Numerical Study on Hydrogen Flow Distribution Characteristics in Small-Scale Space

-

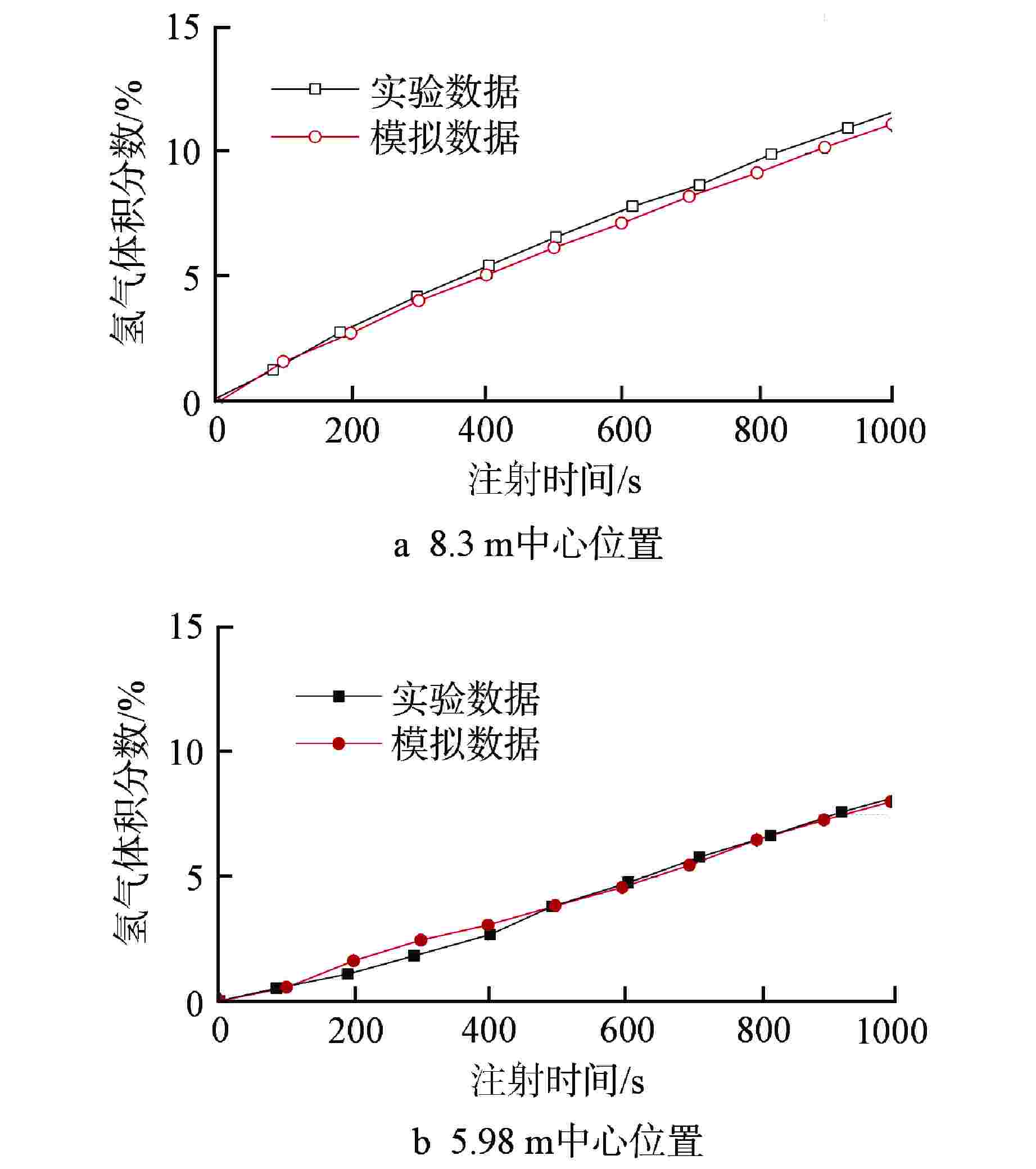

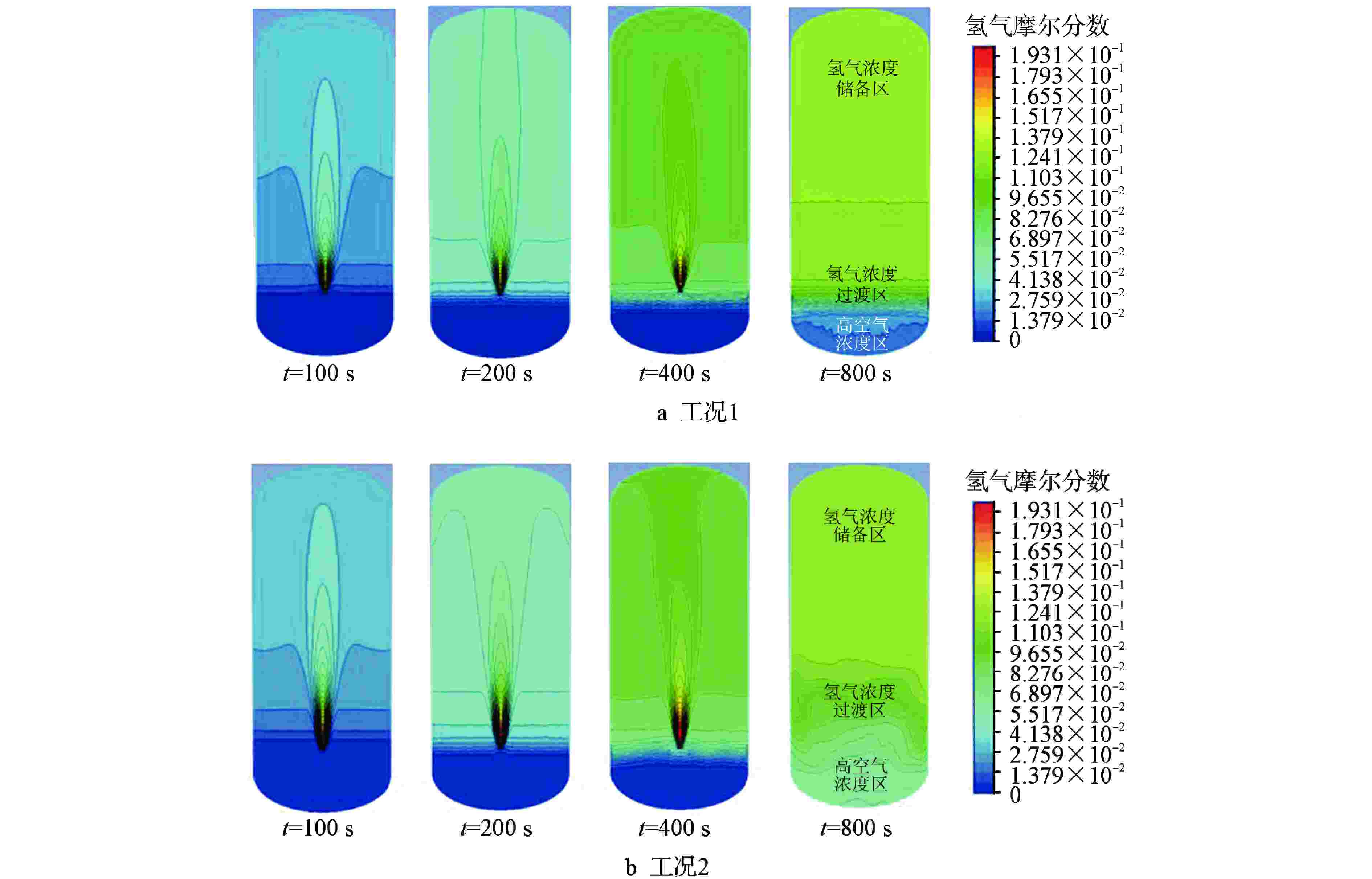

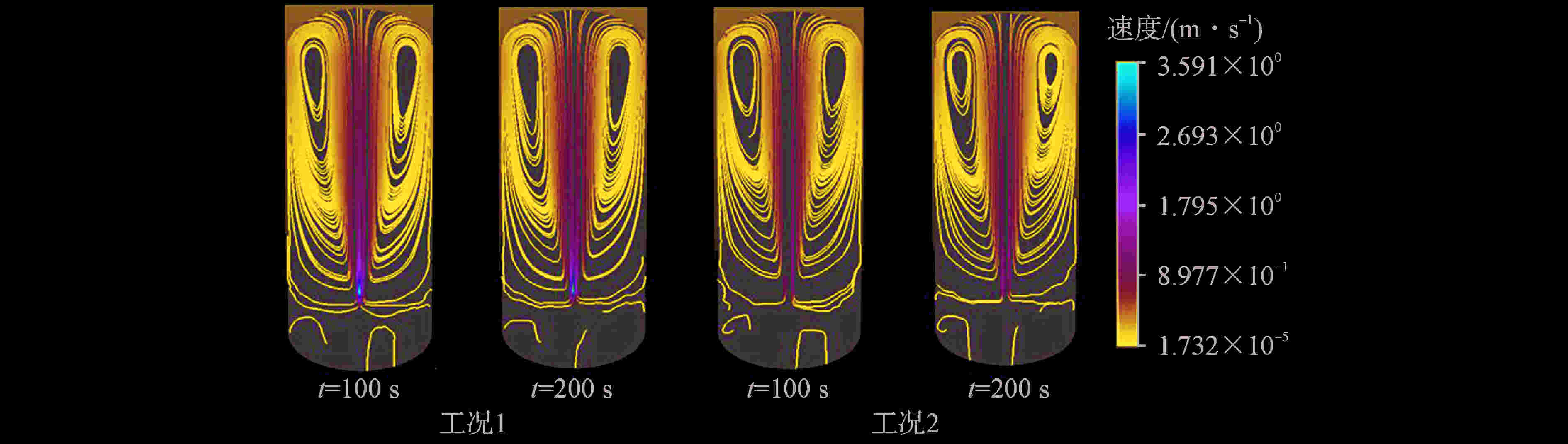

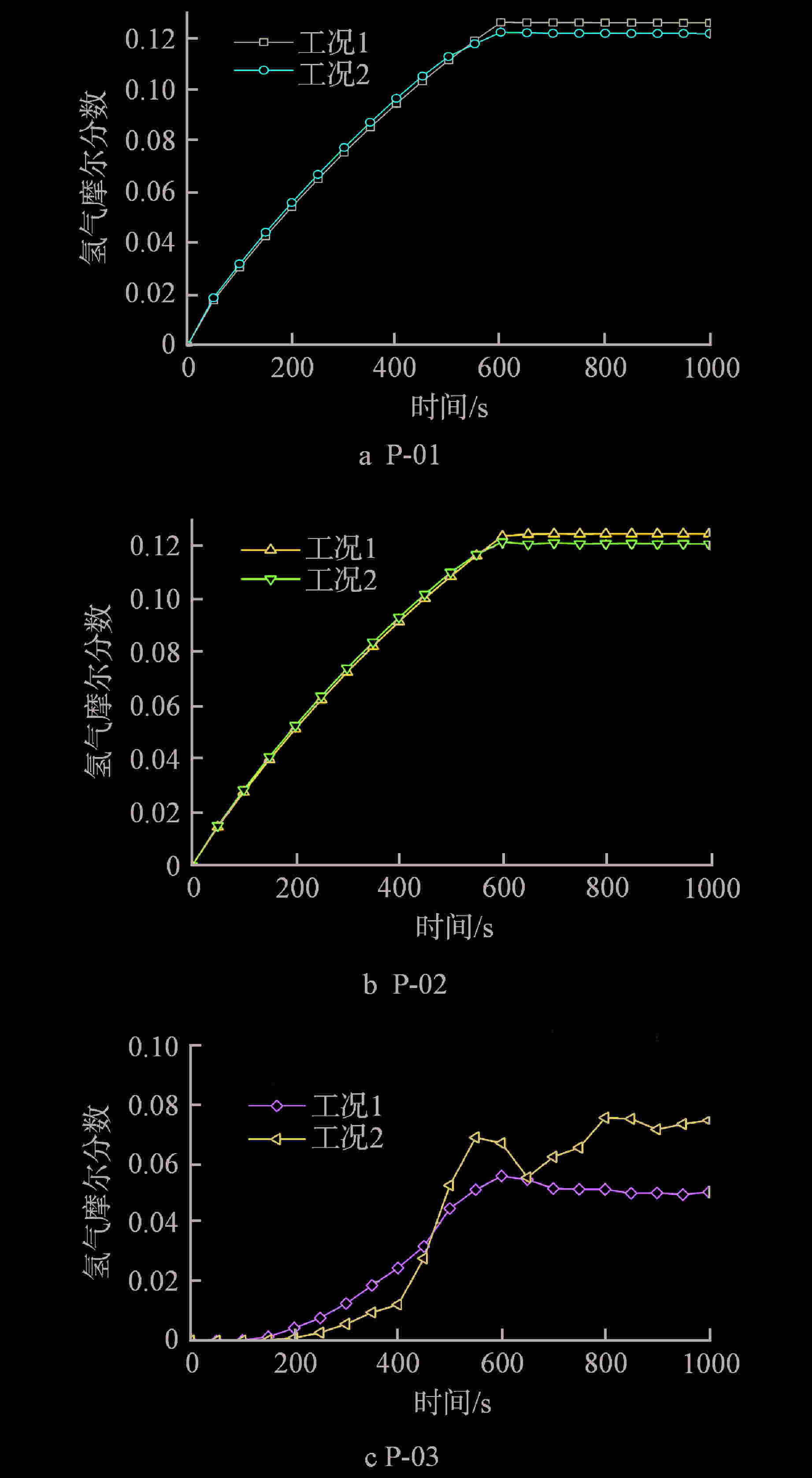

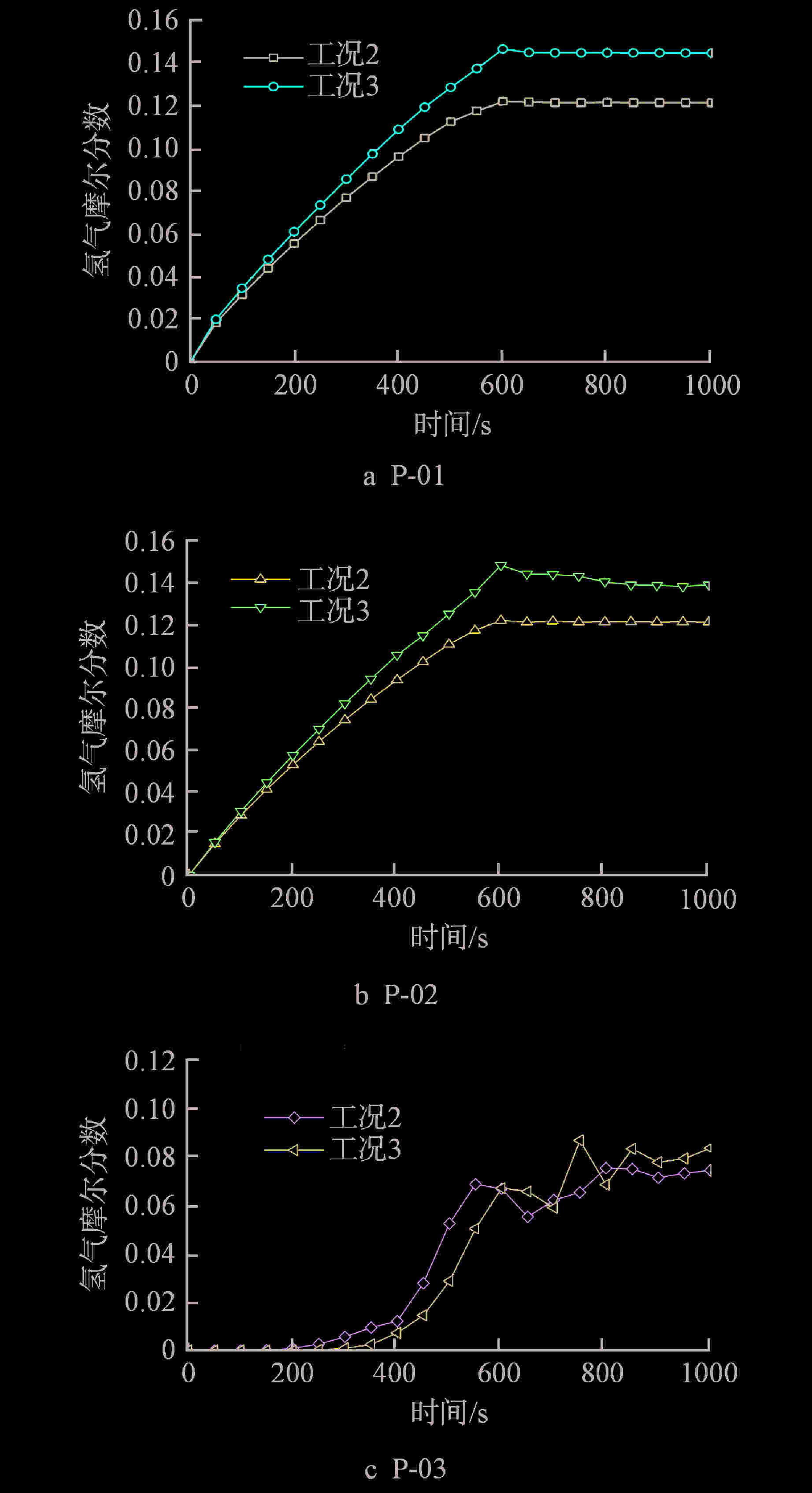

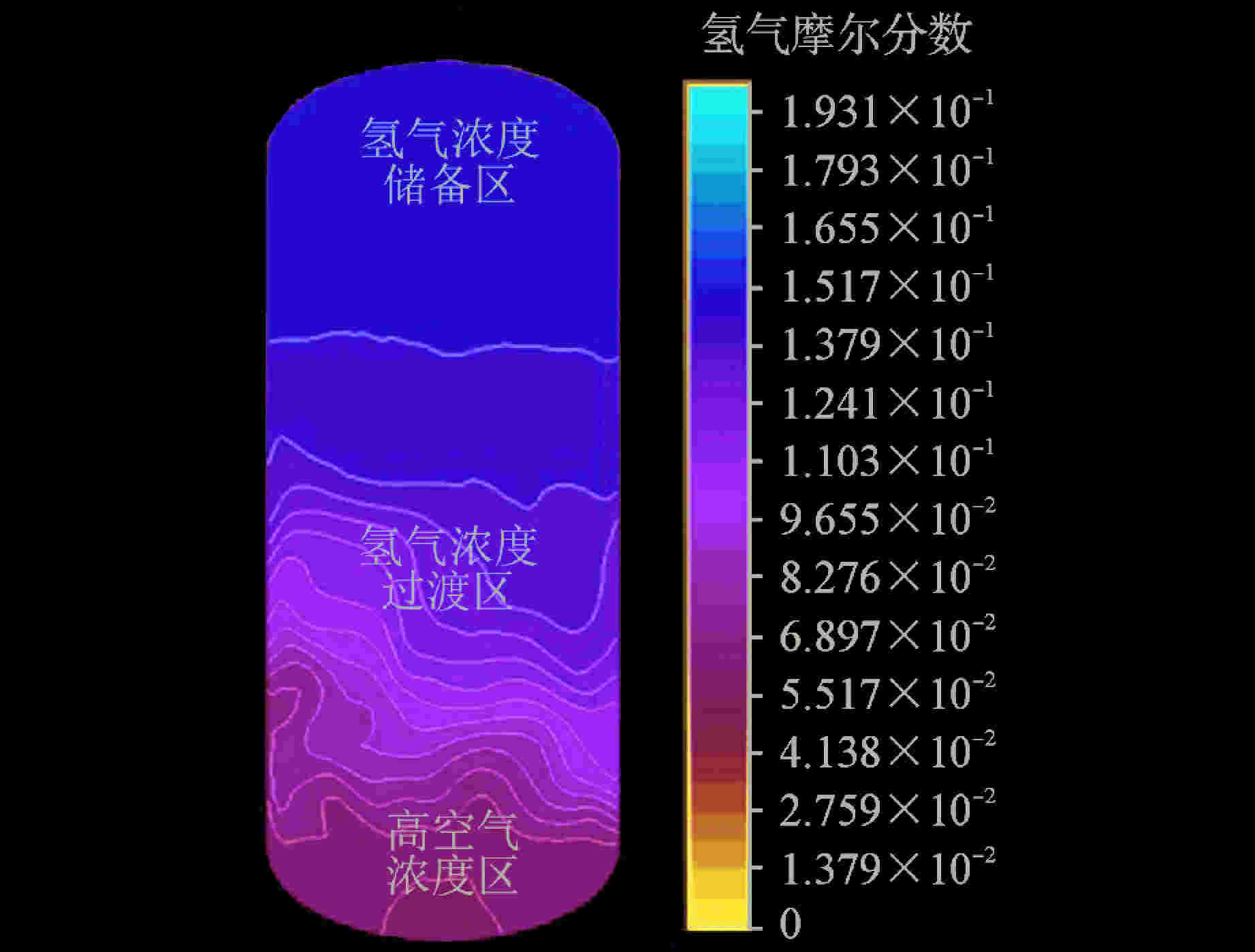

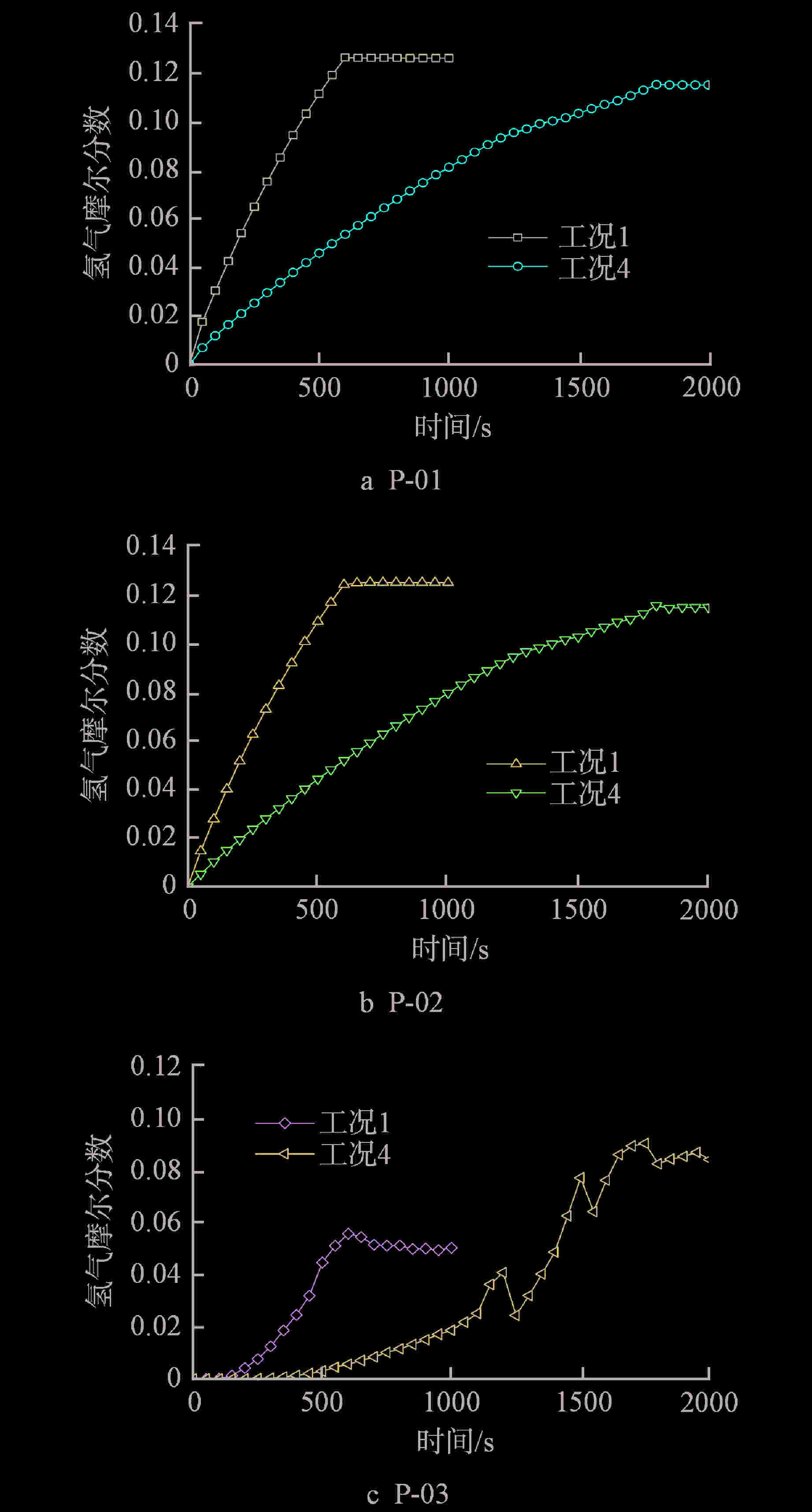

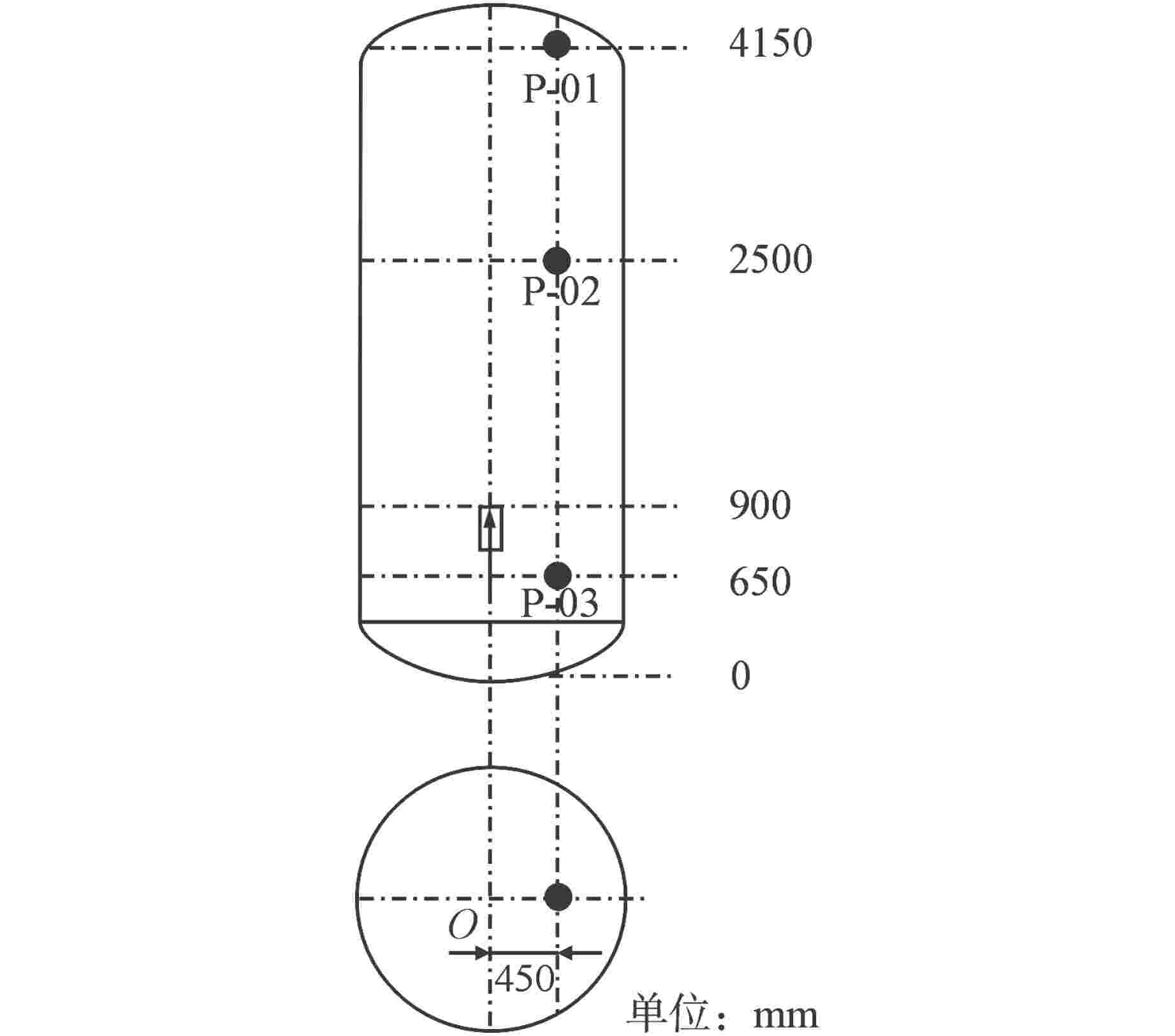

摘要: 与核电厂安全壳大空间不同,安全壳隔间以及先进小型堆等小尺度空间中,氢气与水蒸气的混合气体流动受到壁面的限制,气流不能充分发展,可能导致氢气在某些位置积聚引发氢气风险。本文采用数值模拟与理论分析相结合的方法对小尺度空间内氢气流动分布特性进行了研究。研究发现,典型工况下小尺度空间上部形成了氢气浓度分布比较均匀的氢气浓度储备区,在中部和下部区域分别为氢气浓度过渡区和高空气浓度区;随着源项气体动量的增大,源项气体进入上部空间的能力增大,导致空间上部区域氢气浓度增大。本研究可为后续先进小型堆的氢气风险研究分析提供支持。Abstract: Different from the large space of nuclear power plant containment, in small-scale space such as containment compartment and advanced small reactor, the flow of mixed gas of hydrogen and steam is limited by the wall, and the gas flow cannot fully develop, which may lead to the accumulation of hydrogen in some locations and lead to hydrogen risk. In this paper, the distribution characteristics of hydrogen flow in small-scale space are studied by means of numerical simulation and theoretical analysis. It is found that under typical working conditions, a hydrogen concentration reserve area with relatively uniform hydrogen concentration distribution is formed in the upper part of the small-scale space, and the hydrogen concentration transition zone and high air concentration zone are formed in the middle and lower areas, respectively. With the increase of the momentum of the source term gas, the ability of the source term gas to enter the upper space increases, resulting in the increase of hydrogen concentration in the upper area of the space. This study can provide support for the follow-up hydrogen risk research and analysis of advanced small reactors.

-

Key words:

- Hydrogen distribution /

- Advanced small reactor /

- Small-scale space /

- Numerical study

-

表 1 数值模拟参数表

Table 1. Parameters for Numerical Simulation

名称 工况1 工况2 工况3 工况4 氢气质量流量/(g·s−1) 0.3 0.3 0.3 0.1 水蒸气质量流量/(g·s−1) 3.0 3.0 1.0 1.0 入口直径/mm 30 50 50 30 源项气体入射温度/℃ 151 151 151 151 容器内初始气体温度/℃ 145 145 145 145 容器内初始气体 空气 空气 空气 空气 容器内初始压力/atm① 1 1 1 1 注射时间/s 600 600 600 1800 入口速度/(m·s−1) 11.83 4.26 2.3 3.94 初始Fr 422.2 32.8 19.2 92.8 注:①1 atm=101325 Pa -

[1] TONG L L, ZOU J, CAO X W. Analysis on hydrogen risk mitigation in severe accidents for Pressurized Heavy Water Reactor[J]. Progress in Nuclear Energy, 2015, 80: 128-135. doi: 10.1016/j.pnucene.2014.12.011 [2] 许幼幼,彭欢欢,张明,等. 严重事故下小型安全壳内氢气风险分析[J]. 核动力工程,2020, 41(S2): 64-68. [3] 彭程,邓坚. 安全壳大空间内氢气分层行为的模型研究[J]. 核动力工程,2021, 42(3): 155-159. [4] 肖建军,周志伟,经荥清. 湍流模型对安全壳内氢气浓度场模拟的影响[J]. 原子能科学技术,2006, 40(6): 693-697. doi: 10.3969/j.issn.1000-6931.2006.06.012 [5] 王迪,曹学武. 不同湍流模型对氢气分布影响的数值研究[J]. 原子能科学技术,2016, 50(9): 1622-1628. doi: 10.7538/yzk.2016.50.09.1622 [6] 侯丽强,佟立丽,曹学武,等. 实验装置氢气混合的数值研究[J]. 核动力工程,2015, 36(S2): 146-150. [7] PENG C, TONG L L, CAO X W. Numerical analysis on hydrogen stratification and post-inerting of hydrogen risk[J]. Annals of Nuclear Energy, 2016, 94: 451-460. doi: 10.1016/j.anucene.2016.04.029 [8] WILCOX D C. Turbulence modeling for CFD[M]. 2nd ed. La Caflada, CA: DCW Industry Incorporation, 1998: 87-89. [9] SONNENKALB M, POSS G. The international test programme in the THAI facility and its use for code validation[C]//EUROSAFE Forum. Brussels, Belgium, 2009. [10] EL-AMIN M F, KANAYAMA H. Similarity consideration of the buoyant jet resulting from hydrogen leakage[J]. International Journal of Hydrogen Energy, 2009, 34(14): 5803-5809. doi: 10.1016/j.ijhydene.2009.05.059 [11] EL-AMIN M F. Non-Boussinesq turbulent buoyant jet resulting from hydrogen leakage in air[J]. International Journal of Hydrogen Energy, 2009, 34(18): 7873-7882. doi: 10.1016/j.ijhydene.2009.07.061 -

下载:

下载: