Study on Numerical Simulation Method of Three-Dimensional Flow Field of Spiral Coil Tube Bundle in Lead-Bismuth Medium

-

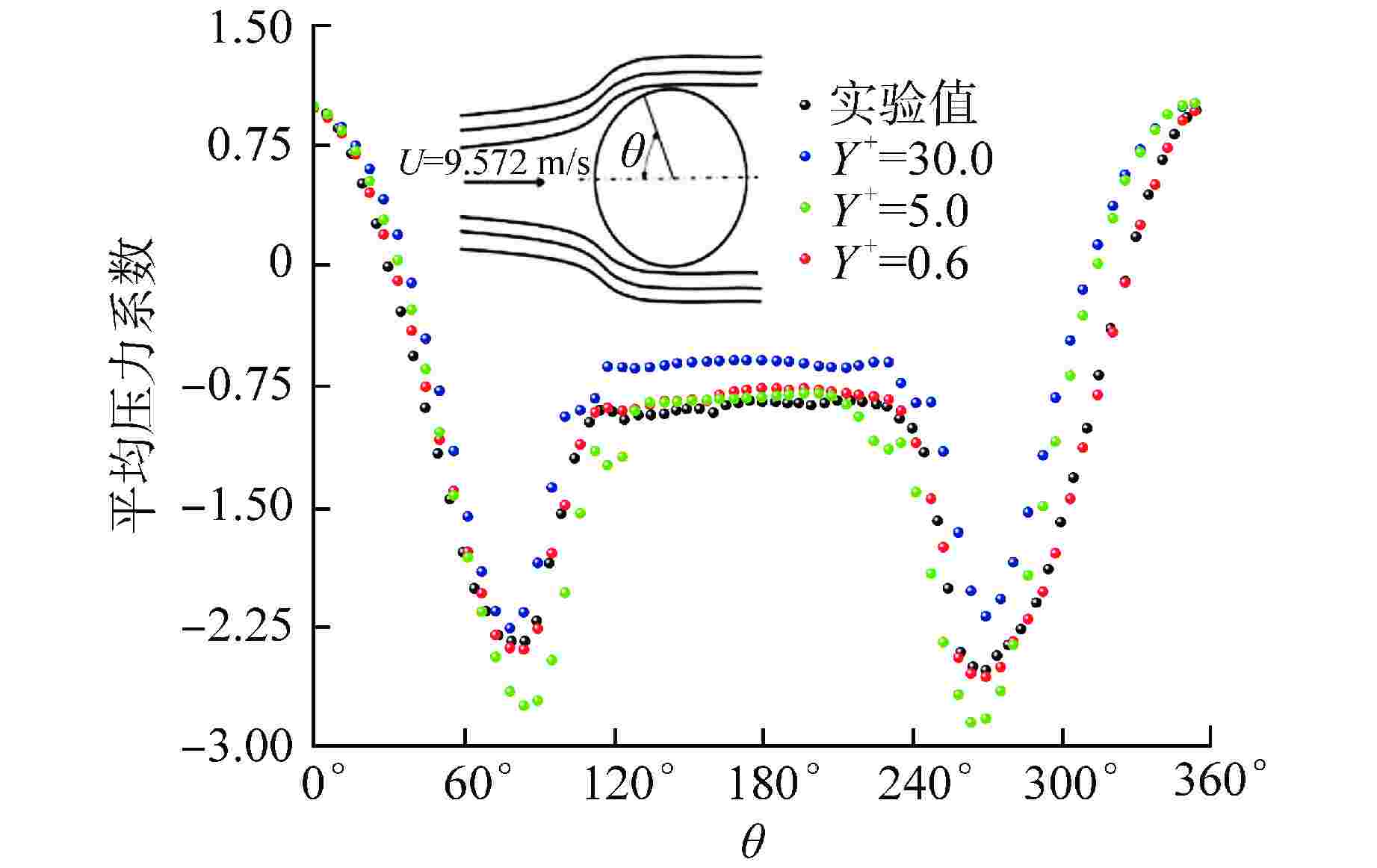

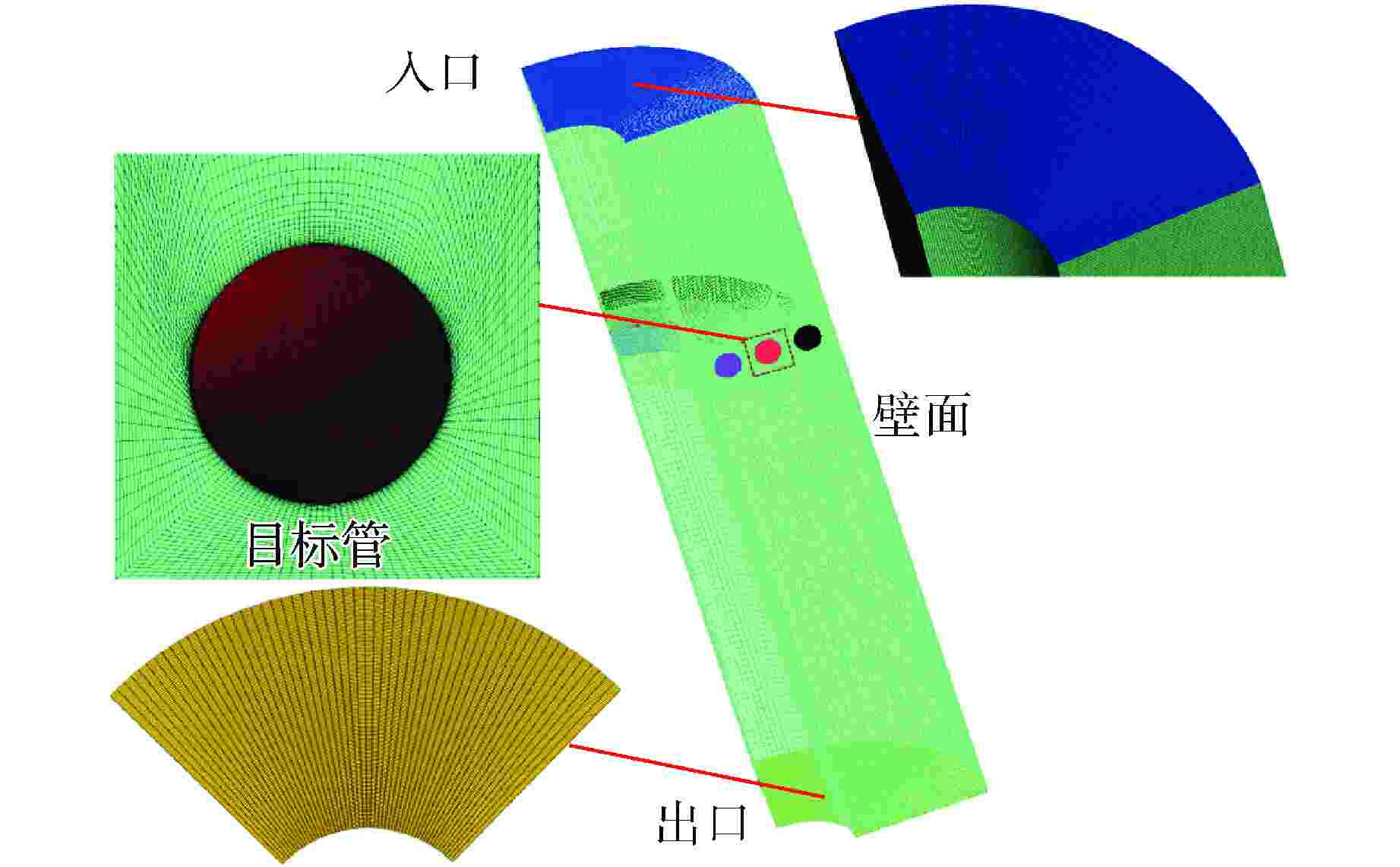

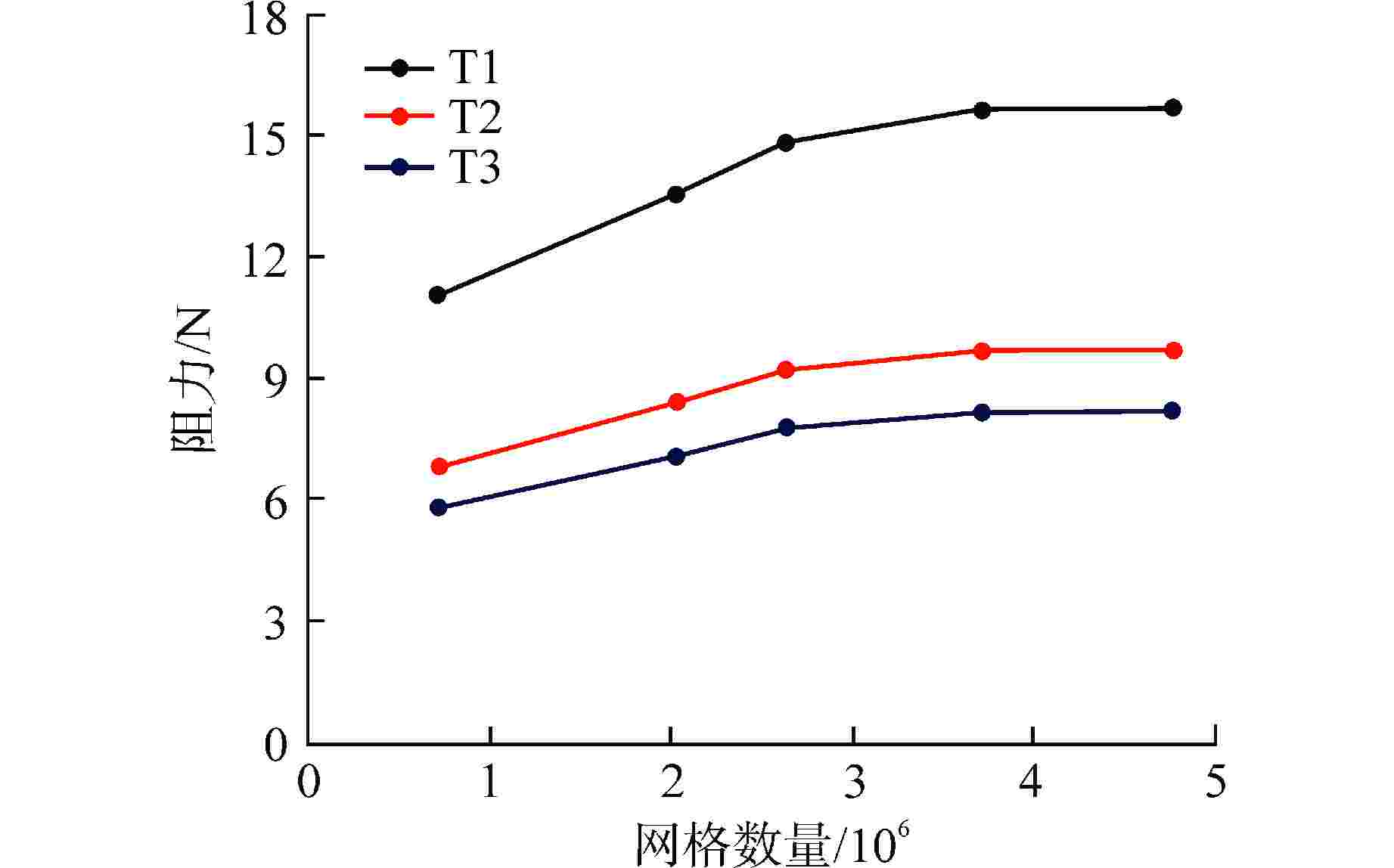

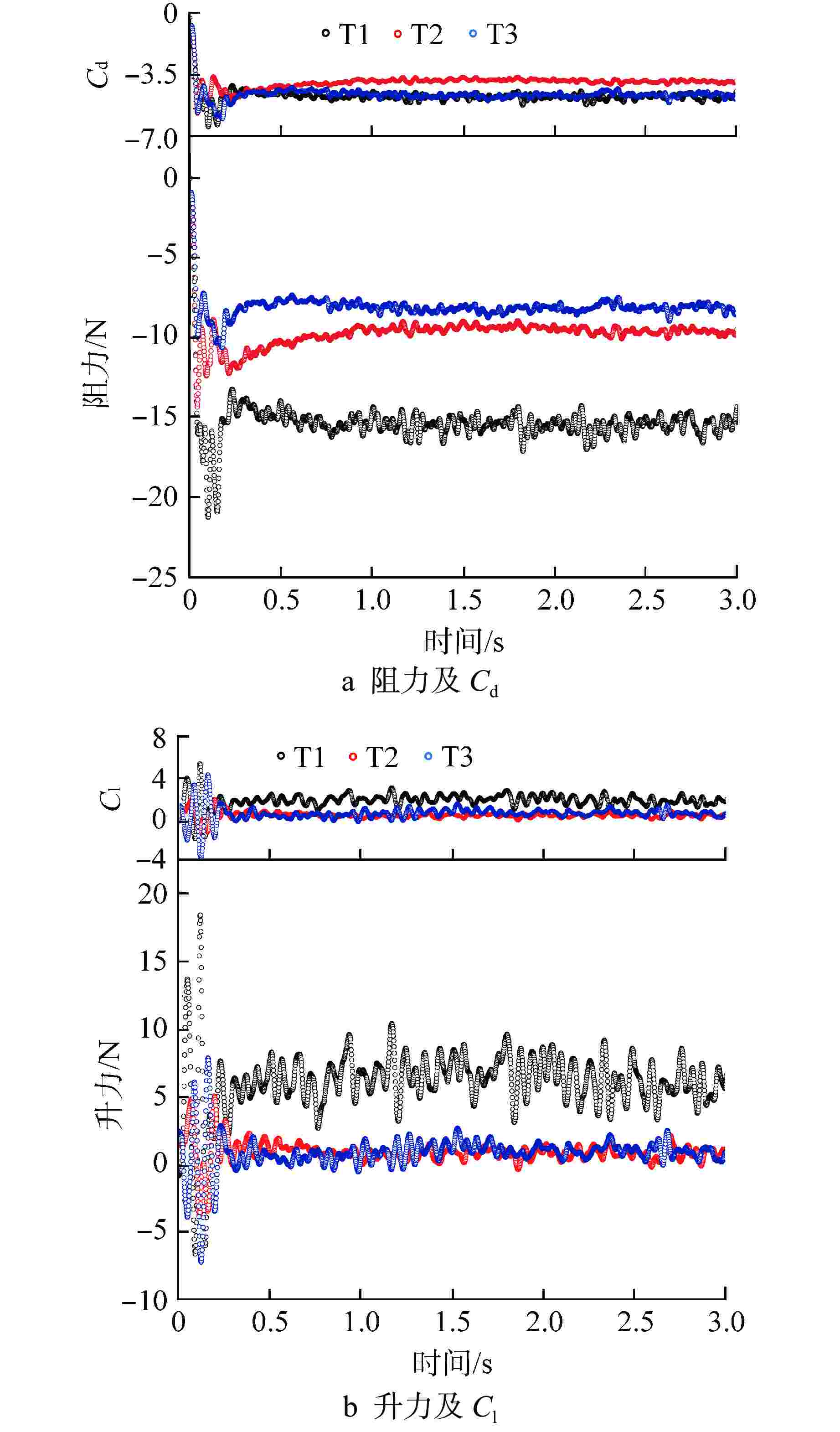

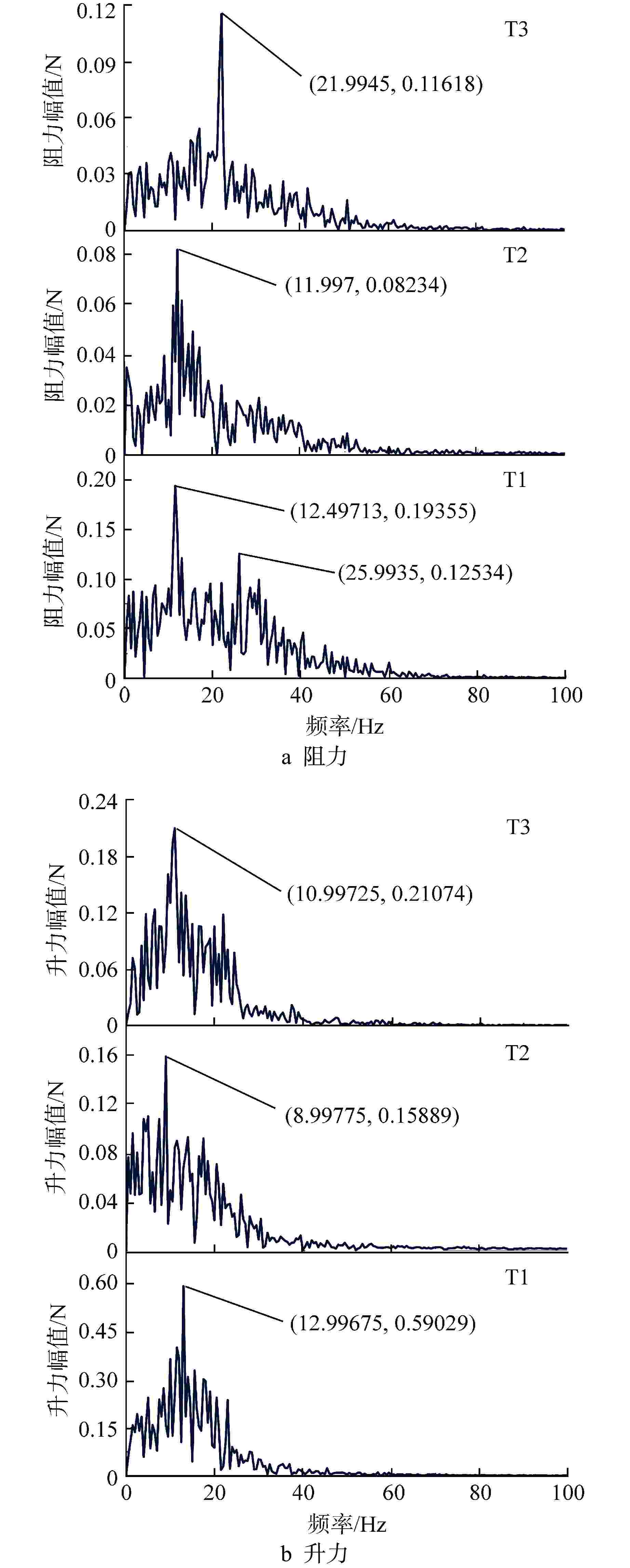

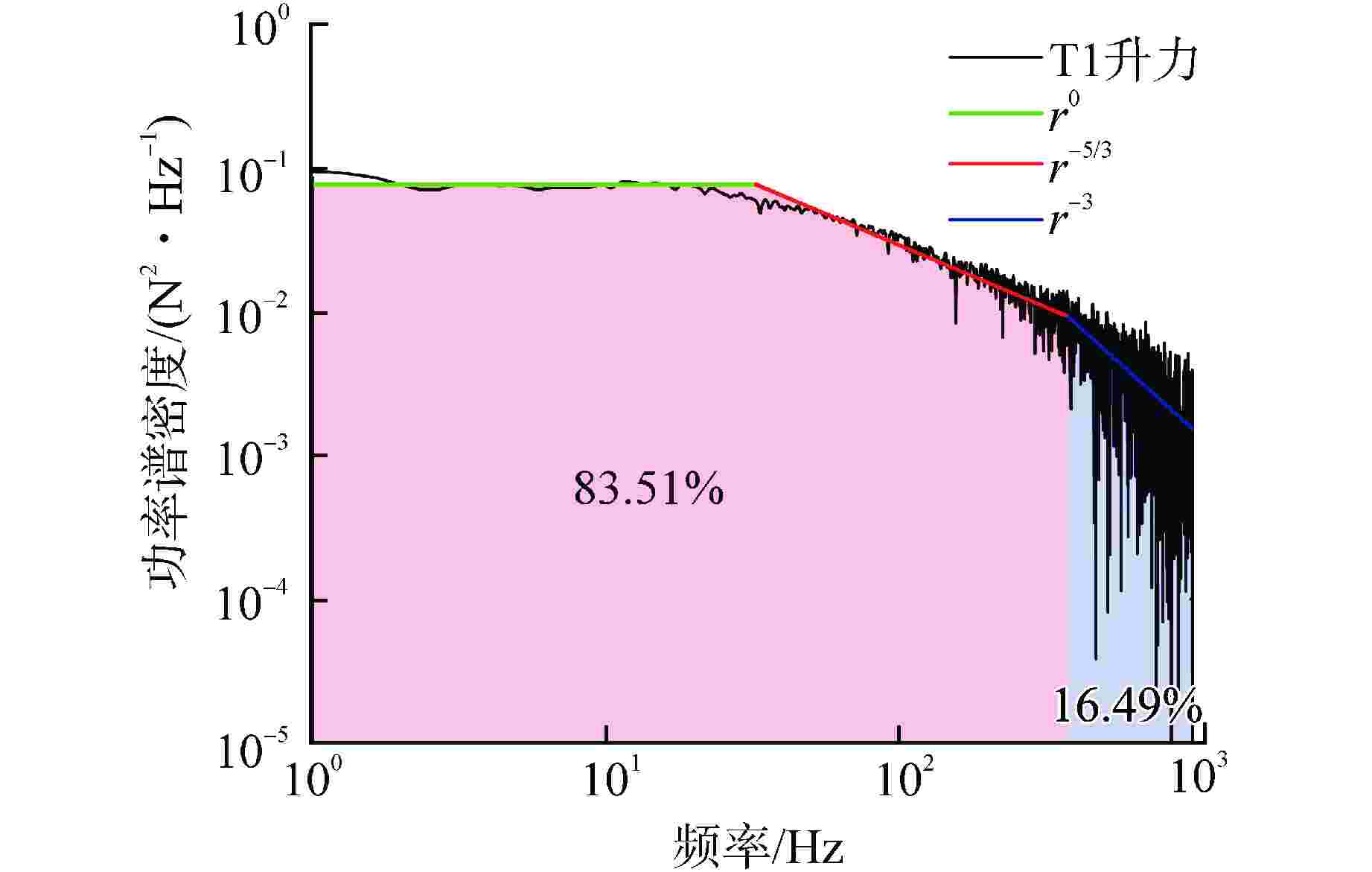

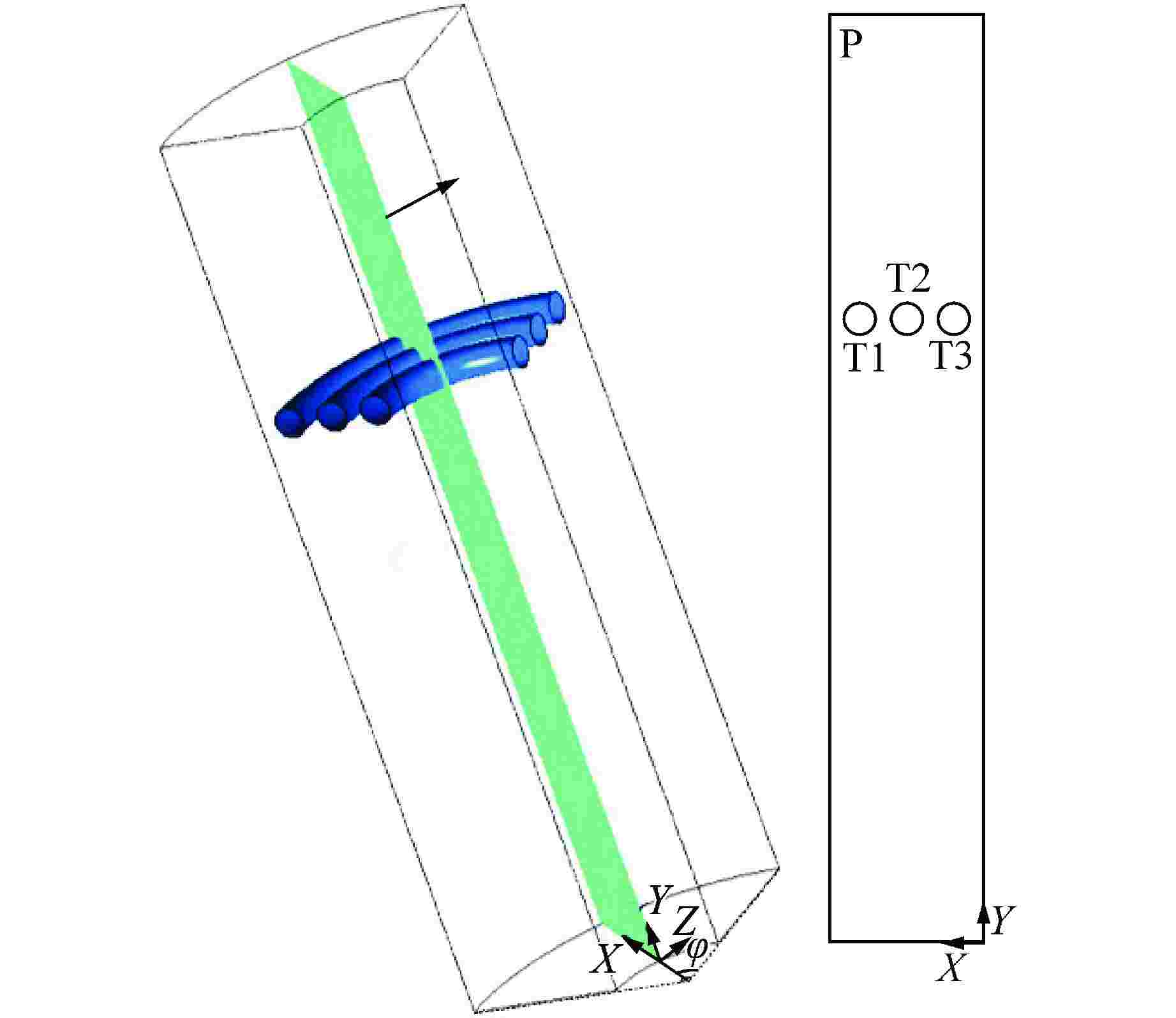

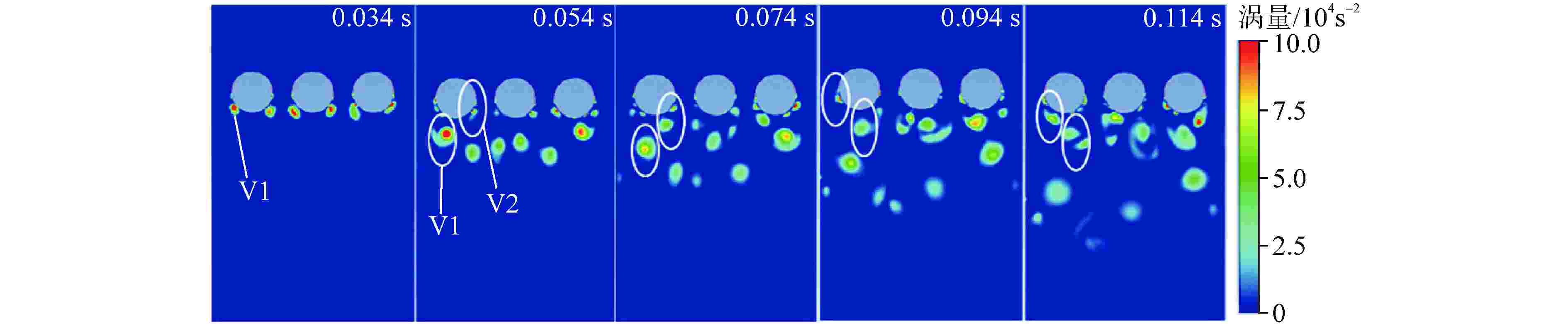

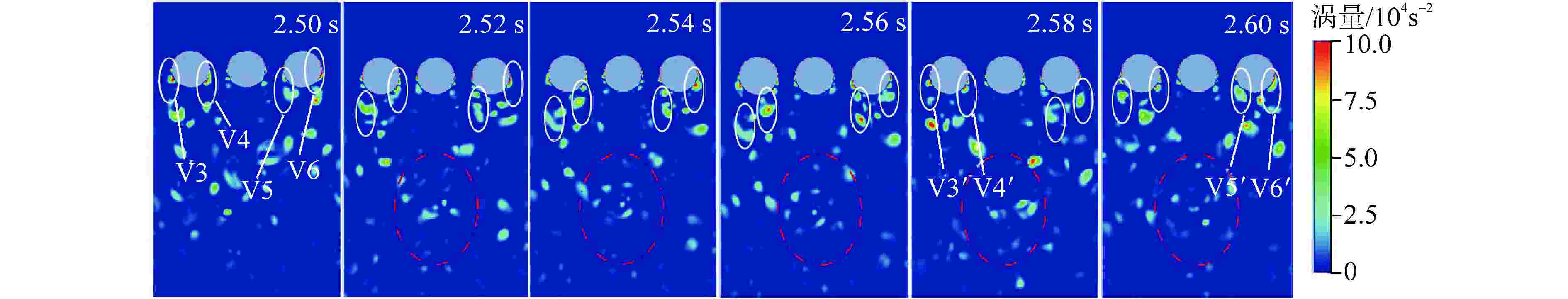

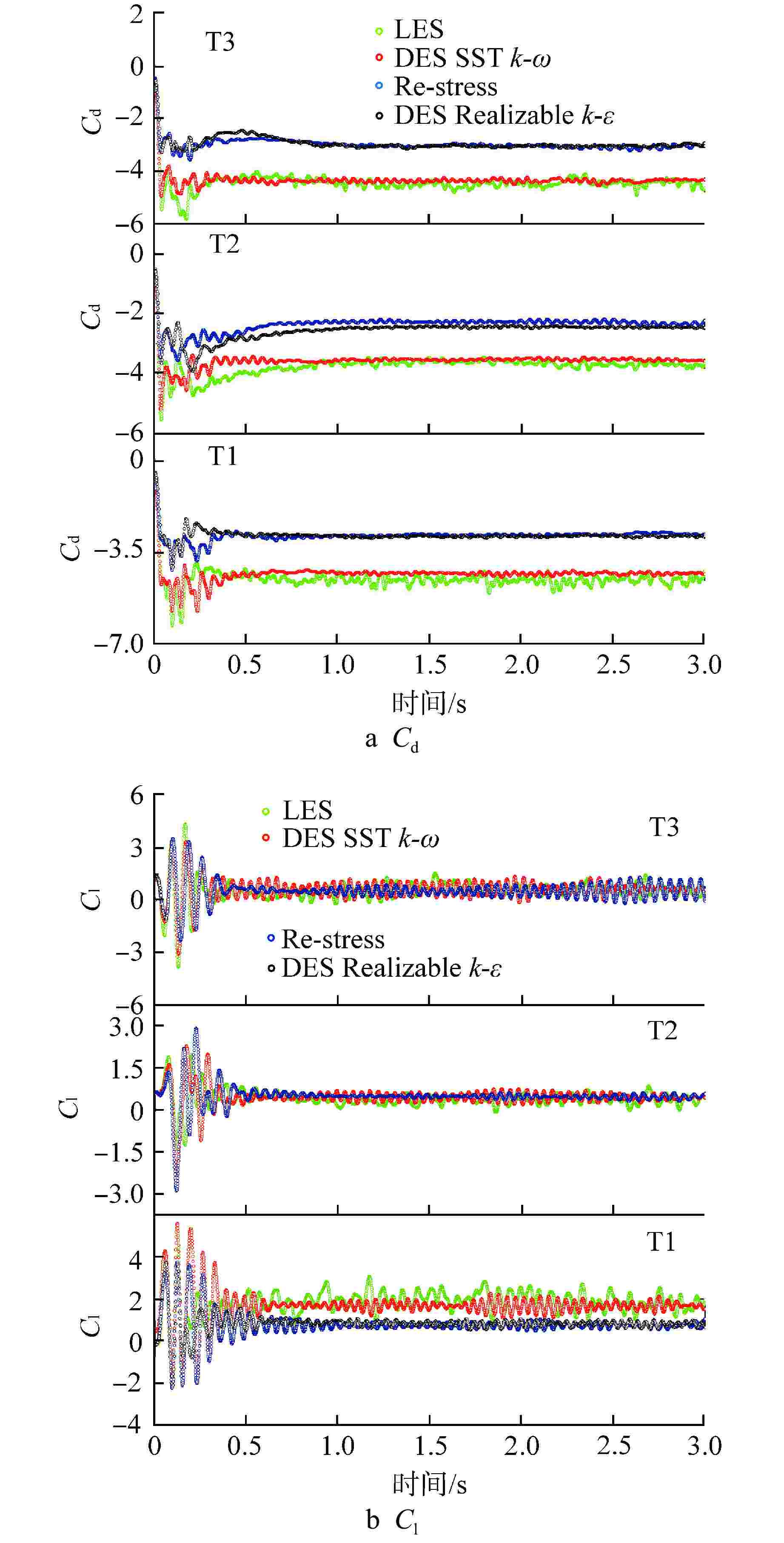

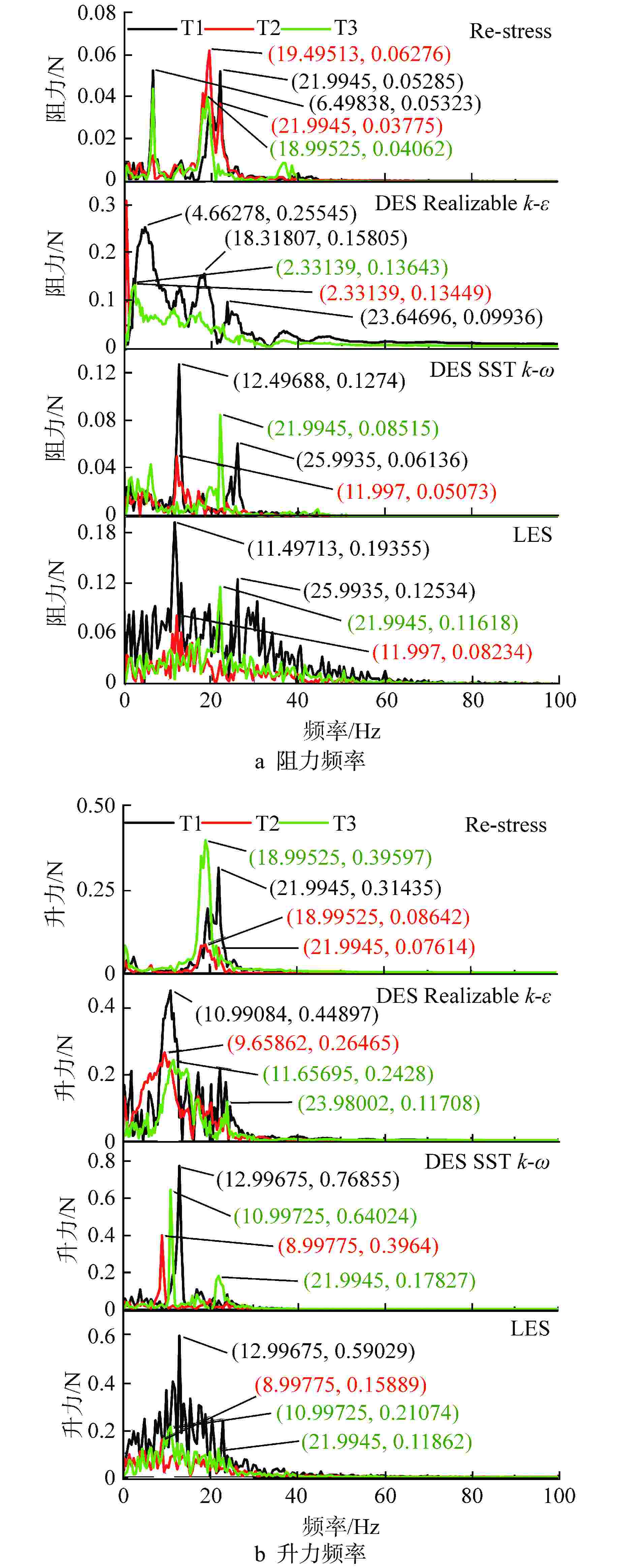

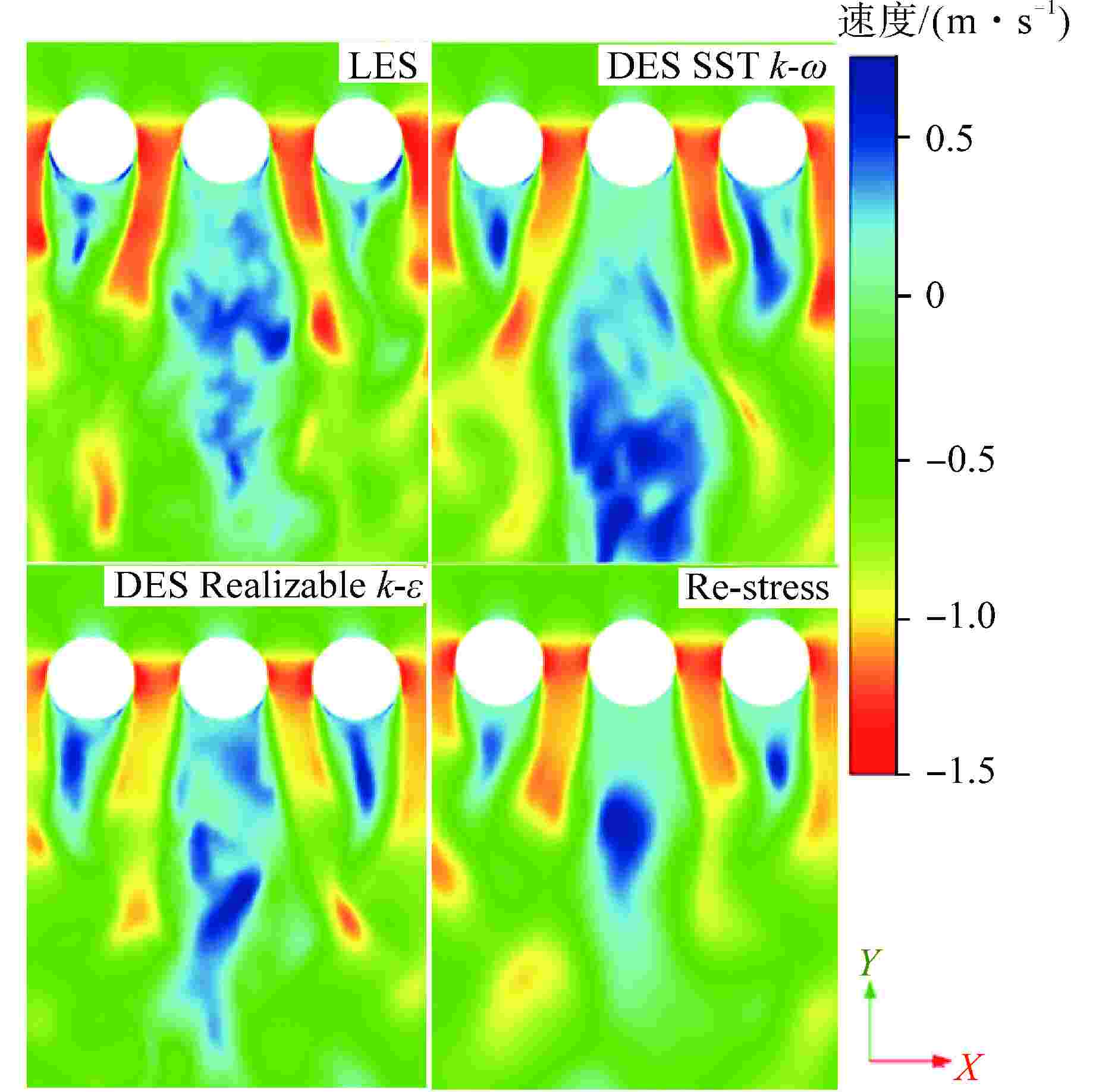

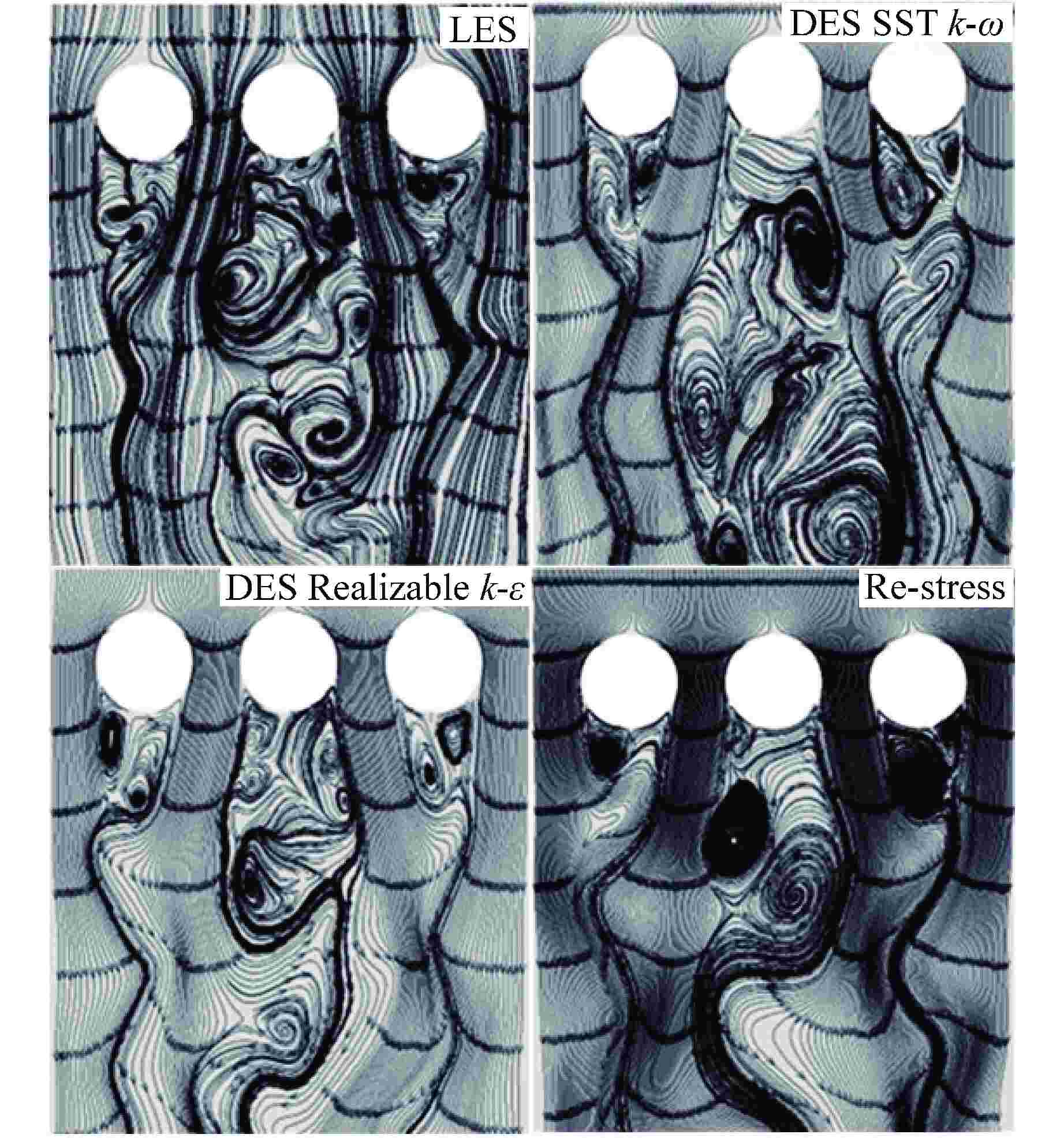

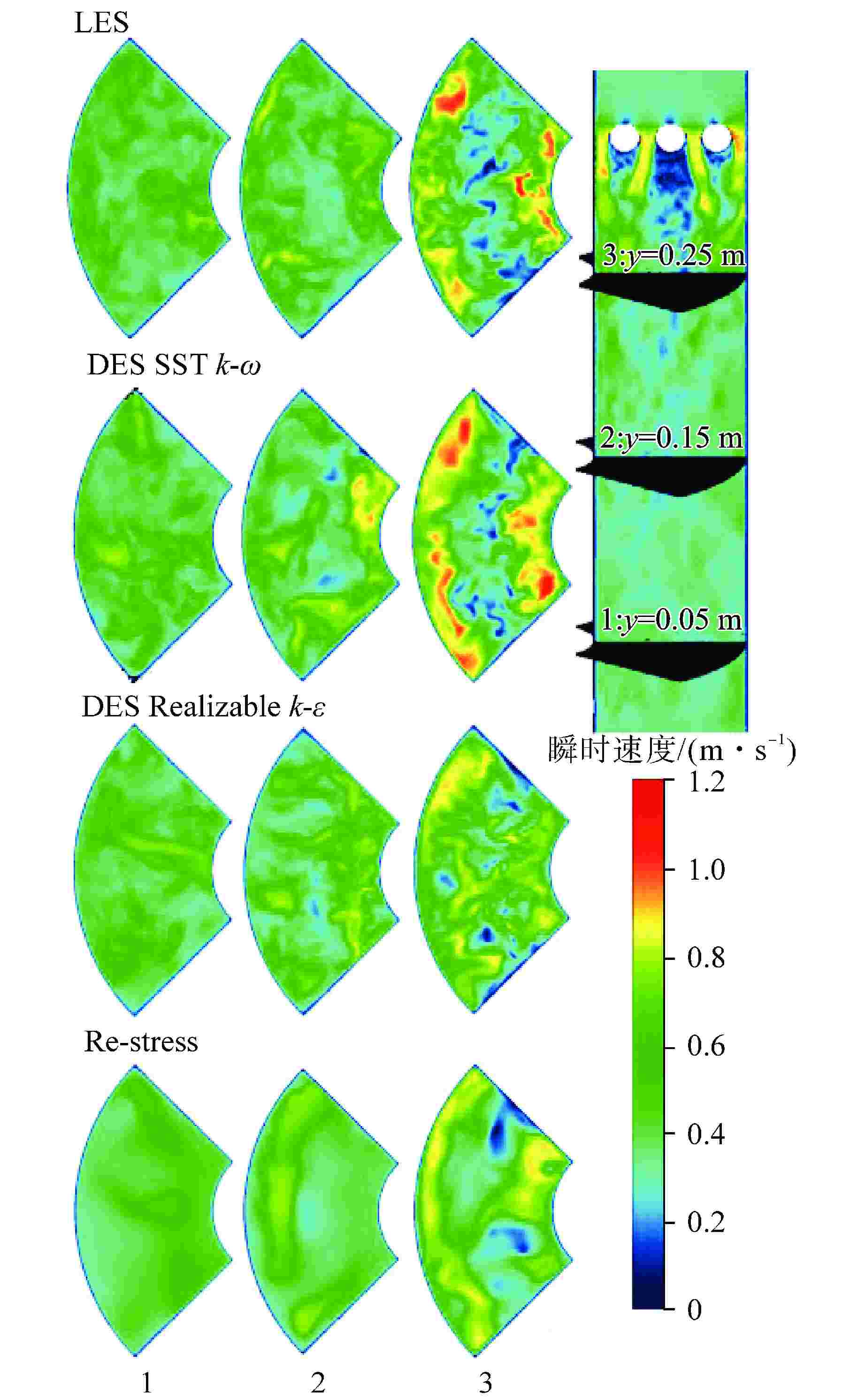

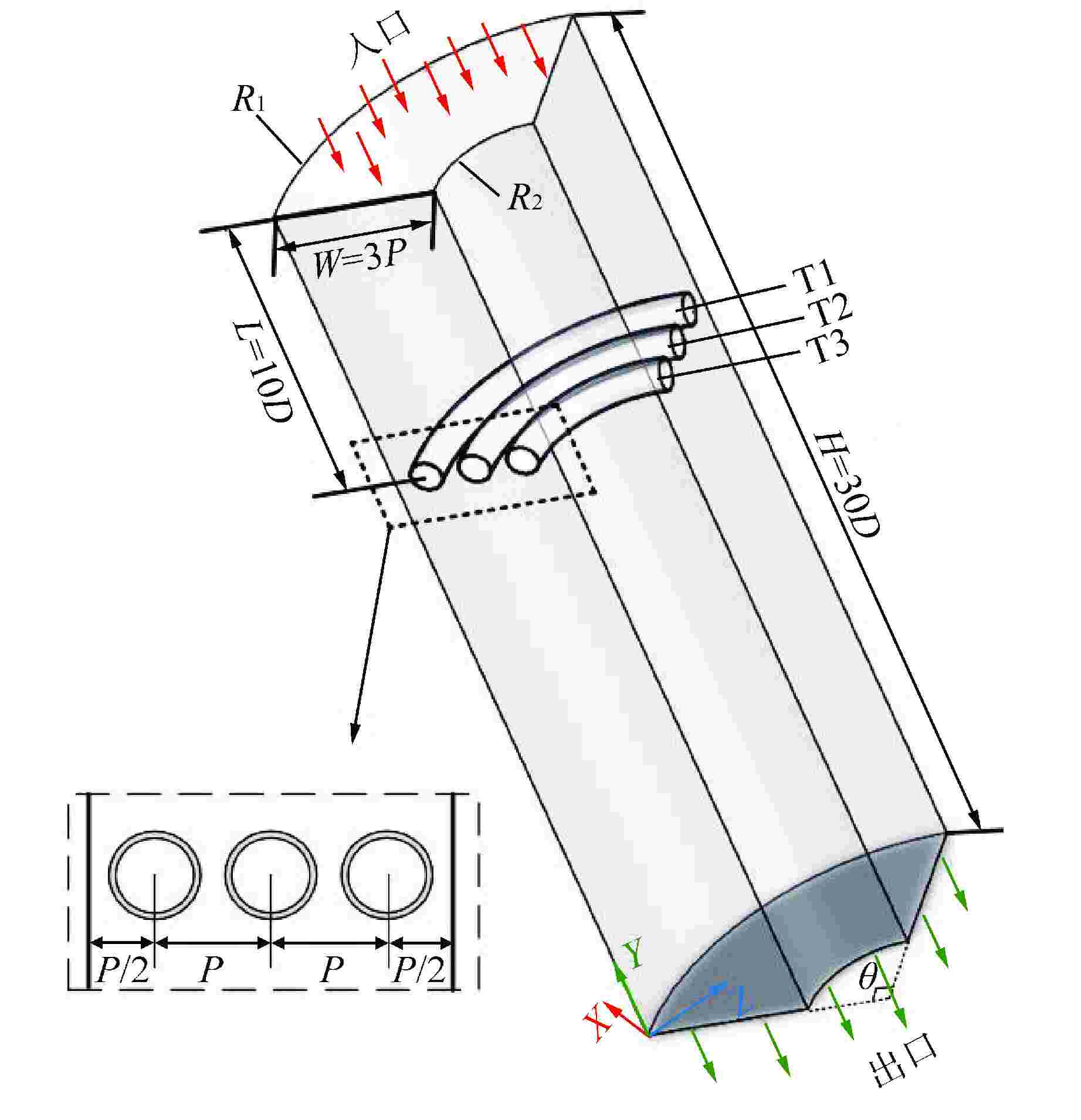

摘要: 在换热器设计中,通过了解铅铋介质在管束中的旋流和涡流等三维流场特性,可以更好地预测和评估换热管设计,确保换热器的安全稳定运行。本研究基于数值模拟对温度为200℃、入口流速为0.5 m/s的铅铋介质在螺旋盘管中的漩涡脱落问题开展研究,以验证后的大涡模拟(LES)方法计算结果为标准,与不同模型进行对比,得到关于此问题的较高计算效率求解模型。结果表明,分离涡模拟(DES)剪切应力传输模型(SST) k-ω与LES模型相比具有较高的计算效率;在研究范围内螺旋盘管至少受漩涡脱落和湍流激振的影响,不同管子之间的脱落漩涡相互影响,导致升阻力频谱出现多峰特征;与直管束不同,螺旋管束下游的流动结构和速度分布都是不对称的,由于螺旋盘管升角的存在,增强了管间间隙的法向速度,且螺旋盘管的盘绕形状使横向速度分布更加不均匀。Abstract: In the design of heat exchanger, by understanding the three-dimensional flow field characteristics such as swirling and vortical flow of the lead-bismuth medium in the tube bundle, the design of heat exchange tube can be better predicted and evaluated to ensure the safe and stable operation of heat exchanger. This study focuses on investigating the phenomenon of vortex shedding of lead-bismuth medium in a helical coil using numerical simulations. The simulations were conducted at a temperature of 200℃ and an inlet flow velocity of 0.5 m/s. The validated large eddy simulation (LES) model results were used as a benchmark to compare with different models, aiming to develop a computationally efficient solution model for this problem. The results show that detached eddy simulation (DES) SST k-ω model has higher computational efficiency than LES model. Within the study range, the spiral coil tube bundle is at least affected by vortex shedding and turbulent excitation. The interaction between shedding vortices from different tubes leads to a multi-peak feature in the lift and drag spectrum. Different from the straight tube bundle, the flow structure and velocity distribution downstream of the spiral coil tube bundle are asymmetrical. Additionally, the normal velocity of the gap between the tubes is enhanced due to the existence of the rise angle of the spiral tube bundle, and the coiling shape of the spiral tube makes the lateral velocity distribution more uneven.

-

表 1 不同湍流模型的Cd计算结果

Table 1. Calculation Results of Drag Coefficient of Different Turbulence Models

湍流模型 计算耗时/h Cd Cd相对偏差/% T1 T2 T3 T1 T2 T3 LES 138 4.58 3.69 4.45 DES SST k-ω 111 4.32 3.55 4.34 5.70 3.82 2.57 DES Realizable k-ε 120 2.89 2.44 3.03 36.88 33.78 32.03 Re-stress 183 2.82 2.28 3.06 38.41 38.12 31.17 表 2 不同湍流模型的Cl计算结果

Table 2. Calculation Results of Lift Coefficient of Different Turbulence Models

湍流模型 计算耗时/h Cl Cl相对偏差/% T1 T2 T3 T1 T2 T3 LES 138 1.81 0.37 0.60 DES SST k-ω 111 1.66 0.40 0.6 8.28 7.14 0.90 DES Realizable k-ε 120 0.81 0.59 0.84 55.19 57.14 39.64 Re-stress 183 0.74 0.47 0.54 59.09 25.51 10.81 -

[1] 魏诗颖,王成龙,田文喜,等. 铅基快堆关键热工水力问题研究综述[J]. 原子能科学技术,2019, 53(2): 326-336. doi: 10.7538/yzk.2018.youxian.0335 [2] ŠADEK S, GRGIĆ D. Operation and performance analysis of steam generators in nuclear power plants[M]//Heat Exchangers-Advanced Features and Applications. Rijeka In Intech, 2017: 182-183. [3] 王钰淇,邬益东,王晓欣,等. 高温气冷堆螺旋管蒸汽发生器出口段流致振动分析[C]//中国核学会. 中国核科学技术进展报告(第八卷)中国核学会2023年学术年会论文集. 西安: 中国核学会,2023: 7,doi: 10.26914/c.cnkihy.2023.103813. [4] 李晓伟,吴莘馨,张作义,等. 高温气冷堆示范工程螺旋管式直流蒸汽发生器工程验证试验[J]. 清华大学学报(自然科学版),2021, 61(4): 329-337, doi: 10.16511/j.cnki.qhdxxb.2021.25.029. [5] YILDIZ M A, MERZARI E, HASSAN Y A. Spectral and modal analysis of the flow in a helical coil steam generator experiment with large eddy simulation[J]. International Journal of Heat and Fluid Flow, 2019, 80: 108486. doi: 10.1016/j.ijheatfluidflow.2019.108486 [6] ABOLMAALI A M, AFSHIN H. Numerical study of heat transfer between shell-side fluid and shell wall in the spiral-wound heat exchangers[J]. International Journal of Refrigeration, 2020, 120: 285-295. doi: 10.1016/j.ijrefrig.2020.08.010 [7] ABOLMAALI A M, AFSHIN H. Development of Nusselt number and friction factor correlations for the shell side of spiral-wound heat exchangers[J]. International Journal of Thermal Sciences, 2019, 139: 105-117. doi: 10.1016/j.ijthermalsci.2019.01.038 [8] WANG Y, GUO S, ZHU G R, et al. Effect of various structures on the shell-side flow over coil tube bundles[J]. Chemical Engineering Science, 2023, 268: 118408. doi: 10.1016/j.ces.2022.118408 [9] FENG J Y, ACTON M, BAGLIETTO E, et al. On the relevance of turbulent structures resolution for cross-flow in a helical-coil tube bundle[J]. Annals of Nuclear Energy, 2020, 140: 107298. doi: 10.1016/j.anucene.2019.107298 [10] 王聪,张巍,李净松,等. 螺旋管式直流蒸汽发生器壳侧流场数值模拟方法研究[J]. 核动力工程,2021, 42(4): 171-175, doi: 10.13832/j.jnpe.2021.04.0171. [11] LEE S J, HASSAN Y A. Numerical investigation of helical coil tube bundle in turbulent cross flow using large eddy simulation[J]. International Journal of Heat and Fluid Flow, 2020, 82: 108529. doi: 10.1016/j.ijheatfluidflow.2019.108529 [12] YILDIZ M A, MERZARI E, HASSAN Y A. Large eddy simulation of 5-tube bundle helical coil steam generator test section[C]//26th International Conference on Nuclear Engineering. London: American Society of Mechanical Engineers, 2018, 51524: V008T09A043. [13] ROLLET-MIET P, LAURENCE D, FERZIGER J. LES and RANS of turbulent flow in tube bundles[J]. International Journal of Heat and Fluid Flow, 1999, 20(3): 241-254. doi: 10.1016/S0142-727X(99)00006-5 [14] LEE S J, LEE S, HASSAN Y A. Numerical investigation of turbulent flow in an annular sector channel with staggered semi-circular ribs using large eddy simulation[J]. International Journal of Heat and Mass Transfer, 2018, 123: 705-717. doi: 10.1016/j.ijheatmasstransfer.2018.03.026 [15] ACHENBACH E. Distribution of local pressure and skin friction around a circular cylinder in cross-flow up to Re=5×106[J]. Journal of Fluid Mechanics, 1968, 34(4): 625-639. doi: 10.1017/S0022112068002120 [16] KOLMOGOROV A N. The local structure of turbulence in incompressible viscous fluid for very large Reynolds numbers[J]. Proceedings of the Royal Society of London. Series A: Mathematical and Physical Sciences, 1991, 434(1890): 9-13. doi: 10.1098/rspa.1991.0075 [17] 张显雄,张志田,张伟峰,等. 五种湍流涡粘模型在二维方柱绕流数值模拟中的对比研究[J]. 空气动力学学报,2018, 36(2): 339-349. -

下载:

下载: