Study on the Smoothness of the Flow Channel of Rapid Pressure Relief Pipeline in Severe Accident of HPR 1000

-

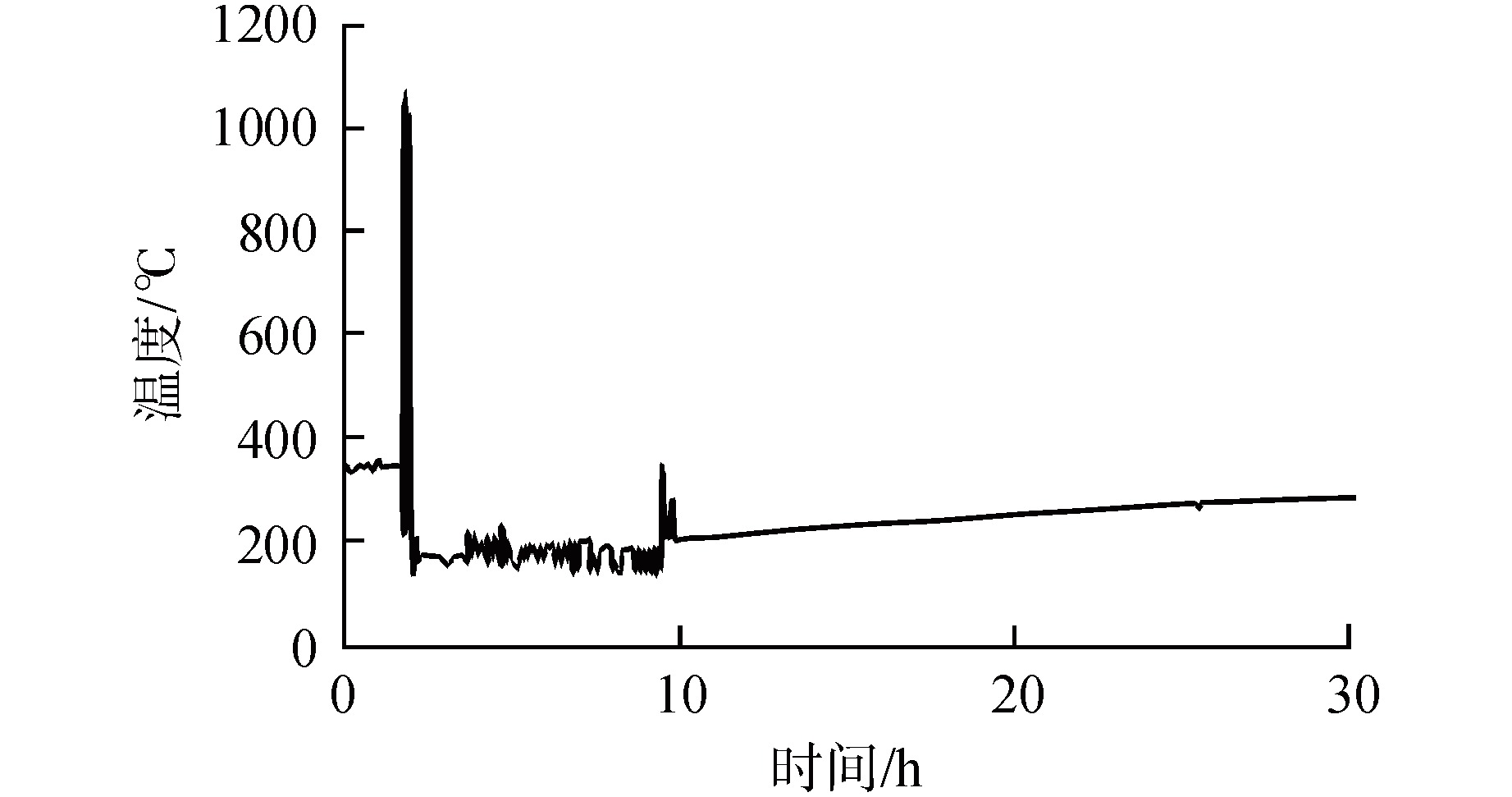

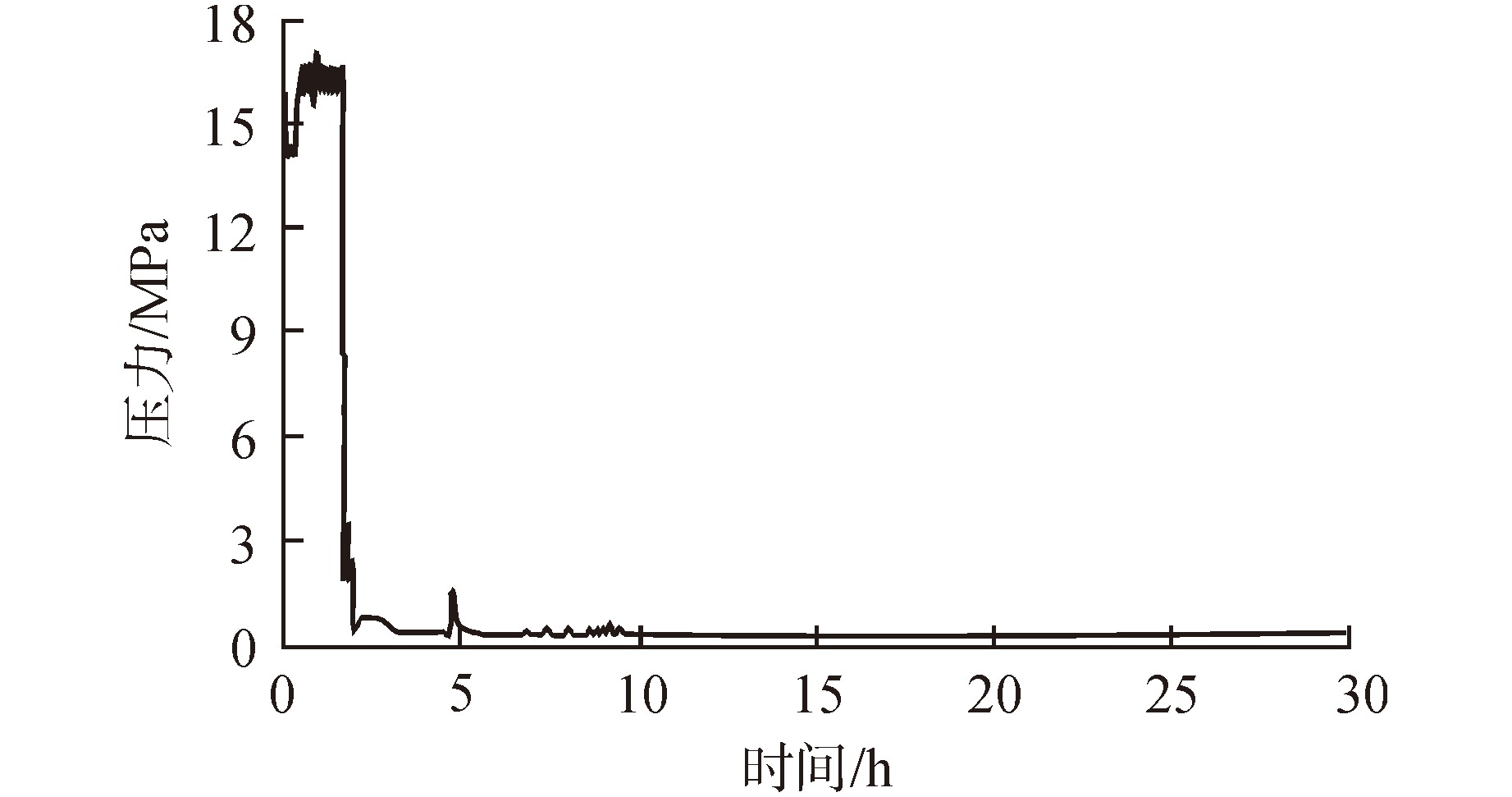

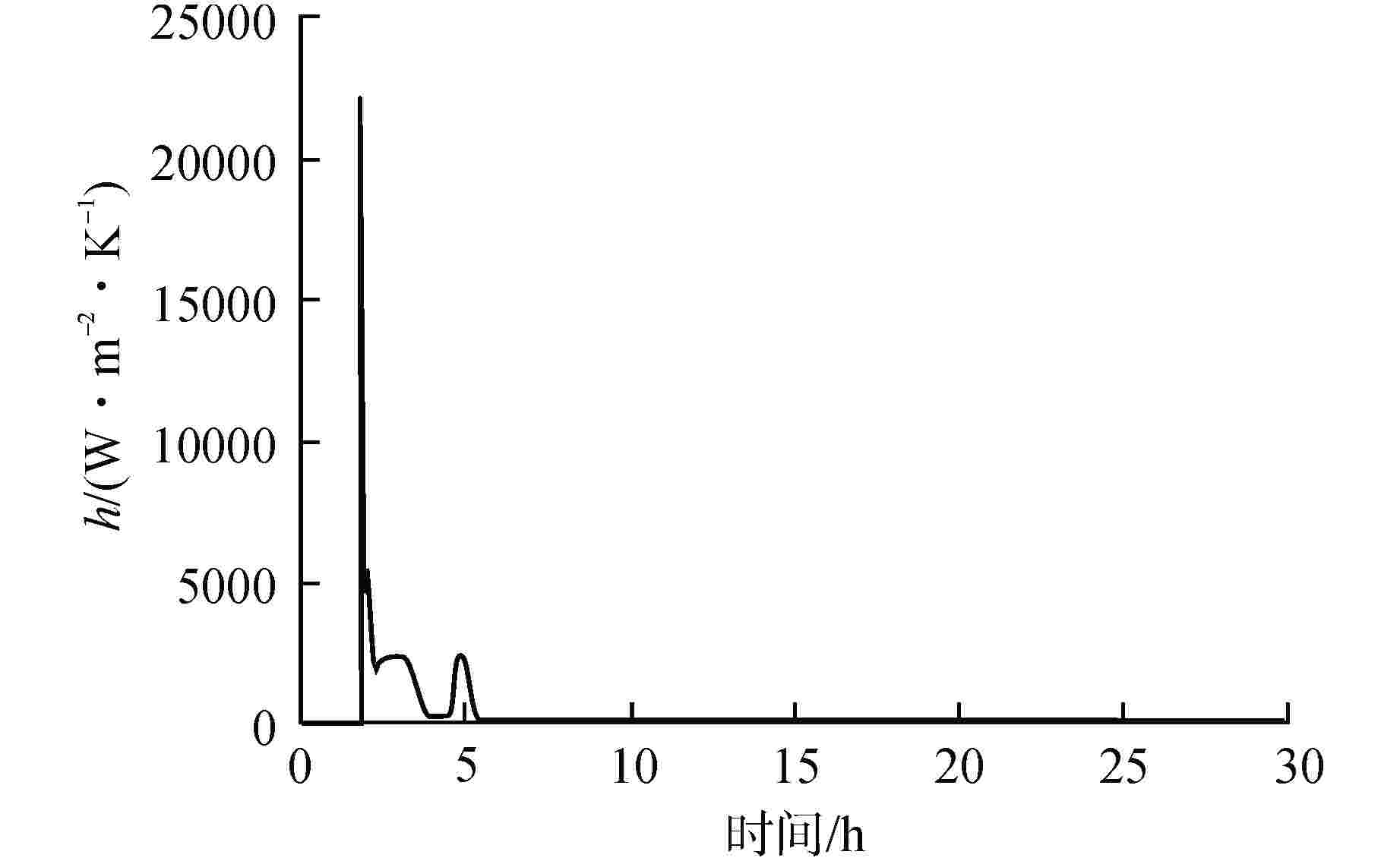

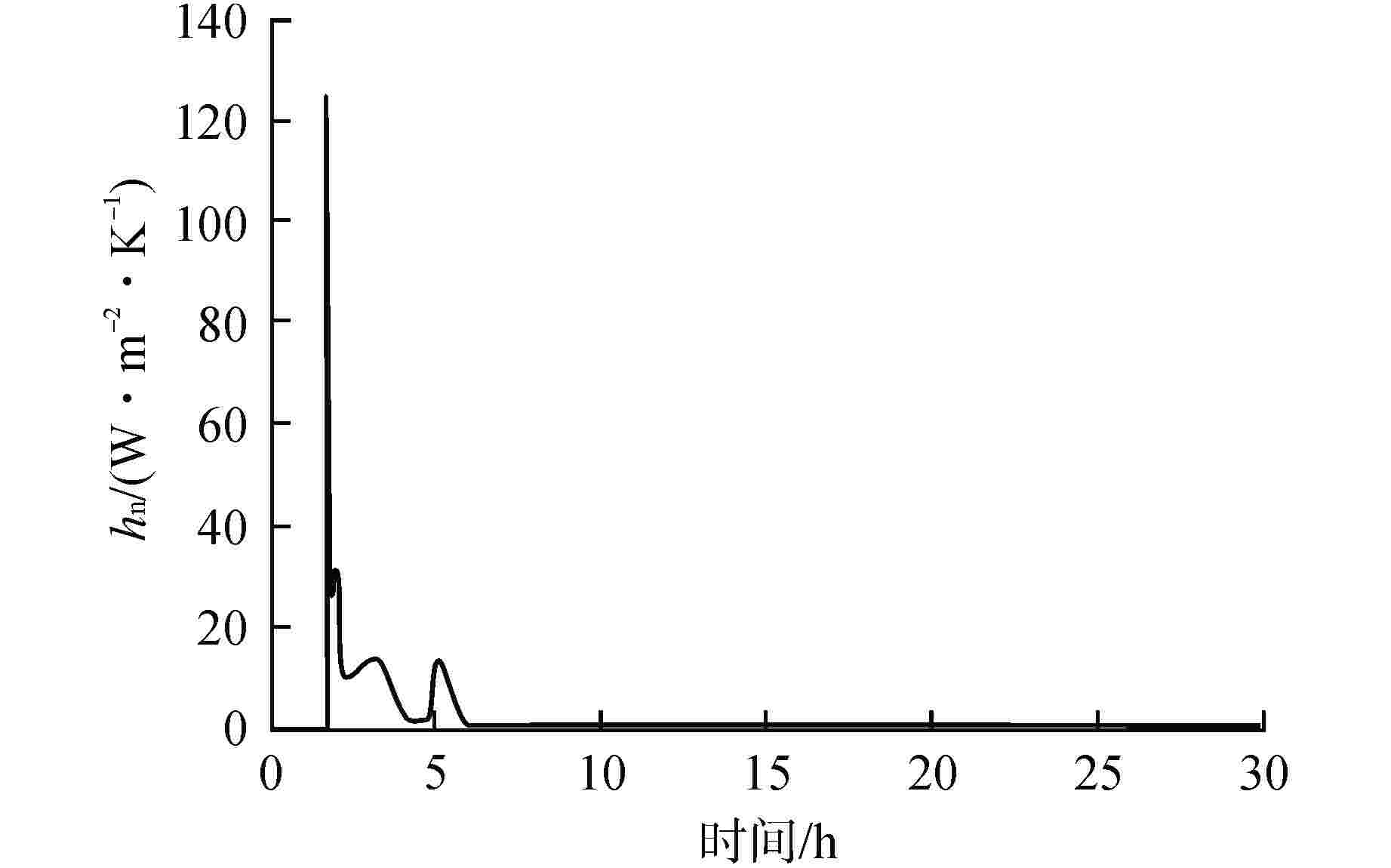

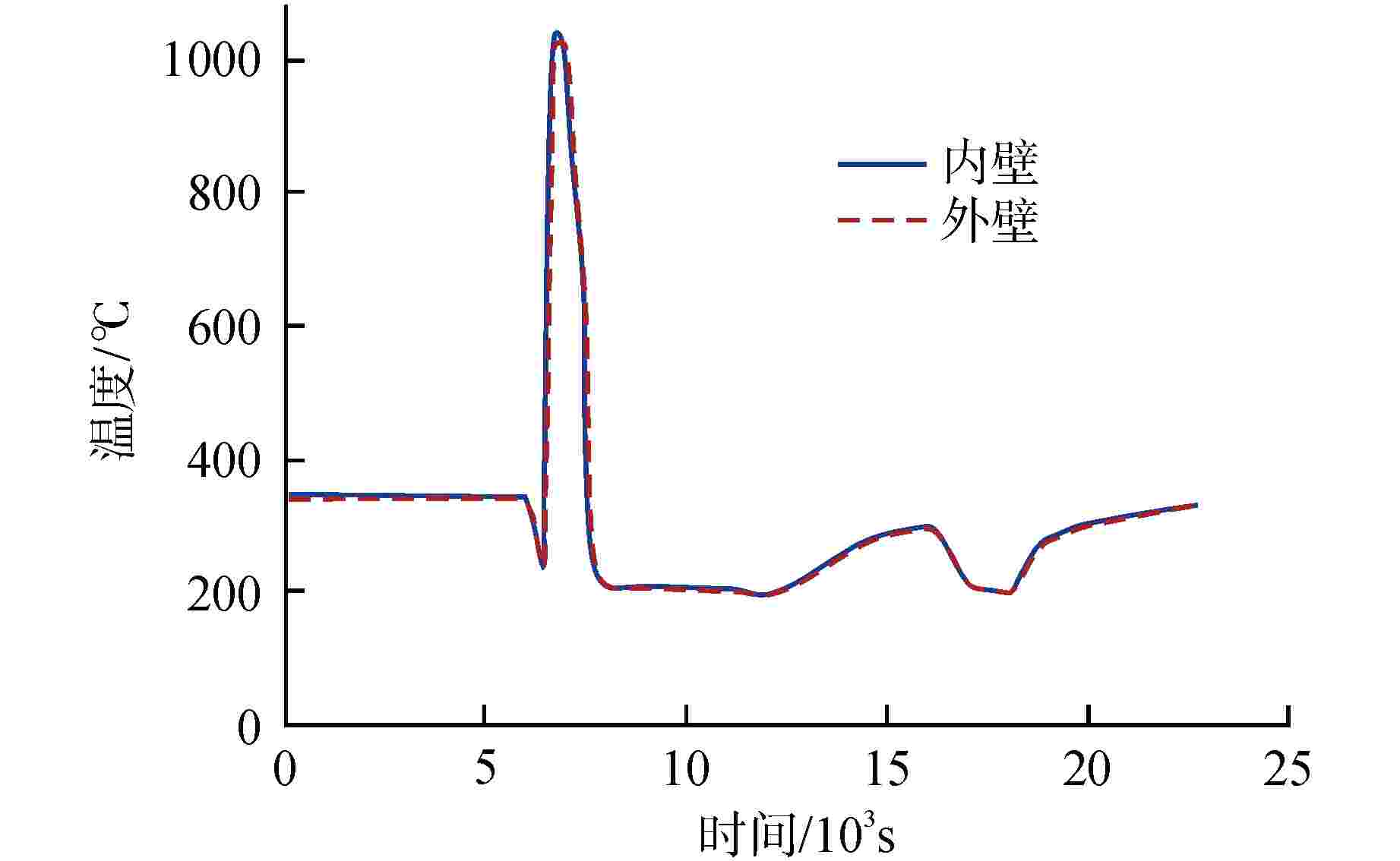

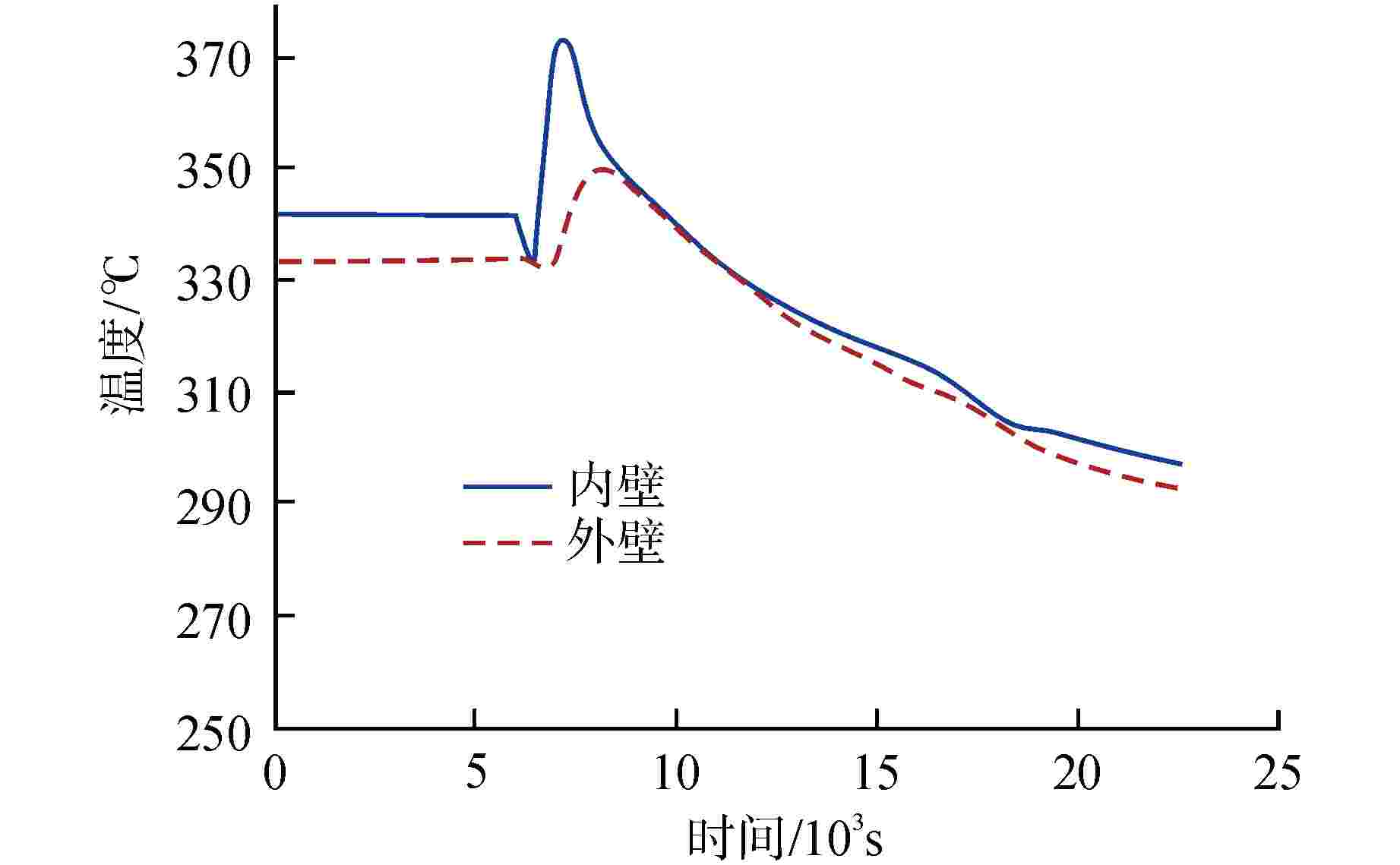

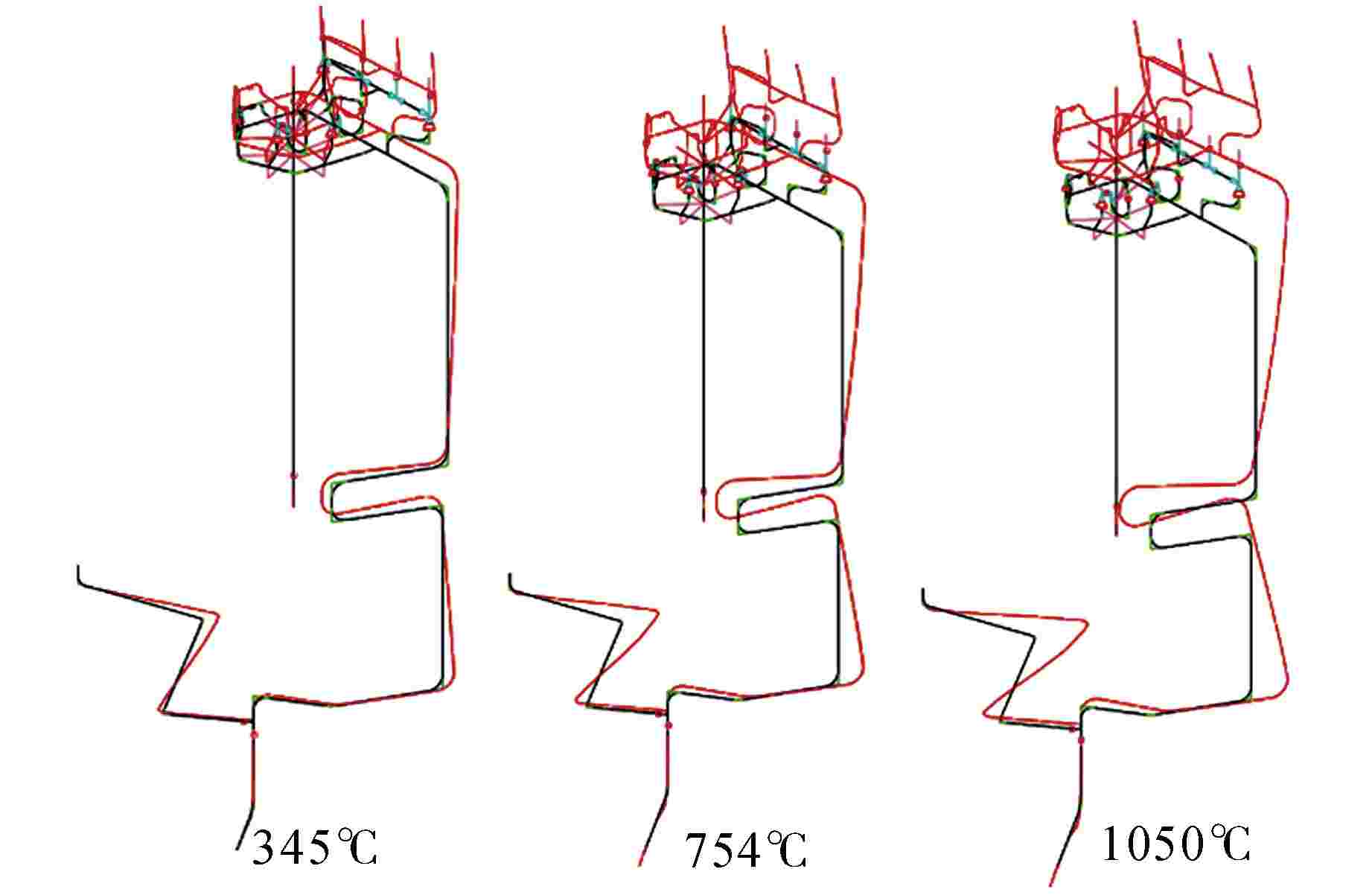

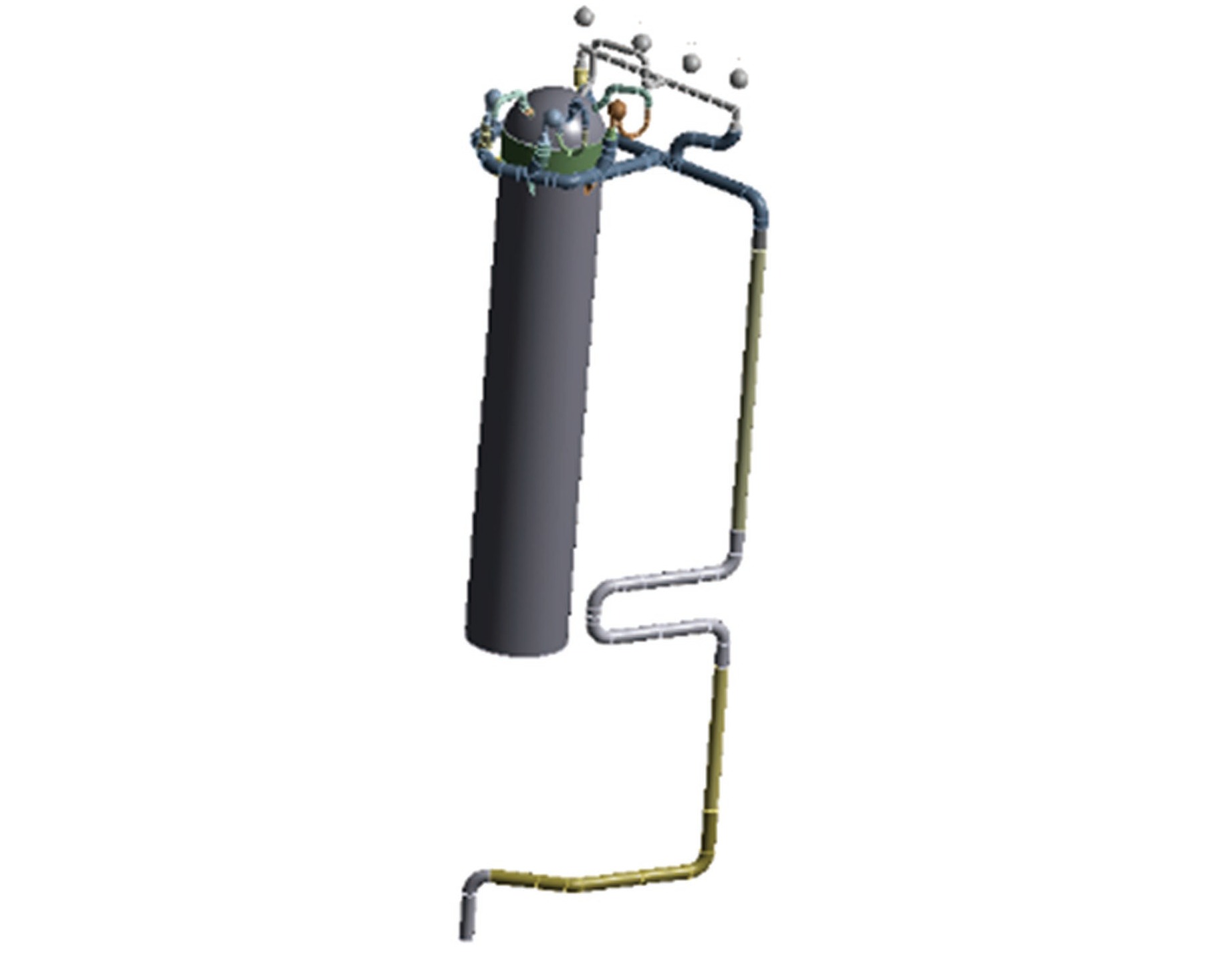

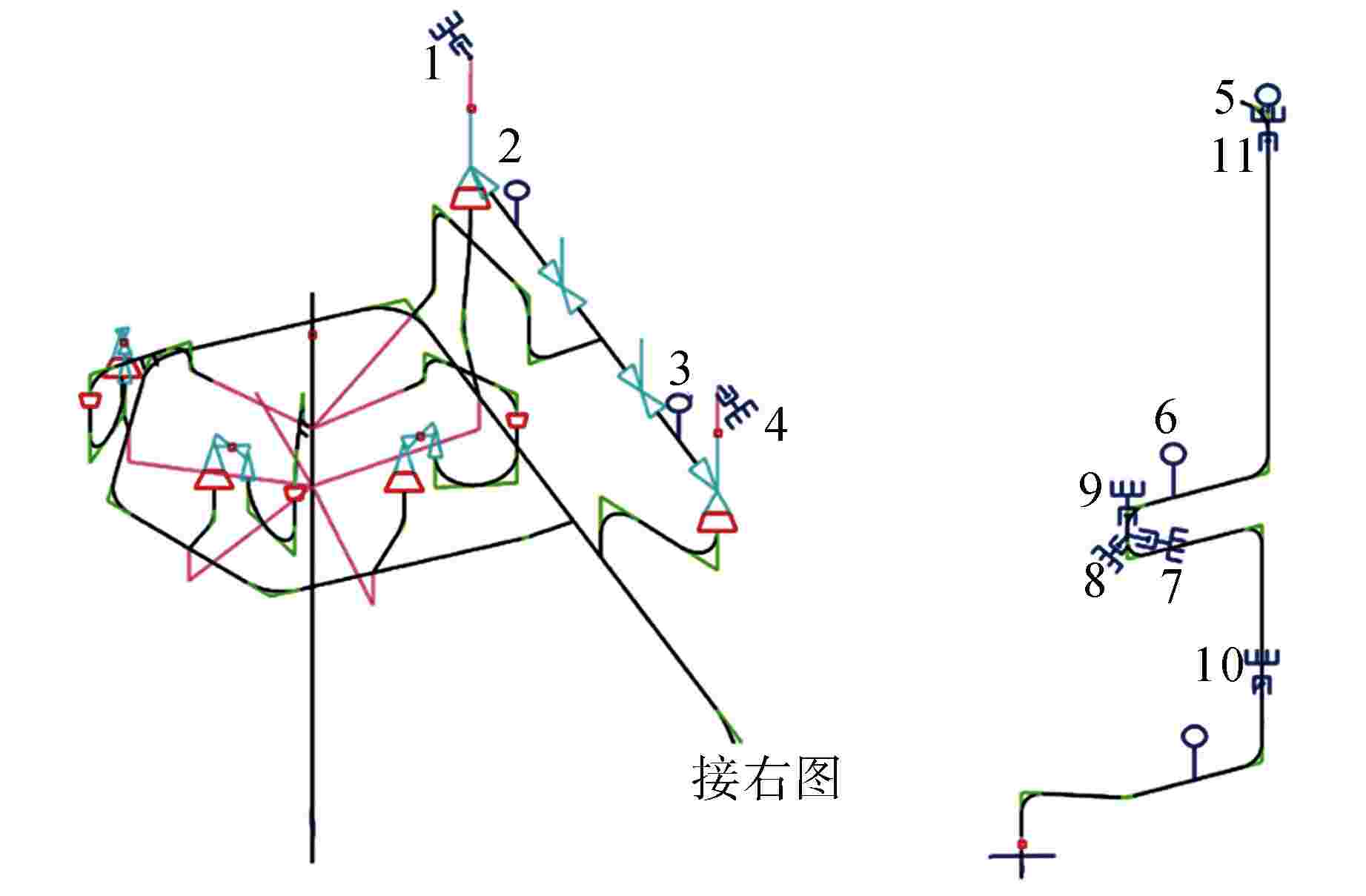

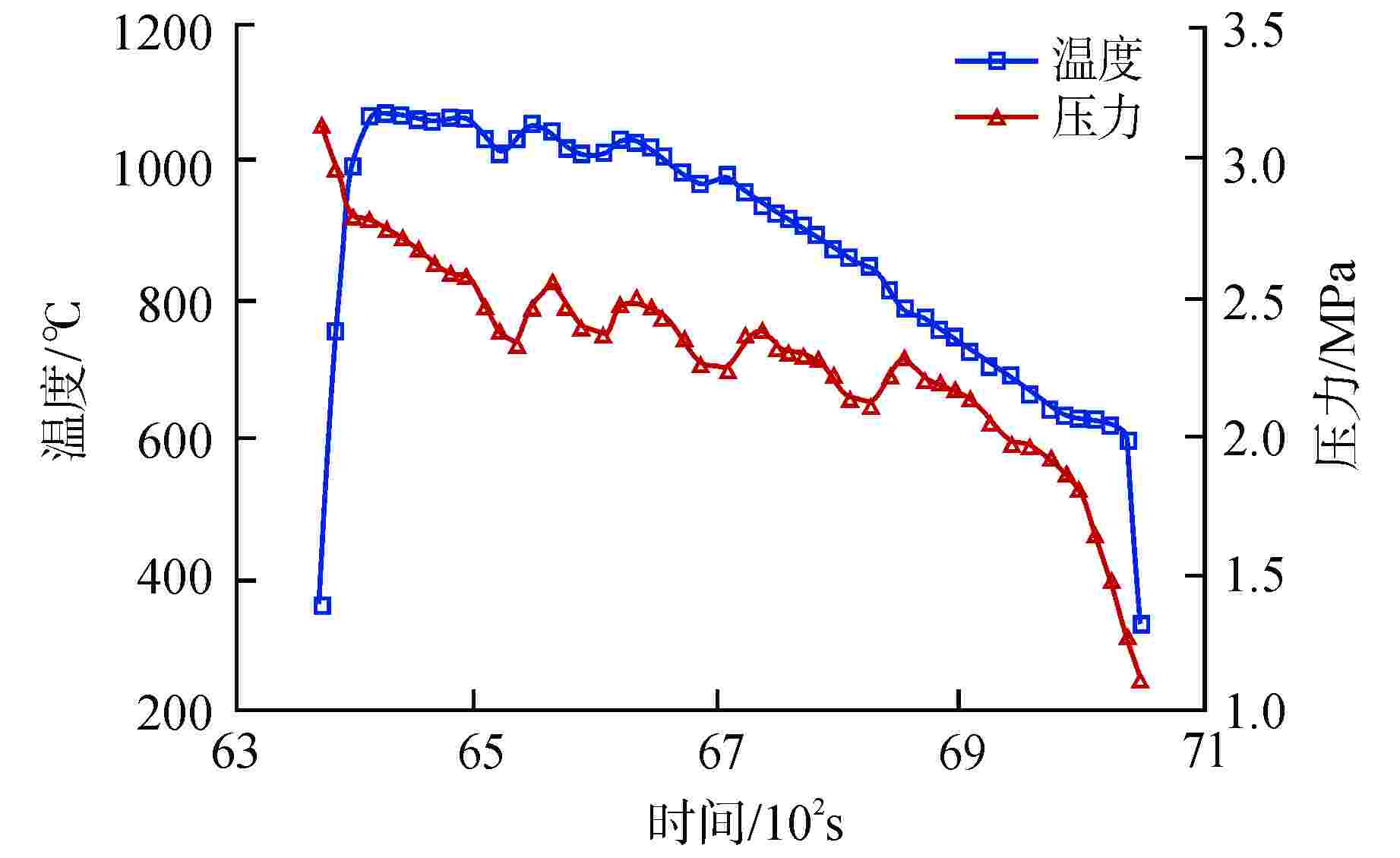

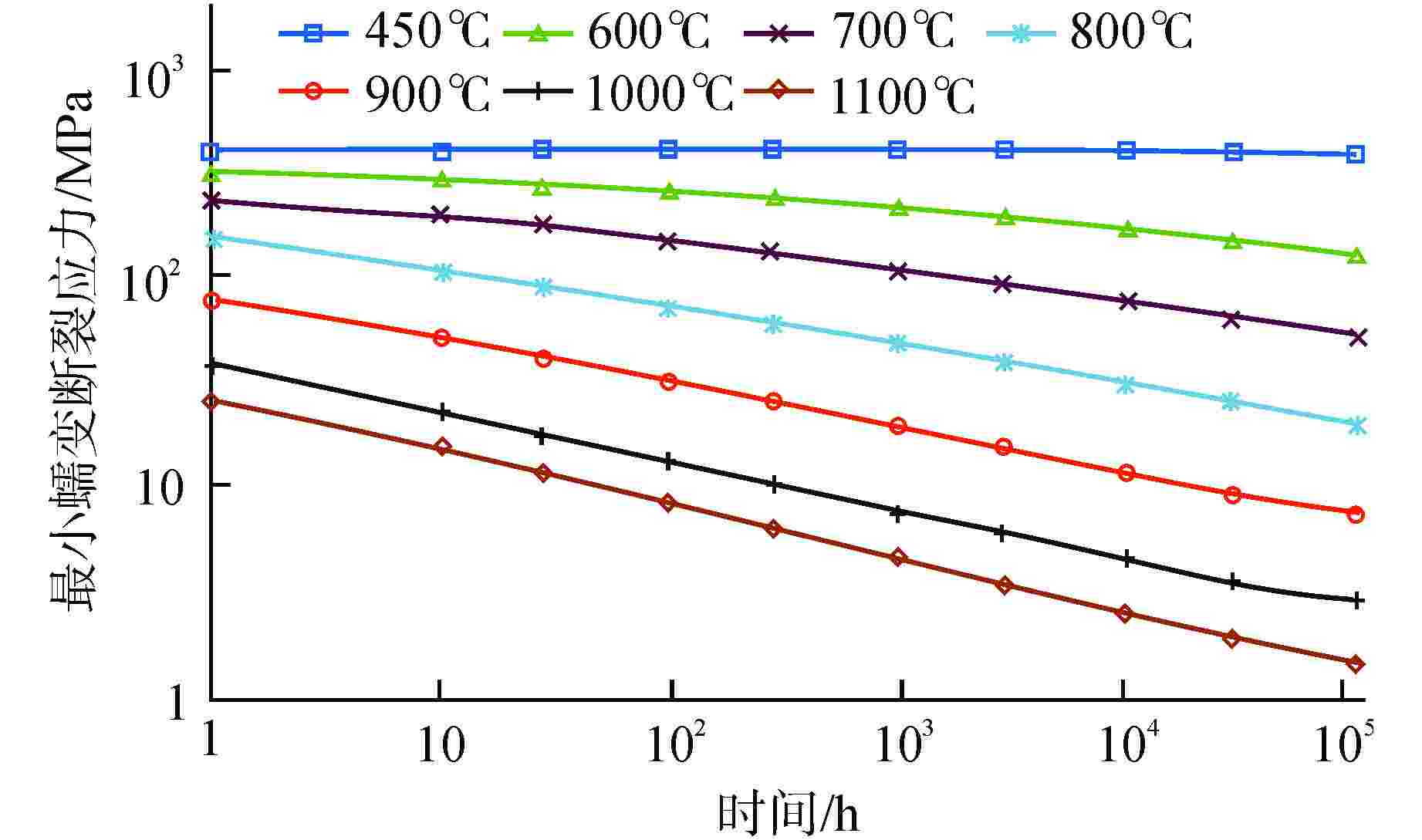

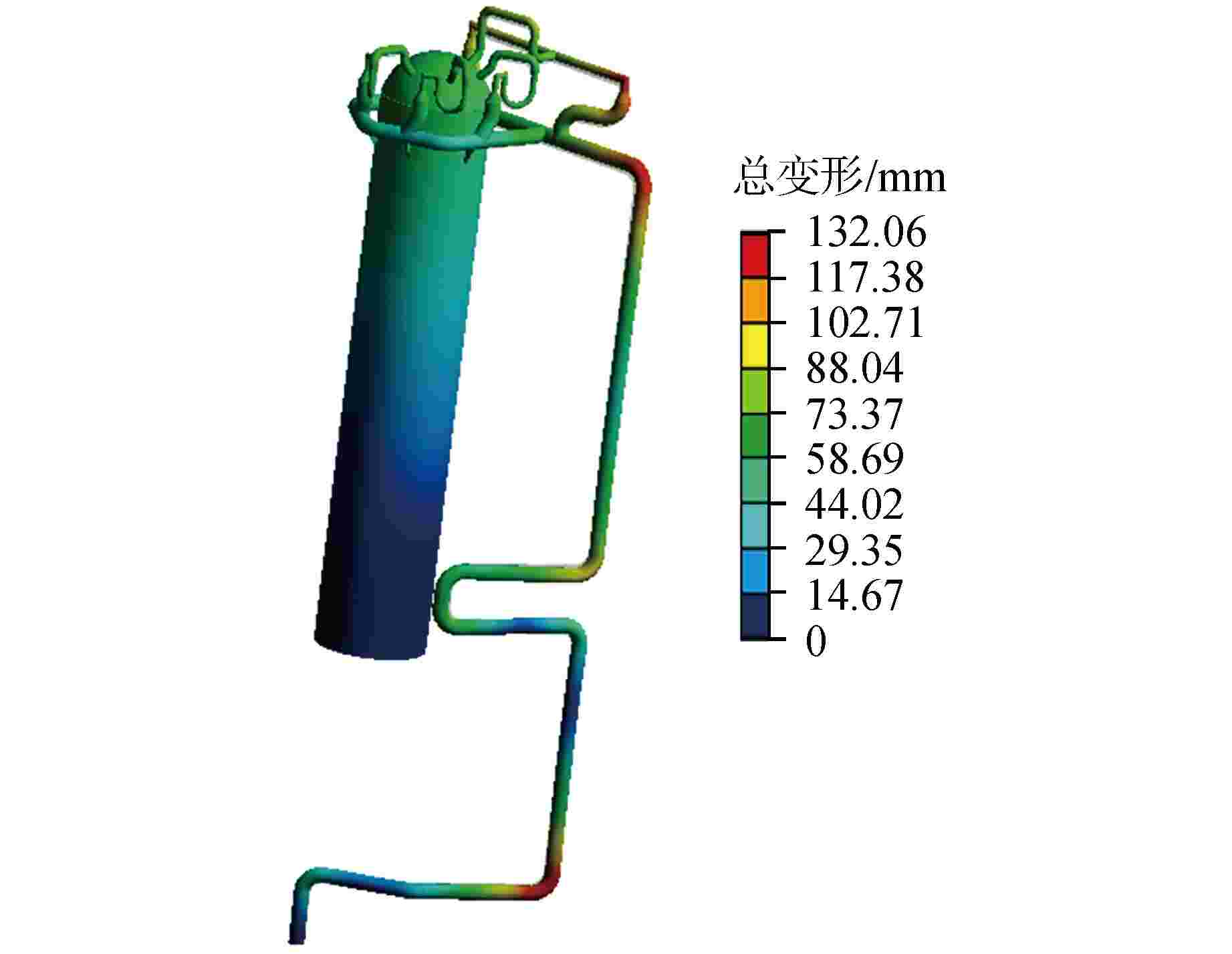

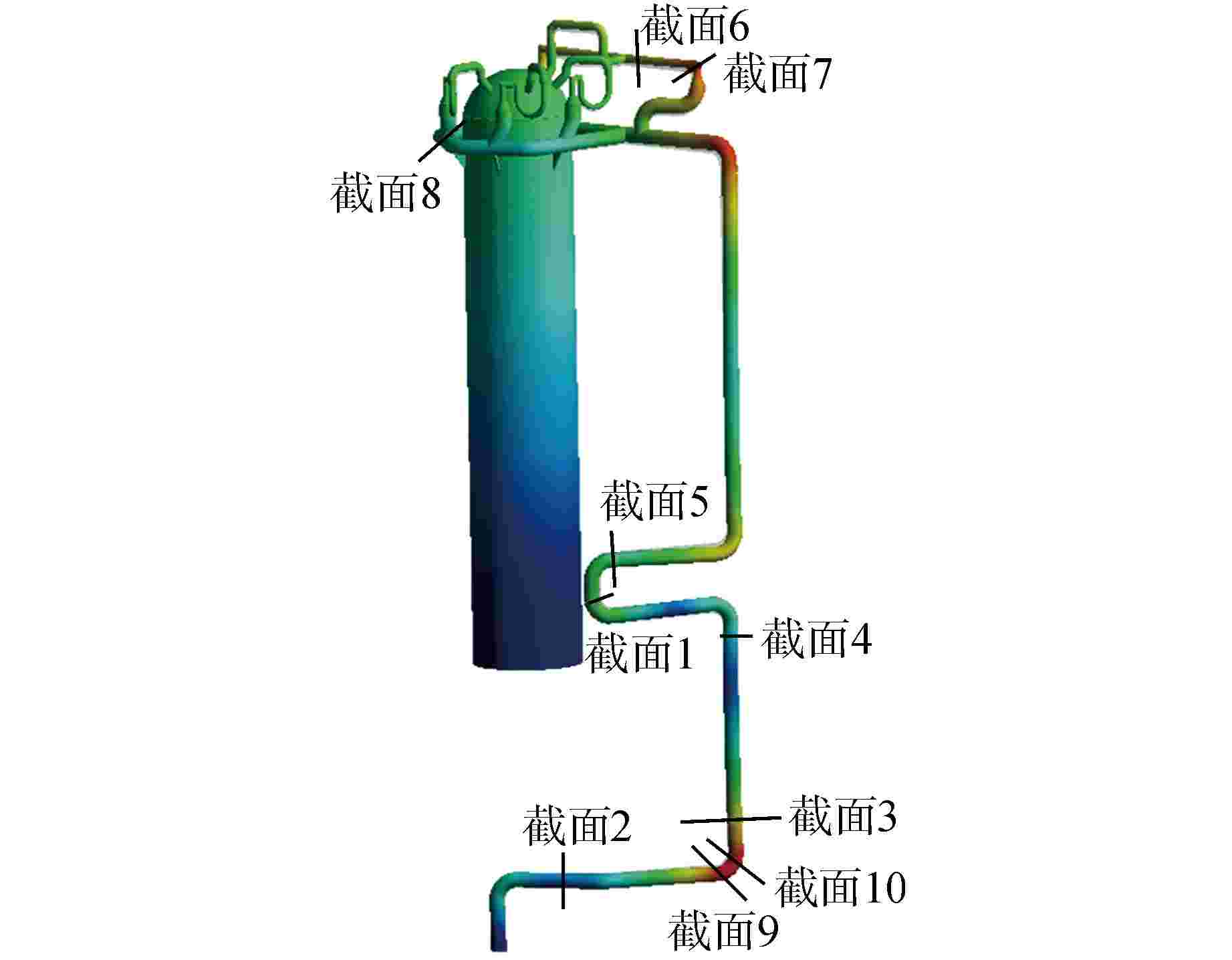

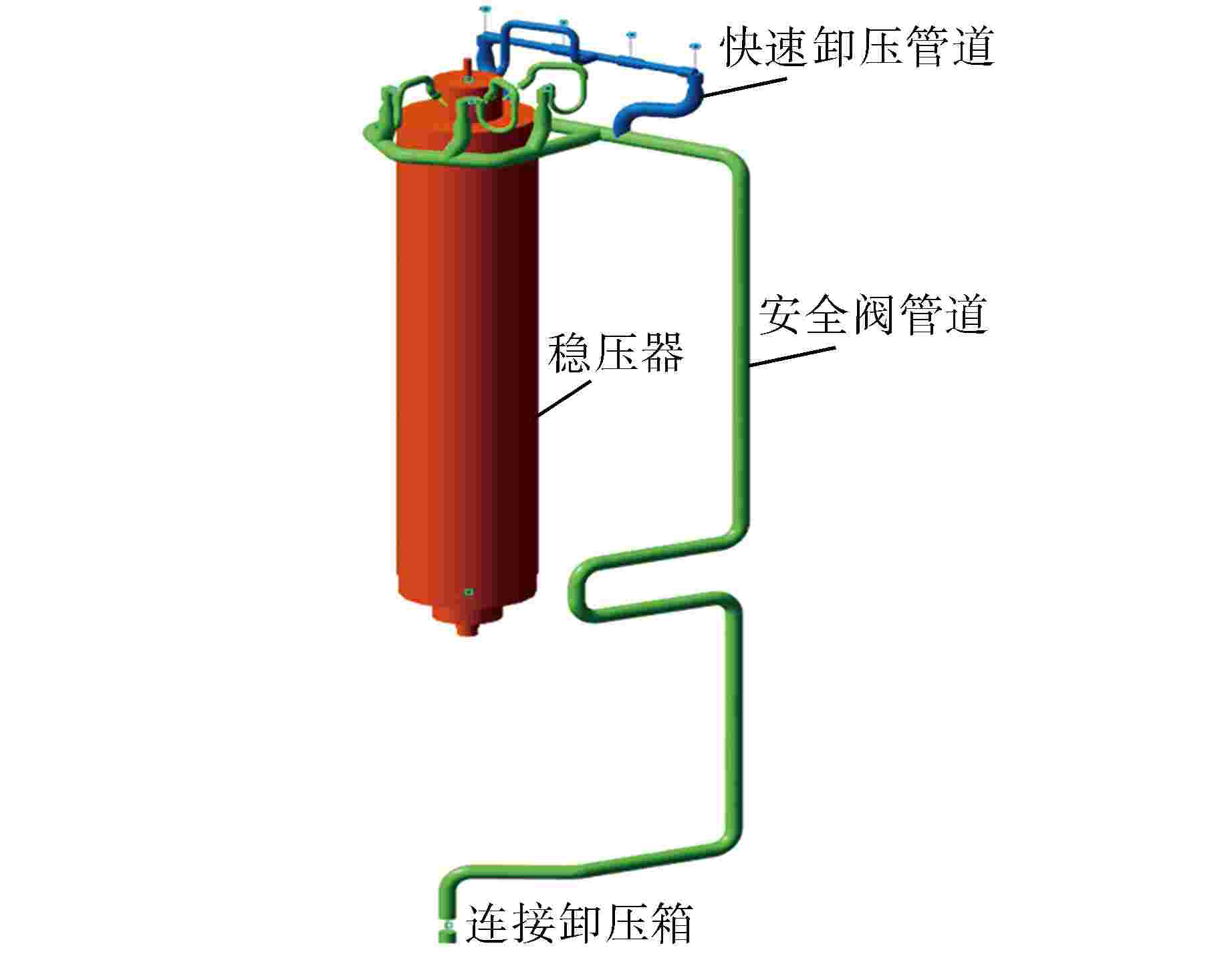

摘要: 核电厂严重事故下,管道与设备将经历极端高温、高压的情况,快速卸压管道作为严重事故下卸压的唯一途径,保证其流道畅通性至关重要,为此,开展“华龙一号”严重事故下快速卸压管道流道畅通性研究。对严重事故下快速卸压管道和稳压器进行传热分析,得到了管道和稳压器的温度变化情况。采用弹性分析的方法模拟了快速卸压管道在严重事故下的变形过程,得到了温度与变形的关系。建立三维模型,引入材料非线性,开展了快速卸压管道弹簧支架和阻尼器位置模拟研究,获取了严重事故下管道弹簧支架与阻尼器所处的状态。针对温度高于450℃的情况,分析了高温蠕变对管道完整性的影响。选取快速卸压管道上变形最大的10个位置开展了管道截面剩余面积研究,得到了严重事故下快速卸压管道最小剩余面积比以及管道最小流通面积。研究结果表明,“华龙一号”严重事故下快速卸压管道流道仍然能保证畅通性,“华龙一号”快速卸压管道能保证反应堆堆芯不会发生熔化。Abstract: Both pipelines and the equipment experience extreme high temperature and pressure in sever accident of the nuclear power plant. As the only way to relieve pressure in case of severe accident, it is very important to ensure the smoothness of the flow channel of rapid pressures relief pipeline. In this paper, the study on the smoothness of the flow channel of rapid pressure relief pipeline in severe accident of HPR 1000 is carried out. Heat transfer analysis is done for rapid pressure relief pipeline and pressurizer in severe accident. The temperature changes of pipeline and pressurizer are obtained. The deformation process of rapid pressure relief pipeline in severe accident is simulated by elastic analysis method. The relationship between temperature and deformation is obtained. The 3D model is established, and the material non-linearity is introduced. The simulation study on the position of spring support and damper of rapid pressure relief pipeline is carried out, and the status of spring support and damper of pipeline under severe accident is obtained. The influence of high temperature creep on pipeline integrity is analyzed for the case of temperature higher than 450℃. 10 positions with the largest deformation on the rapid pressures relief pipeline are selected to study the residual area of the pipeline section, and the minimum residual area ratio and the minimum flow area of the pipeline under severe accidents are obtained. The research results show that the flow channel of the rapid pressures relief pipeline can still ensure the smoothness under the severe accident of HPR 1000, and the rapid pressures relief pipeline of HPR 1000 can ensure that the reactor core will not melt.

-

Key words:

- Severe accident /

- Rapid pressure relief pipeline /

- Creep /

- Smoothness

-

表 1 快速卸压管道材料性能

Table 1. Material Properties of Rapid Pressure Relief Pipeline

温度/℃ 弹性模量(E)/GPa 屈服强度(Sy)/MPa 抗拉强度(Su)/MPa 20 192 262.4 568.7 100 186 215.3 508.9 200 180 181.0 470.1 400 161 146.2 448.9 600 145 132.4 390.9 800 127 108.5 198.1 1000 38 51.8 53.8 1100 18 27.7 28.2 表 2 弹簧支架和阻尼器位移与行程

Table 2. Displacement and Stroke of Spring Support and Damper

序号 类型 行程/mm 位移/mm 支架1 阻尼器 40 57.00 支架2 恒力弹簧支架 97/−33 106.00 支架3 恒力弹簧支架 85/−25 64.00 支架4 阻尼器 40 24.09 支架5 恒力弹簧支架 86/−34 35.09 支架6 弹簧支架 120 99.00 支架7 阻尼器 40 87.00 支架8 阻尼器 40 27.80 支架9 阻尼器 40 90.00 支架10 阻尼器 40 139.00 支架11 阻尼器 60 23.79 表 3 弹簧支架和阻尼器重新分配后的位移与行程

Table 3. Reassigned Displacement and Stroke of Spring Support and Damper

支架号 类型 行程/mm 位移/mm 支架1 阻尼器 40 21.7 支架2 恒力弹簧支架 97/−33 86.1 支架3 恒力弹簧支架 85/−25 64.8 支架4 阻尼器 40 21.9 支架5 恒力弹簧支架 86/−34 37.9 支架6 弹簧支架 120 50 支架7 阻尼器 40 40 支架8 阻尼器 40 40 支架9 阻尼器 40 40 支架10 阻尼器 40 40 支架11 阻尼器 60 42.2 表 4 快速卸压管道蠕变分析结果

Table 4. Creep Analysis Results of Rapid Pressure Relief Pipeline

区间数 tk/s 温度/℃ P1

/MPaP2

/MPaTk/s Wi 1 12 752 9.77 39.91 1×108 0.000 2 164 1073 8.73 34.89 704 0.233 3 110 1046 7.99 37.79 1512 0.073 4 117 987 7.44 37.34 5448 0.021 5 72 894 7.09 37.18 2.5×105 0.000 6 84 786 7.13 37.27 1.5×107 0.000 7 101 692 6.16 36.32 1×108 0.000 8 25 594 3.96 34.14 1×108 0.000 $ {P_{\text{1}}} = 1.35\varOmega {P_{\text{m}}} $; $ {P_{\text{2}}} = {\text{1}}{\text{.35}}\left( {{P_{\text{m}}} + \varPhi {P_{\text{b}}}} \right) $;Wi—P1和P2所对应的最大蠕变断裂使用系数 表 5 快速卸压管道截面积变形结果

Table 5. Deformation Result of Section Area of Rapid Pressure Relief Pipeline

截面

序号最大内

径变化/mm管道原

内径/mm剩余面

积比/%最小流通

面积/mm21 4.00 311.10 97.44 74070 2 17.20 311.10 89.25 67841 3 9.49 311.10 93.99 71445 4 6.64 311.10 95.78 72804 5 8.14 311.10 94.83 72086 6 4.81 150.04 93.69 16566 7 7.06 150.04 90.81 16056 8 6.67 311.10 95.76 72791 9 22.17 311.10 86.26 65566 10 19.18 311.10 88.05 66929 -

[1] 国家核安全局. 核动力厂设计安全规定: HAF 102—2016[Z]. 2016: 17-18. [2] 国家核安全局. 核电厂反应堆冷却剂系统及其有关系统: HAD 102/08—1989[Z]. 1989: 1071-1072. [3] 黄雄,吕雪峰,李依霖,等. AP1000核电厂自动卸压系统功能分析[J]. 热力发电,2016, 45(5): 84-87,99. doi: 10.3969/j.issn.1002-3364.2016.05.014 [4] 叶道权. AP1000反应堆冷却剂系统(RCS)自动卸压设计分析[C]//中国核科学技术进展报告(第二卷)——中国核学会2011年学术年会论文集第3册(核能动力分卷(下)). 贵阳: 中国核学会, 2011. [5] 王小吉,武铃珺,吴清,等. 百万千瓦级压水堆严重事故卸压阀高温瞬态分析[J]. 核动力工程,2021, 42(3): 69-73. doi: 10.13832/j.jnpe.2021.03.0069 [6] 武铃珺,彭欢欢,许幼幼,等. 快速卸压阀延迟开启对严重事故进程的影响分析[J]. 科技视界,2021(10): 111-114. doi: 10.19694/j.cnki.issn2095-2457.2021.10.34 [7] 倪项斌. 核电阀门高温分析方法研究[J]. 通用机械,2020(S2): 56-58. [8] 余煜哲,刘忠伟,邓英剑. 高温高压阀门阀体的可靠性分析与研究[J]. 邵阳学院学报:自然科学版,2020, 17(1): 50-57. [9] MIKHEYEV M. Fundamentals of heat transfer[M]. Moscow: Peace Publishers, 1956: 280-346. [10] AFCEN. Design and construction rules for mechanical components of nuclear installations: RCC-MRx 2012[Z]. 2013: RB21-RB23. -

下载:

下载: