Fatigue Reliability Test and Evaluation of Main Pump Spindle of Nuclear Power Plant Reactor

-

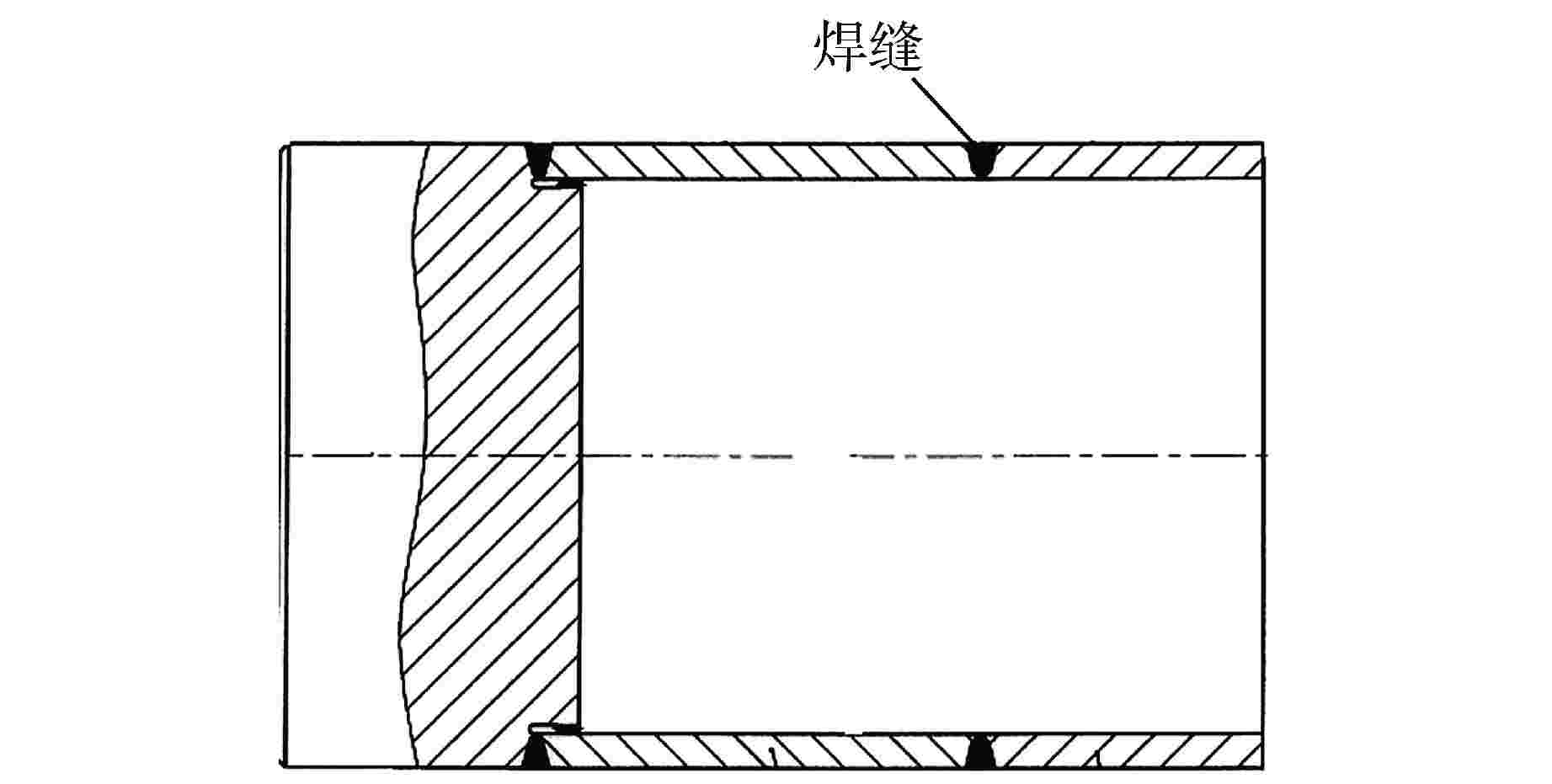

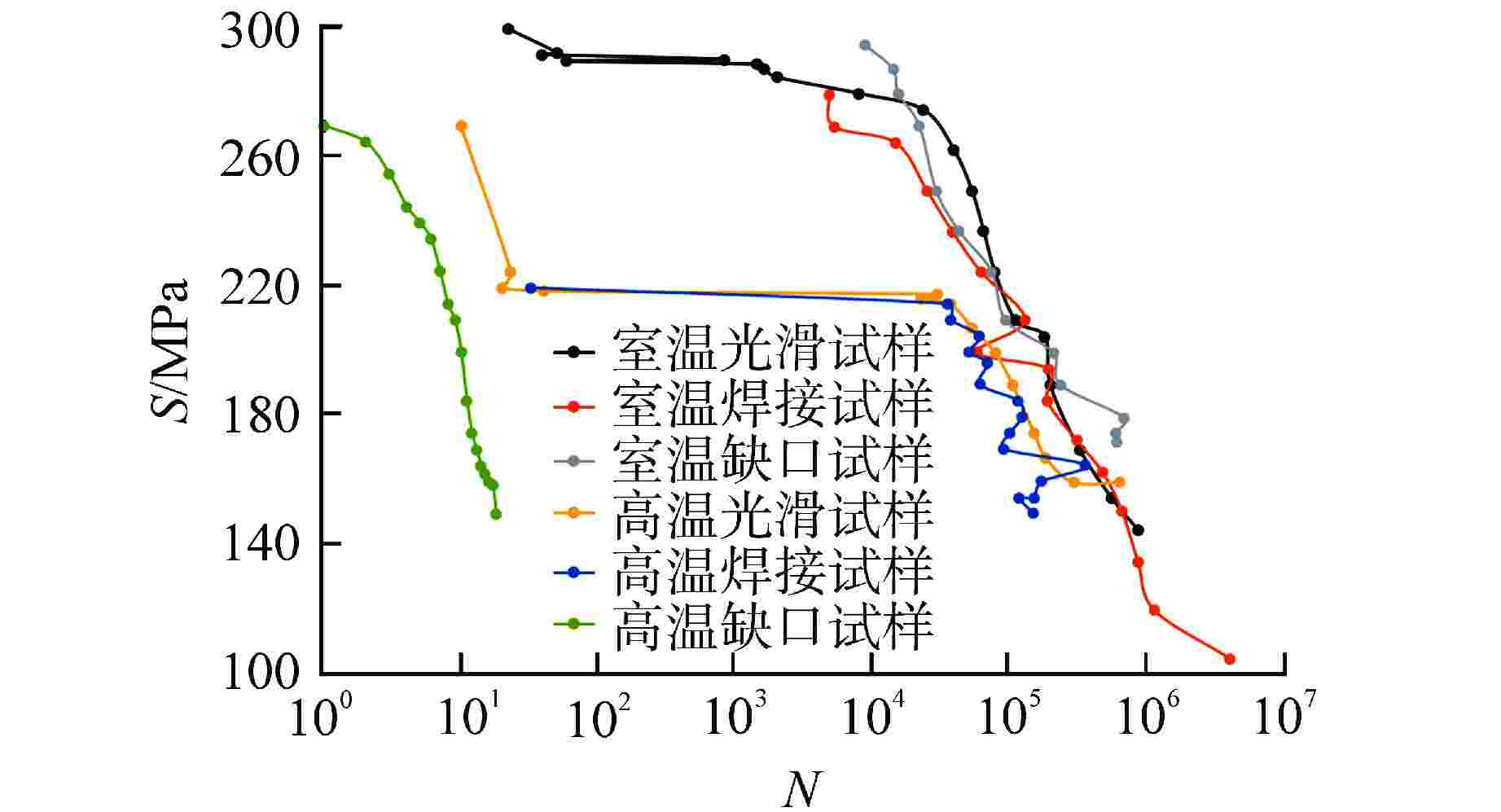

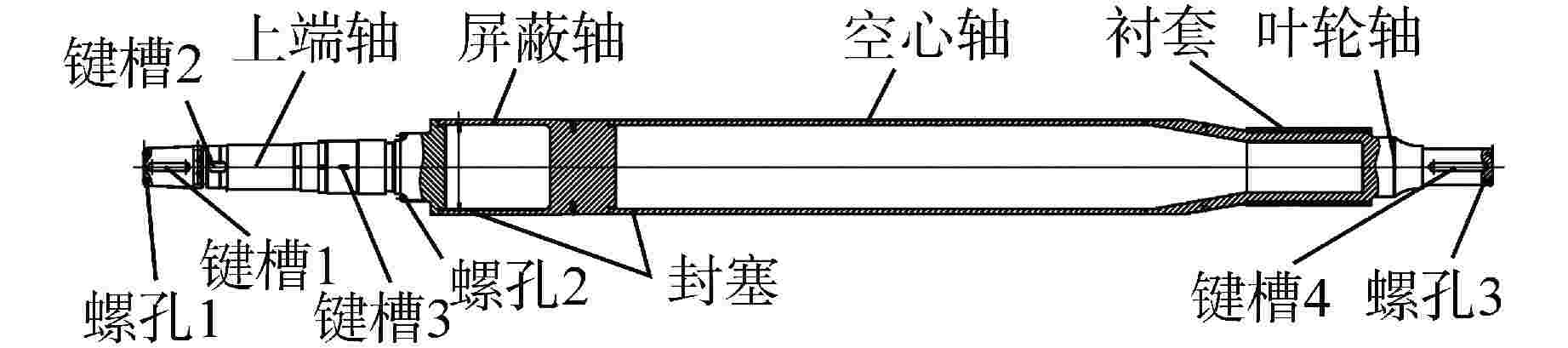

摘要: 为了获得给定置信度、不同可靠度下的核电厂反应堆主泵主轴材料疲劳可靠性数据,制造了一段内外径尺寸、加工工艺与产品主轴完全相同的模拟轴用于取样,测试了常温光滑、常温焊接、常温缺口、高温光滑、高温焊接、高温缺口6种试样的疲劳寿命;应用可靠性统计方法分别确定了置信度为0.9、0.95时,在不同可靠度下6种试样的疲劳可靠性寿命置信下限方程以及6种试样的可靠性疲劳极限;分析了试样与主轴疲劳寿命的区别与修正方法,利用修正后的试样数据对主轴疲劳失效的薄弱环节进行可靠性评估。结果表明,置信度为0.9、0.95时,主轴在寿期内不发生疲劳失效的可靠度超过0.9999。本研究实现了反应堆主泵主轴疲劳失效更为准确的可靠性评估。Abstract: In order to obtain the fatigue reliability data of the main spindle material of the nuclear power plant reactor under a given confidence level and different reliability levels, a simulation spindle with the same inner and outer diameter dimensions and processing technology as the product spindle was manufactured for sampling. The fatigue lives of six kinds of specimens including room temperature smooth, room temperature weld, room temperature notch, high temperature smooth, high temperature weld and high temperature notch were tested. The lower confidence limit equation of the fatigue reliability life with different reliability levels and the reliability fatigue limit of the six kinds of specimens were determined by reliability statistical methods when the confidence level was 0.9 or 0.95. The differences and revised methods between the fatigue life of the specimens and the spindle were analyzed. Using the revised specimen data, the reliability assessment of the spindle fatigue failure weak links were carried out. The results show that the reliability of the spindle without fatigue failure during the lifetime exceeds 0.9999 when the confidence level is 0.9 or 0.95. In this paper, a more accurate reliability assessment of spindle fatigue failure of reactor main pump is achieved.

-

Key words:

- Nuclear power plant /

- Main pump /

- Spindle /

- Fatigue /

- Reliability

-

表 1 316LN的化学成分(质量分数) %

Table 1. Chemical Composition of 316LN (Mass Fraction)

元素 C Mn Ni S P Cu 质量分数 0.03 1.50~2.00 11.0~12.5 0.006 0.03 0.100 元素 Mo Cr N Si Co B 质量分数 2.50~3.00 16.0~18.0 0.05~0.08 0.50 0.10 0.001 表 2 样本均值与方差

Table 2. Mean And Variance of Samples

试样类型 寿命均值 寿命标准差 强度均值 强度标准差 常温光滑 4.9118 0.1285 2.3352 0.0207 常温焊接 4.8938 0.1155 2.3222 0.0200 常温缺口 4.7738 0.1115 2.3552 0.0176 高温光滑 4.9216 0.1579 2.2767 0.0210 高温焊接 4.8180 0.1499 2.2751 0.0233 高温缺口 4.4824 0.0879 2.3001 0.0133 表 3 w计算结果(置信度为0.9)

Table 3. w Calculation Result (Confidence Level of 0.9)

试样类型 可靠度 0.5 0.7 0.9 0.95 0.99 0.999 0.9999 常温光滑试样 0.042 0.117 0.234 0.292 0.403 0.529 0.634 常温

焊接试样0.037 0.105 0.210 0.262 0.362 0.476 0.570 常温

缺口试样0.036 0.101 0.203 0.253 0.350 0.459 0.550 高温

光滑试样0.051 0.144 0.287 0.359 0.495 0.650 0.779 高温

焊接试样0.049 0.136 0.273 0.341 0.470 0.618 0.739 高温

缺口试样0.029 0.080 0.160 0.200 0.276 0.362 0.434 表 4 w计算结果(置信度0.95)

Table 4. w Calculation Result (Confidence Level 0.95)

试样类型 可靠度 0.5 0.7 0.9 0.95 0.99 0.999 0.9999 常温

光滑试样0.054 0.133 0.257 0.320 0.439 0.575 0.687 常温

焊接试样0.049 0.120 0.231 0.287 0.394 0.516 0.618 常温

缺口试样0.047 0.115 0.223 0.277 0.381 0.499 0.596 高温

光滑试样0.067 0.164 0.316 0.393 0.539 0.706 0.844 高温

焊接试样0.063 0.155 0.300 0.373 0.512 0.670 0.802 高温

缺口试样0.037 0.091 0.176 0.219 0.300 0.393 0.470 表 5 置信度0.9疲劳极限(应力幅值) MPa

Table 5. Fatigue Limit with Confidence Level of 0.9 (Stress Amplitude)

试样类型 可靠度 0.5 0.7 0.9 0.95 0.99 0.999 0.9999 常温光滑试样 97.5 93.6 87.5 84.4 78.5 71.7 65.9 常温焊接试样 88.8 85.2 79.6 76.8 71.3 65.0 59.7 常温缺口试样 98.7 94.6 88.0 84.6 78.0 70.2 63.5 高温光滑试样 97.3 91.9 82.9 78.0 67.9 55.0 43.0 高温焊接试样 82.6 75.6 63.5 56.8 42.6 24.9 10.5 高温缺口试样 81.7 78.9 74.3 72.0 67.5 62.2 57.6 表 6 置信度0.95疲劳极限(应力幅值) MPa

Table 6. Fatigue Limit with Confidence Level of 0.95 (Stress Amplitude)

试样类型 可靠度 0.5 0.7 0.9 0.95 0.99 0.999 0.9999 常温光滑试样 96.8 92.7 86.3 83.0 76.6 69.2 63.0 常温焊接试样 88.2 84.4 78.4 75.4 69.5 62.7 57.0 常温缺口试样 98.0 93.7 86.6 83.0 75.9 67.3 59.9 高温光滑试样 96.4 90.7 80.9 75.6 64.4 49.9 36.4 高温焊接试样 81.5 74.1 60.8 53.4 37.8 18.4 4.7 高温缺口试样 81.2 78.2 73.4 70.9 66.0 60.2 55.3 表 7 累积损伤系数(可靠度0.9999)

Table 7. Cumulative Damage Coefficient (Reliability of 0.9999)

位置 置信度0.9 置信度0.95 上部轴承上方卡槽处 7.88×10−6 1.05×10−5 上空腔焊接处 5.10×10−8 7.42×10−8 上空腔底部倒圆处 0.0195 0.0246 下空腔上部焊接处 0.0011 0.0027 下空腔轴身焊接处 0.0013 0.0032 下空腔底部倒圆处 2.60×10−7 9.18×10−7 叶轮连接几何过渡处 2.46×10−6 3.51×10−6 -

[1] 陈侃,刘伟,郭逸,等. 1080MW核电厂主泵轴封浮动O圈失效试验研究及优化[J]. 核动力工程,2021, 42(1): 148-153. [2] 李振,袁少波. 核电厂主泵轴振异常分析[J]. 核动力工程,2019, 40(1): 167-171. [3] 初永越,黄志超,依岩,等. 核电厂PSA数据库平台的创建与应用[J]. 核安全,2016, 15(3): 21-26. [4] 罗娅彬,祁军,刘志军,等. 核电厂PSA可靠性数据采集问题分析[J]. 机电产品开发与创新,2013, 26(5): 49-51. doi: 10.3969/j.issn.1002-6673.2013.05.019 [5] 李松梅,吴凌飞,刘建华,等. 应力比和腐蚀环境对超高强度钢AerMet100疲劳裂纹扩展的影响[J]. 航空材料学报,2014, 34(3): 74-80. doi: 10.11868/j.issn.1005-5053.2014.3.012 [6] 王春生,王雨竹,崔冰,等. 应力比对钢桥腹板间隙面外变形疲劳性能的影响试验[J]. 中国公路学报,2017, 30(3): 72-81. doi: 10.3969/j.issn.1001-7372.2017.03.008 [7] 谢里阳. 疲劳强度可靠性设计[M]. 第二版. 北京: 化学工业出版社, 2020: 22-26. [8] 叶南海, 戴宏亮. 机械可靠性设计与MATLAB算法[M]. 北京: 机械工业出版社, 2018: 127-129. [9] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属材料 疲劳试验 数据统计方案与分析方法: GB/T 24176—2009[S]. 北京: 中国标准出版社, 2010: 8-10. [10] KEISLER J M, CHOPRA O K, SHACK W J. Statistical models for estimating fatigue strain-life behavior of pressure boundary materials in light water reactor environments[J]. Nuclear Engineering and Design, 1996, 167(2): 129-154. doi: 10.1016/S0029-5493(96)01293-9 [11] TODINOV M T. Probability distribution of fatigue life controlled by defects[J]. Computers & Structures, 2001, 79(3): 313-318. [12] 程祥军,黄国龙,魏涛,等. 缸盖材料P-S-N曲线测试及疲劳模型选用方法[J]. 车用发动机,2019(6): 33-37. [13] 谢金标,姚卫星. 建立P-S-N曲线的双加权最小二乘法[J]. 实验力学,2010, 25(5): 611-616. [14] 谭秀峰,谢里阳,马洪义,等. 基于对数正态分布的多部位疲劳结构的疲劳寿命预测方法[J]. 航空学报,2017, 38(2): 220376. [15] 许巍,陈新,李旭东,等. 发动机材料高周疲劳P-S-N曲线优化处理方法[J]. 航空材料学报,2020, 40(5): 96-103. [16] 嵇应凤,姚卫星,夏天翔. 线性疲劳累积损伤准则适用性评估[J]. 力学与实践,2015, 37(6): 674-682. doi: 10.6052/1000-0879-14-331 [17] 翁海平,陈棋. 兆瓦级风机主轴疲劳分析方法研究[J]. 太阳能学报,2013, 34(10): 1714-1719. doi: 10.3969/j.issn.0254-0096.2013.10.008 [18] 许卫宝, 钟涛. 机械产品可靠性设计与试验[M]. 北京: 国防工业出版社, 2015: 93-94. -

下载:

下载: