Research on Calculation Method of Lower Radial Bearing Clearance of Main Pump of Nuclear Power Unit

-

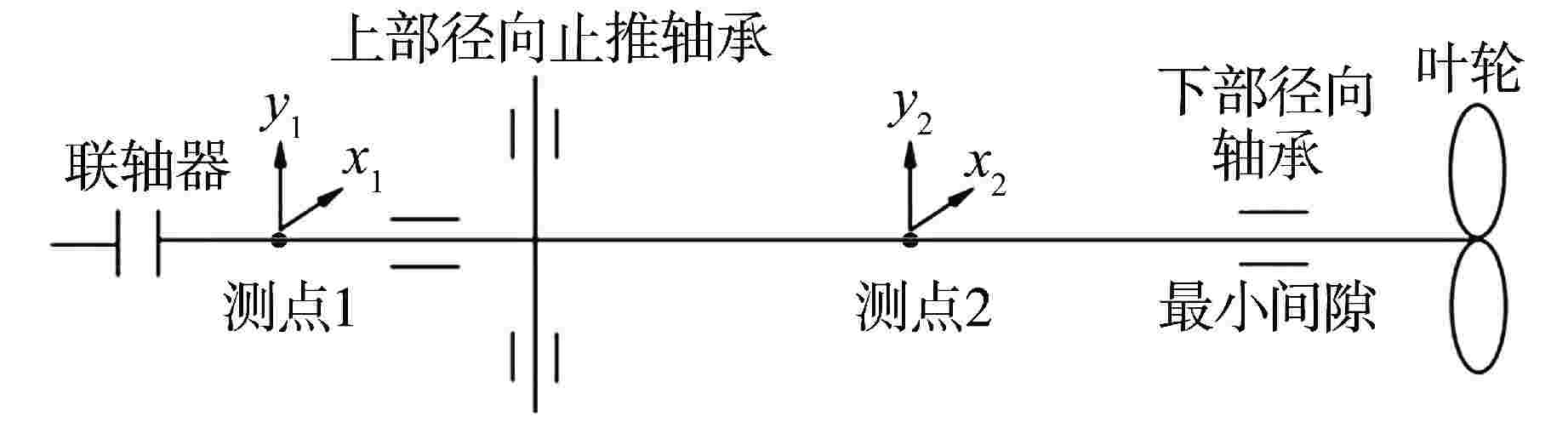

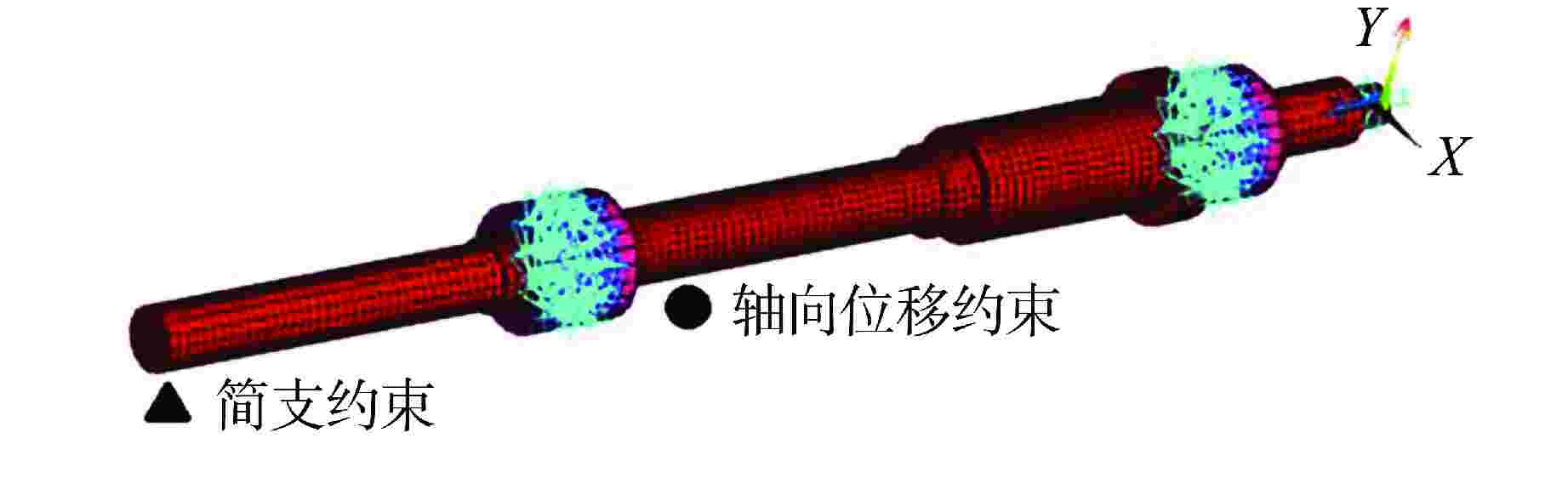

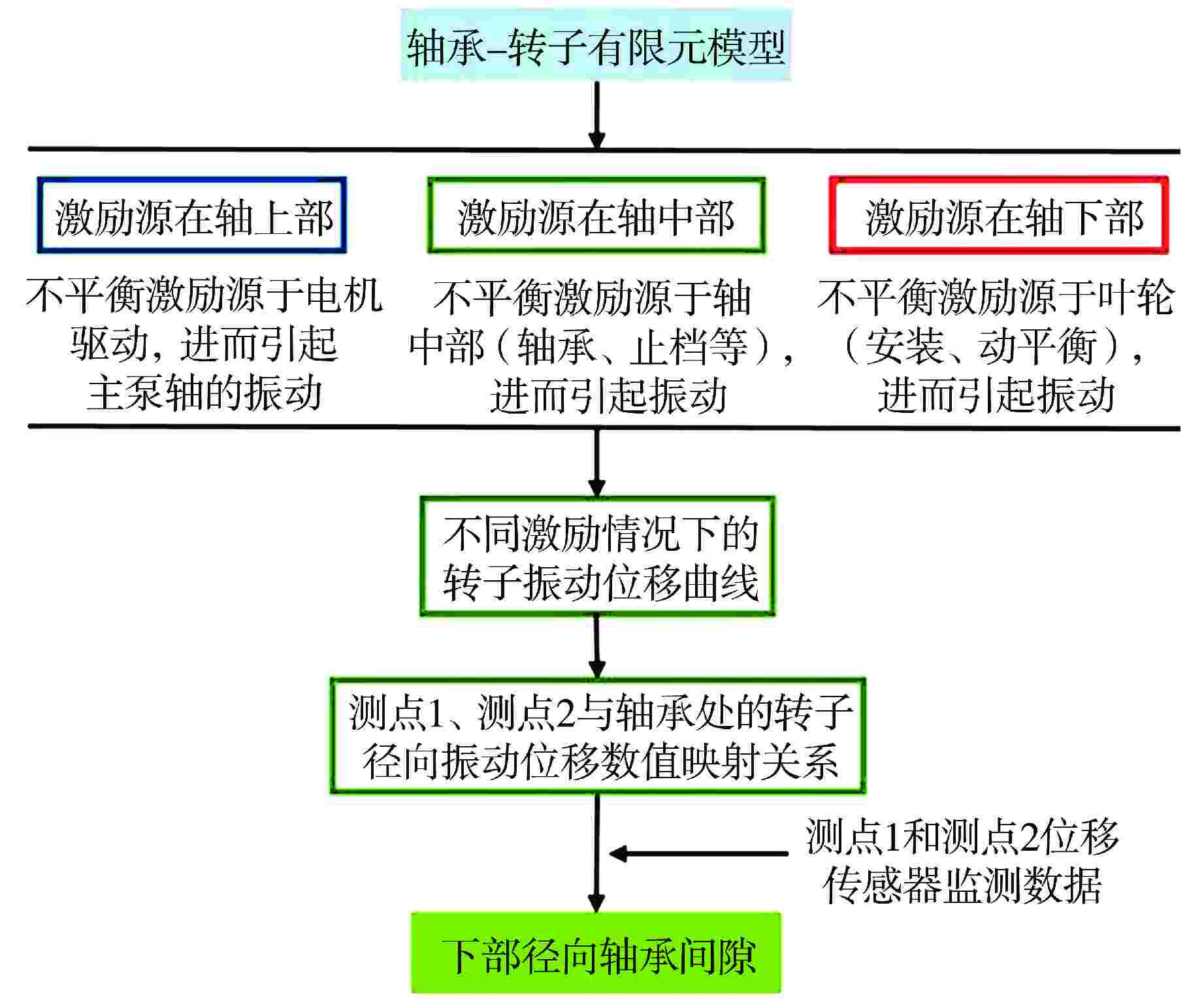

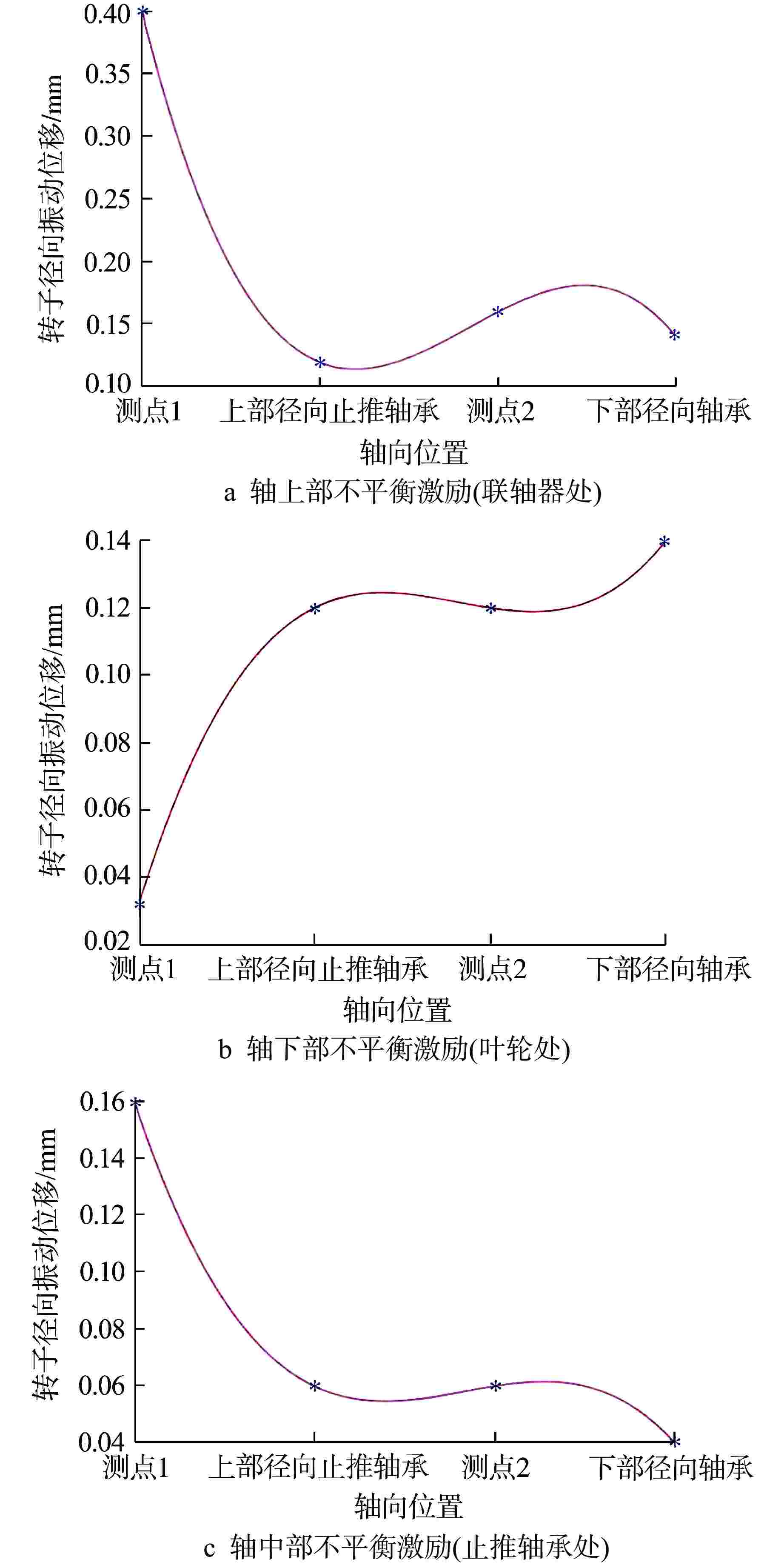

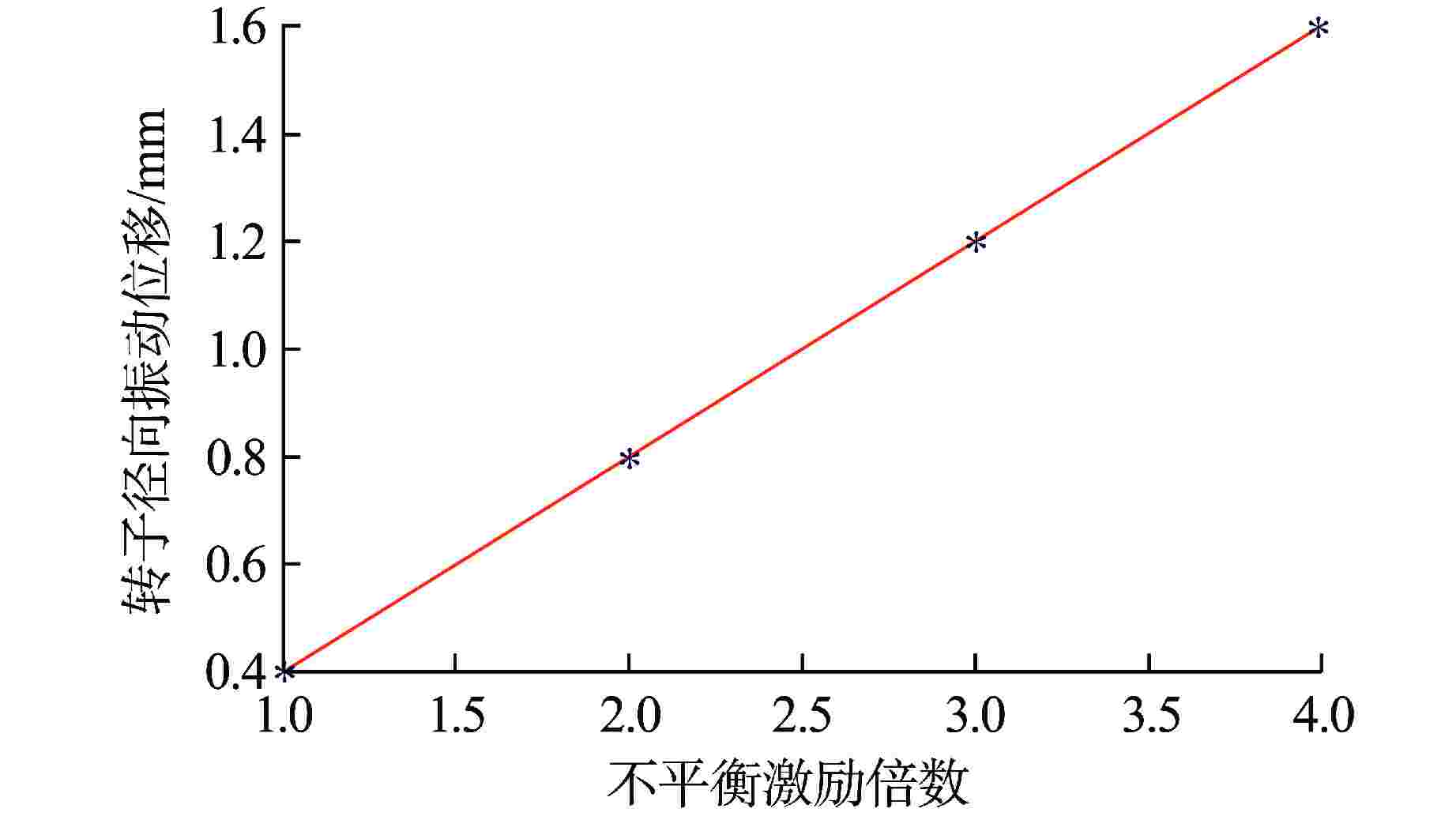

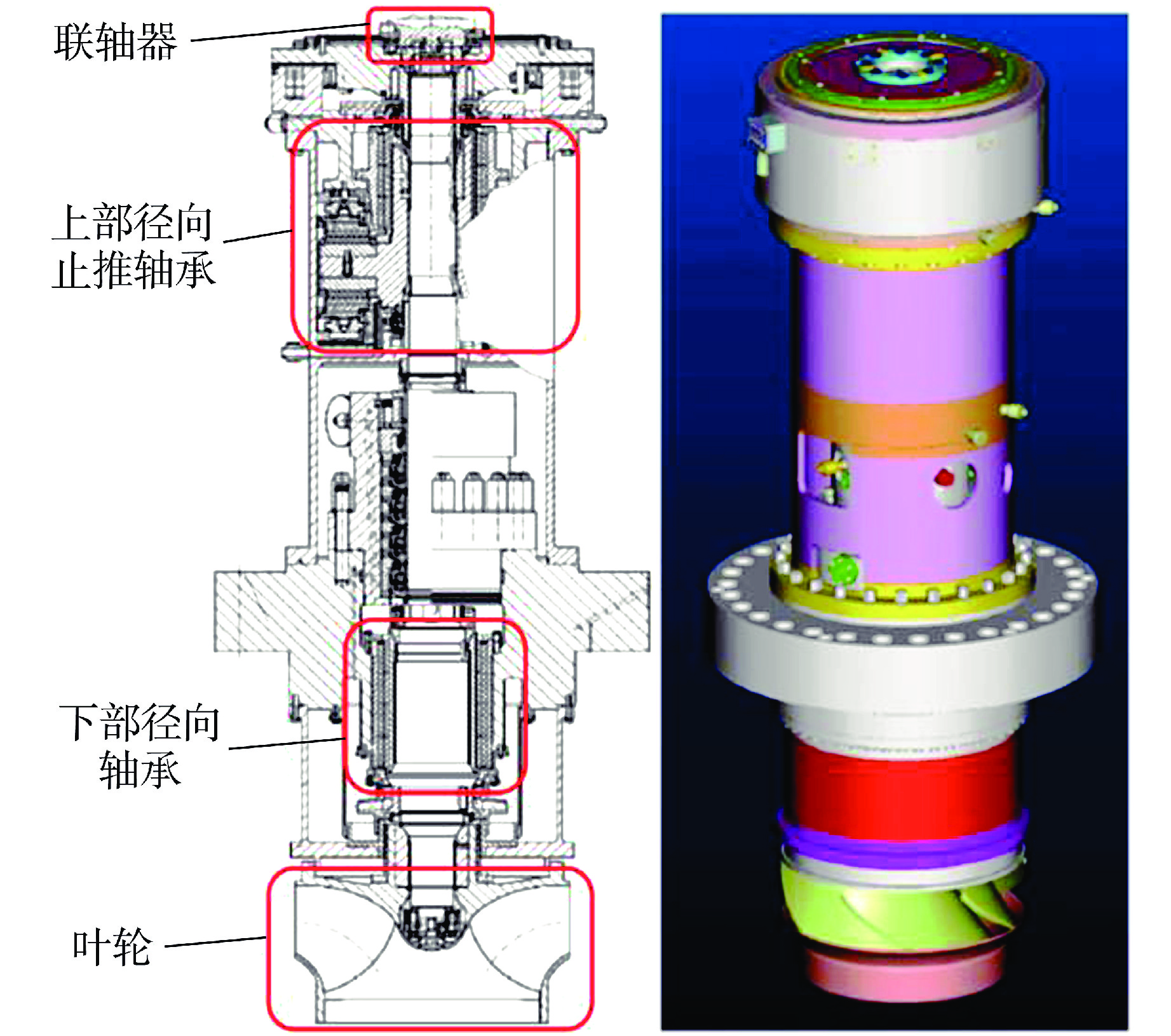

摘要: 俄罗斯百万千瓦级压水堆(VVER)核电机组主泵下部径向轴承间隙无法直接安装传感器进行监测,目前该机组采用俄供加密软件进行预测。为了解决设备老化带来的更新换代需求,需要开展主泵下部径向轴承间隙计算方法研究。首先建立了主泵轴承-转子动力学有限元模型,计算了不同位置和幅值不平衡激励下的转子径向振动位移响应,拟合得到了转子振动位移关系式。进一步结合现场已布测点的转子径向位移,建立了主泵下部径向轴承最小间隙计算方法,并开发了主泵下部径向轴承间隙计算预测软件。利用实际测量结果与软件计算结果进行了对比,结果表明,绝对误差最大为0.017 mm,误差百分比最大为 11.3%;绝对误差最小为0.001 mm,误差百分比最小为0.8%。

-

关键词:

- 主泵 /

- 径向轴承间隙 /

- 预测软件;转子动力学

Abstract: For the Russian million-kilowatt pressurized water reactor (VVER) nuclear power units, the lower radial bearing clearance of the main pump cannot be directly monitored with installed sensors, and these units currently use Russian-supplied encrypted software for predictions. To solve the upgrading demand caused by equipment aging, it is necessary to research the calculation method of the lower radial bearing clearance of the main pump. Firstly, the finite element model of bearing-rotor dynamics was built. The radial vibration displacement response of the pump rotor under unbalanced excitation at different positions and amplitudes was calculated, which was further fitted to obtain the rotor vibration displacement relationship expression. Then, combined with the rotor radial displacement at the measured points, the calculation method of the minimum clearance of the lower radial bearing was established, and the calculation and prediction software of the lower radial bearing clearance of the main pump was developed. A comparison between actual measurement results and software calculations showed that the maximum absolute error was 0.017 mm (maximum percentage error: 11.3%), while the minimum absolute error was 0.001 mm (minimum percentage error: 0.8%).-

Key words:

- Main pump /

- Radial bearing clearance /

- Predictive software, Rotor dynamics

-

表 1 轴承间隙计算预测软件验证结果

Table 1. Verification Results of Calculation Software of Bearing Clearance

序

号转子径向位移/mm 误差 测点1 测点2 下部径向轴承间隙

预测结果绝对值/mm 百分比/% 俄方软件 本研究软件 1 0.055 0.068 0.1275 0.1340 0.0065 5.1 2 0.058 0.066 0.1295 0.1260 0.0035 2.7 3 0.057 0.067 0.1305 0.1295 0.0010 0.8 4 0.063 0.067 0.1345 0.1240 0.0105 7.8 5 0.064 0.150 0.1460 0.1360 0.0100 6.8 6 0.098 0.111 0.1205 0.1175 0.0030 2.5 7 0.098 0.118 0.1215 0.1280 0.0065 5.3 8 0.069 0.151 0.1510 0.1340 0.0170 11.3 9 0.077 0.116 0.1285 0.1260 0.0025 1.9 10 0.065 0.158 0.1470 0.1385 0.0085 5.8 11 0.162 0.081 0.0770 0.0795 0.0025 3.2 12 0.154 0.085 0.0785 0.0755 0.0030 3.8 13 0.169 0.086 0.0800 0.0830 0.0030 3.8 14 0.069 0.147 0.1440 0.1470 0.0030 2.1 15 0.073 0.149 0.1475 0.1555 0.0080 5.4 -

[1] 周涛,朱勇,汤胜楠,等. 核主泵故障诊断研究现状与展望[J]. 排灌机械工程学报,2024, 42(11): 1081-1090. [2] 潘军,黎义斌,瞿泽晖,等. 华龙一号主泵卡轴事故工况瞬态过渡过程数值分析[J]. 核动力工程,2024, 45(1): 201-209. [3] 李振,袁少波. 核电厂主泵轴振异常分析[J]. 核动力工程,2019, 40(1): 167-171. [4] 陶邵佳,丛国辉,李中双,等. 核主泵水润滑径向轴承研究现状及发展趋势[J]. 水泵技术,2015(3): 14-16. [5] 张剑,孙建胜,尹峰,等. 滑动轴承稳定性研究与应用[J]. 设备管理与维修,2013(9): 41-42. [6] 魏维,郭文勇,吴新跃,等. 考虑间隙影响的滑动轴承稳定性分析[J]. 润滑与密封,2018, 43(10): 18-22. [7] 张海英,黄忠,焦少阳,等. 核电主泵轴瓦磨损原因分析[J]. 核动力工程,2022, 43(2): 108-111. [8] 章朝栋,余文念,张路. 考虑瓦块磨损的可倾瓦径向轴承-转子系统动态特性研究[J]. 振动与冲击,2024, 43(11): 255-263. [9] 姚刚. 田湾核电站多机组群堆运行的安全管理策略与实践[J]. 核动力工程,2024, 45(5): 206-212. [10] 陈伯贤,裘祖干,张慧生. 流体润滑理论及其应用[M]. 北京: 机械工业出版社,1991: 390. [11] 谢劲松,杨飞,訾艳阳. 磨损水润滑橡胶轴承承载特性研究[J]. 振动与冲击,2020, 39(24): 225-231,270. -

下载:

下载: