Experimental Study on Quench Temperature Characteristics During Reflooding in an Annular Channel

-

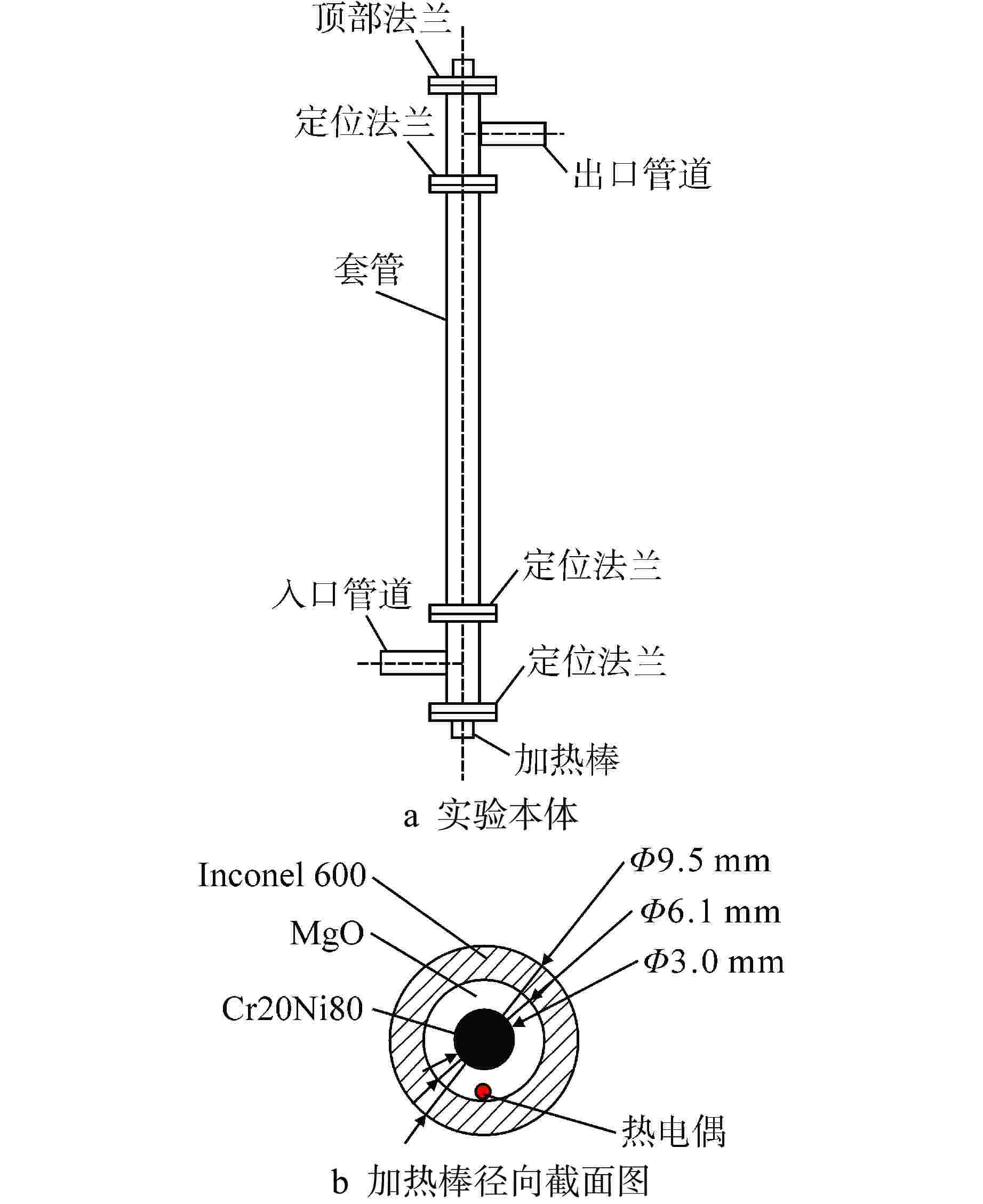

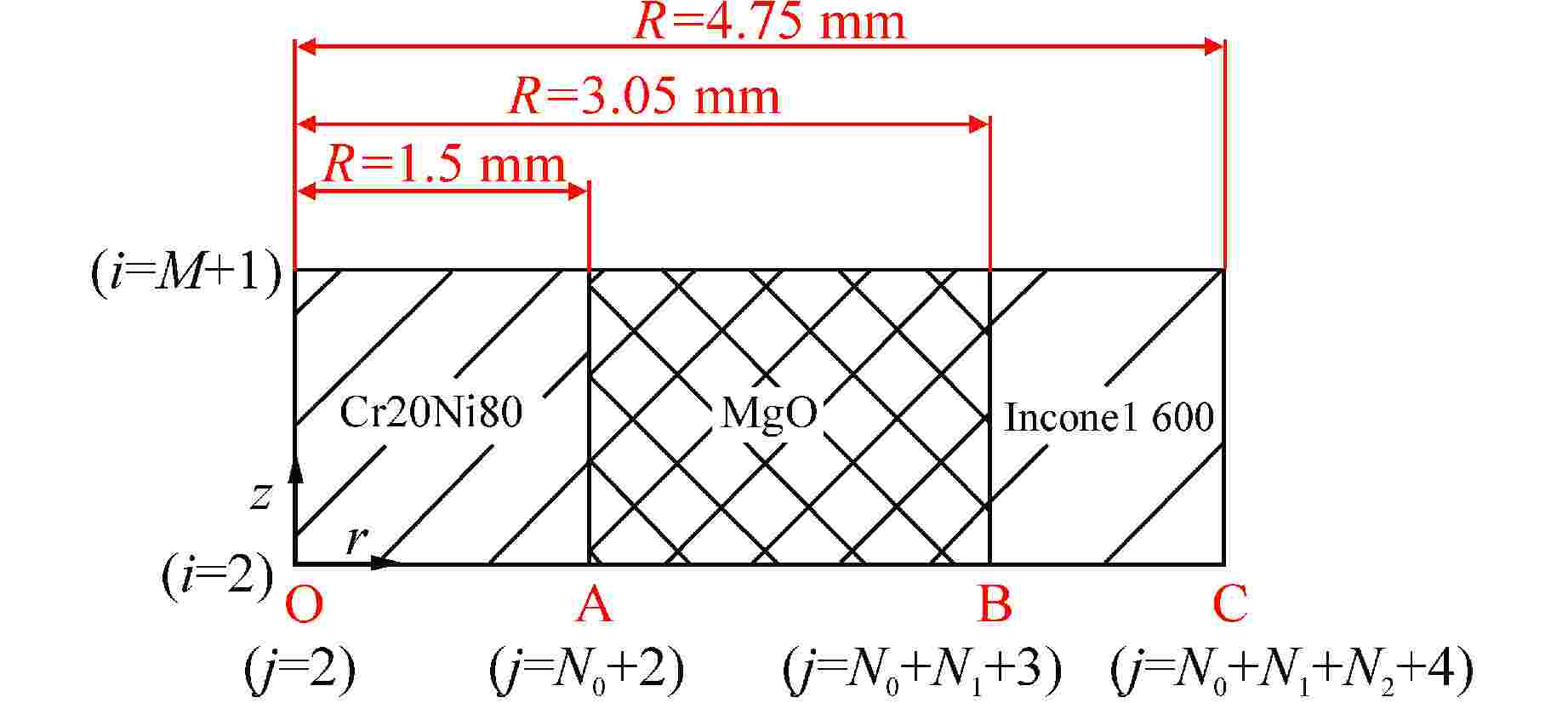

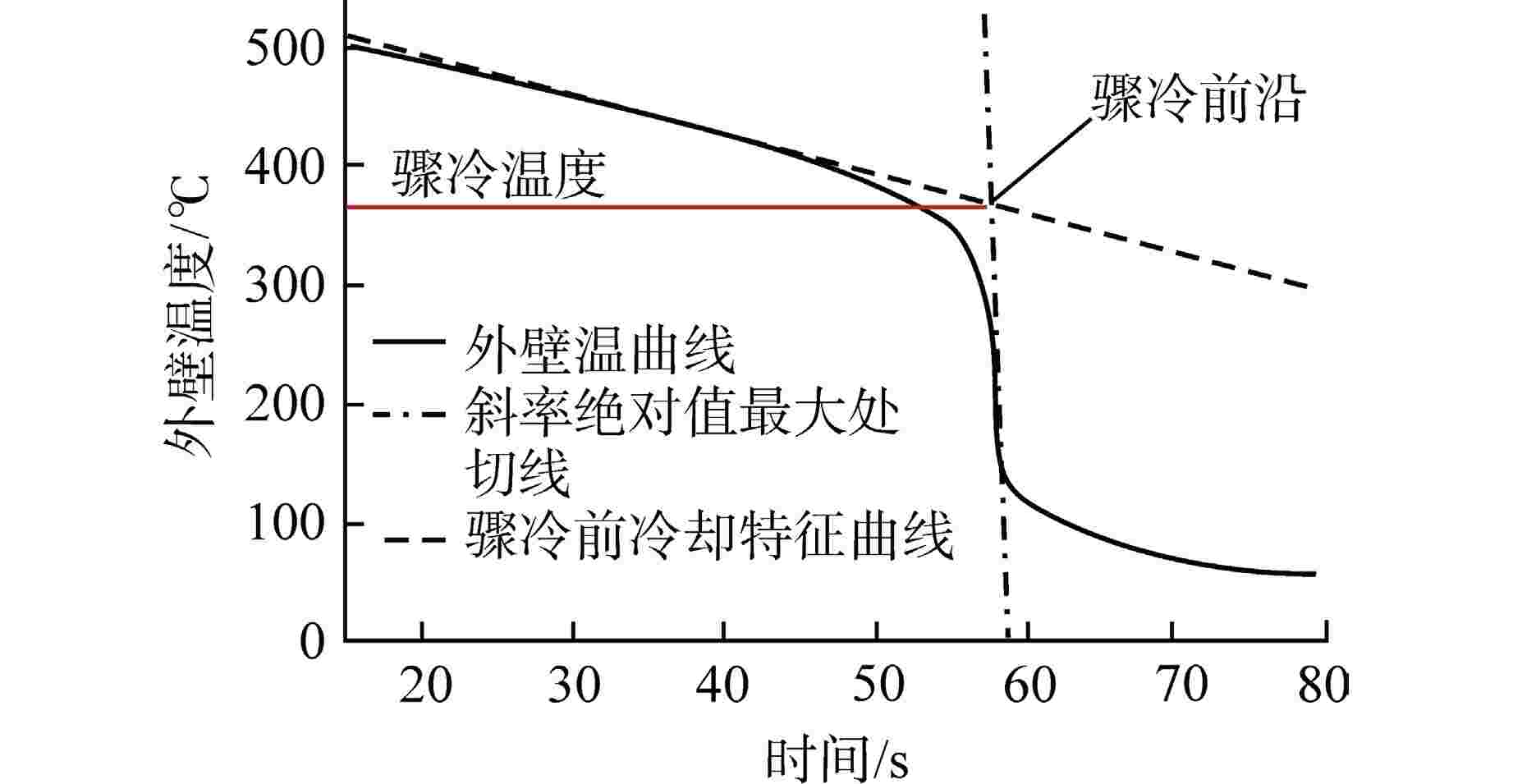

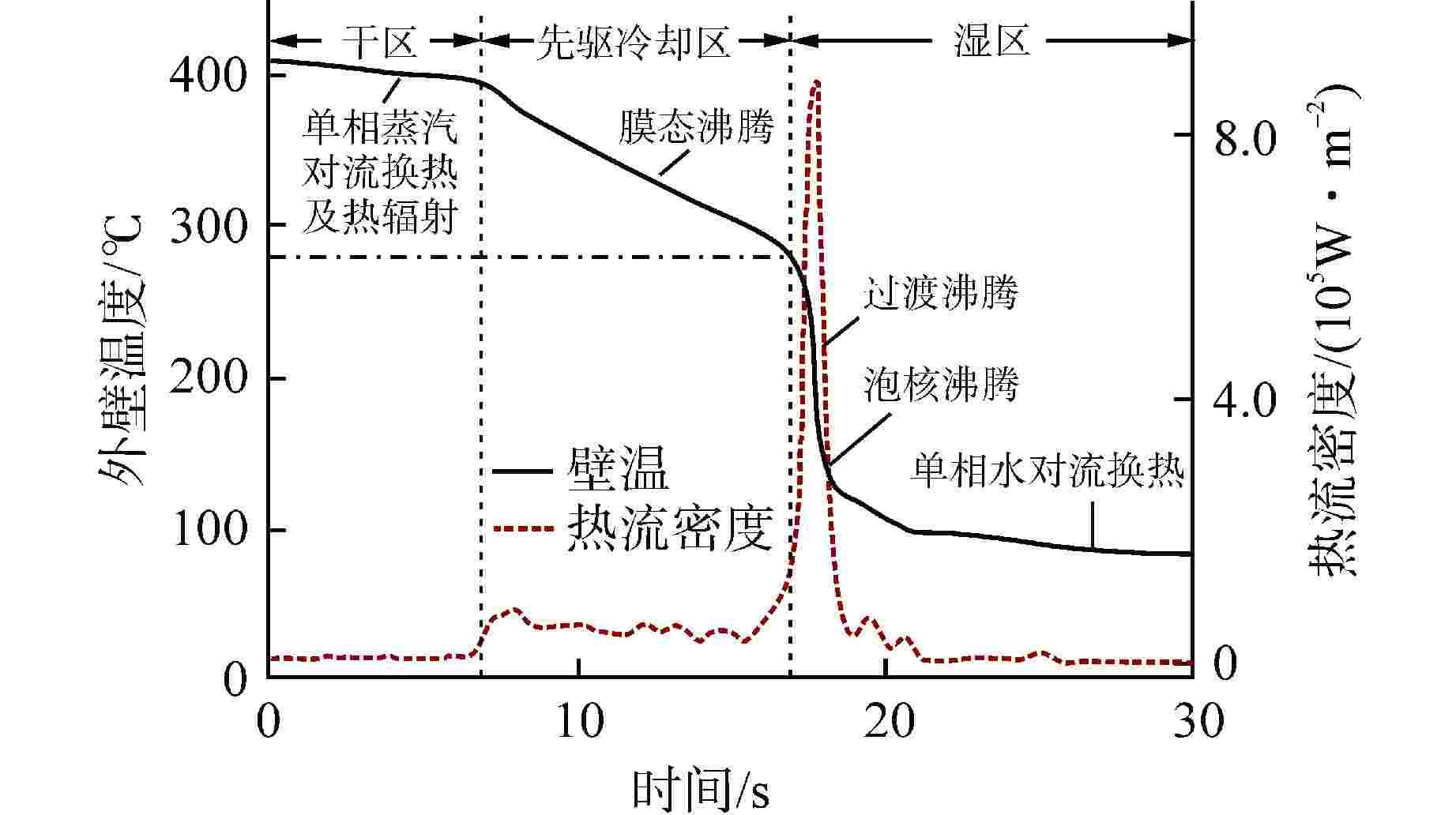

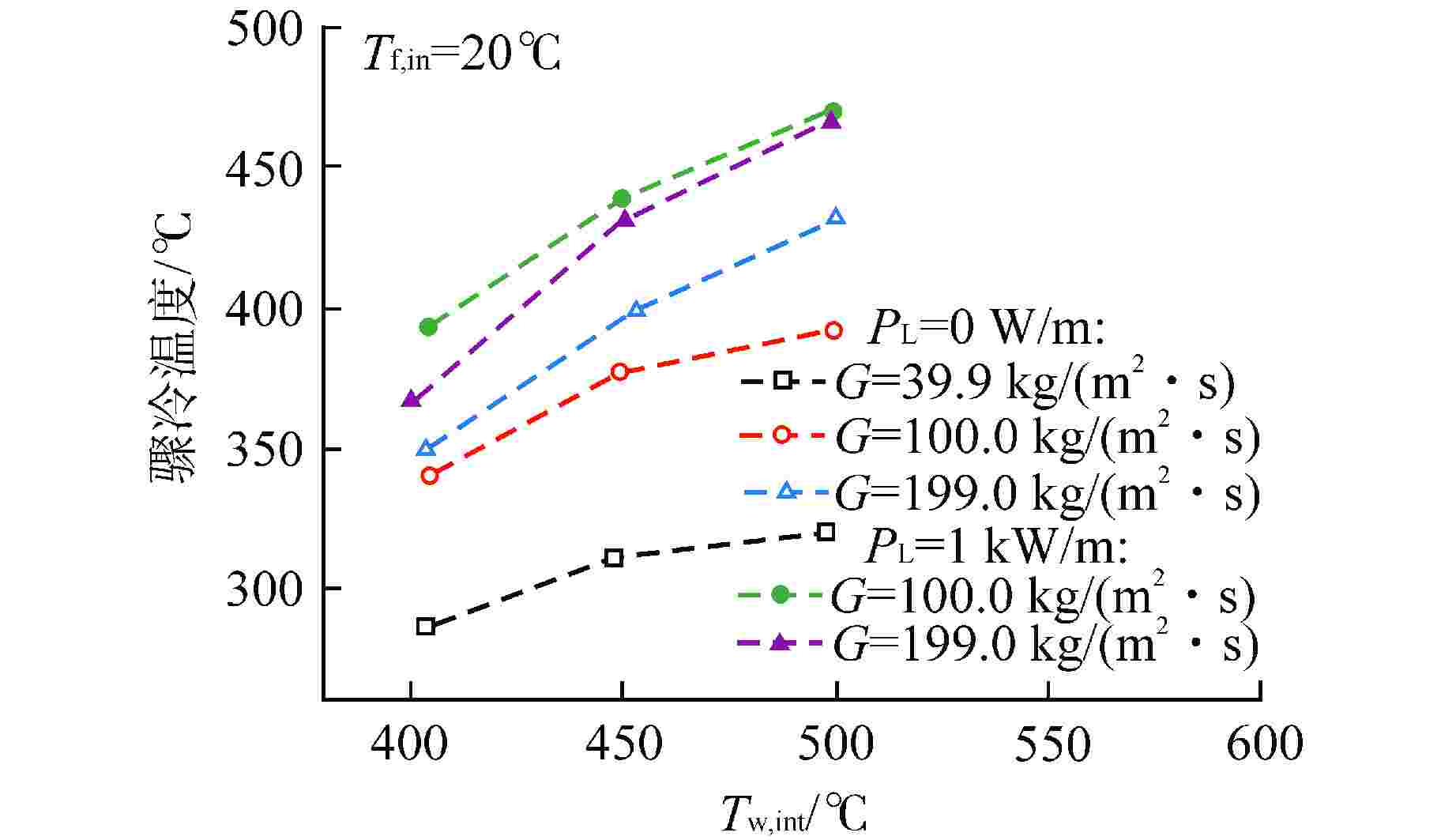

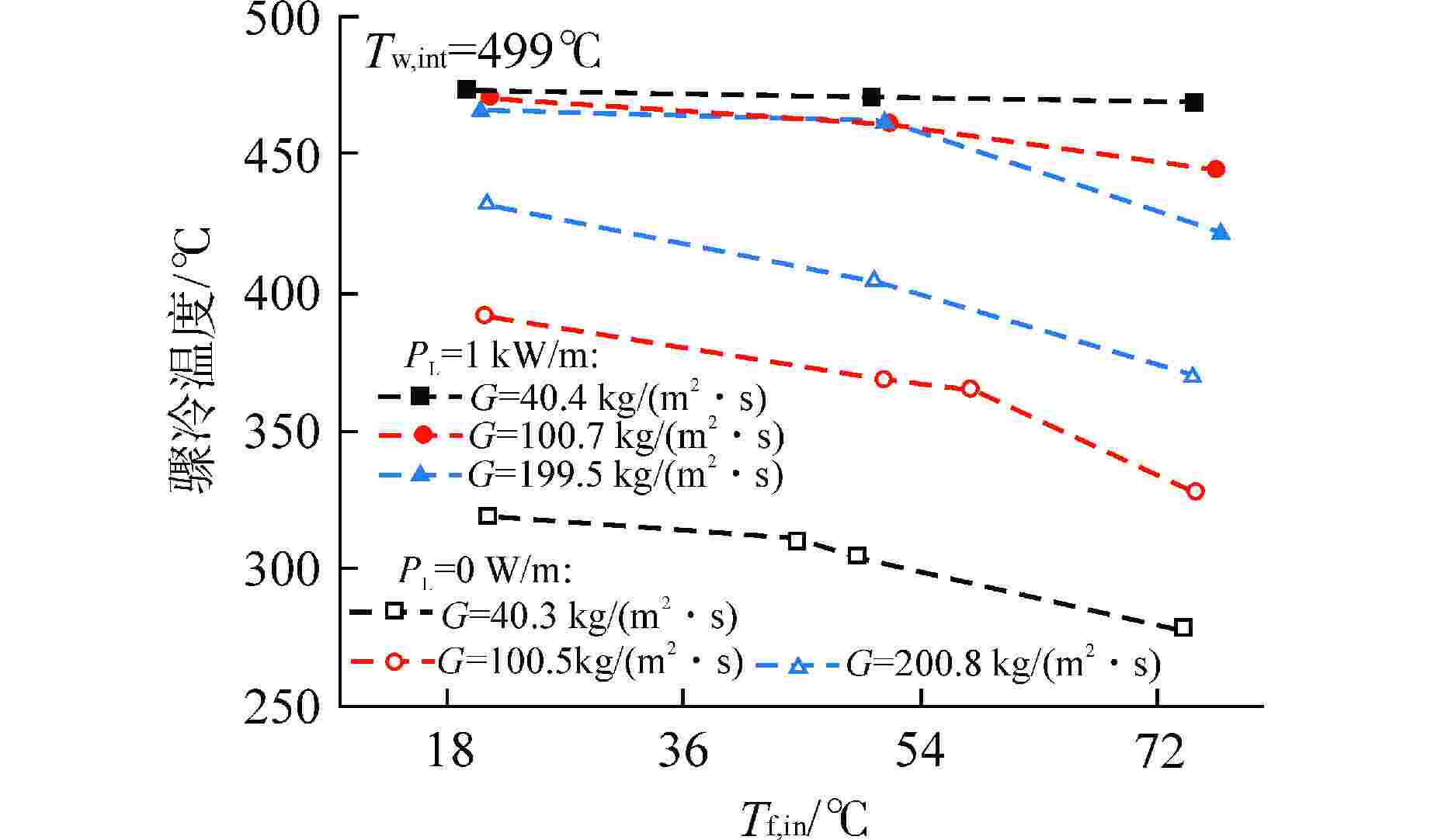

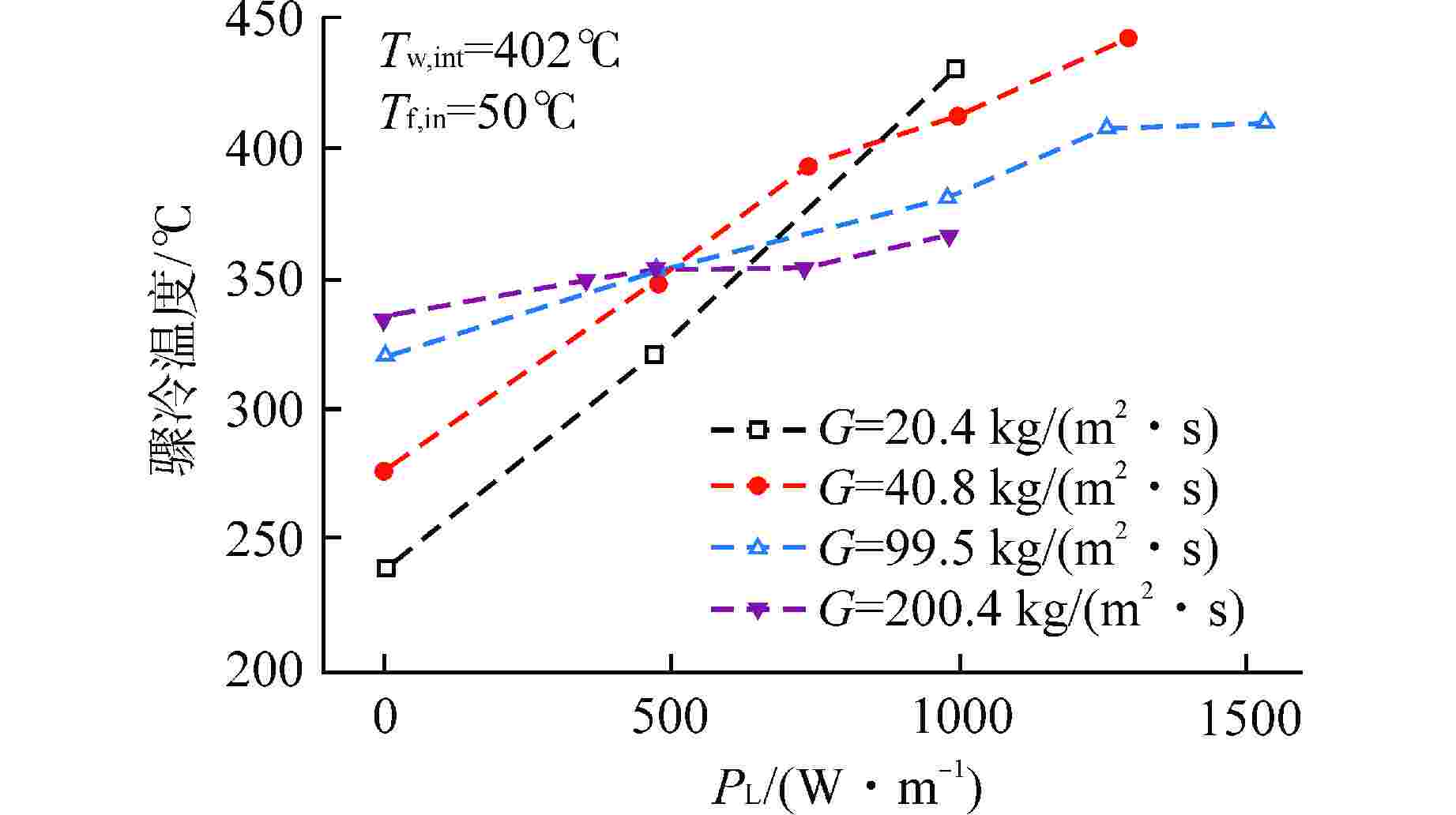

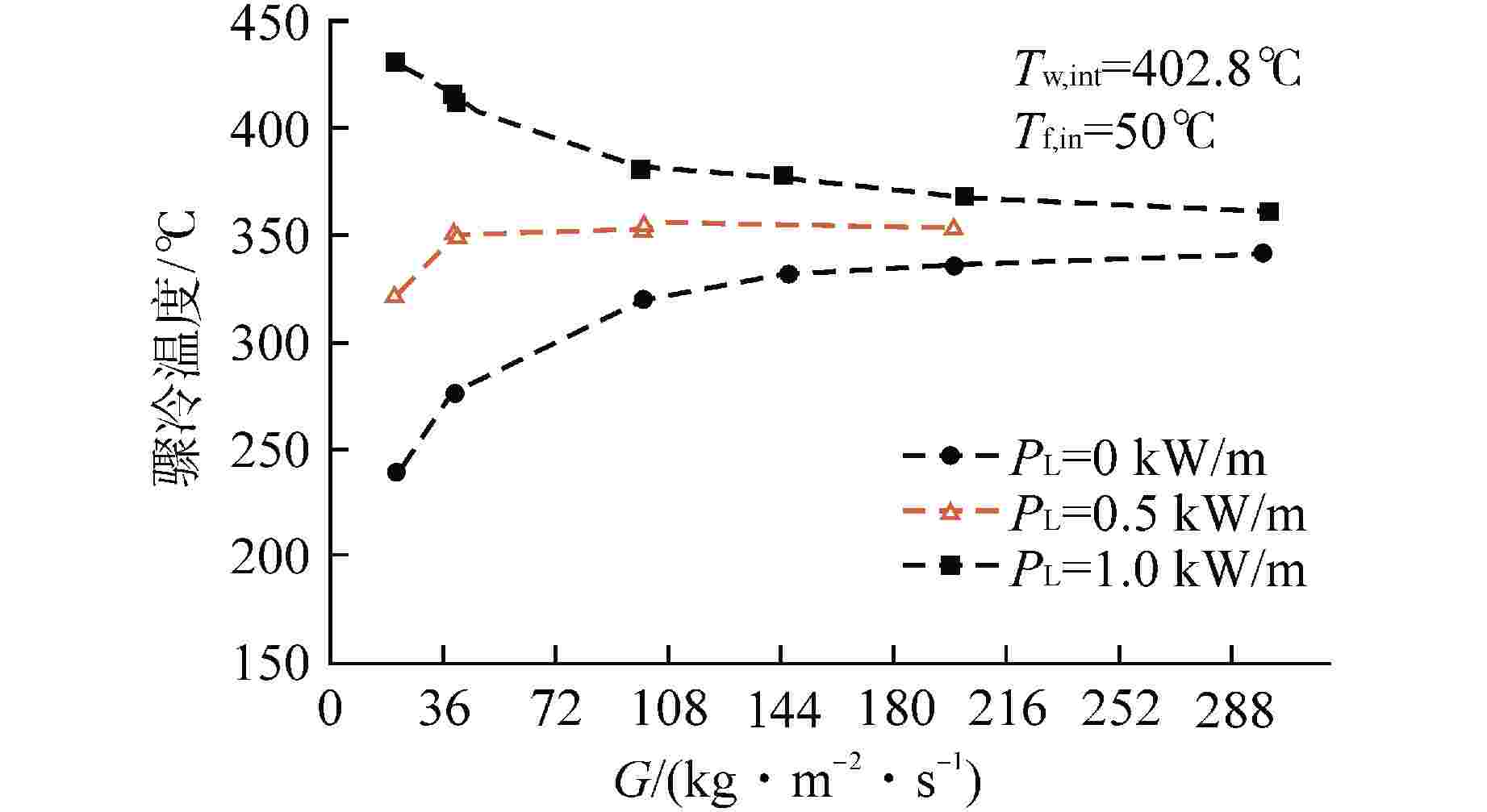

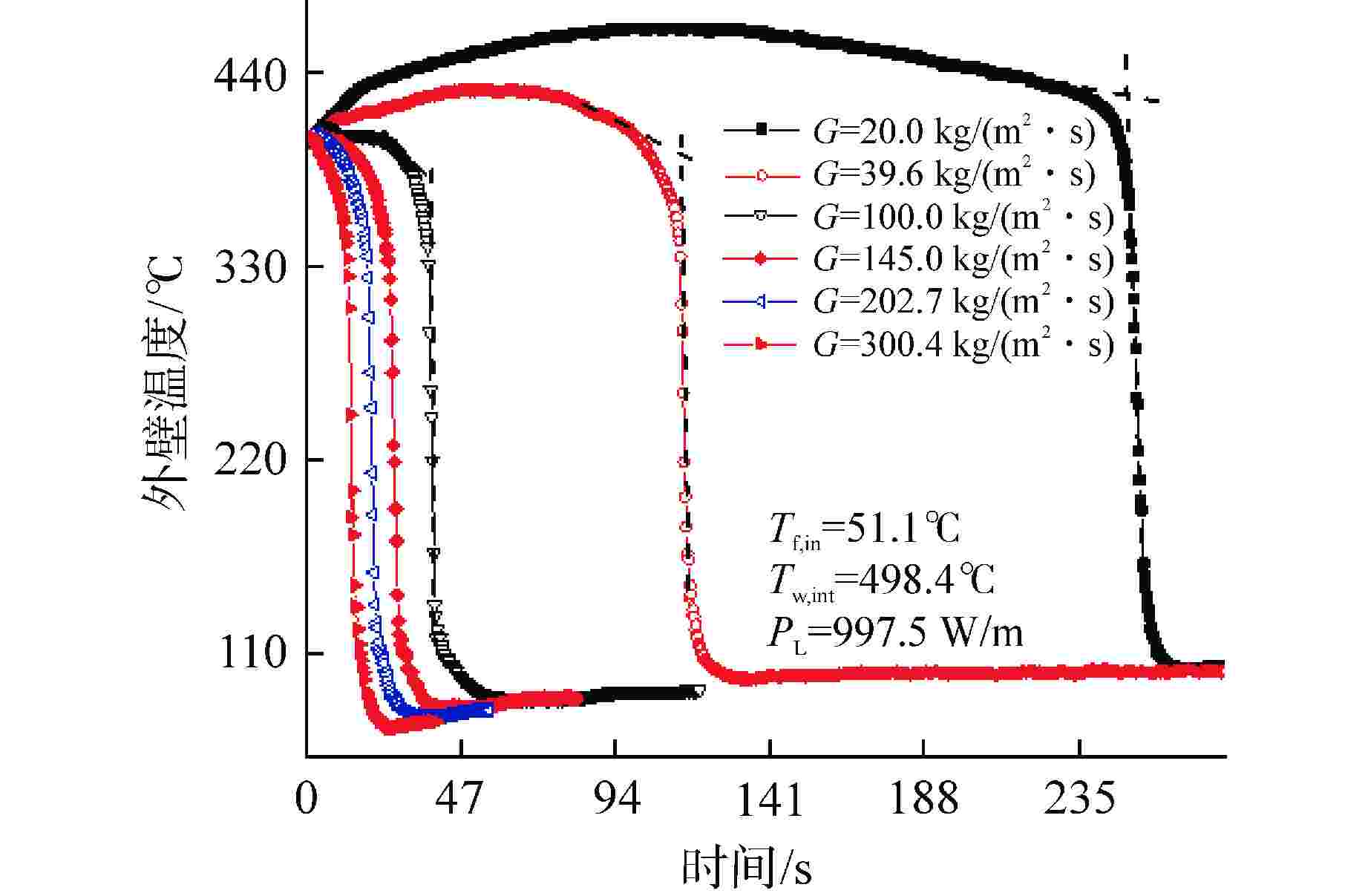

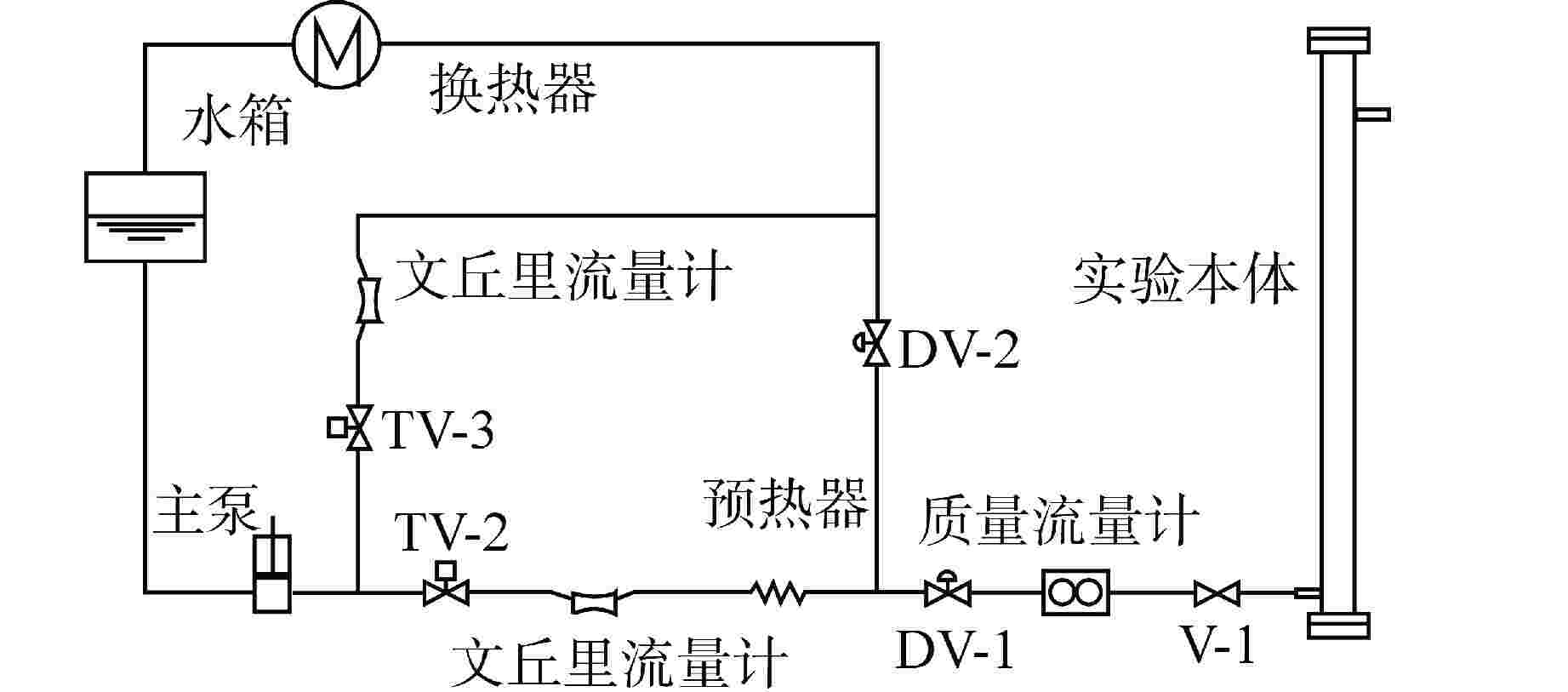

摘要: 堆芯再淹没过程中骤冷温度是发生骤冷的主要标志,表征了燃料元件表面开始发生骤冷的起始壁温,对骤冷温度的研究有助于骤冷机理研究和骤冷模型开发。本研究通过实验分析了环形通道内再淹没骤冷温度特性,获得了初始壁温、入口温度、入口质量流速、加热功率对骤冷温度的影响。实验结果表明:骤冷温度随初始壁温和加热功率的增加、入口温度的减小而增加;加热功率会削弱入口温度对骤冷温度的影响程度;加热功率较小时,骤冷温度随入口质量流速的增加而增加,加热功率较大时,骤冷温度随入口质量流速的增加而减小。Abstract: Quench temperature is a key indicator of quenching in the process of core reflooding, and it characterizes the initial wall temperature at the onset of quenching on the fuel element surface. Study of quench temperature is helpful to understand quench mechanism and develop quench models. Based on an experimental study of characteristics of quench temperature in a vertical annual channel, the influences of initial wall temperature, inlet coolant temperature, inlet mass flow rate, and heating power density on quench temperature were investigated. The results show that the quench temperature increases with the increase of initial wall temperature and heating power and the decrease of inlet coolant temperature. Heating power weakens the effect of inlet coolant temperature on quench temperature. At lower heating power, quench temperature increases with the increase of inlet mass flow rate; at higher heating power, quench temperature decreases with the increase of mass flow rate.

-

Key words:

- Annular channel /

- Reflooding /

- Quench temperature

-

-

[1] CHEN W J, LEE Y, GROENEVELD D C. Measurement of boiling curves during rewetting of a hot circular duct[J]. International Journal of Heat and Mass Transfer, 1979, 22(6): 973-976. doi: 10.1016/0017-9310(79)90039-5 [2] KIM A K, LEE Y. A correlation of rewetting temperature[J]. Letters in Heat and Mass Transfer, 1979, 6(2): 117-123. doi: 10.1016/0094-4548(79)90003-1 [3] KAMINAGA F, UCHIDA H. Reflooding phenomena in a single heated rod: Part1, experimental study[J]. Bulletin of JSME, 1979, 22(169): 960-966. doi: 10.1299/jsme1958.22.960 [4] CHO S, MOON S K, CHOI K Y, et al. Rewetting of vertical hot surface in a centrally heated annulus and a 6x6 rod bundle geometry during reflood phase[C]//Proceedings of the 14th International Conference on Nuclear Engineering. Miami: Nuclear Engineering Division, 2006. [5] NAITOH M, CHINO K, OGASAWARA H. Cooling mechanism during transient reflooding of a reactor fuel bundle after loss of coolant[J]. Nuclear Engineering and Design, 1977, 44(2): 193-200. doi: 10.1016/0029-5493(77)90026-7 [6] LEE Y, SHEN W Q. Effect of coolant vapor quality on rewetting phenomena[J]. International Journal of Heat and Mass Transfer, 1985, 28(1): 139-146. doi: 10.1016/0017-9310(85)90015-8 [7] CHO S, MOON S K, CHUN S Y, et al. Spacer grid effects during a reflood in an annulus flow channel[J]. Journal of Nuclear Science and Technology, 2007, 44(7): 967-976. doi: 10.1080/18811248.2007.9711336 [8] 颜迪民,王健伟,许国华. 套管底部淹没时的再湿传热与夹带特性[J]. 工程热物理学报,1986, 7(4): 355-357. [9] WANG S T, SEBAN R A. Heat transfer during the quench process that occurs in the reflood of a single vertical tube[J]. International Journal of Heat and Mass Transfer, 1988, 31(6): 1189-1198. doi: 10.1016/0017-9310(88)90062-2 [10] 颜迪民,许国华,周润彬,等. 管状试验段底部淹没时的再湿传热[J]. 工程热物理学报,1985, 6(1): 63-65. -

下载:

下载: