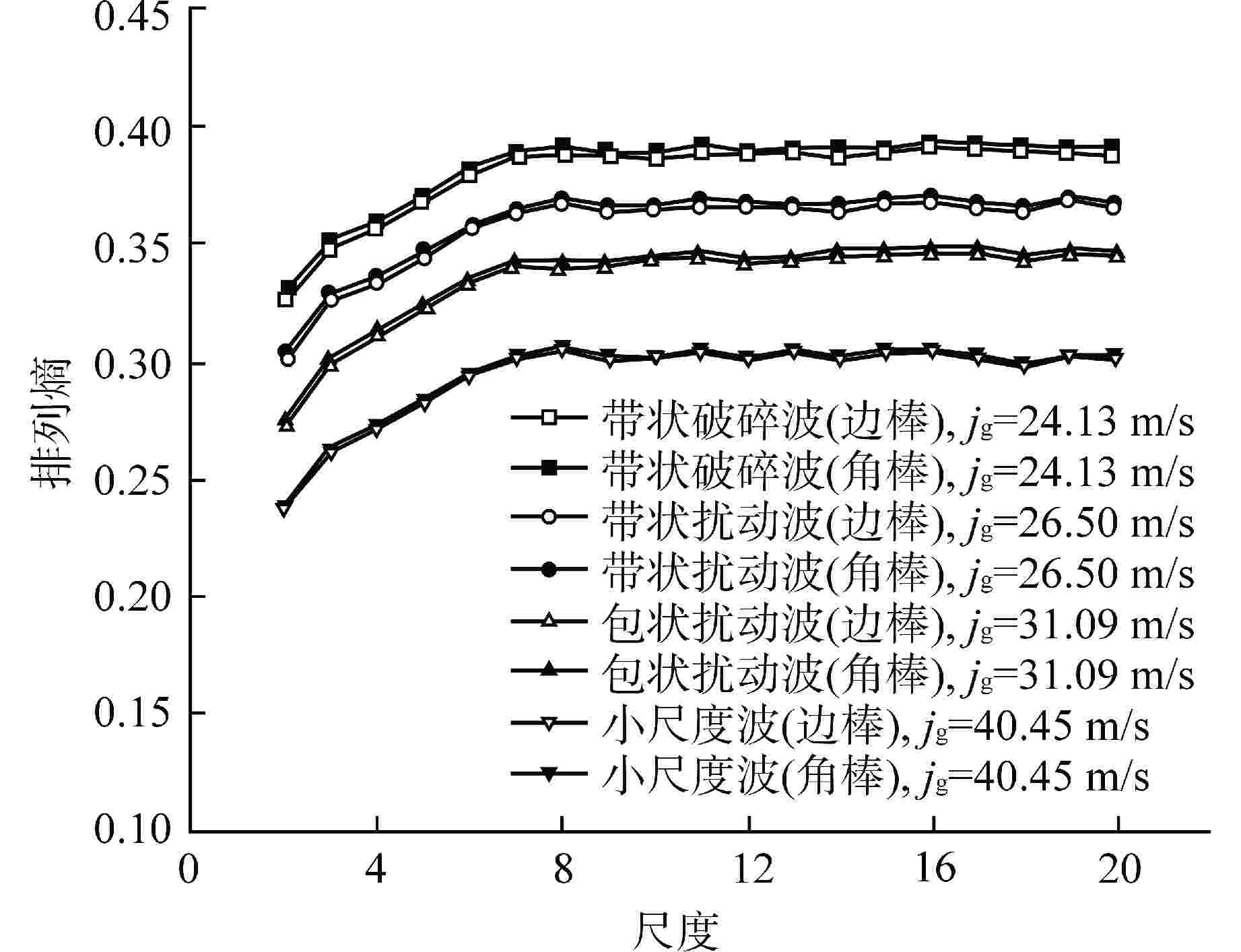

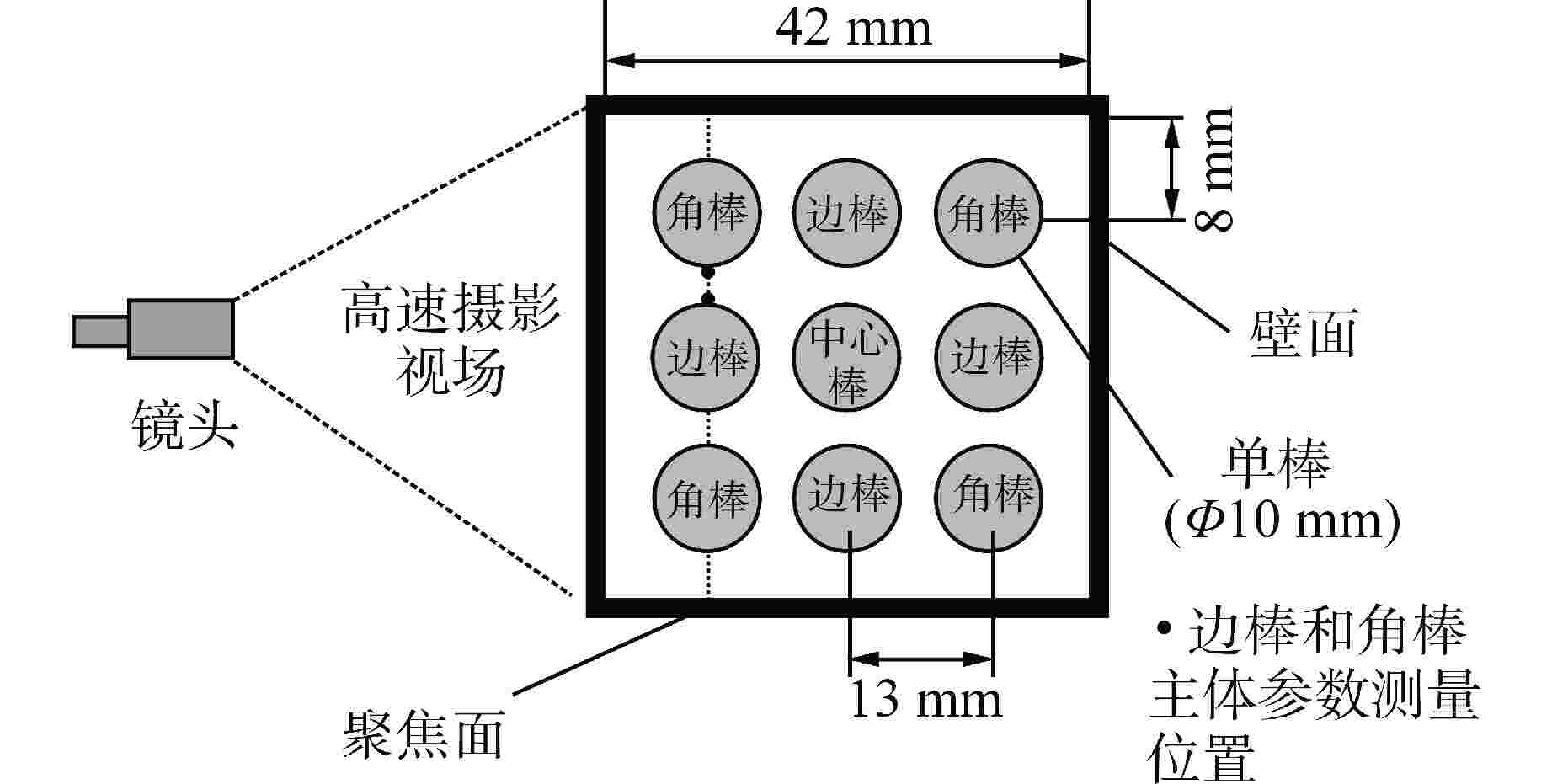

摘要: 研究棒束通道中边棒和角棒环状流扰动波特性,可为核电厂稳态运行和应急处置提供理论支撑。本研究建立棒束通道中环状流可视化实验系统,对边棒和角棒表面扰动波特性进行分析。结果表明,扰动波形态可以分成小尺度波、包状扰动波、带状扰动波和带状破碎波4种;液相折算速度保持不变时,平均液膜厚度随气相折算速度增加而变小,当液相折算速度逐渐变大时,平均液膜厚度数值也逐渐变大;扰动波波高随气相折算速度增加而变小,边棒表面扰动波高度低于角棒的值。当液相折算速度低于0.41 m/s时,扰动波波速随着气、液相折算速度增加而变大;当液相折算速度高于0.41 m/s时,扰动波波速高于气相折算速度。扰动波波频随气相折算速度增加而变大,随液相折算速度变化规律不明显,这取决于波动形态的变化。边棒和角棒表面液膜厚度数据的熵均值随着扰动波形态从小尺度波、包状扰动波、带状扰动波到带状破碎波逐步增加,因此可以使用多尺度排列熵分析方法判定棒束通道中扰动波形态。Abstract: The research on disturbance wave characteristics of annular flow on edge and corner rods of rod bundle channel can provide theoretical supports for the steady-state operation and emergency disposal of nuclear power plants. In this study, a visualize experimental system for annular flow in rod bundle channel was set up to analyze the disturbance wave characteristics on edge and corner rod surface. The results show that the disturbance wave behaviors can be divided into the small-scale waves, the bag-shaped waves, the ligament-shaped waves and the ligament-shaped waves with liquid-loss. When the liquid superficial velocity remains constant, the average film thickness decreases with the increase of gas superficial velocity; when the liquid superficial velocity is increasing, the average film thickness is also increasing. The disturbance wave height decreases with the increasing gas superficial velocity, and the disturbance wave height on side rod is lower than that of corner rod. When the liquid superficial velocity is lower than 0.41 m/s, the wave velocity increases with the increasing gas and liquid velocity. The wave velocity is higher than the gas superficial velocity when the liquid velocity is higher than 0.41 m/s. The wave frequency becomes larger with the increasing gas superficial velocity, but the law of change with liquid superficial velocity is not obvious, which depends on the change of wave form. The average entropy value of liquid film thickness of side and corner rods increases with the wave behaviors from small-scale waves, bag-shaped waves, ligament-shaped waves to ligament-shaped waves with liquid-loss, so the wave form in rod bundle channel can be determined by the multiscale permutation entropy analysis method.

-

Key words:

- Rod bundle channel /

- Annular flow /

- Disturbance wave /

- Multiscale permutation entropy

-

表 1 测量参数、仪表信息和总不确定度

Table 1. Measurement Parameters, Instrument Information, and Total Uncertainty

参数 仪表名称 仪表量程 精度等级/% 总不确定度/% 压力 压力传感器 30、50、100 kPa 0.1 0.5~3.26 水流量 质量流量计 6000 kg/h 0.1 0.23~3.12 气流量 转子流量计 50、100、200 m3/h 2 2.37~4.28 流体温度 水银温度计 100℃ 0.2 0.25~1.5 -

[1] 阎昌琪,孙中宁. 竖直管内两相流逆向流动特性研究[J]. 核动力工程,2001, 22(1): 15-18. doi: 10.3969/j.issn.0258-0926.2001.01.004 [2] 田文喜,蔚江涛,汪志伟,等. AP1000波动管内空气-水液泛特性试验研究[J]. 核动力工程,2017, 38(5): 151-155. [3] 米争鹏,谭思超,李兴,等. 棒束通道温度场可视化实验研究[J]. 原子能科学技术,2018, 52(5): 847-854. doi: 10.7538/yzk.2018.52.05.0847 [4] CLARK C, GRIFFITHS M, CHEN S W, et al. Drift-flux correlation for rod bundle geometries[J]. International Journal of Heat and Fluid Flow, 2014, 48: 1-14. doi: 10.1016/j.ijheatfluidflow.2014.03.008 [5] ALEKSEENKO S, ANTIPIN V, CHERDANTSEV A, et al. Two-wave structure of liquid film and wave interrelation in annular gas-liquid flow with and without entrainment[J]. Physics of Fluids, 2009, 21(6): 061701. doi: 10.1063/1.3151999 [6] ALEKSEENKO S, CHERDANTSEV A, CHERDANTSEV M, et al. Application of a high-speed laser-induced fluorescence technique for studying the three-dimensional structure of annular gas-liquid flow[J]. Experiments in Fluids, 2012, 53(1): 77-89. doi: 10.1007/s00348-011-1200-5 [7] PHAM S H, KAWARA Z, YOKOMINE T, et al. Detailed observations of wavy interface behaviors of annular two-phase flow on rod bundle geometry[J]. International Journal of Multiphase Flow, 2014, 59: 135-144. doi: 10.1016/j.ijmultiphaseflow.2013.11.004 [8] PHAM S H, KAWARA Z, YOKOMINE T, et al. Measurements of liquid film and droplets of annular two-phase flow on a rod-bundle geometry with spacer[J]. International Journal of Multiphase Flow, 2015, 70: 35-57. doi: 10.1016/j.ijmultiphaseflow.2014.11.010 [9] KUNUGI T. Summary: study on wavy interface behavior and droplet entrainment of annular two-phase flow in rod bundle geometry with spacers[J]. Nuclear Engineering and Design, 2018, 336: 45-53. doi: 10.1016/j.nucengdes.2017.05.025 [10] 金光远,张文超,杜利鹏. 棒束通道内环状流气液界面行为及形成机理研究[J]. 原子能科学技术,2018, 52(9): 1618-1624. doi: 10.7538/yzk.2018.youxian.0018 [11] WANG G Y, DANG Z R, ISHII M. Wave structure and velocity in vertical upward annular two-phase flow[J]. Experimental Thermal and Fluid Science, 2021, 120: 110205. doi: 10.1016/j.expthermflusci.2020.110205 [12] 陆廷济,胡德敬,陈铭南. 物理实验教程[M]. 上海: 同济大学出版社,2000: 6-13. [13] BERNA C, ESCRIVÁ A, MUÑOZ-COBO J L, et al. Review of droplet entrainment in annular flow: interfacial waves and onset of entrainment[J]. Progress in Nuclear Energy, 2014, 74: 14-43. doi: 10.1016/j.pnucene.2014.01.018 [14] FUKANO T, FURUKAWA T. Prediction of the effects of liquid viscosity on interfacial shear stress and frictional pressure drop in vertical upward gas-liquid annular flow[J]. International Journal of Multiphase Flow, 1998, 24(4): 587-603. doi: 10.1016/S0301-9322(97)00070-0 [15] JU P, BROOKS C S, ISHII M, et al. Film thickness of vertical upward co-current adiabatic flow in pipes[J]. International Journal of Heat and Mass Transfer, 2015, 89: 985-995. doi: 10.1016/j.ijheatmasstransfer.2015.06.002 [16] PAN L M, HE H, JU P, et al. Experimental study and modeling of disturbance wave height of vertical annular flow[J]. International Journal of Heat and Mass Transfer, 2015, 89: 165-175. doi: 10.1016/j.ijheatmasstransfer.2015.05.073 [17] RIVERA Y, MUÑOZ-COBO J L, CUADROS J L, et al. Experimental study of the effects produced by the changes of the liquid and gas superficial velocities and the surface tension on the interfacial waves and the film thickness in annular concurrent upward vertical flows[J]. Experimental Thermal and Fluid Science, 2021, 120: 110224. doi: 10.1016/j.expthermflusci.2020.110224 [18] JU P, LIU Y, YANG X H, et al. Wave characteristics of vertical upward adiabatic annular flow in pipes[J]. International Journal of Heat and Mass Transfer, 2019, 145: 118701. doi: 10.1016/j.ijheatmasstransfer.2019.118701 [19] KUMAR R, GOTTMANN M, SRIDHAR K R. Film thickness and wave velocity measurements in a vertical duct[J]. Journal of Fluids Engineering, 2002, 124(3): 634-642. doi: 10.1115/1.1493808 [20] SCHUBRING D, SHEDD T A, HURLBURT E T. Planar laser-induced fluorescence (PLIF) measurements of liquid film thickness in annular flow. Part II: analysis and comparison to models[J]. International Journal of Multiphase Flow, 2010, 36(10): 825-835. doi: 10.1016/j.ijmultiphaseflow.2010.02.002 [21] ALAMU M B, AZZOPARDI B J. Wave and drop periodicity in transient annular flow[J]. Nuclear Engineering and Design, 2011, 241(12): 5079-5092. doi: 10.1016/j.nucengdes.2011.08.015 [22] AZZOPARDI B J. Gas-liquid flows[M]. New York: Begell House, 2006: 98-105. [23] CUADROS J L, RIVERA Y, BERNA C, et al. Characterization of the gas-liquid interfacial waves in vertical upward co-current annular flows[J]. Nuclear Engineering and Design, 2019, 346: 112-130. doi: 10.1016/j.nucengdes.2019.03.008 [24] 周云龙,尹洪梅,丁会晓. 多尺度熵在棒束通道气液两相流压差信号分析中的应用[J]. 化工学报,2016, 67(9): 3625-3632. -

下载:

下载: