CHF Mechanism Model in Narrow Rectangular Channel Based on Energy Balance on Heating Wall

-

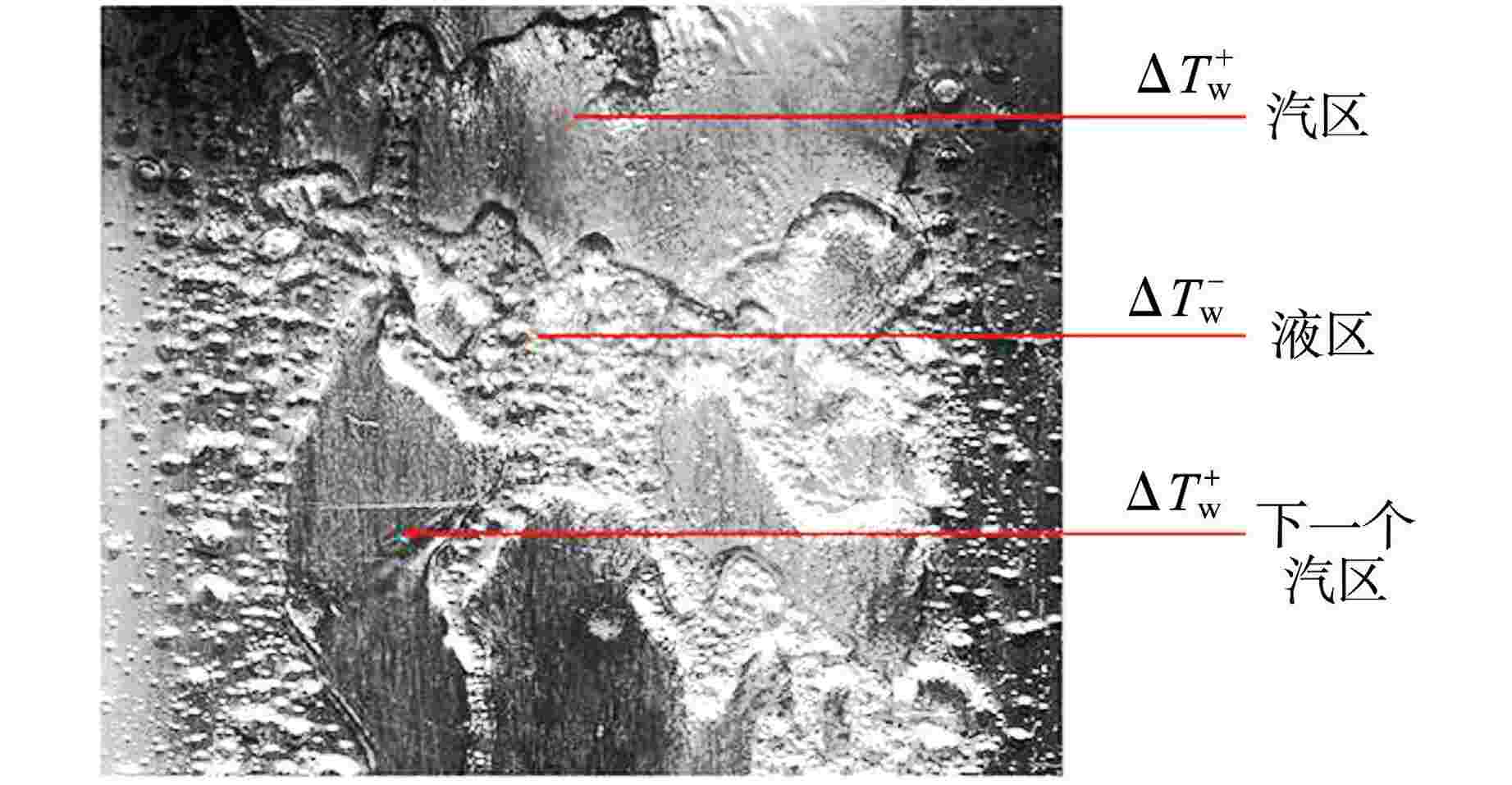

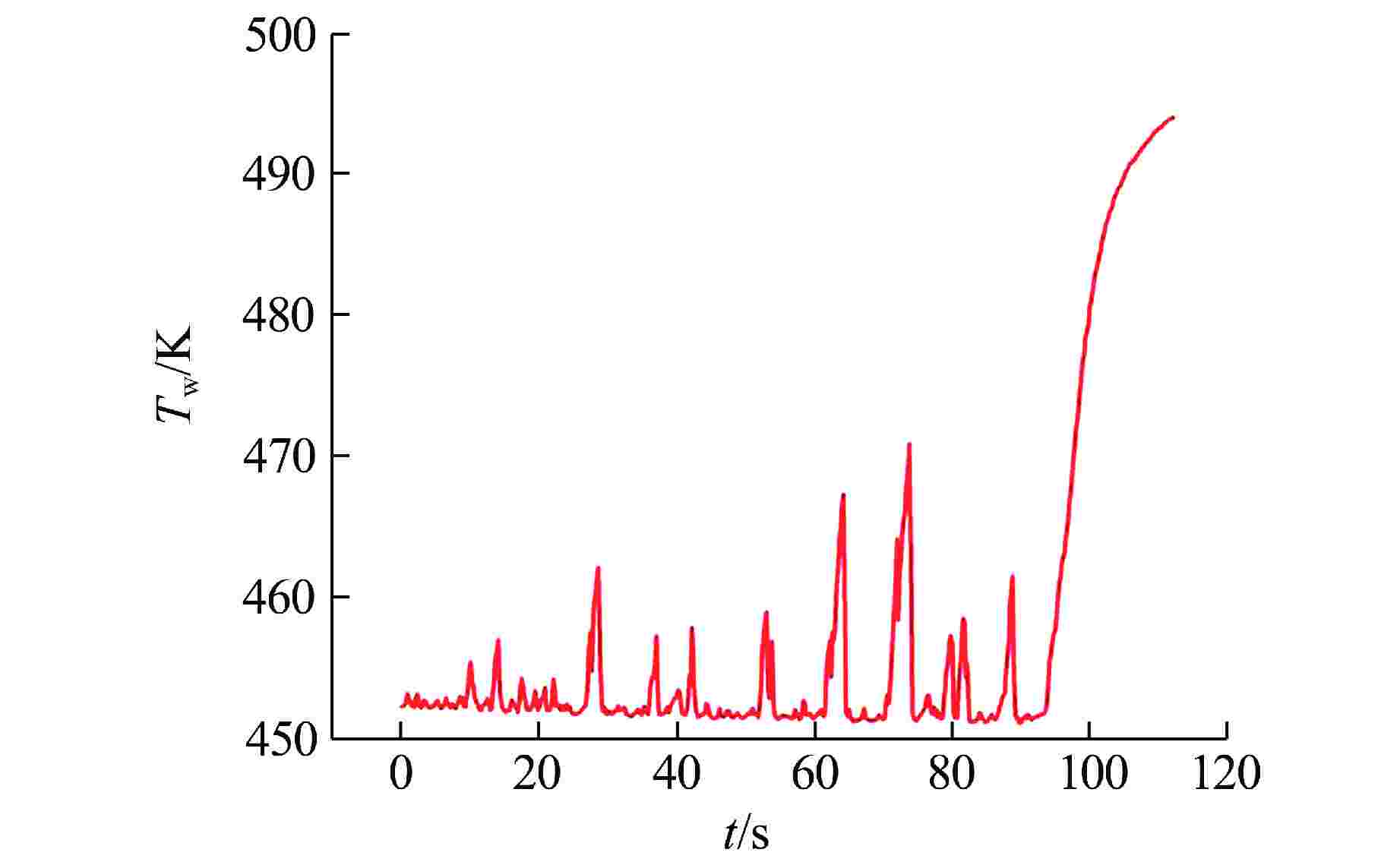

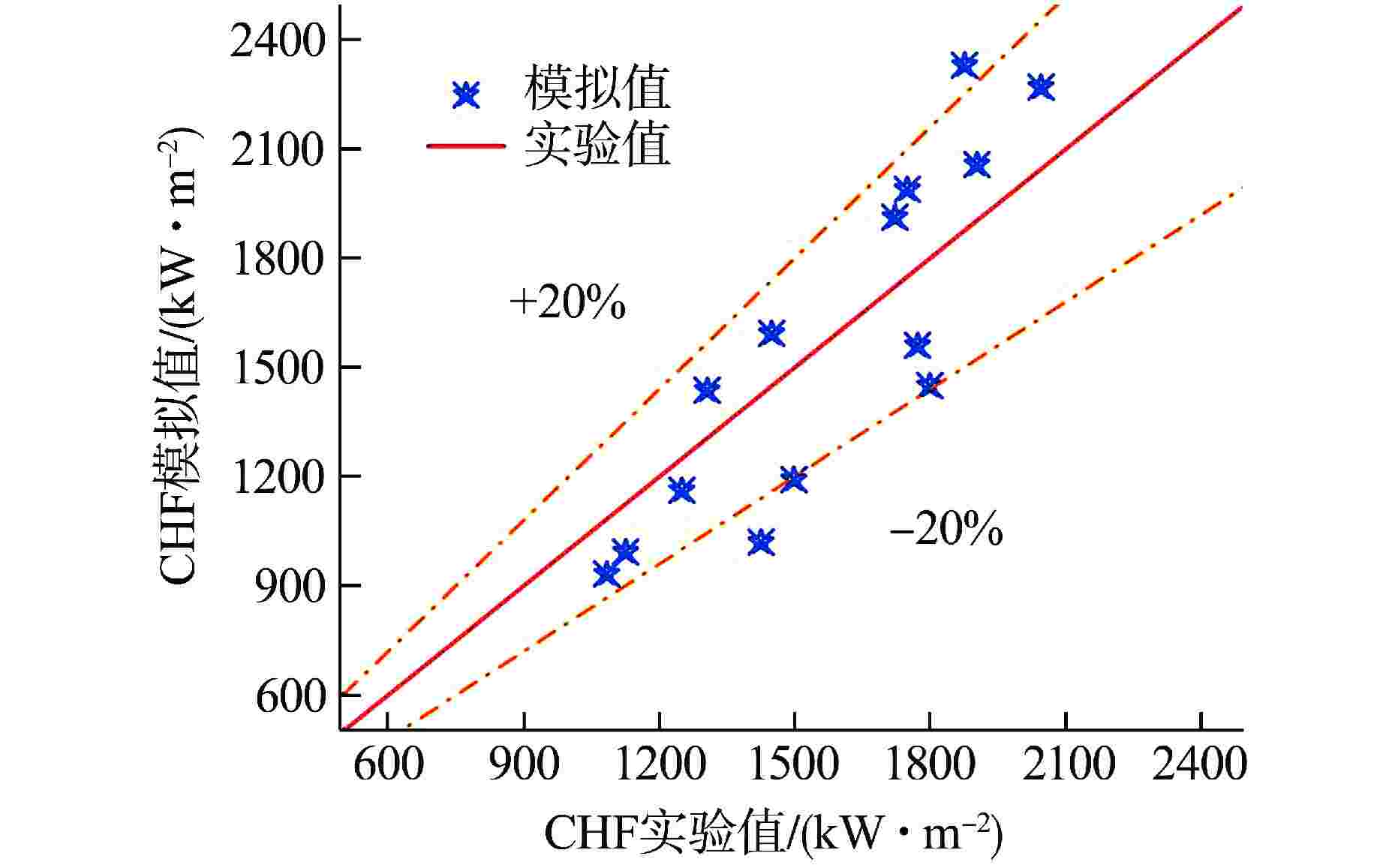

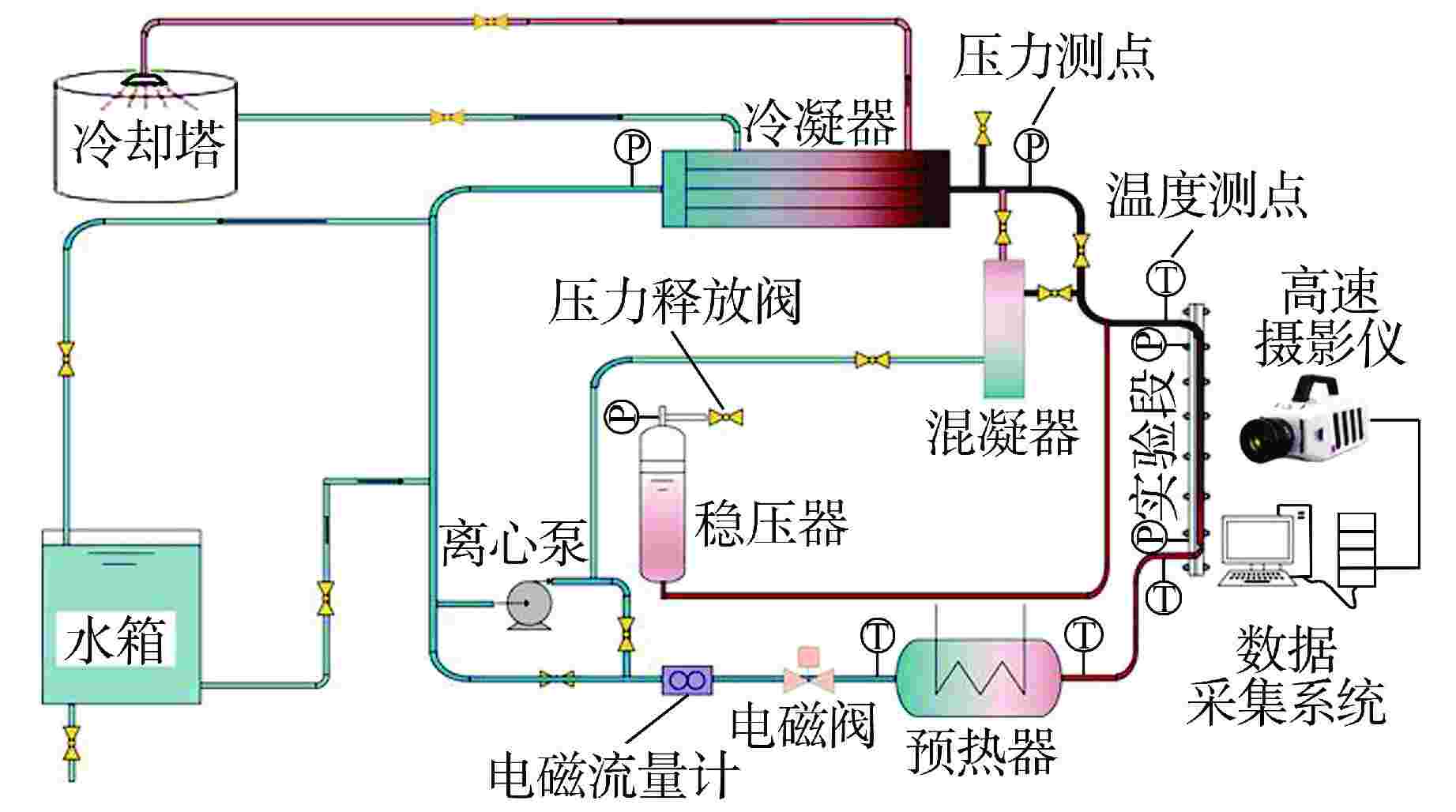

摘要: 窄矩形通道因具有结构紧凑、换热面积大等优点而被广泛应用于各个领域。通过完善窄矩形通道中临界热流密度(CHF)的预测方法,建立CHF机理模型,可以提高反应堆的安全性和经济性。本文对窄矩形通道内竖直向上流动CHF进行了可视化实验研究,在此基础上开发了一种基于加热壁面能量平衡的CHF机理模型,并提供一组本构关系用于封闭所开发的新模型,同时使用实验数据对新模型进行对比评价,对比结果发现,新模型在窄矩形通道中模拟结果良好,偏差基本都在±20%之间。

-

关键词:

- 窄矩形通道 /

- 临界热流密度(CHF) /

- 能量平衡 /

- 机理模型

Abstract: Narrow rectangular channel is widely used in various fields because of its compact structure and large heat transfer area. The safety and economy of reactor can be improved by improving the prediction method of critical heat flux (CHF) in the narrow rectangular channel and establishing a CHF mechanism model. In this paper, a visual experimental study is conducted on the CHF flowing vertically upward in a narrow rectangular channel. On this basis, a CHF mechanism model based on the heating wall energy balance is developed. A set of constitutive relations are provided to close the developed model, and the experimental data are used to compare and evaluate the new model. The narrow rectangular channel and it has good accuracies of less than ±20% as relative to the experimental values.-

Key words:

- Narrow rectangular channel /

- Critical heat flux (CHF) /

- Energy balance /

- Mechanism model

-

表 1 实验参数及取值范围

Table 1. Experimental Parameters and Value Range

参数名 参数值 实验压力psys/MPa 1~4 窄矩形通道宽度ε/mm 3 加热长度L/mm 600 质量流速G/[kg·(m2·s)−1] 350~2000 入口过冷度ΔTin,sub/K 60~120 工质 去离子水 -

[1] 刘伟,彭诗念,江光明,等. 临界热流密度机理模型发展综述[J]. 核动力工程,2021, 42(3): 211-217. doi: 10.13832/j.jnpe.2021.03.0211 [2] ABDULHAMEED M, SHAABAN A, GAMAL H, et al. A methodology for CHF prediction in VVER rod bundles[J]. Nuclear Engineering and Design, 2022, 393: 111751. doi: 10.1016/j.nucengdes.2022.111751 [3] SONG J H, JUNG J Y, CHANG S H, et al. Mechanistic CHF model development for subcooled flow boiling in a vertical rectangular channel under low pressure[J]. International Journal of Heat and Mass Transfer, 2021, 174: 121328. doi: 10.1016/j.ijheatmasstransfer.2021.121328 [4] 周磊,刘祥锋,闫晓,等. 矩形窄缝通道临界热流密度数值预测[J]. 核动力工程,2011, 32(4): 46-51. [5] 何辉,任全耀,叶停朴,等. 环状流液膜界面扰动波湍流诱导形成机制研究[J]. 核动力工程,2021, 42(2): 77-81. doi: 10.13832/j.jnpe.2021.02.0077 [6] LEE C H, MUDAWWAR I. A mechanistic critical heat flux model for subcooled flow boiling based on local bulk flow conditions[J]. International Journal of Multiphase Flow, 1988, 14(6): 711-728. doi: 10.1016/0301-9322(88)90070-5 [7] WEISMAN J, PEI B S. Prediction of critical heat flux in flow boiling at low qualities[J]. International Journal of Heat and Mass Transfer, 1983, 26(10): 1463-1477. doi: 10.1016/S0017-9310(83)80047-7 [8] 闫美月. 竖直窄矩形通道内壁面热流分配模型的实验研究[D]. 哈尔滨: 哈尔滨工程大学, 2019. [9] GNIELINSKI V. Heat transfer coefficients for turbulent flow in concentric annular ducts[J]. Heat Transfer Engineering, 2009, 30(6): 431-436. doi: 10.1080/01457630802528661 [10] 俞胜之. 摇摆条件下自然循环系统特性研究[D]. 哈尔滨: 哈尔滨工程大学, 2018. [11] YAN M Y, HE Q C, MA Z Y, et al. Experimental investigation and a mechanical model of critical heat flux in a narrow rectangular channel[J]. Experimental Thermal and Fluid Science, 2021, 128: 110432. doi: 10.1016/j.expthermflusci.2021.110432 [12] ZUBER N, FINDLAY J A. Average volumetric concentration in two-phase flow systems[J]. Journal of Heat Transfer, 1965, 87(4): 453-468. doi: 10.1115/1.3689137 [13] 闫超星,阎昌琪,孙立成,等. 倾斜通道内泡状流空泡份额分布特性[J]. 化工学报,2014, 65(3): 855-861. doi: 10.3969/j.issn.0438-1157.2014.03.013 [14] WILMARTH T, ISHII M. Interfacial area concentration and void fraction of two-phase flow in narrow rectangular vertical channels[J]. Journal of Fluids Engineering, 1997, 119(4): 916-922. doi: 10.1115/1.2819517 [15] MISHIMA K, HIBIKI T, NISHIHARA H. Some characteristics of gas-liquid flow in narrow rectangular ducts[J]. International Journal of Multiphase Flow, 1993, 19(1): 115-124. doi: 10.1016/0301-9322(93)90027-R -

下载:

下载: