Numerical Simulation Research on Reforming Fluidization of Radioactive Waste in Nuclear Power Plant

-

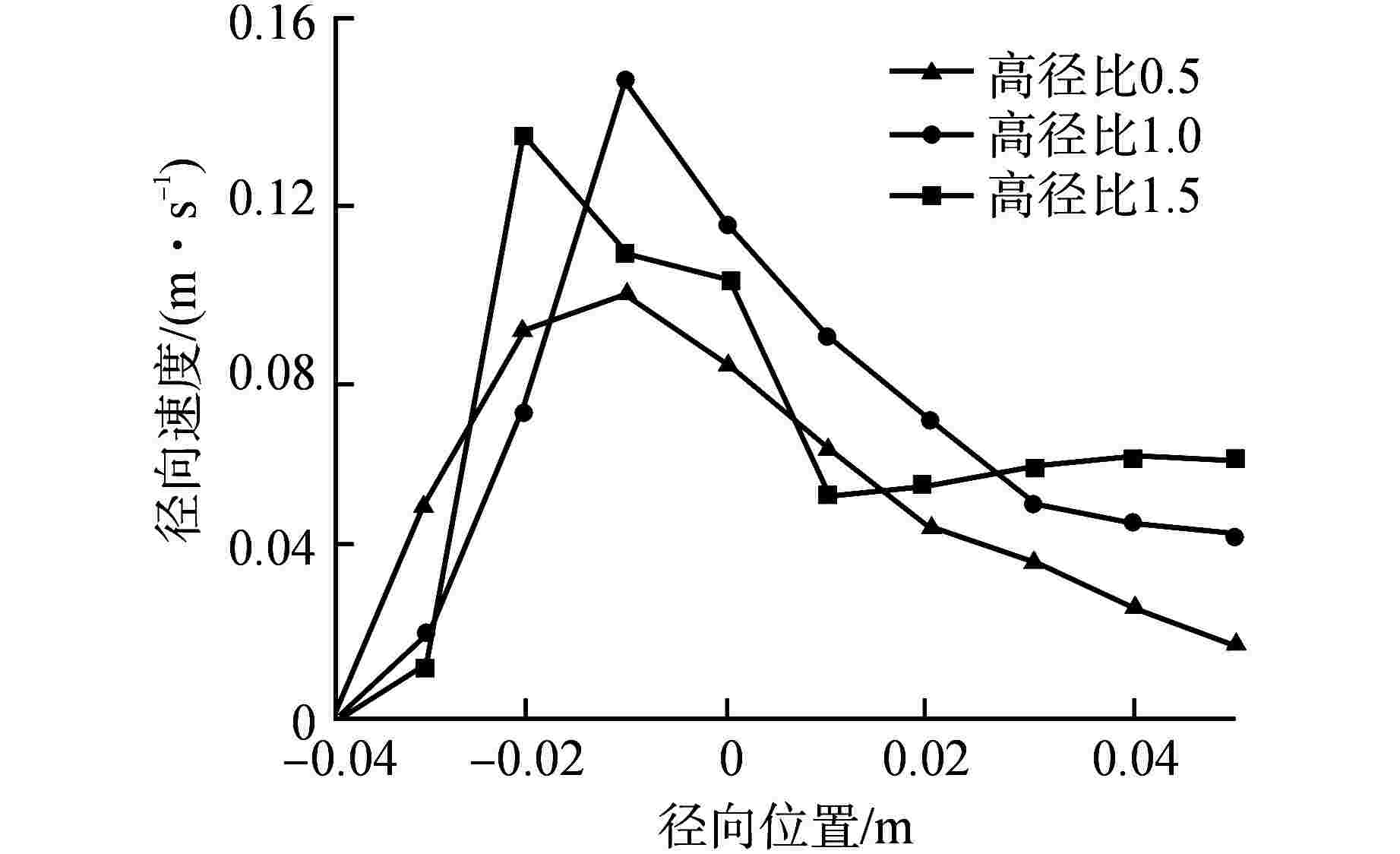

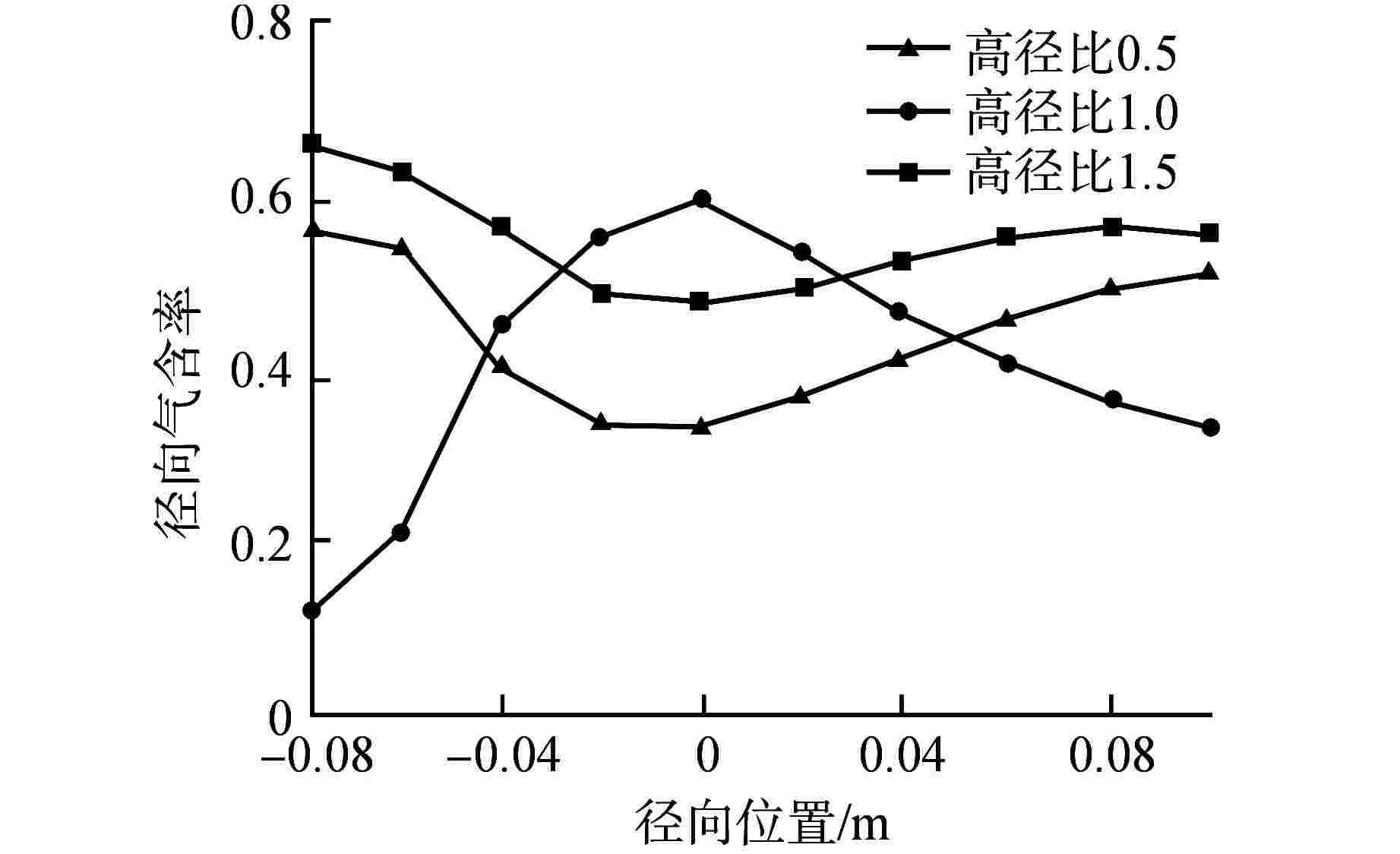

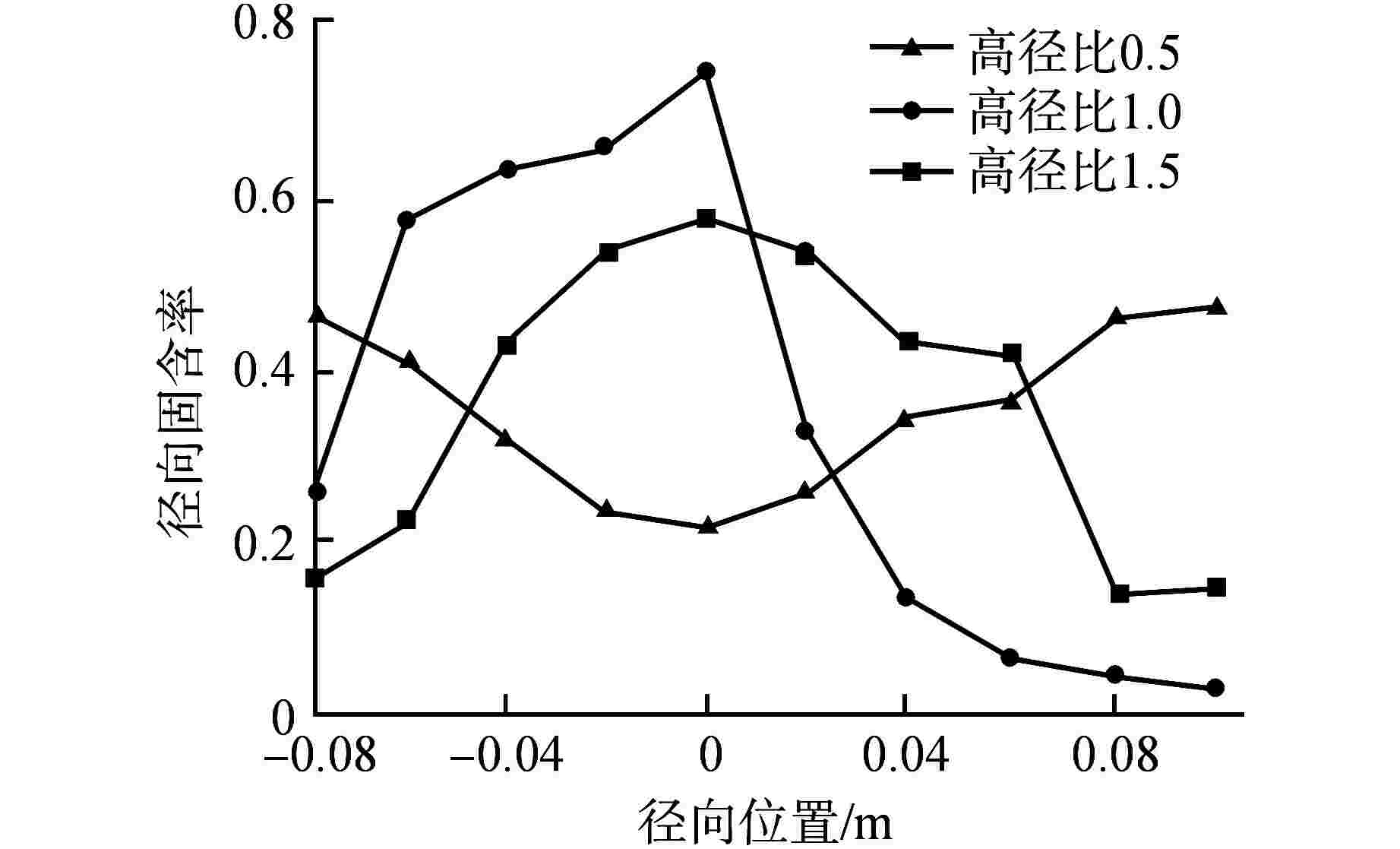

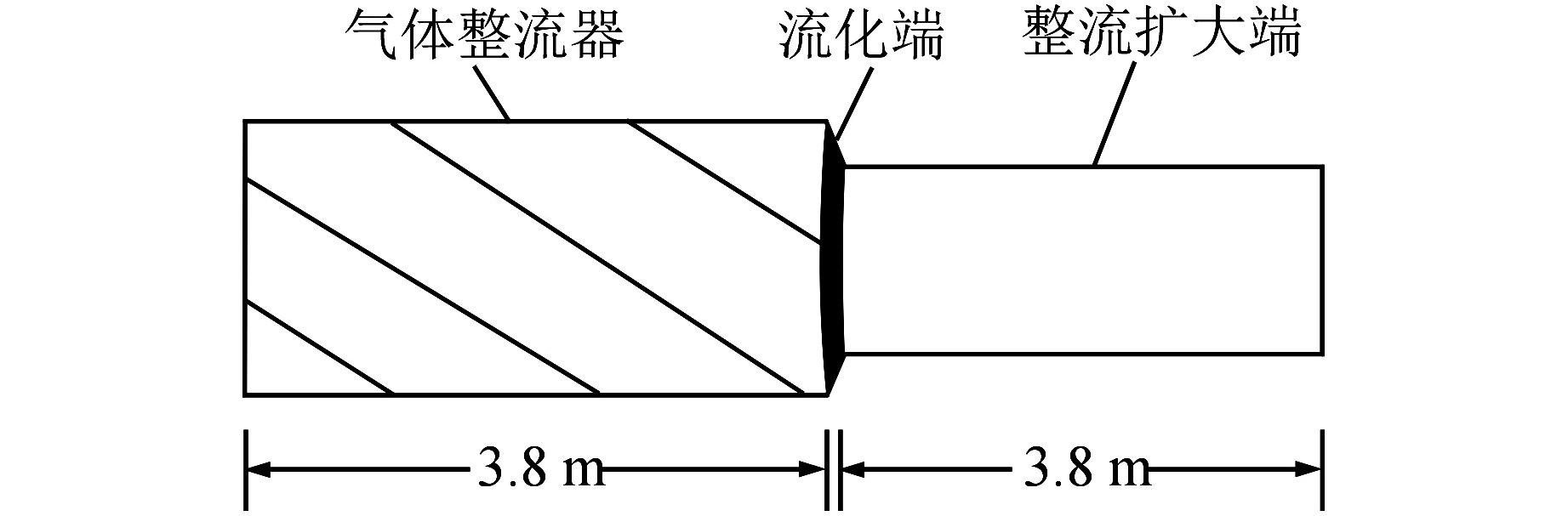

摘要: 核电厂排放的放射性废物高温重整过程中会以流化态的形式存在,为获取这个过程中的详细参数,设计出更优秀的运行条件,提出了一种新的核电厂放射性废物重整流态化数值模拟方法。该设计数值计算模型建立了气-固流体力学控制方程以及湍流模型;建立了核电厂放射性有机化学废物几何模型、对象几何模型,并划分网格结构,设置边界初始条件。通过数值计算研究不同高径比对颗粒的径向速度、径向固含率、径向气含率的影响。计算结果表明,高径比为1.0时,流化床中气-固颗粒的流化效果最好。Abstract: During the high-temperature reforming process, the radioactive organic nuclear waste discharged from the nuclear power plant will exist in a fluidized state. In order to obtain the detailed parameters of this process and design better operating conditions, a new numerical simulation method for reforming fluidization of radioactive waste in nuclear power plant is proposed. The numerical calculation model is designed, the governing equations of gas-solid hydrodynamics are established, and the turbulence model is established; The geometric model of radioactive organic chemical waste in nuclear power plant is established, the object geometric model is established, the grid structure is divided, and the initial boundary conditions are set. The effects of different height-diameter ratios on the radial velocity, radial solid holdup and radial gas holdup of particles are studied by numerical calculation. The calculation results show that when the height-diameter ratio is 1.0, the fluidization effect of gas-solid particles in the fluidized bed is the best.

-

Key words:

- Nuclear power plant /

- Radioactive waste /

- Catalytic reforming /

- Fluidization /

- Numerical simulation /

- Nuclear waste

-

[1] 王庆武,李聪. 二甲醚水蒸气重整制氢的模型和数值模拟[J]. 内燃机工程,2021, 42(3): 41-46. doi: 10.13949/j.cnki.nrjgc.2021.03.006 [2] 张晓光. 生物甘油化学链吸附强化重整的数值模拟[J]. 能源化工,2021, 42(2): 23-27. doi: 10.3969/j.issn.1006-7906.2021.02.006 [3] 钟旺燊,陈野力,钱沐杨,等. 大气压非平衡等离子体甲烷干法重整零维数值模拟[J]. 物理学报,2021, 70(7): 075206. [4] 刘娇阳,张庆,晁龙,等. 单相多流态下缠绕管流动换热数值模拟模型研究[J]. 广东化工,2020, 47(21): 53-55. doi: 10.3969/j.issn.1007-1865.2020.21.023 [5] 林力,章航洲,李文钰,等. 基于流体体积模型的放射性废树脂蒸汽重整流态化数值模拟分析[J]. 科学技术与工程,2020, 20(30): 12657-12663. doi: 10.3969/j.issn.1671-1815.2020.30.058 [6] 张晓光. 流化床二氧化碳吸附强化甘油重整的数值模拟[J]. 工业催化,2020, 28(8): 73-77. doi: 10.3969/j.issn.1008-1143.2020.08.015 [7] 王晓静,臧明华,武宸宇,等. 异直式气体分布板气流分布数值模拟及分析[J]. 化工机械,2020, 47(4): 478-484,529. doi: 10.3969/j.issn.0254-6094.2020.04.012 [8] 张仪,李兵,白玉龙,等. 液固流态化动态过程中相间作用力的数值模拟及实验验证[J]. 化工学报,2020, 71(11): 5129-5139. [9] 郭昊乾,李雪飞,李小亮. 窄筛分颗粒气固流态化特性数值模拟研究[J]. 洁净煤技术,2020, 26(4): 84-89. doi: 10.13226/j.issn.1006-6772.19121001 [10] 王帅,王会宁,唐宇翔,等. 流化床膜反应器甘油强化重整的数值模拟[J]. 哈尔滨工业大学学报,2020, 52(7): 89-95. doi: 10.11918/201910087 [11] 周刚. 汽车空气动力学数值模拟中的湍流模型分析[J]. 汽车工程师,2020(3): 49-52. doi: 10.3969/j.issn.1674-6546.2020.03.012 [12] 胡小金,刘三举,刘俊,等. 生物质流化床流化特性试验研究与数值模拟[J]. 河南理工大学学报:自然科学版,2020, 39(3): 94-99. [13] 殷文佳,罗敏,冷德成,等. 制氢转化炉内甲烷蒸汽重整模拟及影响因素分析[J]. 化工机械,2019, 46(6): 651-656. doi: 10.3969/j.issn.0254-6094.2019.06.010 [14] 罗丹,李爱蓉,蒋乐乐,等. 天然气水合物颗粒-水流态化特性模拟研究[J]. 天然气化工,2019, 44(5): 50-56. [15] 马树辉,王若瑾,王德武,等. Geldart A类颗粒节涌床气固流动特性的实验及模拟[J]. 过程工程学报,2019, 19(5): 967-974. doi: 10.12034/j.issn.1009-606X.219123 -

下载:

下载: