Wear Analysis of Thermal Sleeve of Reactor Control Rod Drive Mechanism Based on Archard Model

-

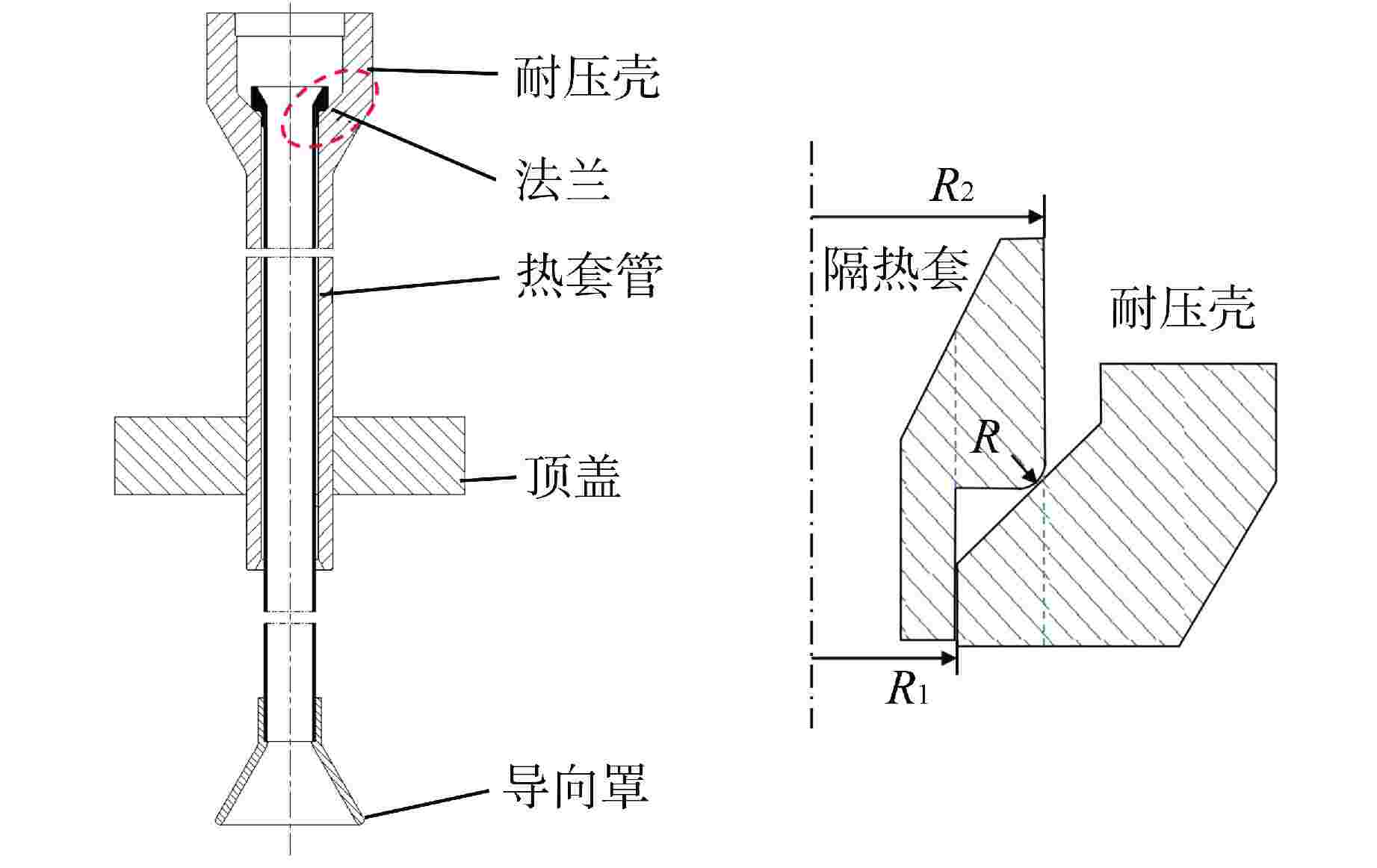

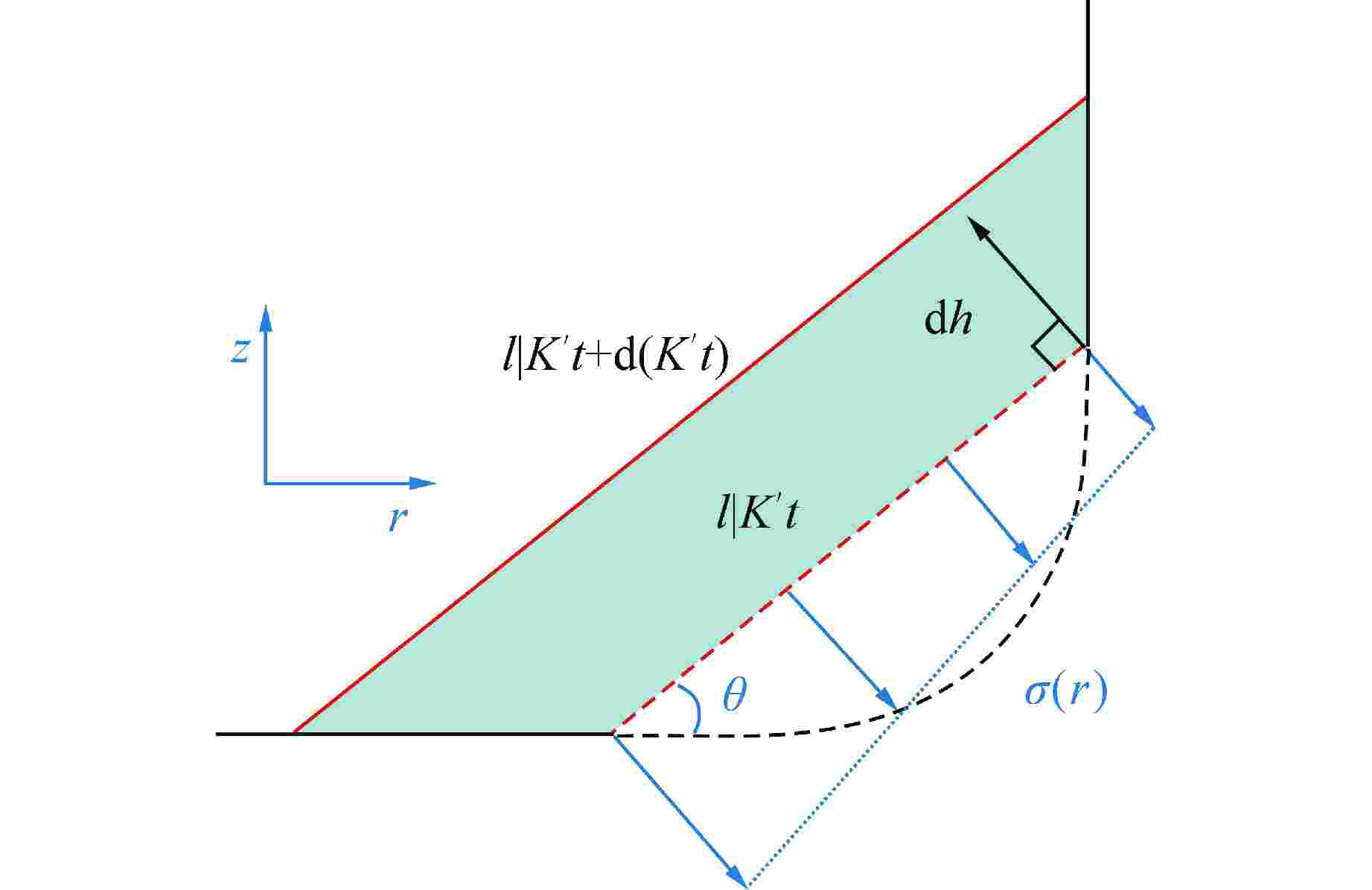

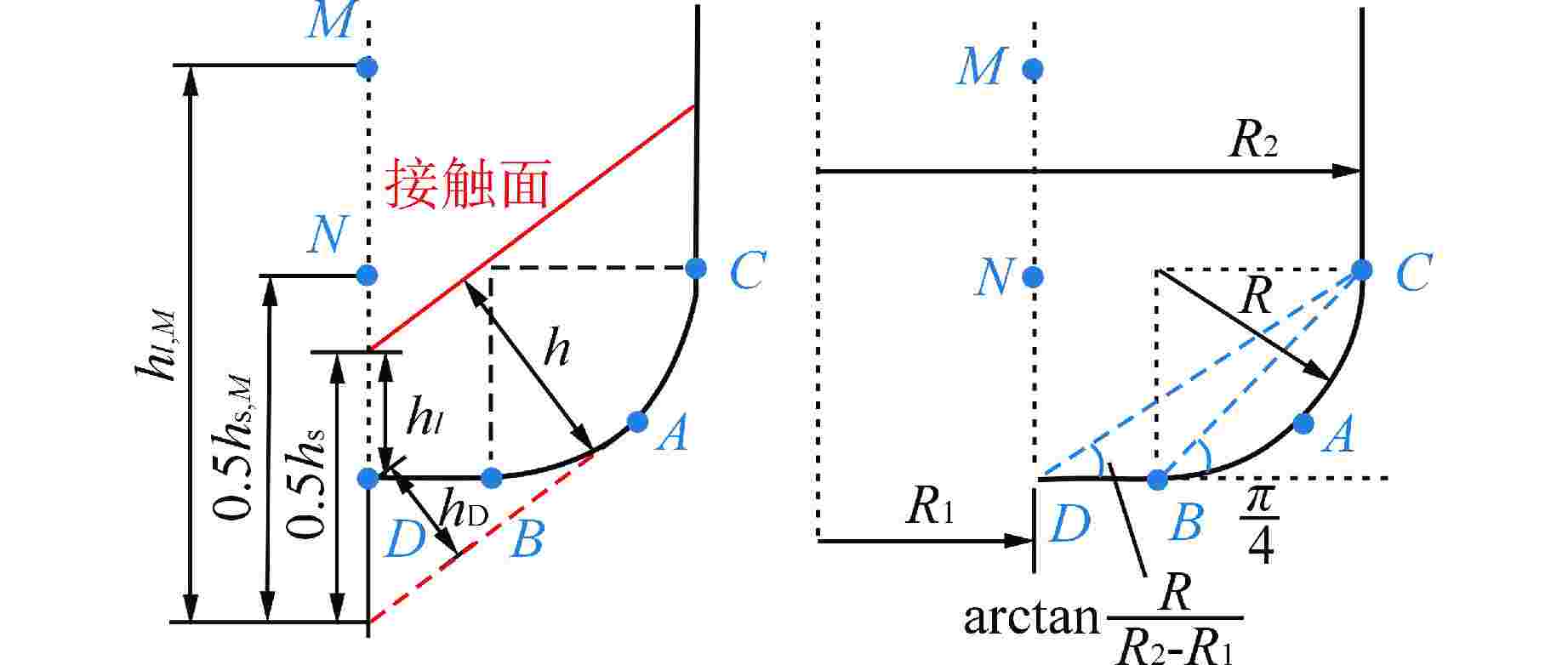

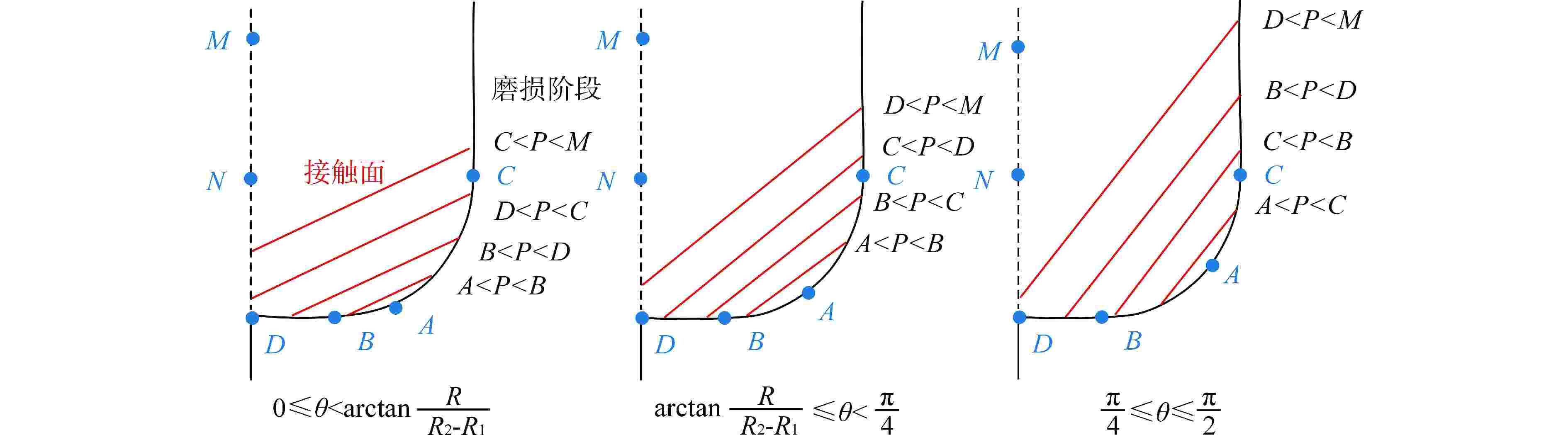

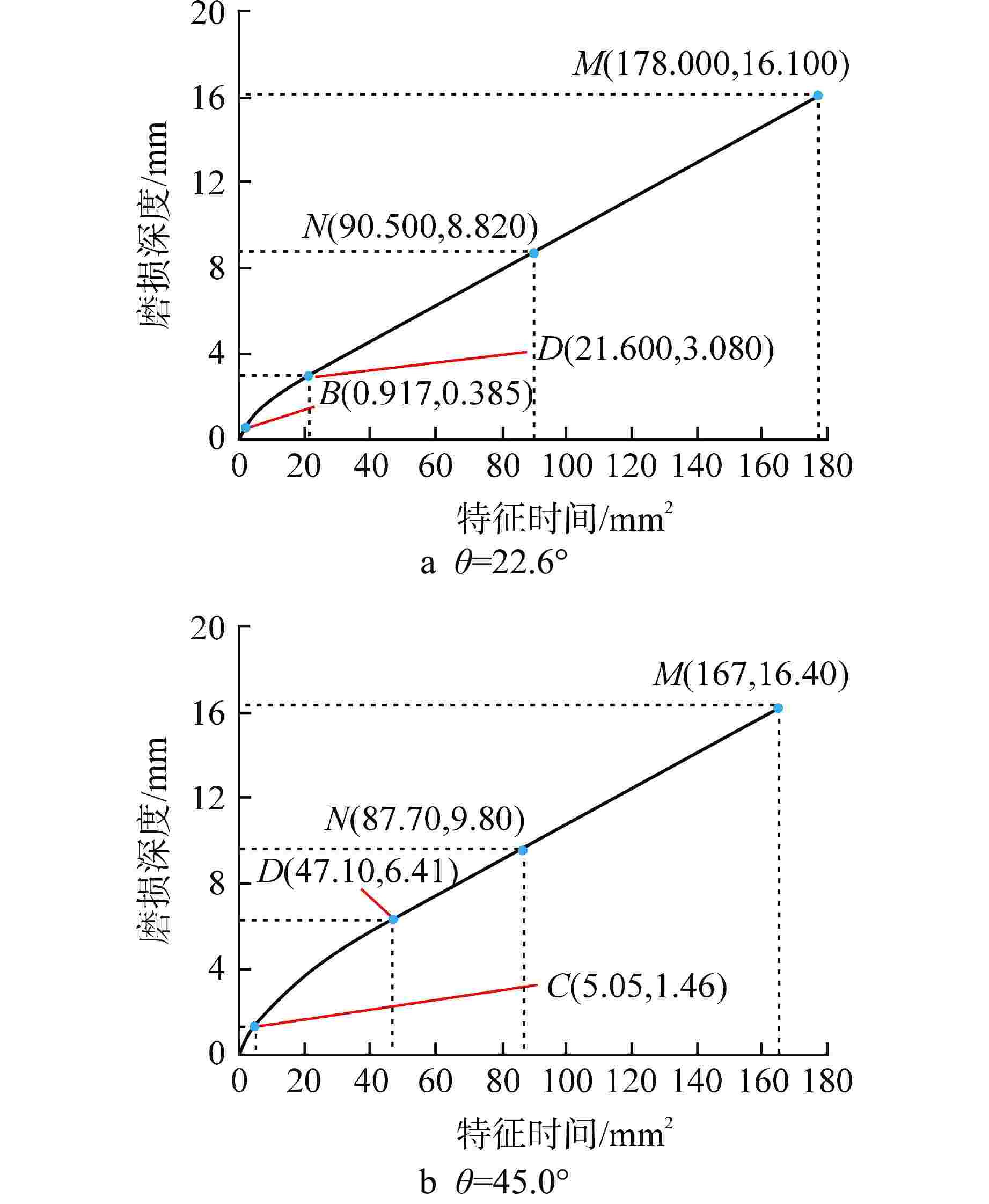

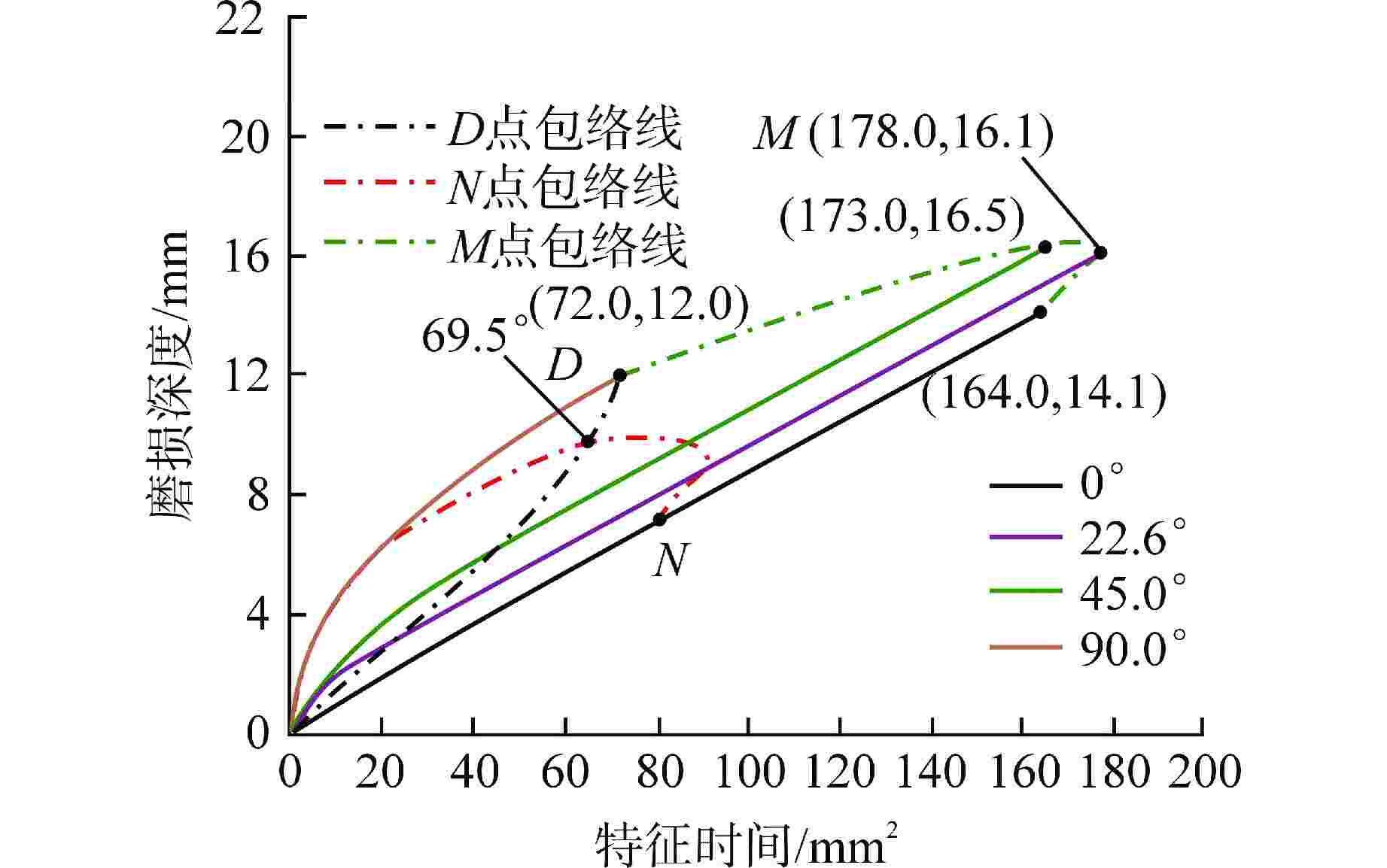

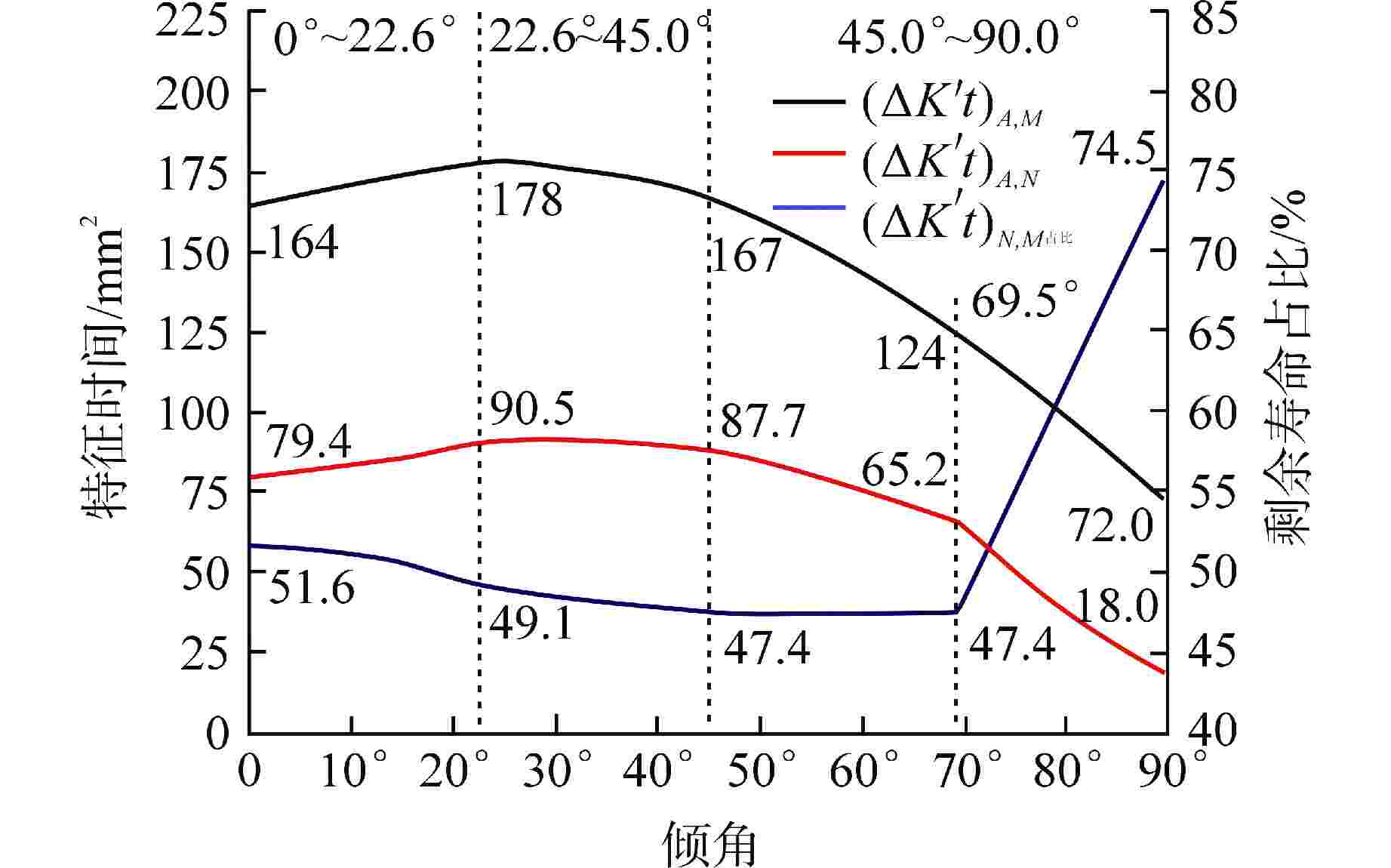

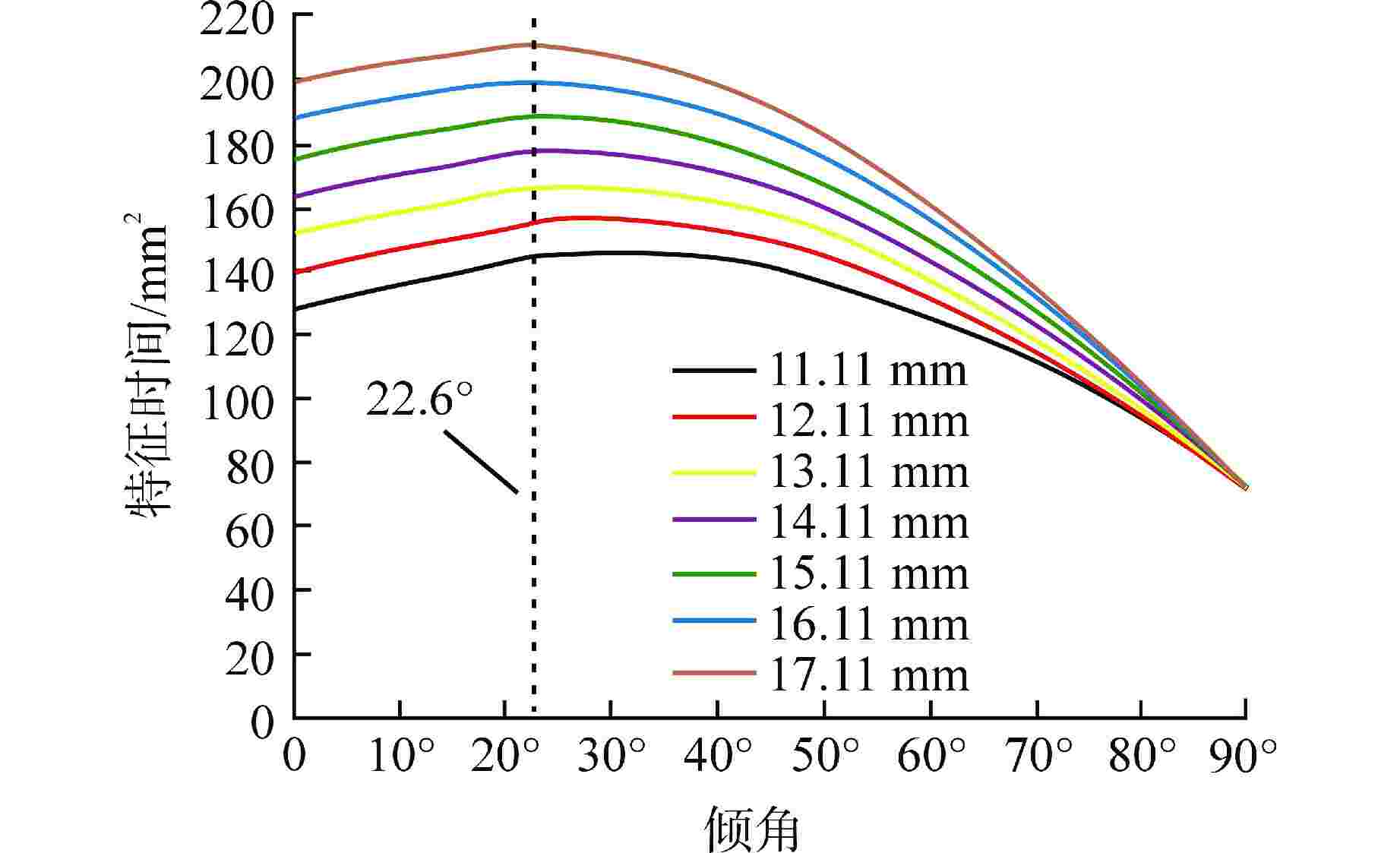

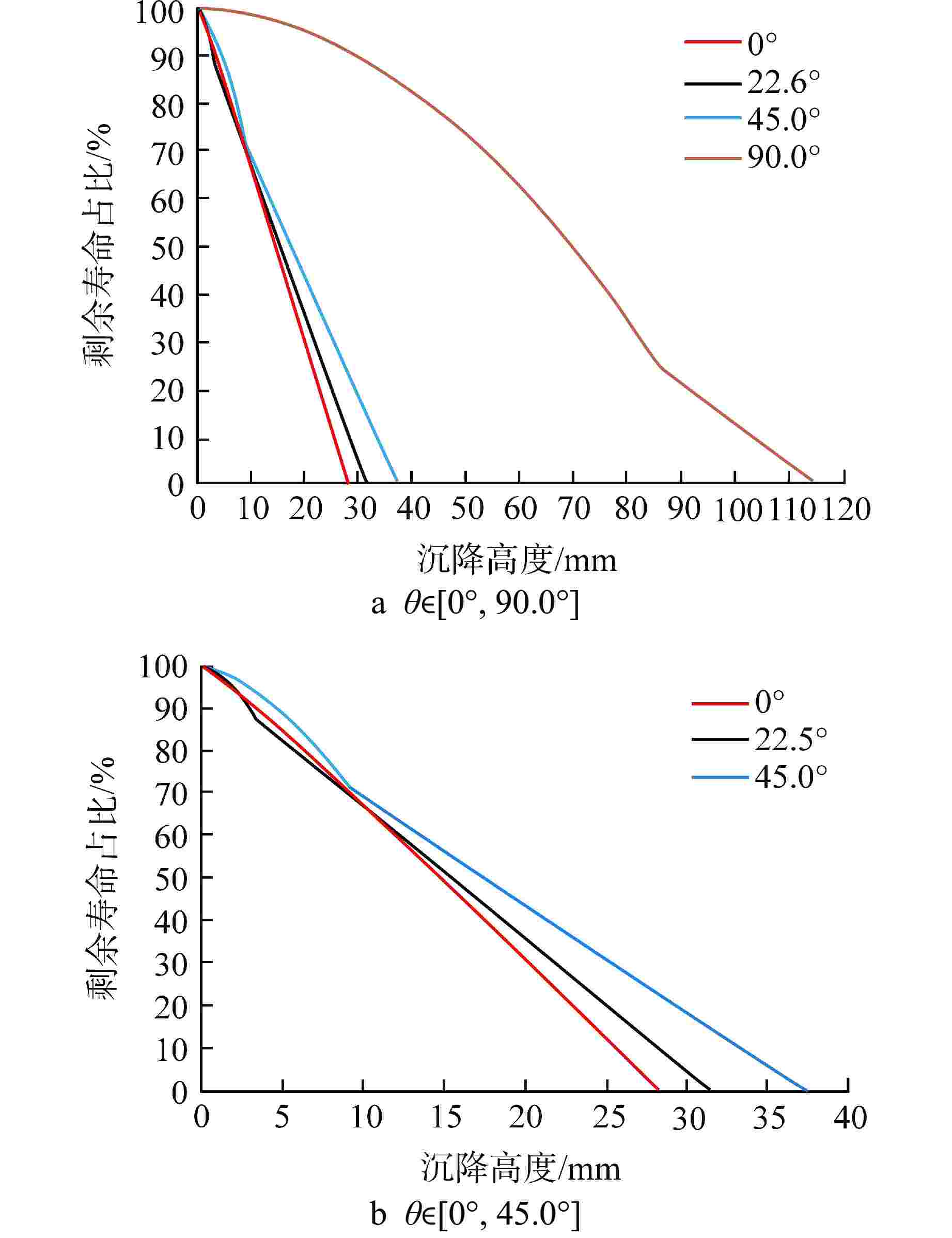

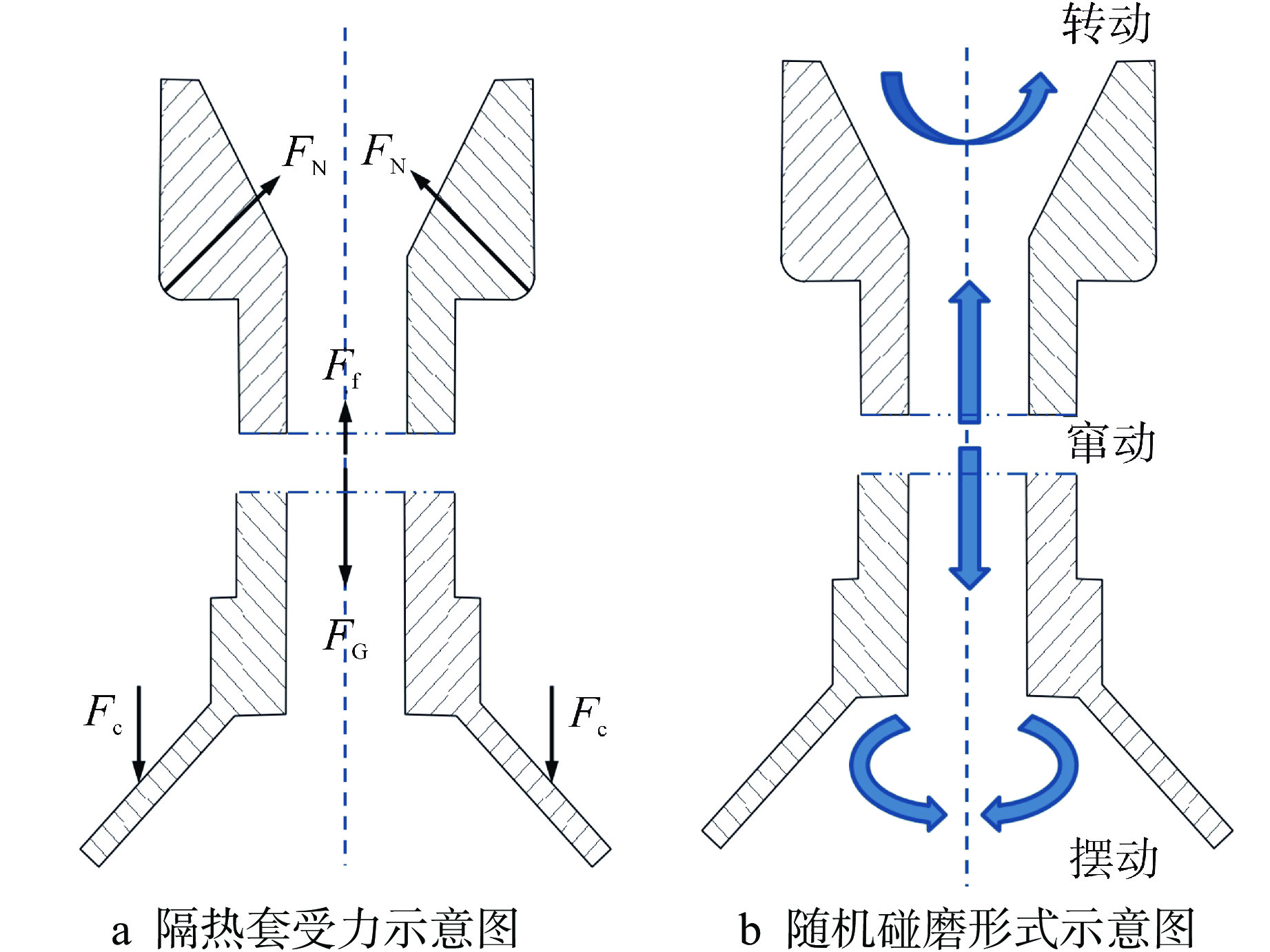

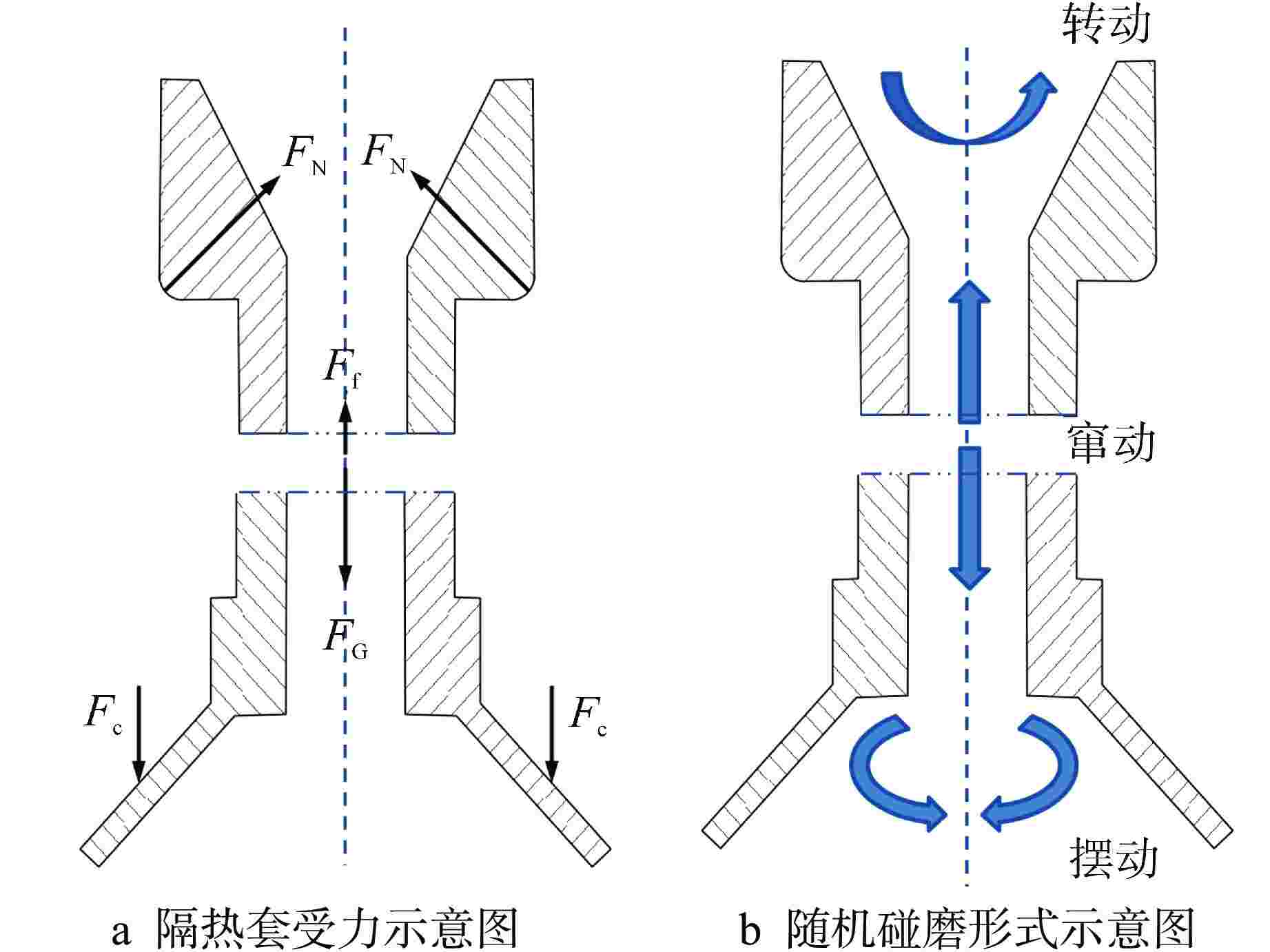

摘要: 隔热套组件(简称隔热套)是核电厂反应堆控制棒驱动机构的主要部件之一,由于下端部受到喷射流体冲击,法兰与耐压壳发生接触磨损,导致承载能力和抗冲击能力下降,影响控制棒落棒功能。本文基于Archard模型,提出结构磨损特征时间和隔热套磨损微分方程,将结构磨损与运行工况参数及材料物性参数解耦,建立了适用于隔热套的静力学磨损分析模型,得到了沉降高度随结构磨损特征时间变化规律。计算结果表明,对于华龙一号机组驱动机构,其隔热套结构安全运行寿命最长时的倾角为22.6°。通过给出剩余运行寿命与沉降高度对照曲线,为核电厂运行单位提供了隔热套更换评价方法与磨损缺陷处理方案。Abstract: The thermal sleeve assembly (referred to as thermal sleeve) is one of the main components of the control rod drive mechanism of the nuclear power plant reactor. Due to the impact of jet fluid on the lower end, the flange and the pressure housing are in contact and wear, which leads to the decrease of bearing capacity and impact resistance and affects the rod dropping function of the control rod. Based on Archard model, this paper puts forward the differential equations of structural wear characteristic time and thermal sleeve wear, decouples structural wear from operating condition parameters and material physical parameters, establishes a static wear analysis model suitable for thermal sleeve, and obtains the variation law of sedimentation with structural wear characteristic time. The results show that for the CRDM structure of HPR 1000, the maximum safety operation life of the thermal sleeve is at an inclination angle with 22.6°. By giving the contrast curve between the remaining operation life and sedimentation height, the evaluation method of thermal sleeve replacement and the treatment scheme of wear defects are provided for the operators of nuclear power plants.

-

Key words:

- Control rod drive mechanism /

- Thermal sleeve wear /

- Archard model /

- Safety operation life

-

表 1 隔热套沉降处理方案

Table 1. Solution for Thermal Sleeve Sedimentation

评价指标 评价标准 选用标准 剩余寿命 ≥50% 维持现状,定期检查 10%~50% 建议缓解,采取缓解措施 ≤10% 需要更换,采取更换措施 -

[1] 核与辐射安全中心二司. 关于法国多个核电厂发生压力容器顶盖热套管磨损下沉导致控制棒卡涩的信息通告[R]. 北京: 中华人民共和国生态环境部, 2021. [2] Goryacheva I G. Contact Mechanics in Tribology [M]. Springer, Dordrecht, 1998, 163-324. [3] Williams J A .Wear modelling: analytical, computational and mapping: a continuum mechanics approach[J].Wear, 1999, s 225–229(part-P1):1-17. [4] Meng H C , Ludema K C .Wear models and predictive equations: their form and content[J].Wear, 1995, 181(part-P2):443-457. [5] Ludema K C .Mechanism-based modeling of friction and wear[J].Wear, 1996, 200(1-2):1-7. [6] 桂长林. Archard的磨损设计计算模型及其应用方法[J]. 润滑与密封,1990(1): 12-21. [7] JANAKIRAMAN V, LI S, KAHRAMAN A. An investigation of the impacts of contact parameters on wear coefficient[J]. Journal of Tribology, 2014, 136(3): 031602. doi: 10.1115/1.4027440 [8] ARCHARD J F. Contact and rubbing of flat surfaces[J]. Journal of Applied Physics, 1953, 24(8): 981-988. doi: 10.1063/1.1721448 [9] 温诗铸. 摩擦学原理 [M]. 清华大学出版社, 1990, 268-312. [10] Bayer R G , Clinton W C , Sirico J L .A note on the application of the stress dependency of wear in the wear analysis of an electrical contact[J].Wear, 1964, 7(3): 282-289. [11] 克拉盖尔斯基. 摩擦磨损计算原理 [M]. 机械工业出版社, 1982, 272-342. [12] ROWE C N. Some aspects of the heat of adsorption in the function of a boundary lubricant[J]. A S L E Transactions, 1996, 9(1): 101-111. [13] 章易程. 齿轮乏油传动的摩擦学研究[D]. 长沙: 中南大学,2011. [14] Lisowski Z, Stolarski T A. A modified theory of adhesive wear in lubricated contacts[J].Wear, 1981, 68(3):333-345. [15] 占旺龙. 弹性接触下的摩擦磨损数值分析与实验研究[D]. 广州: 华南理工大学,2019. [16] 胡波. 摩擦磨损计算及专家系统的研究与开发[D]. 广州: 华南理工大学,2018. [17] PARK D, KAHRAMAN A. A surface wear model for hypoid gear pairs[J]. Wear, 2009, 267(9-10): 1595-1604. doi: 10.1016/j.wear.2009.06.017 [18] FLODIN A, ANDERSSON S. A simplified model for wear prediction in helical gears[J]. Wear, 2001, 249(3-4): 285-292. doi: 10.1016/S0043-1648(01)00556-7 [19] OSMAN T, VELEX P. Static and dynamic simulations of mild abrasive wear in wide-faced solid spur and helical gears[J]. Mechanism and Machine Theory, 2010, 45(6): 911-924. doi: 10.1016/j.mechmachtheory.2010.01.003 [20] 赵蕾磊. 滚珠丝杠副磨损特性分析及研磨技术研究[D]. 南京: 南京理工大学,2019. [21] 于洪亮. 数控机床进给系统摩擦磨损与磨损特性的研究[D]. 沈阳: 东北大学,2018. [22] 徐向红,汤文成,俞涛,等. 基于Archard理论的滚珠丝杠磨损预测[J]. 组合机床与自动化加工技术,2016(2): 54-59. [23] 姜洪奎,宋现春,李彦凤,等. 滚珠丝杠副磨损失效机理研究进展[J]. 山东建筑大学学报,2015, 30(2): 163-169. doi: 10.3969/j.issn.1673-7644.2015.02.010 -

下载:

下载: