Study on Heat Transfer Characteristics and Optimization of Spent Fuel Storage and Transportation Containers Based on Heat-Fluid-Solid Coupled Model for Radiation, Convection and Conduction

-

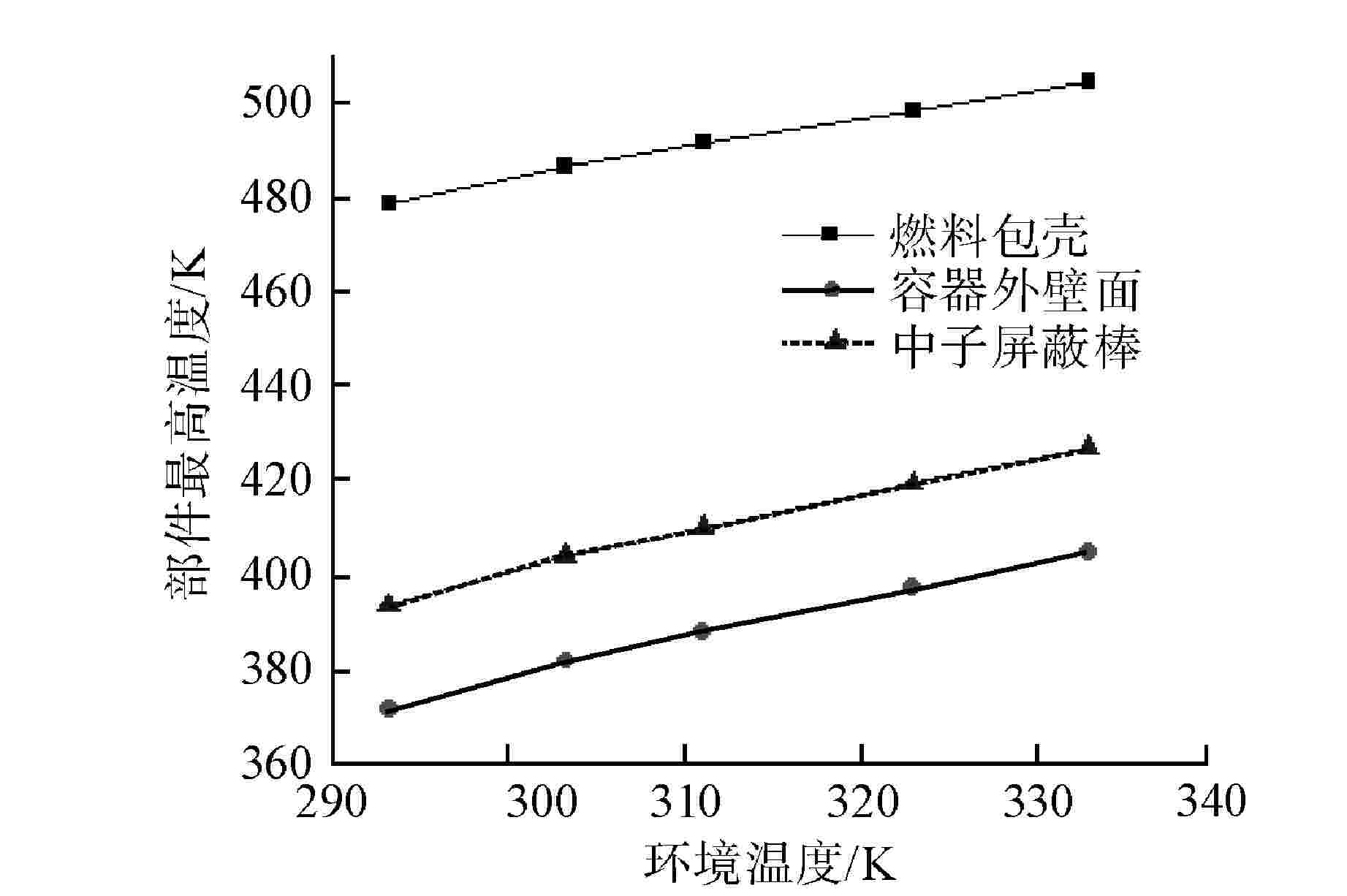

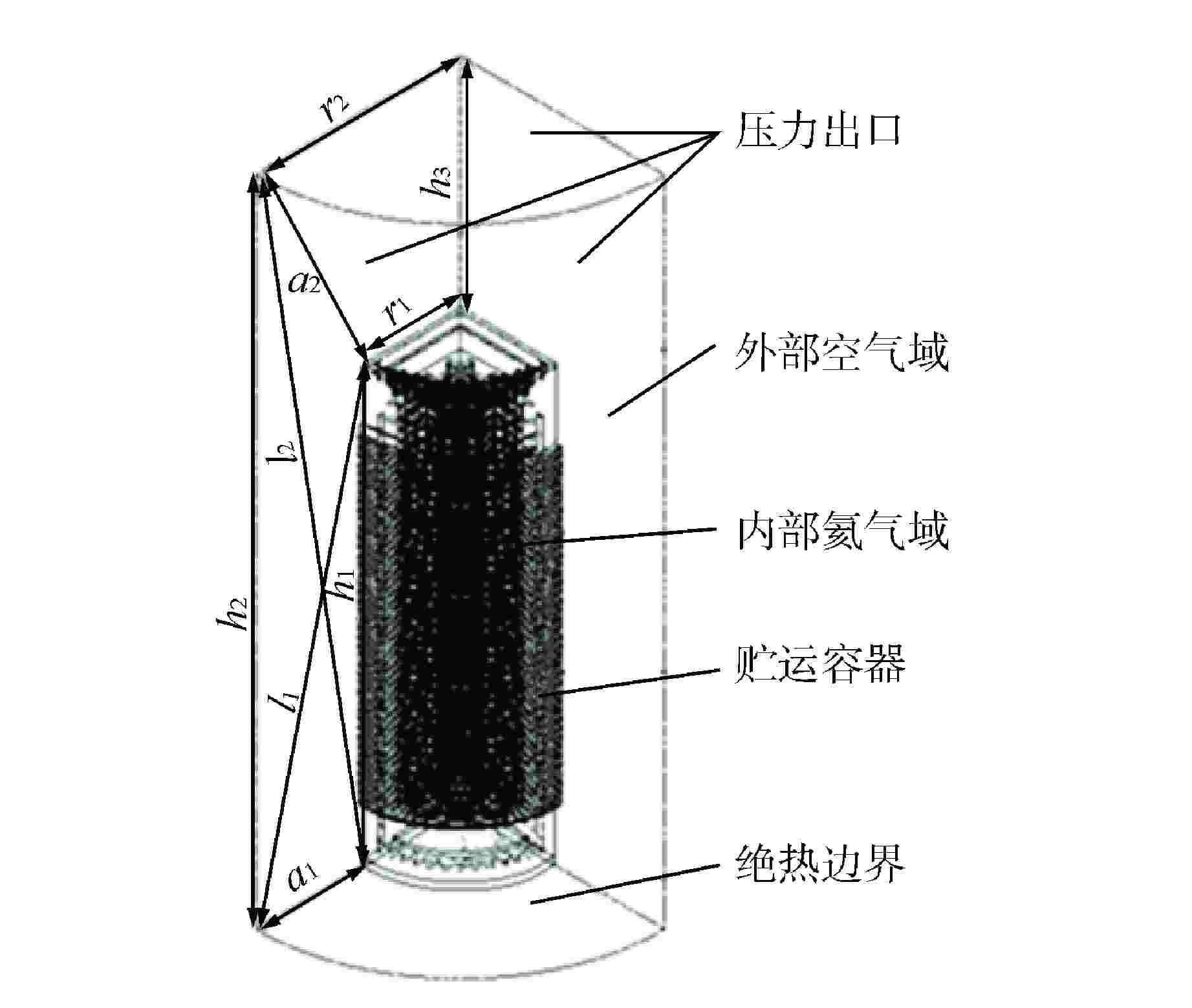

摘要: 基于辐射-对流-传导的热流固耦合计算流体动力学(CFD)模型,对比不同放置状态、环境温度、容器内部填充介质和有无环形翅片情况下,各部件最高温度、自然对流流速、外表面辐射及对流功率的变化。结果表明,水平放置有利于强化环形翅片的对流传热;环境温度每升高10℃,燃料包壳温度增加6.5℃,外壁面温度增加8.3℃;燃料篮内部填充物由中子吸收板或铝块更换为氦气后,容器整体导热性能明显降低,容器内部温度升高,但容器壁面温度基本不变;如不考虑太阳暴晒,环形翅片可增加对流传热,使得容器整体温度降低;如考虑太阳暴晒,环形翅片会增加太阳暴晒能量的吸收,使容器整体温度反而比光滑壁面容器高;基于代数分析法和漫灰表面模型对CFD辐射模型进行验证,CFD辐射功率和公式法计算结果基本一致。Abstract: Based on the heat-fluid-solid coupled computational fluid dynamics (CFD) model for radiation,convection and conduction, this paper compares the changes in maximum temperature, natural convection flow rate, outer surface radiation and convection power of various parts under different storage status and ambient temperatures, with different packing media in the containers, and with or without annular fin. According to the study results, horizontal arrangement improves the convection heat transfer on the annular fin; each time the ambient temperature increases by 10 ℃, the fuel cladding temperature and outer wall surface temperature increase by 6.5 ℃ and 8.3℃, respectively; when the medium filling the fuel basket is changed from neutron absorption plate or aluminum block to helium, the overall heat transfer capacity of the container deteriorates dramatically, with the temperature inside the container increasing and the outer wall surface temperature remaining almost unchanged; with the solar radiation ignored, a annular fin will help improve convection heat transfer and thus decrease the overall temperature of the container, otherwise, the annular fin absorbs more solar energy, causing the overall temperature of the container to exceed that of a container with smooth wall; and the CFD radiation power is basically same as the calculation results gained in the formula method, as shown in the verification of the CFD radiation model based on the algebraic analysis method and diffuse gray surface model.

-

Key words:

- Spent fuel container /

- Storage status /

- Ambient temperature /

- Fin /

- Optimization

-

表 1 燃料组件等效导热率与当地温度的关系[5]

Table 1. Relationship between Equivalent Thermal Conductivity of Fuel Assembly and Local Temperature

方向 当地温度/℃ 导热率/[W·(m·K)−1] 轴向 93 0.946 149 0.998 204 1.050 316 1.137 427 1.233 径向 81 0.347 181 0.477 283 0.671 388 0.922 599 1.480 表 2 不同放置方式的传热特性

Table 2. Heat Transfer Characteristics under Different Storage Modes

放置方式 竖直 水平 燃料包壳最高温度/K 490.98 484.50 中子屏蔽棒最高温度/K 409.68 407.03 侧表面最高温度/K 393.53 392.94 顶面最高温度/K 369.46 373.80 总辐射功率/W 11867 11235 总对流功率/W 7053 7686 表 3 不同燃料篮内部填充方式下传热特性

Table 3. Heat Transfer Characteristics under Different Filling Modes of Fuel Basket

格架填充物 基准填充方式 备选方案1 备选方案2 燃料包壳最高温度/K 490.98 596.37 617.80 中子屏蔽棒最高温度/K 409.68 409.37 417.97 侧表面最高温度/K 393.53 393.69 402.99 顶面最高温度/K 369.46 369.27 370.98 辐射功率/W 11867 11868 11506 对流功率/W 7054 7046 6839 表 4 无暴晒下翅片对传热特性的影响

Table 4. Influence of Fins on Heat Transfer Characteristics without Solar Radiation

有无环形翅片 有环形翅片 无环形翅片 燃料包壳最高温度/K 475.72 479.07 中子屏蔽棒最高温度/K 390.16 397.61 侧表面最高温度/K 374.21 382.72 顶面最高温度/K 349.25 352.40 辐射功率/W 8062 8498 对流功率/W 4645 4196 表 5 有暴晒下翅片对传热特性的影响

Table 5. Influence of Fins on Heat Transfer Characteristics with Solar Radiation

有无环形翅片 有环形翅片 无环形翅片 燃料包壳最高温度/K 490.98 488.13 中子屏蔽棒最高温度/K 409.68 408.93 侧表面最高温度/K 393.56 393.53 顶面最高温度/K 369.46 368.54 辐射功率/W 11867 10714 对流功率/W 18920 16202 表 6 辐射验证工况

Table 6. Radiation Verification Conditions

工况序号 暴晒 环境温度/℃ 环形翅片 1 有 38 有 2 有 20 有 3 有 30 有 4 有 50 有 5 有 60 有 6 无 38 有 7 无 38 无 8 有 38 无 表 7 有无暴晒下光滑壁面和带翅片壁面的辐射模型验证

Table 7. Verification of Radiation Models for Smooth Wall and Finned Wall with and without Solar Radiation

工况 F1→3 Q1+2→3/W CFD结果/W 相对误差/% 1 0.53 11105 10317 7.64 2 0.53 9761 9111 7.13 3 0.53 10748 10005 7.42 4 0.53 11737 10867 8.01 5 0.53 12163 11220 8.40 6 0.53 7573 8062 −6.07 7 0.92 7802 8499 −8.20 8 0.92 9845 10714 −8.11 -

[1] NRC. Standard review plan for dry cask storage systems: NUREG-1536[S]. US: NRC, 1997: 1054-2122. [2] LO FRANO R, PUGLIESE G, FORASASSI G. Thermal analysis of a spent fuel cask in different transport conditions[J]. Energy, 2011, 36(4): 2285-2293. doi: 10.1016/j.energy.2010.01.041 [3] 蒋兴,姚彦贵,谢永诚,等. 乏燃料干式储存模块衰变热导出的三维仿真计算分析[J]. 原子能科学技术,2008, 42(S1): 477-483. [4] CARSLAW H S, JAEGER J C. Conduction of heat in solids[J]. Physics Today, 1962, 15(11): 74. [5] 汪俊,刘杨. 压水堆核电厂AFA3G燃料组件径向等效导热率研究[J]. 核安全,2014, 13(2): 66-70. doi: 10.3969/j.issn.1672-5360.2014.02.013 [6] LONG T, ZHANG G H, XIONG G M, et al. Accurate numerical simulation of turbulent natural convection for fatigue analysis of heat exchanger high temperature difference region[C]//Proceedings of 2018 International Conference on Power System Technology. Guangzhou: IEEE, 2018. [7] ÇENGEL Y A. Heat transfer: a practical approach[M]. 2nd ed. Boston: McGraw-Hill, 2003: 561-652. -

下载:

下载: