Novel Measurement Method for Shear Failure Strength of Oxide Scales on Inner Surface of Supercritical Carbon Dioxide PCHE

-

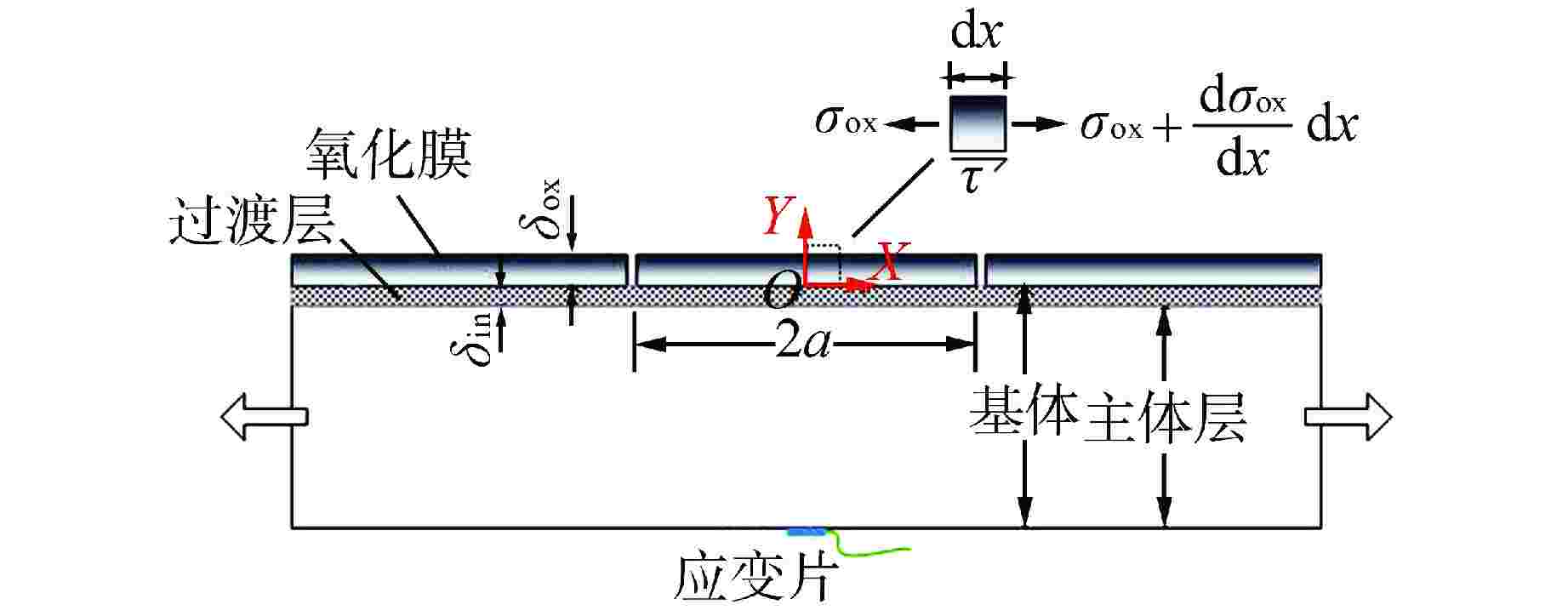

摘要: 印刷电路板式换热器(PCHE)内壁金属氧化膜脱落问题严重影响超临界二氧化碳布雷顿循环机组的安全高效运行。现有的脱落预测模型因缺少氧化膜剪切失效强度这一关键参数而难以做出准确预测。针对这一问题,对氧化膜/金属基体界面的过渡层应用弹性-线性强化力学假设,建立拉伸载荷作用下界面剪切应力演变解析模型,在此基础上,联合采用声发射技术的带氧化膜试样拉伸加载试验,提出了一种测量氧化膜剪切失效强度的新方法。分析结果表明,在不需要对氧化膜/金属基体界面处的剪切应力分布做任何预先假设的情况下,所提新方法可以准确预测氧化膜/金属基体界面的剪切应力演化过程并确定氧化膜的剪切失效强度。该方法可为构建超临界二氧化碳PCHE内壁金属氧化膜脱落判别准则和预测模型提供关键数据。

-

关键词:

- 超临界二氧化碳 /

- 印刷电路板式换热器(PCHE) /

- 氧化膜 /

- 脱落

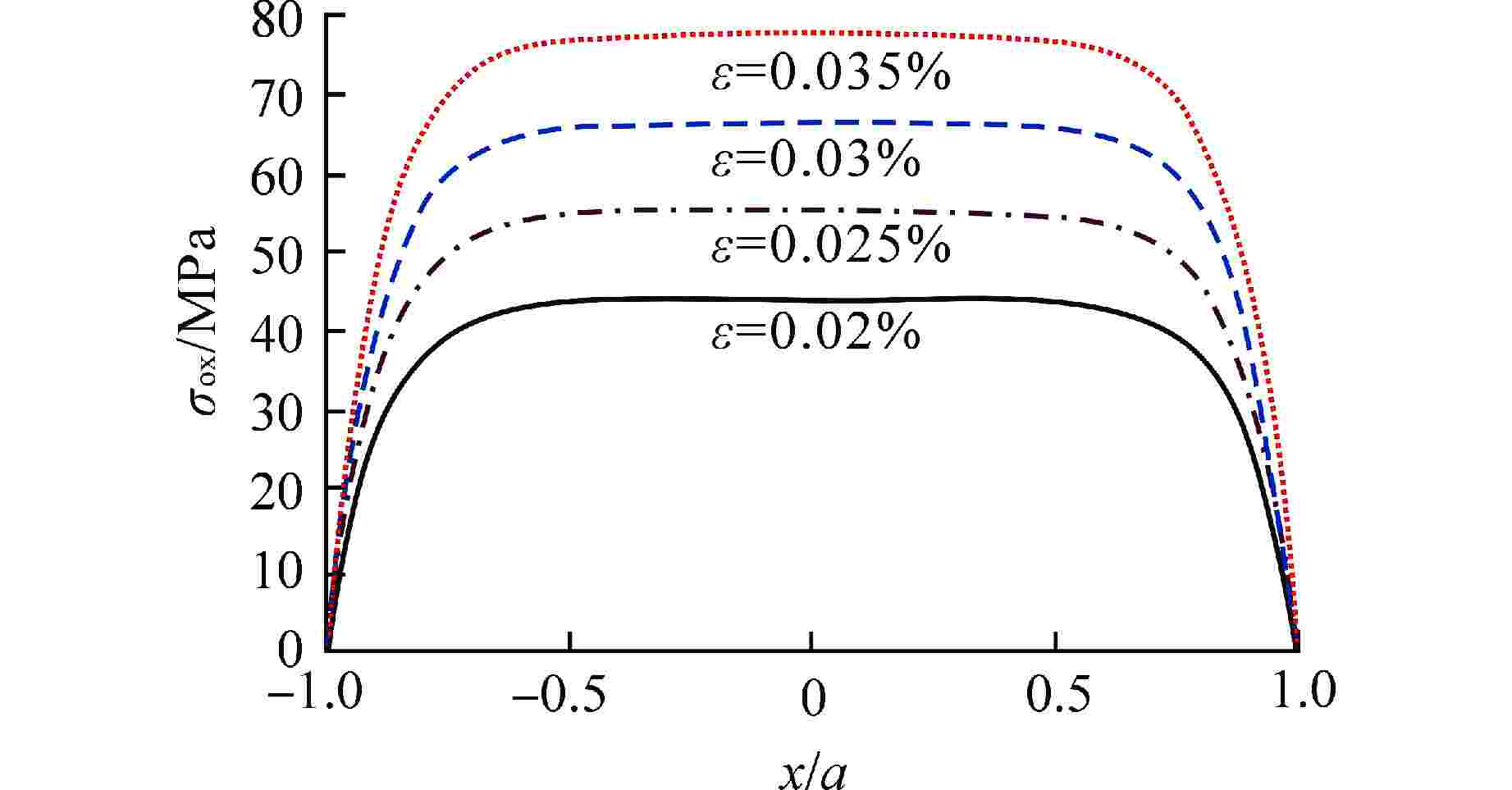

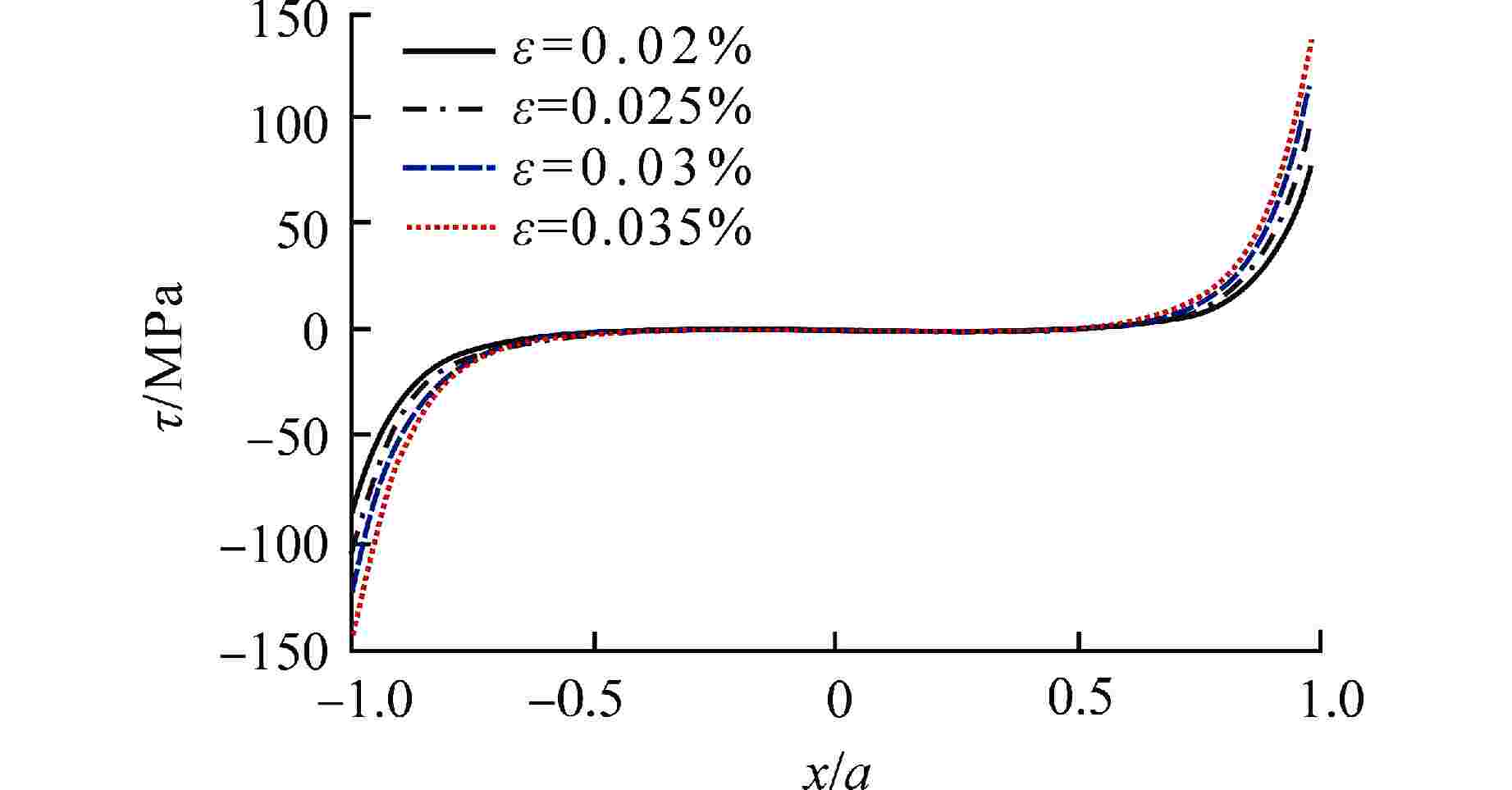

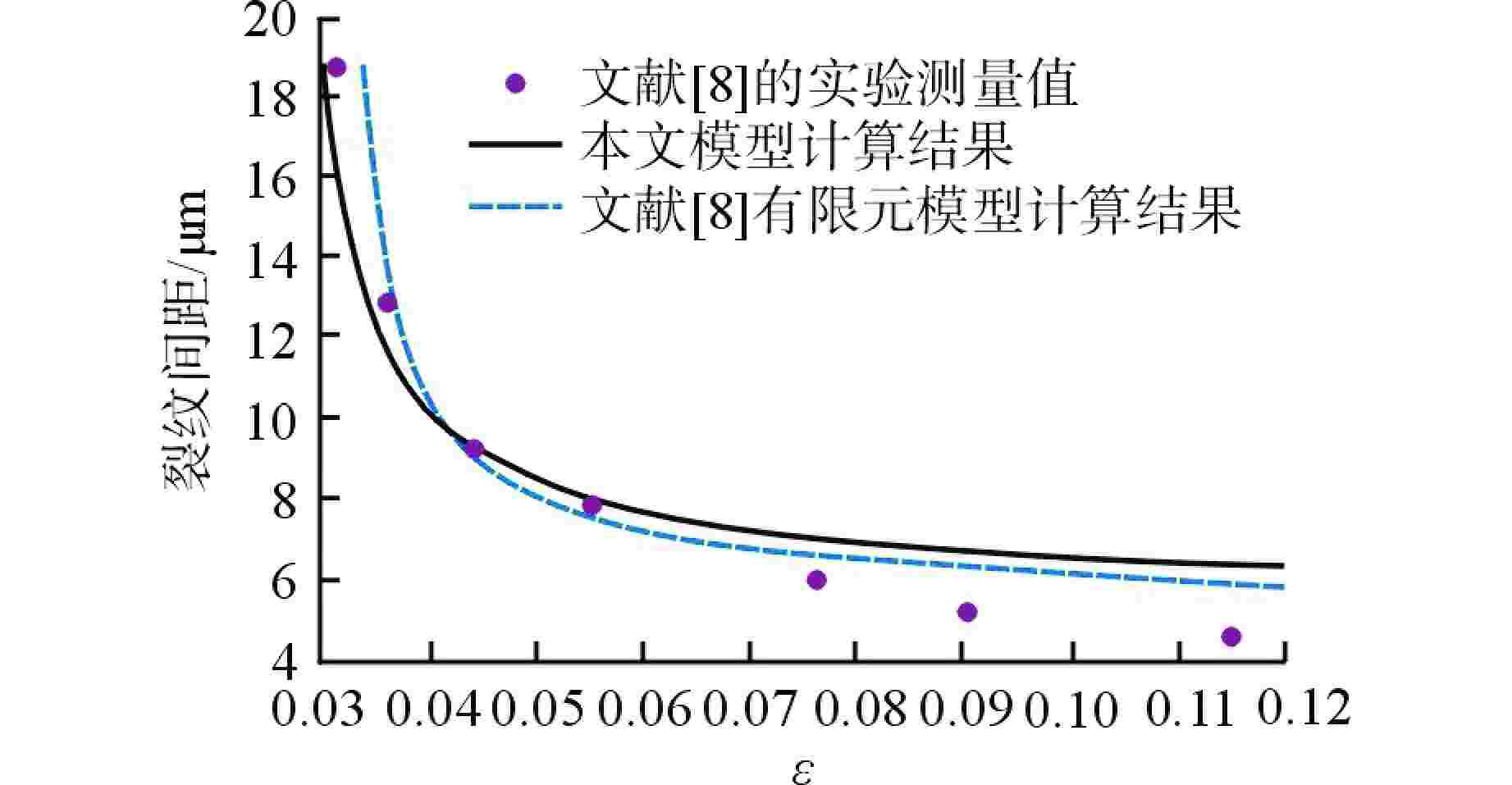

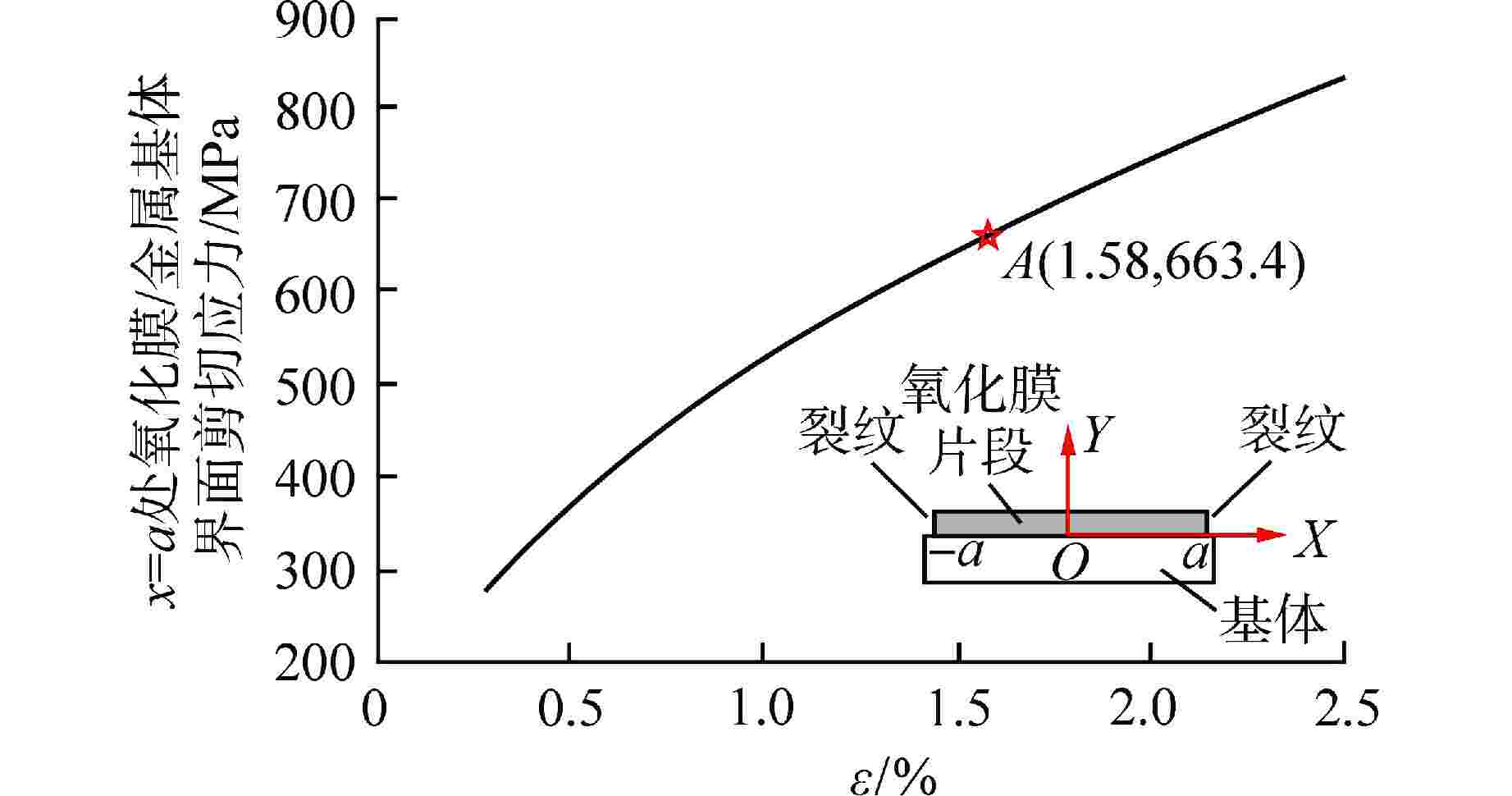

Abstract: The spalling of oxide scales formed on the inner surface of printed circuit heat exchanger (PCHE) seriously influences the safe and efficient operation of supercritical CO2 Brayton cycle units. The existing prediction model for spalling is difficult to make accurate prediction because it lacks the key parameter of shear failure strength of oxide scale. To address this issue, an analytical model for the evolution of interfacial shear stress under tensile loading was established based on the assumption of elastic-linear hardening mechanics for the transition layer at the oxide scale/substrate interface. Then, a new method for measuring the shear failure strength of the oxide scale was proposed, which involved tensile loading tests combined with acoustic emission technology and specimens with oxide scales. The results indicate that the proposed method accurately predicts the evolution of shear stress at the oxide scale/substrate interface and determines the shear failure strength of the oxide scale without making any prior assumptions about the interfacial shear stress distribution. This method can provide key data for constructing the criterion and prediction model of oxide scale spalling on the inner surface of supercritical CO2 PCHE. -

-

[1] 刘生晖,黄彦平,刘光旭,等. 不同状态方程对超临界二氧化碳强迫对流传热中流动加速因子的影响[J]. 核动力工程,2019, 40(1): 18-22. doi: 10.13832/j.jnpe.2019.01.0018 [2] TAN L, ANDERSON M, TAYLOR D, et al. Corrosion of austenitic and ferritic-martensitic steels exposed to supercritical carbon dioxide[J]. Corrosion Science, 2011, 53(10): 3273-3280. doi: 10.1016/j.corsci.2011.06.002 [3] ABE F. Research and development of heat-resistant materials for advanced USC power plants with steam temperatures of 700℃ and above[J]. Engineering, 2015, 1(2): 211-224. doi: 10.15302/J-ENG-2015031 [4] MCGUIGAN A P, BRIGGS G A D, BURLAKOV V M, et al. An elastic–plastic shear lag model for fracture of layered coatings[J]. Thin Solid Films, 2003, 424(2): 219-223. doi: 10.1016/S0040-6090(02)01124-0 [5] CHEREPANOV G P, MARTINEZ L. A computerized model for thermal stresses in thin films[J]. Computers & Structures, 1997, 63(6): 1095-1100. [6] YANG B Q, ZHANG K, CHEN G N, et al. Measurement of fracture toughness and interfacial shear strength of hard and brittle Cr coating on ductile steel substrate[J]. Surface Engineering, 2008, 24(5): 332-336. doi: 10.1179/174329408X282587 [7] COX H L. The elasticity and strength of paper and other fibrous materials[J]. British Journal of Applied Physics, 1952, 3(3): 72-79. doi: 10.1088/0508-3443/3/3/302 [8] XIE C J, TONG W. Cracking and decohesion of a thin Al2O3 film on a ductile Al-5%Mg substrate[J]. Acta Materialia, 2005, 53(2): 477-485. doi: 10.1016/j.actamat.2004.10.005 [9] AGRAWAL D C, RAJ R. Ultimate shear strengths of copper-silica and nickel-silica interfaces[J]. Materials Science and Engineering:A, 1990, 126(1-2): 125-131. doi: 10.1016/0921-5093(90)90118-M [10] HUANG J L, ZHOU K Y, WANG X M, et al. Acoustic emission analysis on tensile failure of steam-side oxide scales formed on T22 alloy superheater tubes[J]. Journal of Applied Physics, 2014, 116(4): 044907. doi: 10.1063/1.4891456 -

下载:

下载: