Study on the Applicability of Transition Boiling Heat Transfer Models Based on LOCUST Code

-

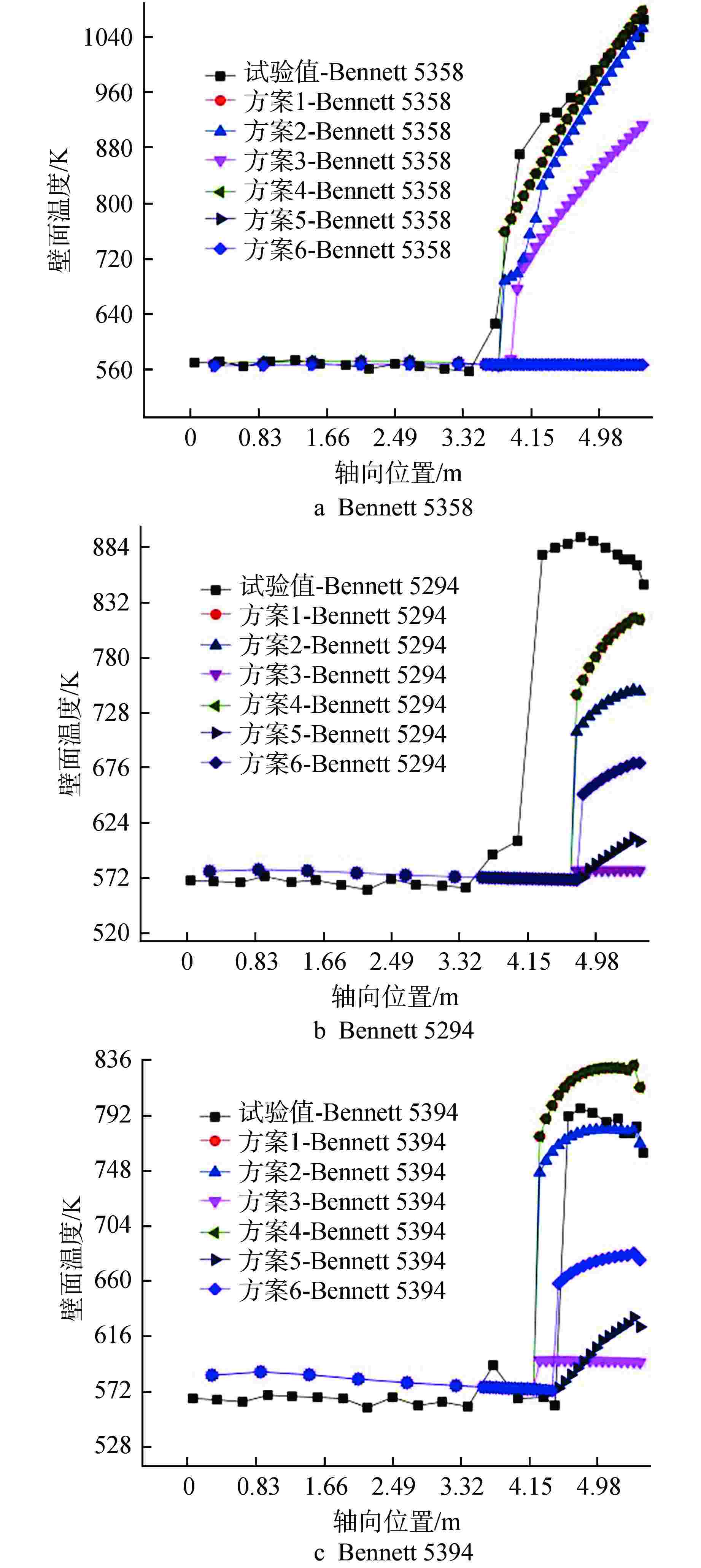

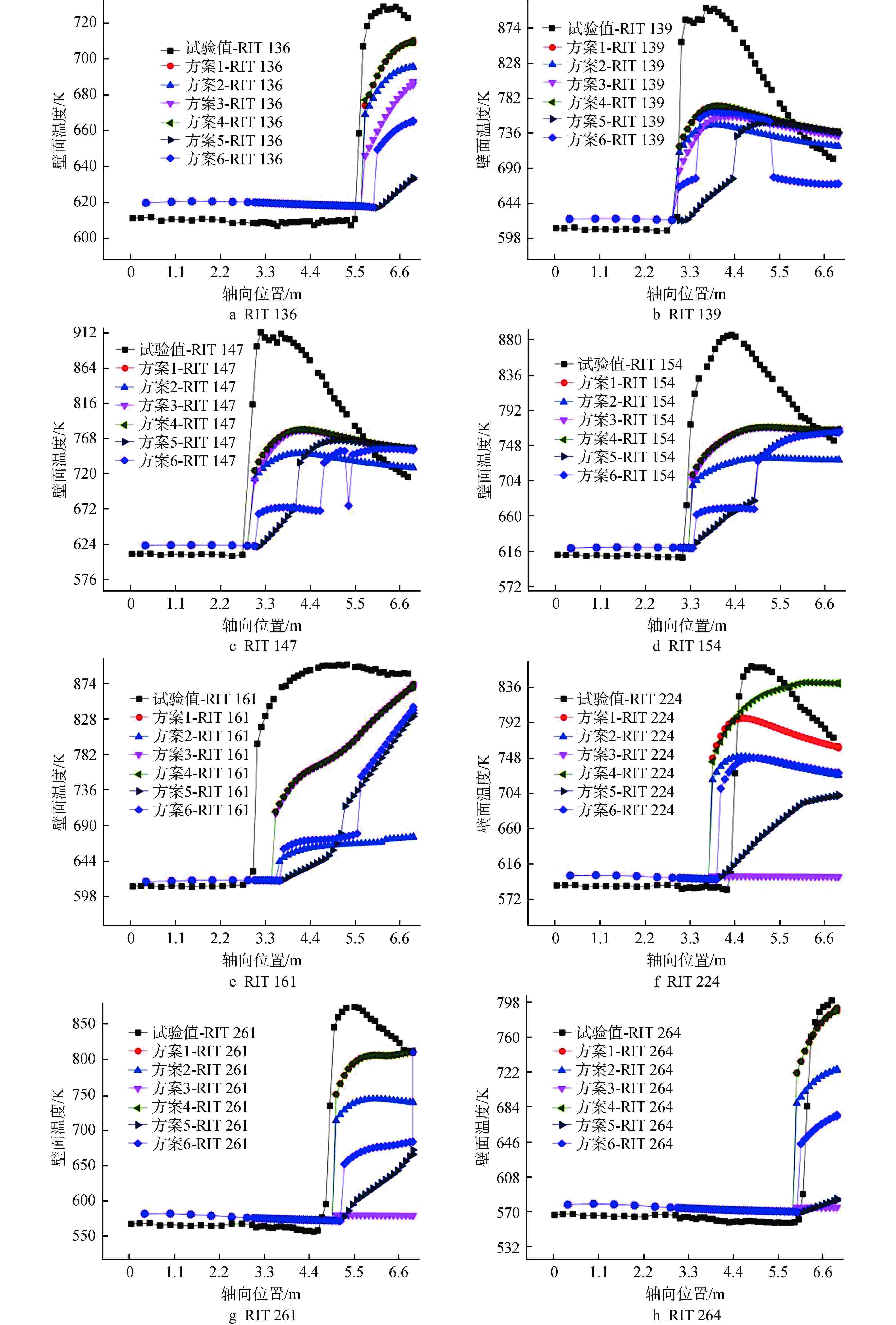

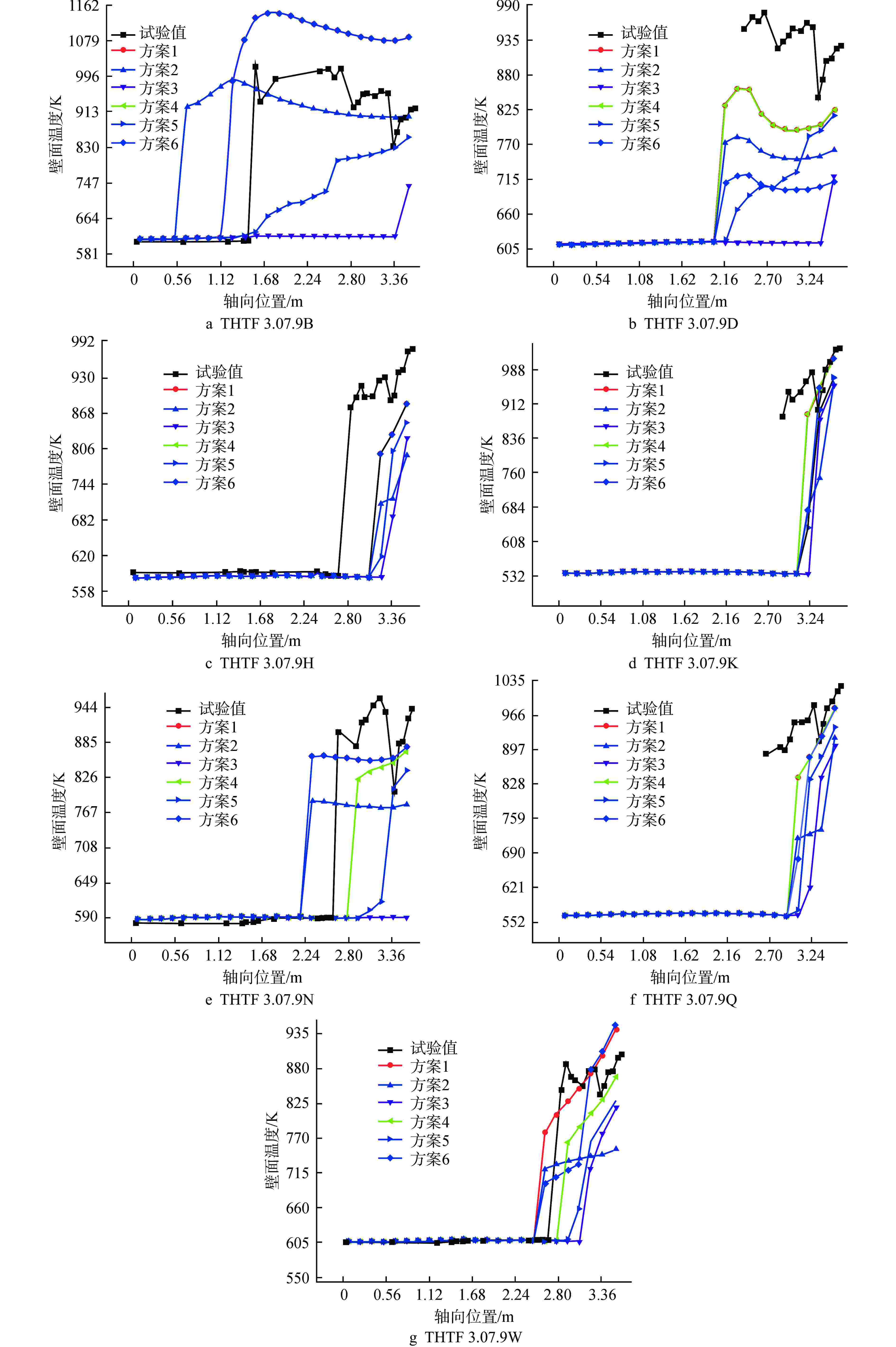

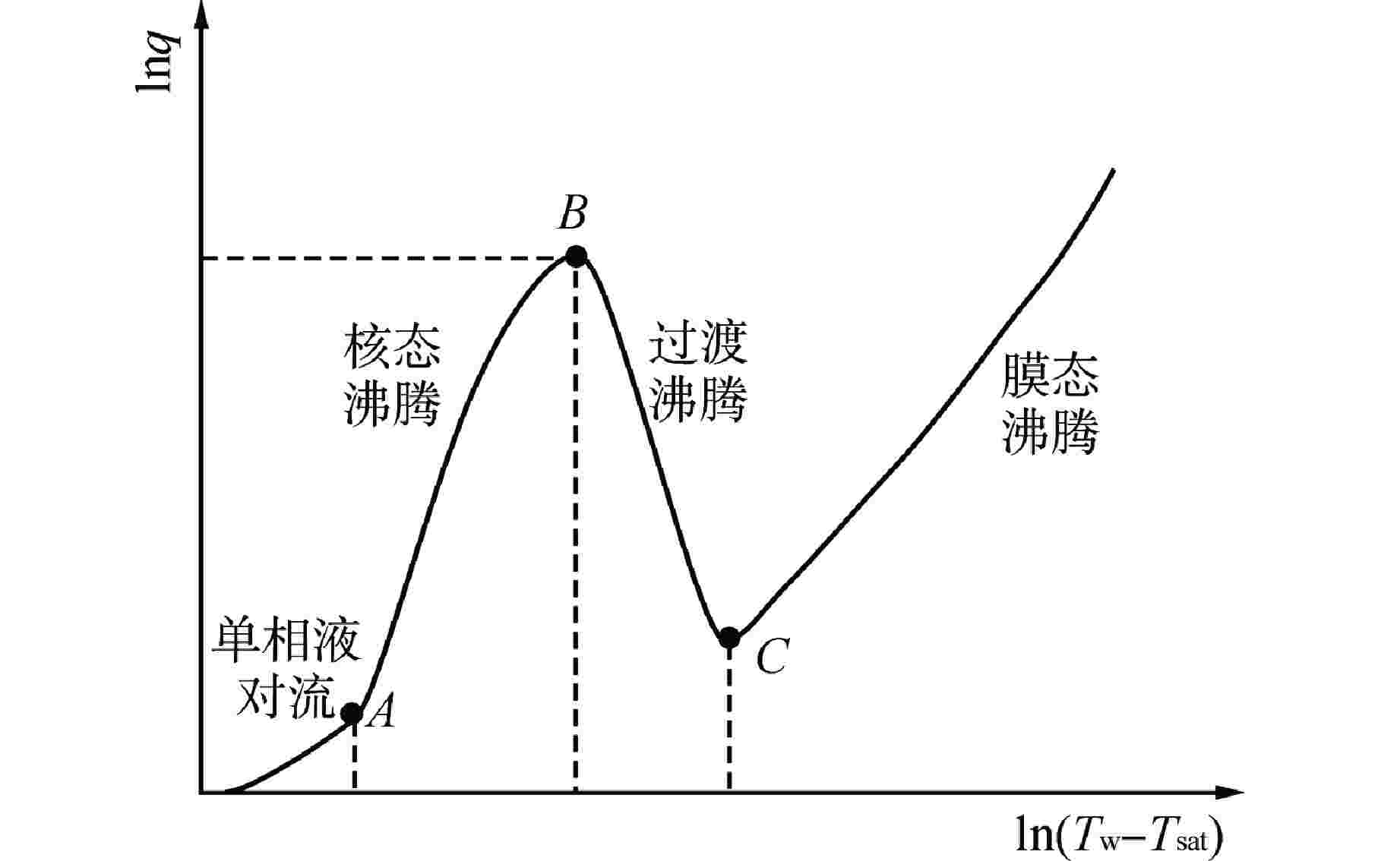

摘要: 过渡沸腾是压水堆(PWR)堆芯分析(特别是事故分析)中一类非常重要的热工水力现象,准确模拟该现象可以提高软件对堆芯壁面温度预测的精确度。考虑到过渡沸腾区域范围小且参数变化大,同时受试验方法的限制,目前缺乏公认的且适用性较好的过渡沸腾传热模型。为评估不同过渡沸腾传热模型的计算效果,对国际上常用的6种过渡沸腾传热模型开展了比较研究。基于中国广核集团有限公司自主开发的热工水力系统分析软件LOCUST,实现了6种过渡沸腾传热模型的代码开发及软件计算结果与试验数据的对比研究。结果表明,Chen关系式与Bjornard-Griffith关系式对过渡沸腾现象的模拟效果最佳,与试验数据的吻合度较好。本研究成果为进一步探究各种过渡沸腾传热模型的差异及计算效果奠定了基础,为热工水力系统分析软件开发过程中过渡沸腾传热模型的选取提供了参考。Abstract: Transition boiling is a very important thermo-hydraulic phenomenon in the core analysis of pressurized water reactor (PWR), especially in the accident analysis. The accurate simulation of this phenomenon can improve the accuracy of core wall temperature prediction by software. Considering the small range of the transition boiling area and the large variation of the parameters, and the limitation of the test method, there is a lack of recognized and suitable transition boiling model. In order to evaluate the effect of different transition boiling models, six transition boiling models commonly used in the world are compared in this paper. Based on LOCUST, a thermo-hydraulic system analysis software independently developed by China General Nuclear Power Corporation, code development of the six transition boiling models and comparative study of software calculation results and test data were realized. The results show that the Chen relation and the Bjornard-Griffith relation are the best in simulating transition boiling phenomenon, showing good agreement with the experiment data. The results of this study lay the foundation for further exploring the differences and computational effects of various transition boiling heat transfer models, and provide reference for the selection of transition boiling heat transfer models in the development of thermo-hydraulic system analysis software.

-

Key words:

- LOCUST /

- Transition boiling /

- Study on model applicability

-

表 1 hTB与p的关系

Table 1. Relationship between Heat Transfer Coefficient and Pressure

p/MPa hTB/[W·(m2·K)−1] 13.79 0.2468 8.274 0.2976 5.516 0.3783 表 2 Bennett试验工况

Table 2. Bennett Test Conditions

试验名称 初始条件和边界条件 Bennett 5358 p=6.9 MPa;q=0.512×106 W/m2;

G=380 kg/(m2·s);∆T=34.41 KBennett 5294 p=6.9 MPa;q=1.09×106 W/m2;

G=1953 kg/(m2·s);∆T=18.8 KBennett 5394 p=6.9 MPa;q=1.75×106 W/m2;

G=5181 kg/(m2·s);∆T=13.78 K表 3 RIT试验工况

Table 3. RIT Test Conditions

试验名称 初始条件和边界条件 RIT 136 p=13.99 MPa;q=5.09×105 W/m2;

G=1977 kg/(m2·s);∆T=10.0 KRIT 139 p=14.00 MPa;q=7.57×105 W/m2;

G=1970 kg/(m2·s);∆T=9.8 KRIT 147 p=14.00 MPa;q=7.04×105 W/m2;

G=1494.3 kg/(m2·s);∆T=9.7 KRIT 154 p=13.98 MPa;q=5.52×105 W/m2;

G=1006.6 kg/(m2·s);∆T=9.3 KRIT 161 p=13.99 MPa;q=4.05×105 W/m2;

G=503.2 kg/(m2·s);∆T=2.88 KRIT 224 p=10.02 MPa;q=8.6×105 W/m2;

G=1990.3 kg/(m2·s);∆T=10.02 KRIT 261 p=7.02 MPa;q=1.05×106 W/m2;

G=1988 kg/(m2·s);∆T=10.68 KRIT 264 p=6.99 MPa;q=7.66×105 W/m2;

G=1500.2 kg/(m2·s);∆T=11.0 K表 4 THTF试验工况

Table 4. THTF Test Conditions

试验名称 初始条件和边界条件 THTF 3.07.9B p=12.7 MPa;q=9.1×105 W/m2;

G=713.0 kg/(m2·s);∆T=19.11 KTHTF 3.07.9N p=8.52 MPa;q=9.4×105 W/m2;

G=806 kg/(m2·s);∆T=14.29 KTHTF 3.07.9W p=12.55 MPa;q=3.8×105 W/m2;

G=256.0 kg/(m2·s);∆T=34.07 KTHTF 3.07.9D p=12.75 MPa;q=6.93×105 W/m2;

G=517.47 kg/(m2·s);∆T=28.5 KTHTF 3.07.9H p=8.89 MPa;q=4.17×105 W/m2;

G=256 kg/(m2·s);∆T=38.0 KTHTF 3.07.9K p=4.38 MPa;q=4.4×105 W/m2;

G=225.73 kg/(m2·s);∆T=45.84 KTHTF 3.07.9Q p=6.53 MPa;q=5.65×105 W/m2;

G=325.150 kg/(m2·s);∆T=45.84 K -

[1] 琚忠云, 徐财红, 袁红胜, 等. LOCUST 1.2软件现象级验证[C]. 黑龙江哈尔滨: 国家能源核电软件重点实验室2020年学术年会. 2020. [2] 袁红胜, 贺青云, 琚忠云, 等. LOCUST堆芯壁面传热模型分离效应确认[C]. 黑龙江哈尔滨: 国家能源核电软件重点实验室2020年学术年会. 2020. [3] 袁红胜, 徐财红, 琚忠云, 等. 基于THTF稳态传热试验的LOCUST 1.2确认[J]. 核科学与工程, 2022, 42(6): 1377-1382. [4] 赵宁宁, 袁红胜, 文青龙, 等. 堆芯功率分布对CCTF试验再淹没现象影响的评价研究[J]. 核动力工程, 2021, 42(6): 58-64. [5] DU Q, WEN Q L, YUAN H S, et al. Benchmark study of RBHT experiment for the effect of spacer grids on reflood heat transfer with locust code[C]. Los Angeles, USA: Proceedings of 2021 28th International Conference on Nuclear Engineering, 2021. [6] CHEN J C, SUNDARAM R K, OZKAYNAK F T. A phenomenological correlation for post-CHF heat transfer: NUREG-0237[R]. Washington: Nuclear Regulatory Commission, 1977. [7] ELLION M E. A study of the mechanism of boiling heat transfer[D]. Pasadena: California Institute of Technology, 1954. [8] 徐济鋆. 沸腾传热和气液两相流[M]. 第二版. 北京: 原子能出版社, 2001: 314-315. [9] TONG L S. Boiling heat transfer and two-phase flow[M]. New York: Routledge, 1997: 275-277. [10] MATTSON R J, CONDIE K G, BENGSTON S J, et al. Regression analysis of post-CHF flow boiling data[C]//Proceedings of the Fifth International Heat Transfer Conference. Tokyo: Atomic Energy Commission, 1974. [11] HSU Y Y. A tentative correlation for the regime of transition boiling and film boiling during reflood[C]//Paper Presented at the 3rd Water Reactor Safety Review Information Meeting. Washington: United States Nuclear Regulatory Commission, 1986. [12] GROENEVELD D C, FUNG K K. Forced convective transition boiling: review of literature and comparison of predictive methods: AECL-5543[R]. Chalk River, Ontario: Atomic Energy of Canada Limited, 1976. [13] BJORNARD T A, GRIFFITH P. PWR blowdown heat transfer[C]//Proceedings of the Thermal and Hydraulic Aspects of Nuclear Reactor Safety. Atlanta: American Society of Mechanical Engineers, 1977: 17-41. [14] U. S. Nuclear Regulatory Commission. TRACE V5.0 theory manual: field equations, solution methods, and physical models: DC 20555-0001[R]. Washington: U. S. Nuclear Regulatory Commission, 2007. [15] KIRCHNER W L. Reflood heat transfer in a light water reactor[D]. Cambridge: Massachusetts Institute of Technology, 1976. [16] JOHANNSEN K, WEBER P, FENG Q. Experimental investigation of heat transfer in the transition region: EUR 13235 EN[R]. Brussels: Commission of the European communities, 1990. [17] Information Systems Laboratories. RELAP5/MOD3.3 code manual volume I: code structure, system models, and solution methods: Rev 1[R]. Washington, U. S: Nuclear Regulatory Commission, 2001. [18] Gesellschaft für Anlagenund Reaktorsicherheit(GRS) mbH. ATHLET mod 3.0 cycle a models and methods: GRS-P-1/Vol.3, Rev.3[R]. Germany: Gesellschaft für Anlagen-und Reaktorsicherheit, 2014. [19] BROMLEY L A. Heat transfer in stable film boiling[J]. Chemical Engineering Progress, 1950, 46: 221-227. [20] BERENSON P J. Film-boiling heat transfer from a horizontal surface[J]. Journal of Heat Transfer, 1961, 83(3): 351-356. doi: 10.1115/1.3682280 [21] TONG L S. Heat-transfer mechanisms in nucleate and film boiling[J]. Nuclear Engineering and Design, 1972, 21(1): 1-25. doi: 10.1016/0029-5493(72)90082-9 [22] BENNETT A W, HEWITT G F, KEARSEY H A, et al. Heat transfer to steam-water mixtures flowing in uniformly heated tubes in which the critical heat flux has been exceeded: AERE-R5373[R]. Harwell: Atomic Energy Research Establishment 1968. [23] SJOBERG A, CARAHER D. Assessment of RELAP5/MOD2 against 25 dryout experiments conducted at the royal institute of technology: NUREG/IA-0009[R]. Washington: U. S. Nuclear Regulatory Commission, 1986. [24] YODER G L, MORRIS D G, MULLINS C B, et al. Dispersed-flow film boiling in rod-bundle geometry: steady-state heat-transfer data and correlation comparisons: NUREG/CR-2435[R]. Oak Ridge: Oak Ridge National Laboratory, 1982. [25] ANKLAM T M, MILLER R J, WHITE M D. Experimental investigations of uncovered-bundle heat transfer and two-phase mixture-level swell under high-pressure low heat-flux conditions: NUREG/CR-2456[R]. Oak Ridge: Oak Ridge National Laboratory, 1982. -

下载:

下载: