Design and Development of Intelligent Operator Support System for Nuclear Power Plants

-

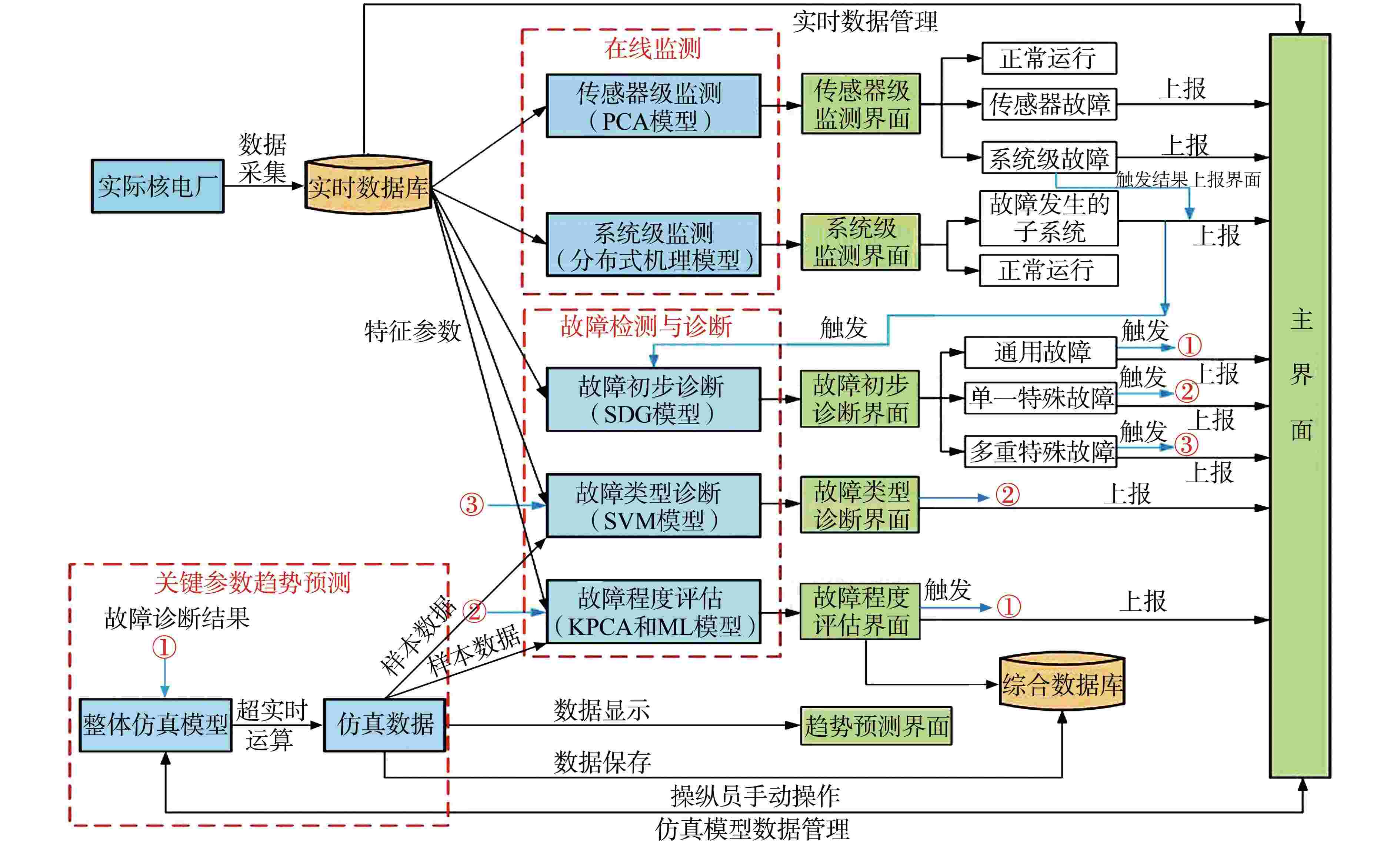

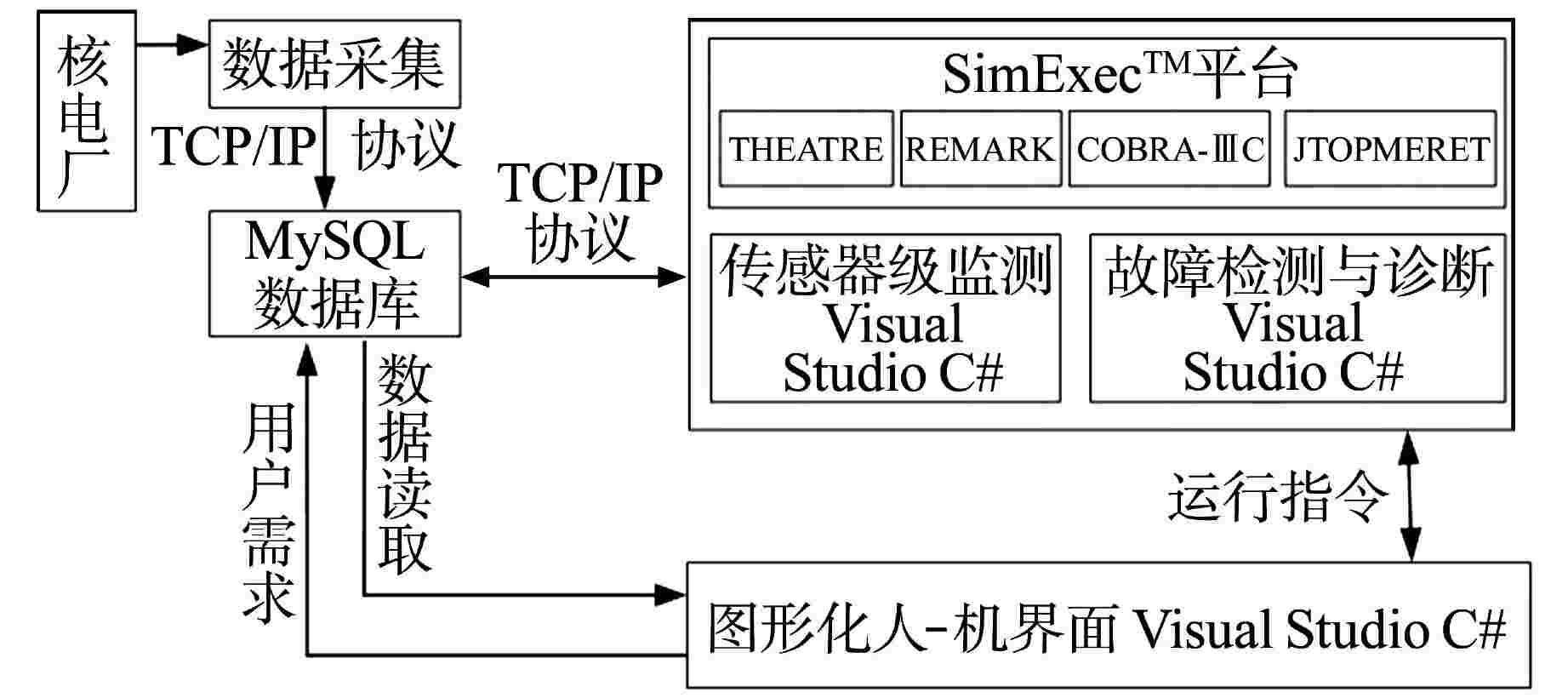

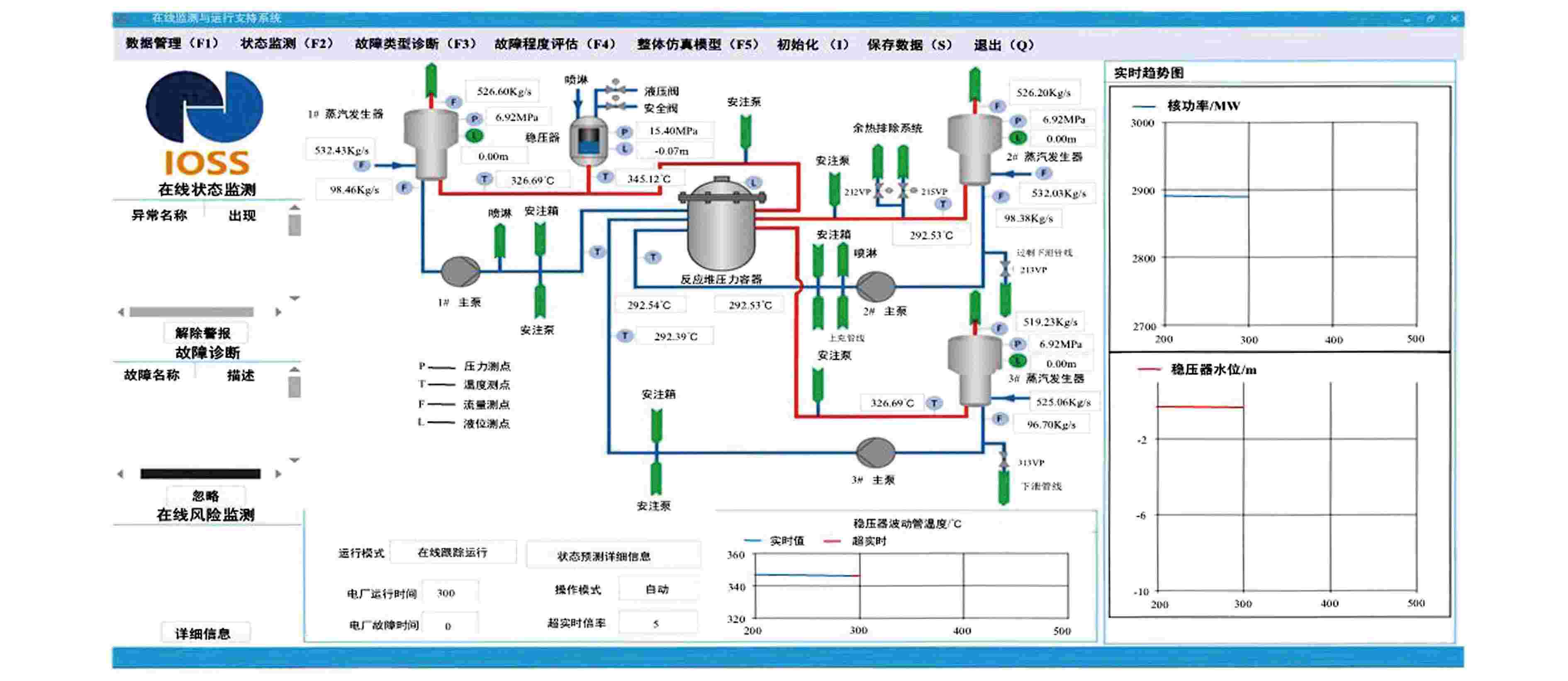

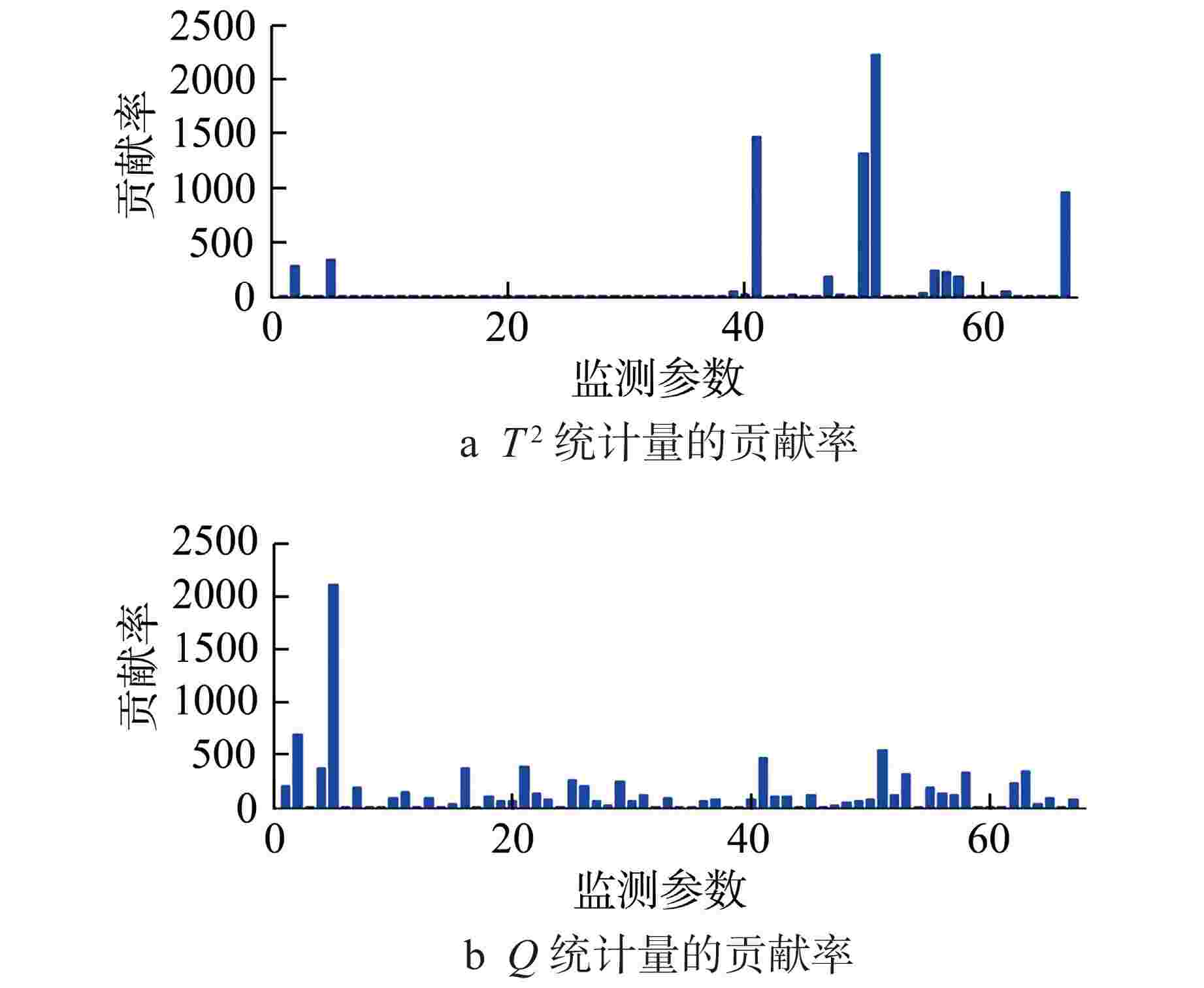

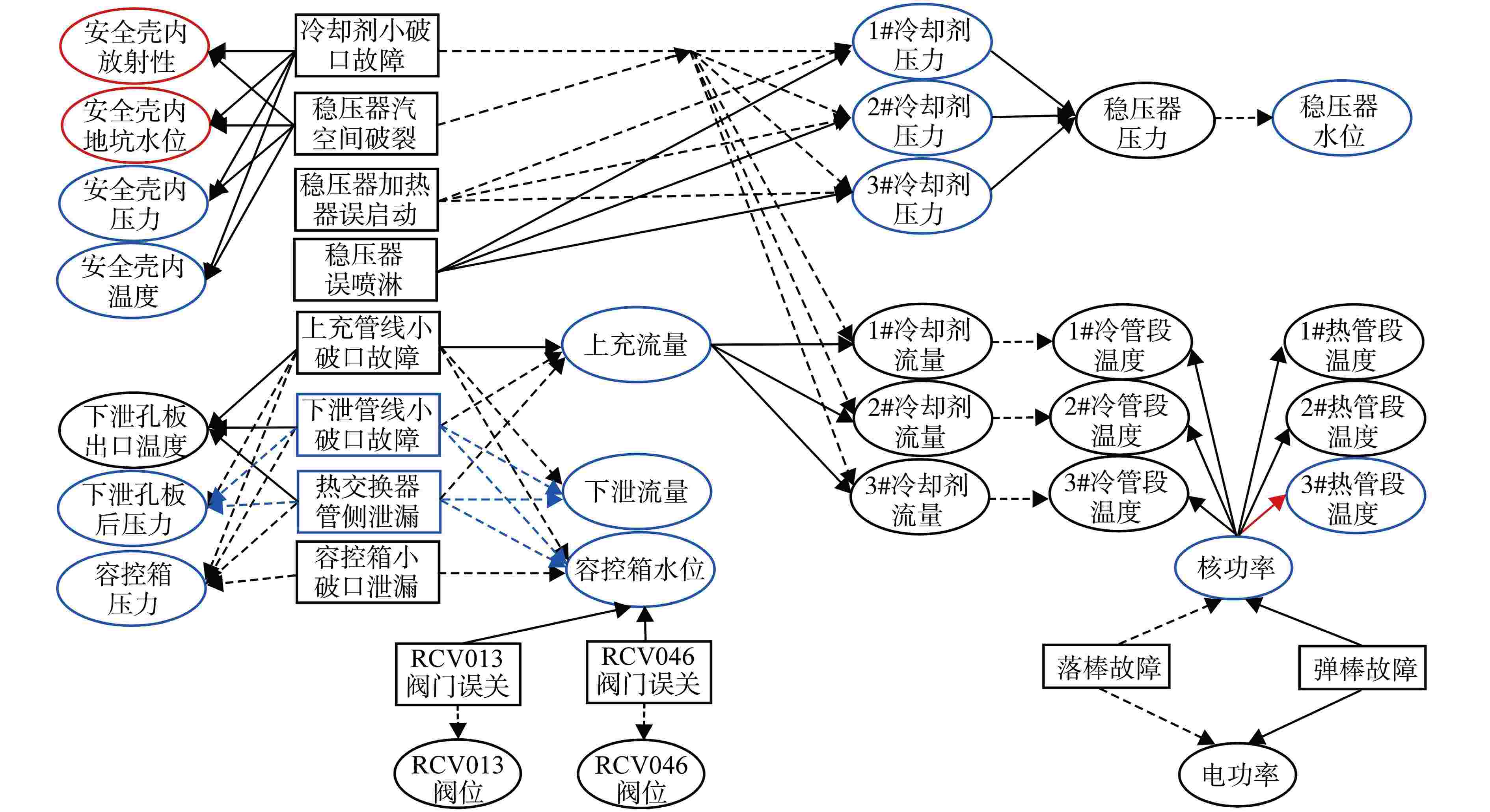

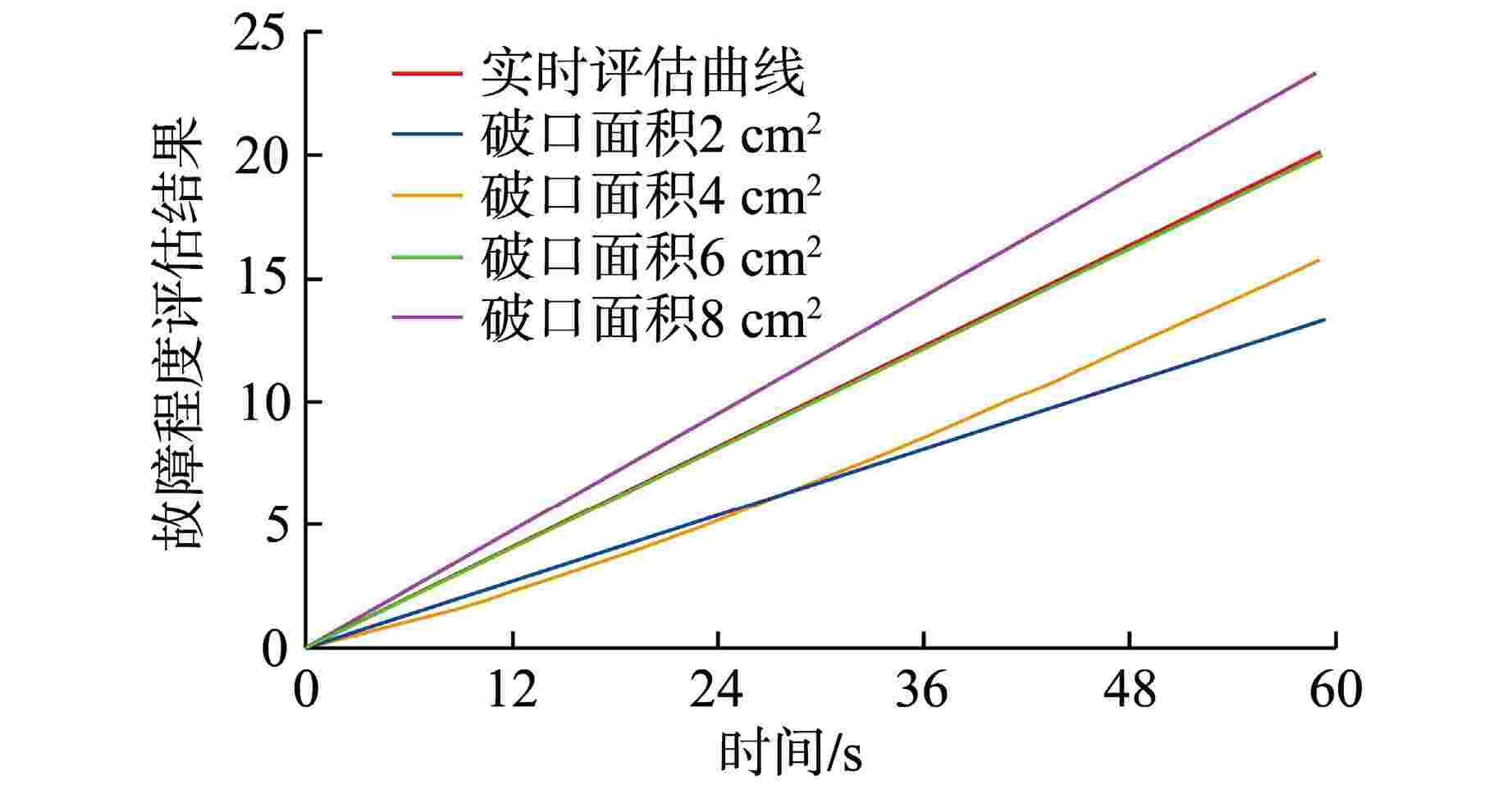

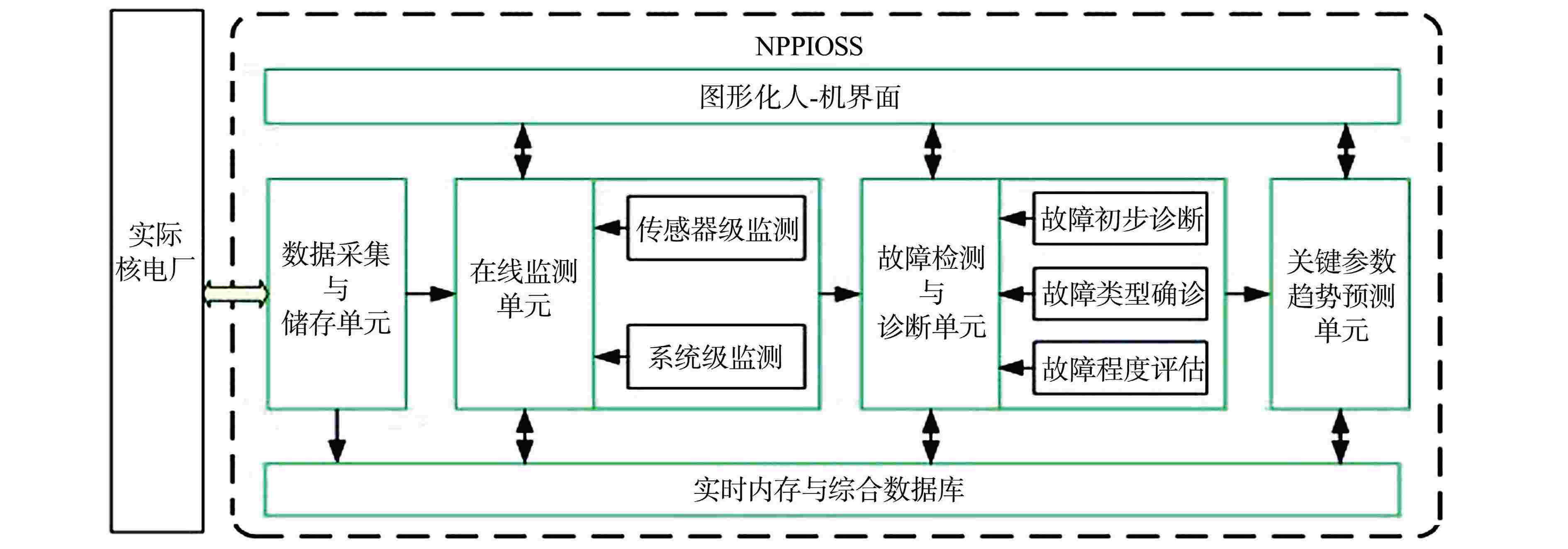

摘要: 为了减轻核电厂操纵员在处理异常或事故工况时的工作压力和心理负担,以避免误判或误操作,本研究针对核电厂反应堆一回路系统及其关键辅助系统设计并开发了一套集数据采集与存储、在线监测、故障检测与诊断、关键参数趋势预测等功能于一体的核电厂智能操纵员支持系统(NPPIOSS),仿真验证结果表明NPPIOSS能够准确检测并识别核电厂的典型故障,从而帮助操纵员准确判断核电厂状态,以减少人因失误。因此,NPPIOSS能够在核电厂故障后辅助操纵员进行后续的决策处理,达到提高核电厂运行安全性的目的。

-

关键词:

- 核电厂智能操纵员支持系统(NPPIOSS) /

- 状态监测 /

- 故障检测与诊断

Abstract: In order to reduce the nuclear power plants operator ’s work pressure and psychological burden when dealing with abnormal and accident conditions, and avoid misjudgment or misoperation, this research has designed and developed a set of nuclear power plant intelligent operator support system (NPPIOSS) for the reactor primary circuit system and its key auxiliary system, which integrates data acquisition and storage, online monitoring, fault detection and diagnosis, key parameter trend prediction and other functions. The simulation results show that NPPIOSS system can accurately detect and identify typical faults of nuclear power plant, so as to help operators accurately judge the state of power plant and reduce human error. Therefore, NPPIOSS system can assist operators in subsequent decision-making after the failure of nuclear power plant, so as to improve the operation safety of nuclear power plant. -

表 1 NPPIOSS测试典型故障集

Table 1. NPPIOSS Test Typical Fault Set

故障类型 故障名称 所属系统 传感器

故障稳压器波动管温度传感器漂移、

偏差故障RCS 蒸汽发生器水位传感器漂移、

偏差故障冷管段温度传感器漂移、偏差故障 稳压器喷淋流量传感器漂移、

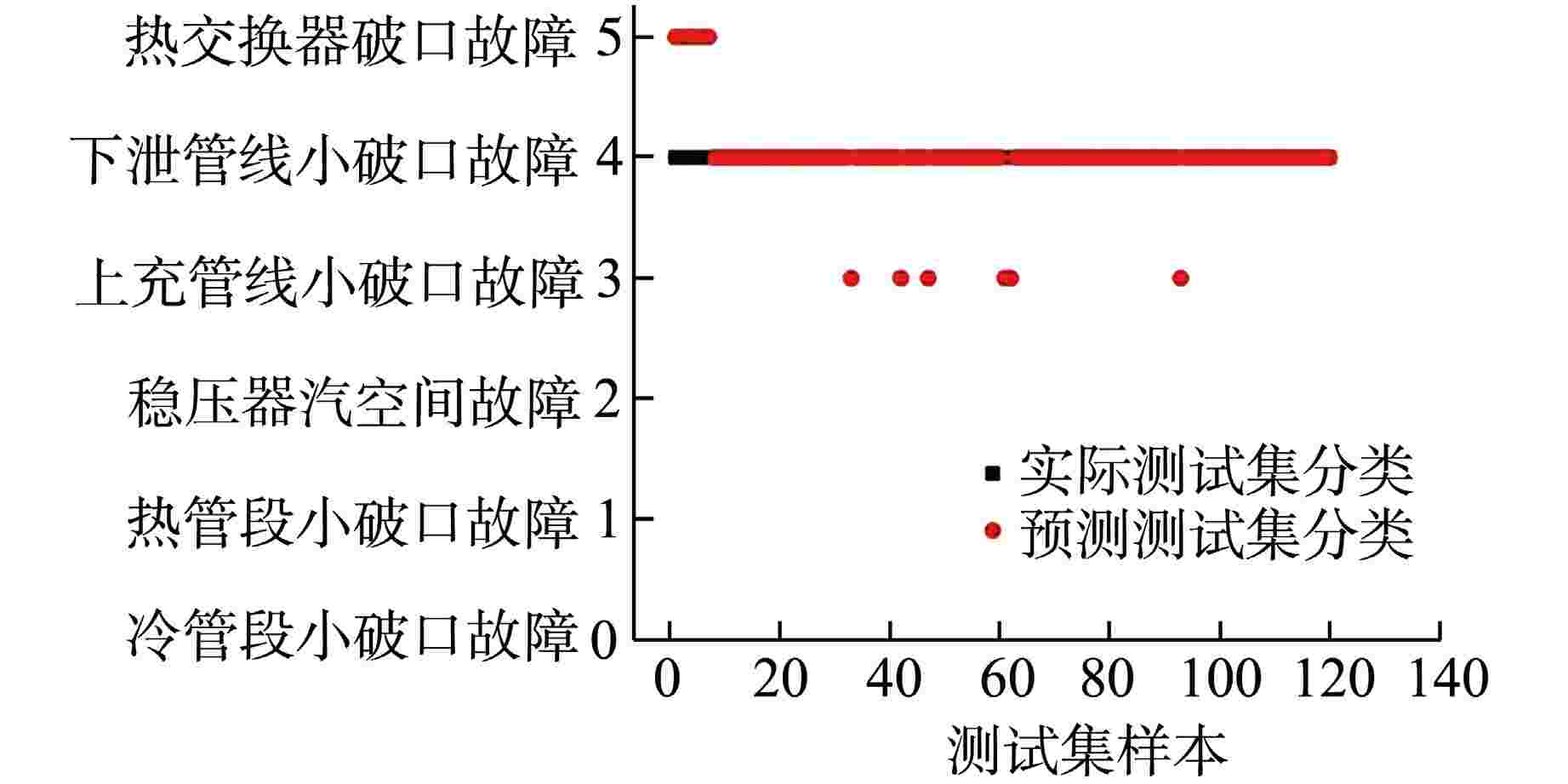

偏差故障通用故障 稳压器加热器误启动 RCS 稳压器喷淋阀误启动 弹棒故障 落棒故障 下泄管线调节阀013VP误关 RCV 上充管线调节阀046VP误关 特殊故障 冷管段小破口故障 RCS 热管段小破口故障 稳压器汽空间破裂 上充管线小破口故障 RCV 下泄管线小破口故障 再生式热交换器破口故障 容控箱小破口故障 表 2 NPPIOSS测试典型故障集测试结果

Table 2. Test Results of NPPIOSS Test Typical Fault Set

故障名称 异常检测模型与时间 故障诊断模型与时间 稳压器波动管温度传感器漂移、偏差故障 PCA模型(传感器漂移1%~3%):<35 s

PCA模型(传感器偏差3%~10%):<5 s蒸汽发生器水位传感器漂移、偏差故障 冷管段温度传感器漂移、偏差故障 稳压器喷淋流量传感器漂移、偏差故障 稳压器加热器误启动 分布式模型:<5 s SDG模型:<7 s 稳压器喷淋阀误启动 分布式模型:<5 s SDG模型:<7 s 弹棒故障 分布式模型:<5 s SDG模型:<7 s 落棒故障 分布式模型:<5 s SDG模型:<7 s 下泄管线调节阀013VP误关 分布式模型:<5 s SDG模型:<10 s 上充管线调节阀046VP误关 分布式模型:<5 s SDG模型:<10 s 冷管段小破口故障 分布式模型:<5 s SDG预诊断:<10 s

SVM故障类型确诊:<20 s热管段小破口故障 分布式模型:<5 s 稳压器汽空间破裂 分布式模型:<5 s 上充管线小破口故障 分布式模型:<5 s SDG预诊断:<10 s

SVM故障类型确诊:<20 s下泄管线小破口故障 分布式模型:<5 s 再生式热交换器破口故障 分布式模型:<5 s 容控箱小破口故障 分布式模型:<5 s SDG模型:<10 s -

[1] ISAAC A, SHORROCK S T, KIRWAN B. Human error in European air traffic management: the HERA project[J]. Reliability Engineering & System Safety, 2002, 75(2): 257-272. [2] NAITO N, SAKUMA A, SHIGENO K. A real-time expert system for nuclear power plant failure diagnosis and operational guide[J]. Nuclear Technology, 1987, 79(3): 284-296. doi: 10.13182/NT87-A34018 [3] CHANG S H, KIM H G, CHOI S S, et al. Development of the on-line operator aid system (oasysm) using rule based expert system and fuzzy logic for nuclear power plants[J]. Advances in Human Factors/Ergonomics, 1995, 20: 1051-1056. [4] 王航. 模型驱动的核电站混合式故障诊断策略研究[D]. 哈尔滨: 哈尔滨工程大学, 2018: 2-3. [5] HSIEH M H, HWANG S L, LIU K H, et al. A decision support system for identifying abnormal operating procedures in a nuclear power plant[J]. Nuclear Engineering and Design, 2012, 249: 413-418. doi: 10.1016/j.nucengdes.2012.04.009 [6] LIU Y K, PENG M J, XIE C L, et al. Research and design of distributed fault diagnosis system in nuclear power plant[J]. Progress in Nuclear Energy, 2013, 68: 97-110. doi: 10.1016/j.pnucene.2013.06.002 [7] AYODEJI A, LIU Y K, XIA H. Knowledge base operator support system for nuclear power plant fault diagnosis[J]. Progress in Nuclear Energy, 2018, 105: 42-50. doi: 10.1016/j.pnucene.2017.12.013 [8] XU R Y, PENG M J, WANG H, et al. Research on fault detection and diagnosis method for nuclear power plants based on distributed strategy[C].International Conference on Nuclear Engineering, Proceedings, ICONE, May 18, 2019. -

下载:

下载: