Study on Crack Impact Toughness Evaluation Method for Metallic Materials

-

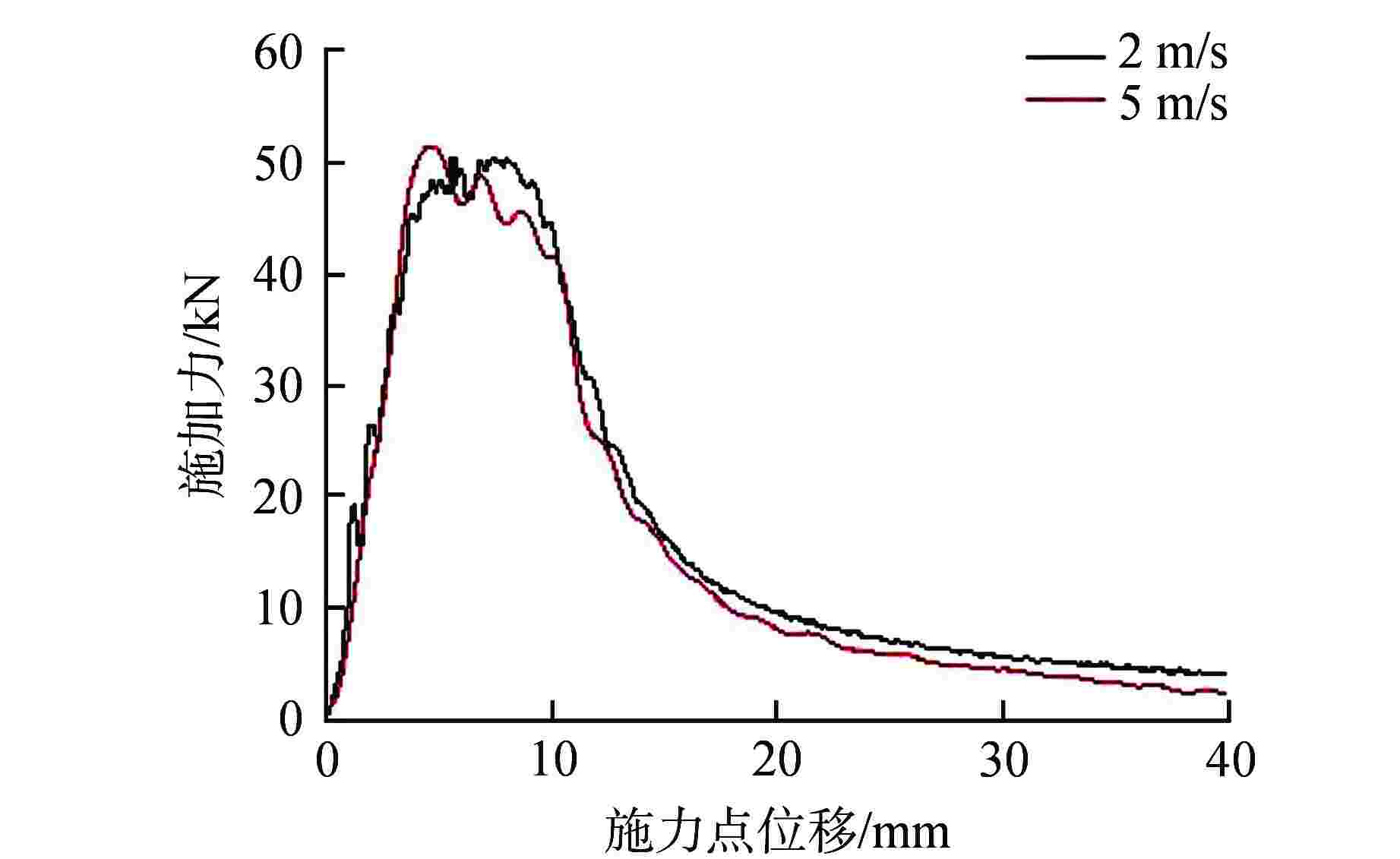

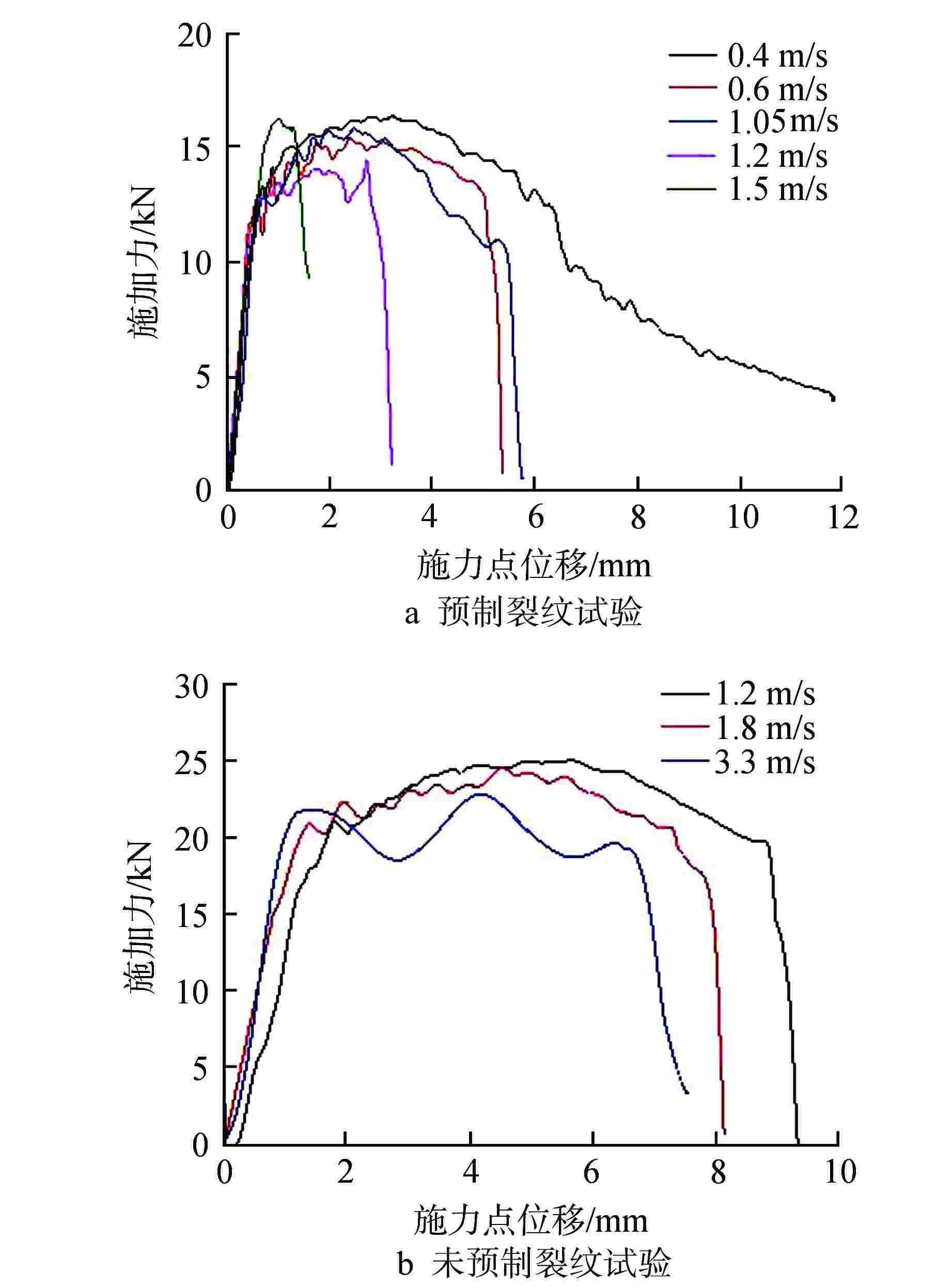

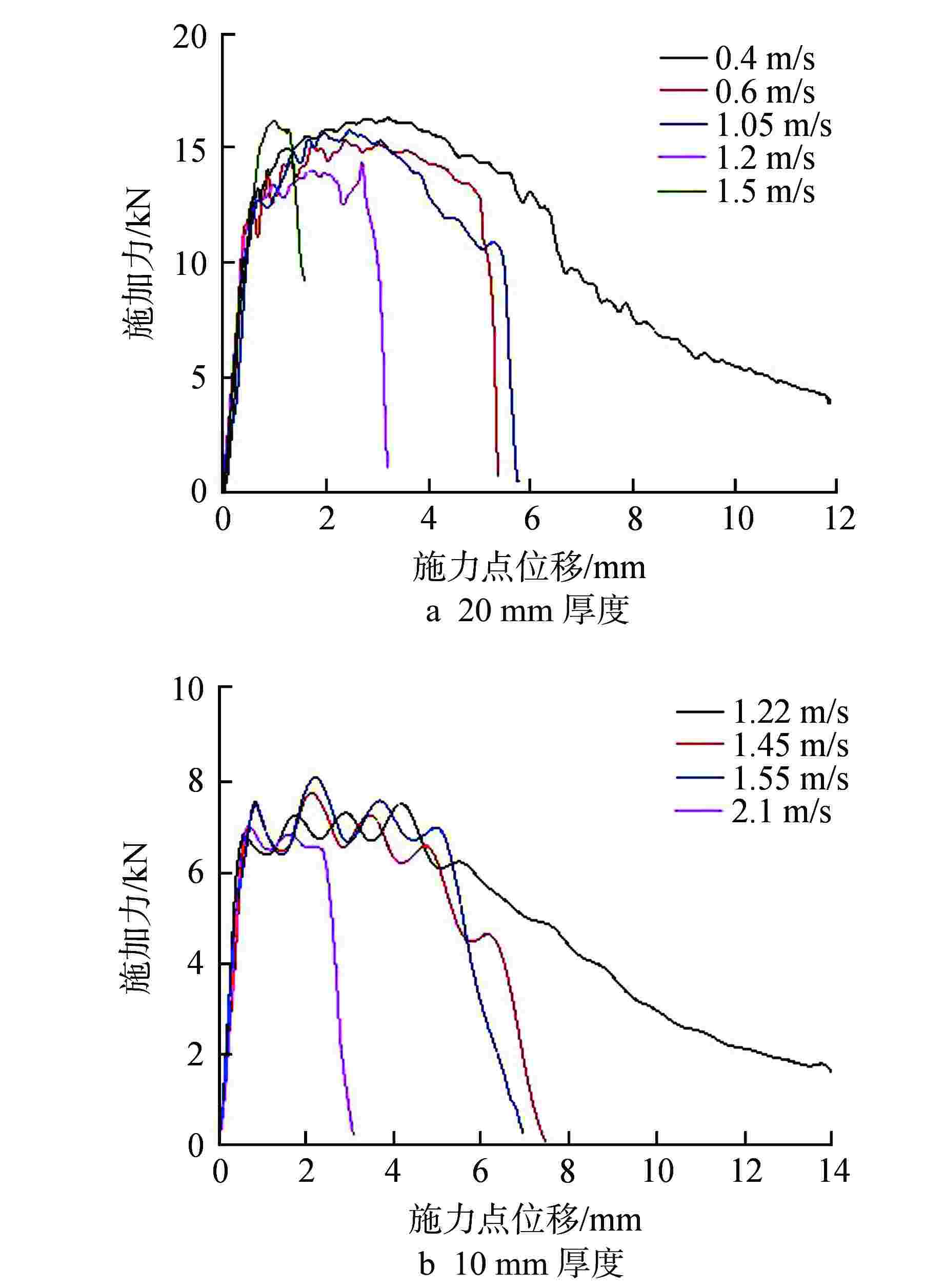

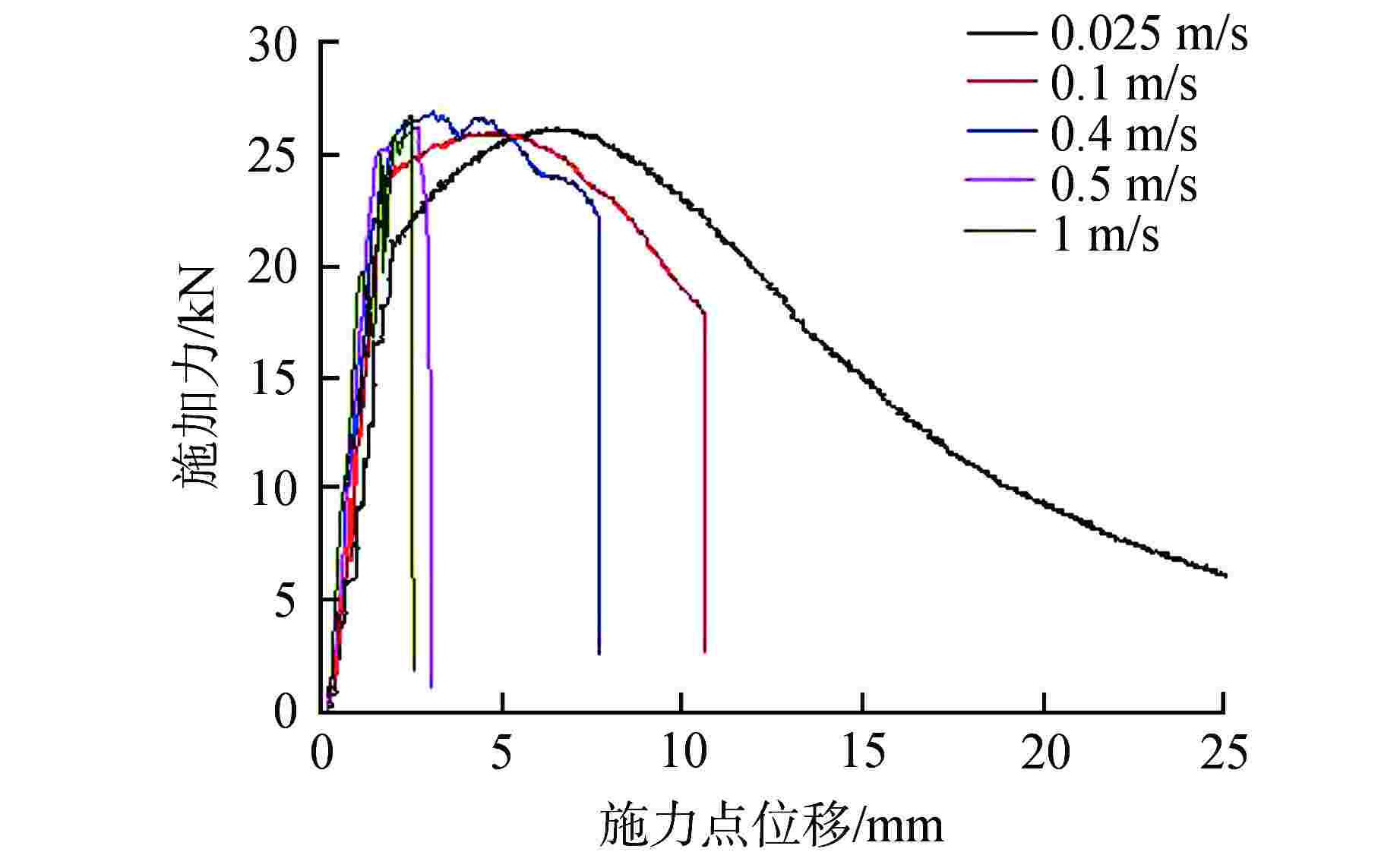

摘要: 工程结构在复杂环境下长期服役后,裂纹的萌生和发展难以避免。对于需要承受爆炸与冲击的工程结构,需要对所用材料的裂纹冲击韧性进行评定,避免裂纹出现可能导致的冲击脆性断裂。基于Instron VHS高速材料试验机,开发了一套材料动态断裂试验装置,测量了4种具有高冲击功金属材料的裂纹冲击韧脆转变过程,并研究了影响金属材料裂纹冲击韧脆转变速率的因素。发现材料夏比冲击功并不能完全反应裂纹的冲击韧性,预制裂纹与否、试样约束方式和试样裂尖约束因子都会影响金属材料裂纹冲击试验中的韧脆转变速率。基于以上研究结果,提出了金属材料裂纹冲击韧性评定方法的基本思路。Abstract: For the engineering structures in service for a long period in the complex environment, crack initiation and growth are difficult to avoid. Therefore, for the engineering structures required to withstand explosion and impact, the crack impact toughness of their materials must be evaluated to prevent the possible brittle fracture under impact due to crack occurrence. This study, relying on the Instron VHS high strain rate material testing machine, develops a set of dynamic fracture testing device to measure the crack ductile-brittle transition process of 4 different kinds of metallic material with high impact energy under impact, and studies the factors influencing the crack ductile-brittle transition rate of these materials. According to the findings, the Charpy impact energy can not fully reflect the crack impact toughness,and the absence and existence of preformed cracks, the specimen constraint mode and the specimen crack tip constraint factor all have an effect on the ductile-brittle transition rate in the crack impact test of metallic materials. Based on the results above, this study finally propose the basic ideas about the crack impact toughness evaluation method for metallic materials.

-

Key words:

- Charpy impact test /

- Crack /

- Impact toughness /

- Dynamic fracture

-

表 1 4种材料常温冲击功试验结果

Table 1. Impact Energy Test Results of 4 Materials under Room Temperature

材料 冲击功/J 第1次 第2次 第3次 平均值 15MnTi 208.4 186.8 189.2 194.8 8Ni5CrMnMo 208.0 217.2 192.1 205.8 11MnNiMo 275.3 277.1 279.0 277.1 9Ni3CrMn 288.6 284.6 280.9 284.7 -

[1] 江洪,王微. 国内外船舶用钢初探[J]. 新材料产业,2014(7): 9-14. doi: 10.3969/j.issn.1008-892X.2014.07.003 [2] 王任甫,赵彩琴,蒋颖,等. 美国舰船用钢板规范的演变与分析[J]. 材料开发与应用,2012, 27(4): 80-85. [3] 邵军. 舰船用钢研究现状与发展[J]. 鞍钢技术,2013(4): 1-4. doi: 10.3969/j.issn.1006-4613.2013.04.001 [4] 曹昱澎. 压力容器用钢在韧脆转变区的断裂韧性预测方法研究[D]. 上海: 华东理工大学, 2012. [5] 潘建华. 冲击载荷作用下压力容器用金属材料动态断裂行为的研究[D]. 合肥: 中国科学技术大学, 2013. [6] QIN H B, ZHANG X P, ZHOU M B, et al. Size and constraint effects on mechanical and fracture behavior of micro-scale Ni/Sn3.0Ag0.5Cu/Ni solder joints[J]. Materials Science and Engineering: A, 2014(617): 14-23. doi: 10.1016/j.msea.2014.08.008 [7] HOHE J, HARDENACKE V, LUCKOW S, et al. An enhanced probabilistic model for cleavage fracture assessment accounting for local constraint effects[J]. Engineering Fracture Mechanics, 2010, 77(18): 3573-3591. doi: 10.1016/j.engfracmech.2010.08.001 [8] FERREÑO D, LACALLE R, GORROCHATEGUI I, et al. Fracture characterisation of a nuclear vessel steel under dynamic conditions in the transition region[J]. Engineering Failure Analysis, 2010, 17(2): 464-472. doi: 10.1016/j.engfailanal.2009.09.001 [9] 王钟羡,吴春笃. 22NiMoCr3-7钢韧-脆转变区断裂韧度及断裂失效曲线[J]. 核动力工程,2009, 30(2): 46-50. [10] ZHAO J H, GUO W L, SHE C M. Three-parameter approach for elastic-plastic fracture of the semi-elliptical surface crack under tension[J]. International Journal of Mechanical Sciences, 2008, 50(7): 1168-1182. doi: 10.1016/j.ijmecsci.2008.04.006 [11] ZHAO J H. Three-parameter approach for elastic-plastic stress field of an embedded elliptical crack[J]. Engineering Fracture Mechanics, 2009, 76(16): 2429-2444. doi: 10.1016/j.engfracmech.2009.06.013 [12] HUANG X L, LIU Y H, HUANG X B. New constraint parameters based on crack tip plastic zone: theoretical derivations and effectiveness verification[J]. International Journal of Solids and Structures, 2020(190): 129-147. doi: 10.1016/j.ijsolstr.2019.11.009 [13] BAO C, CAI L X, HE G W, et al. Normalization method for evaluating J-resistance curves of small-sized CIET specimen and crack front constraints[J]. International Journal of Solids and Structures, 2016, 94-95: 60-75. doi: 10.1016/j.ijsolstr.2016.05.008 -

下载:

下载: