Investigation of Radial Thermal-Hydraulic Characteristics of Sodium Heated Once-Through Steam Generator

-

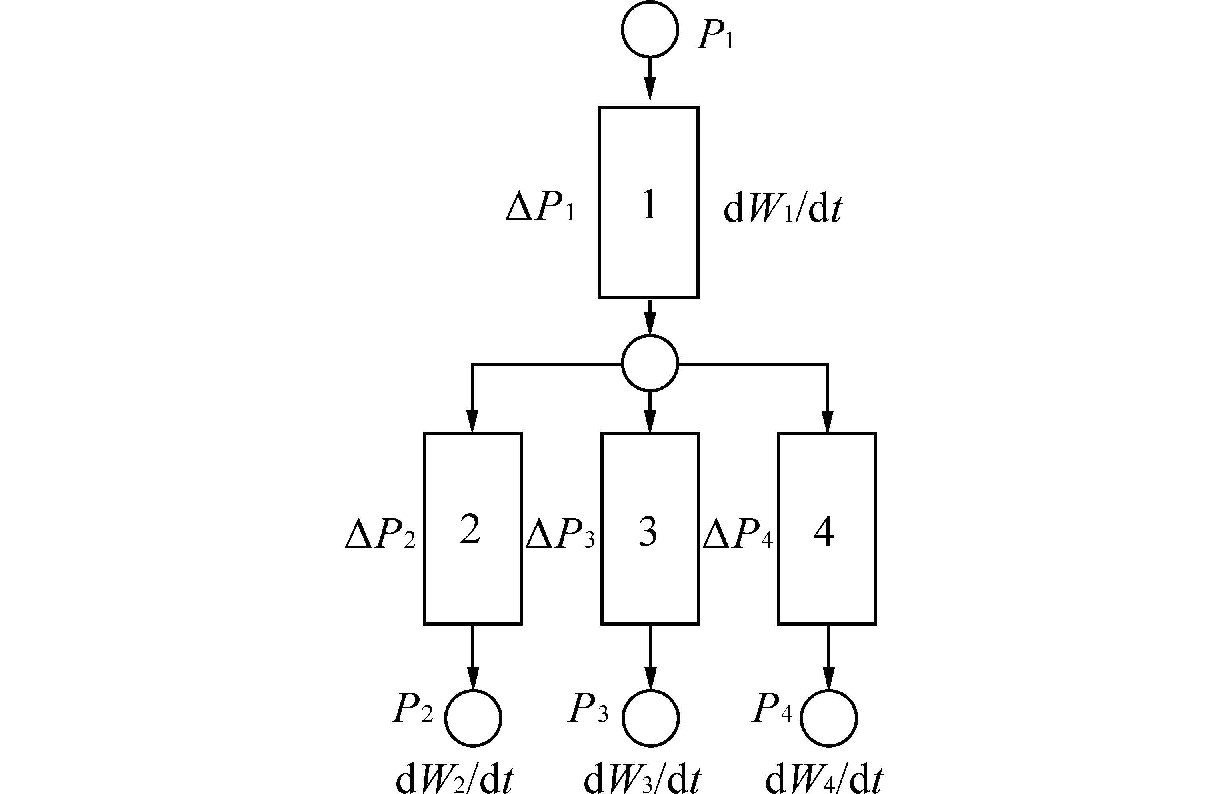

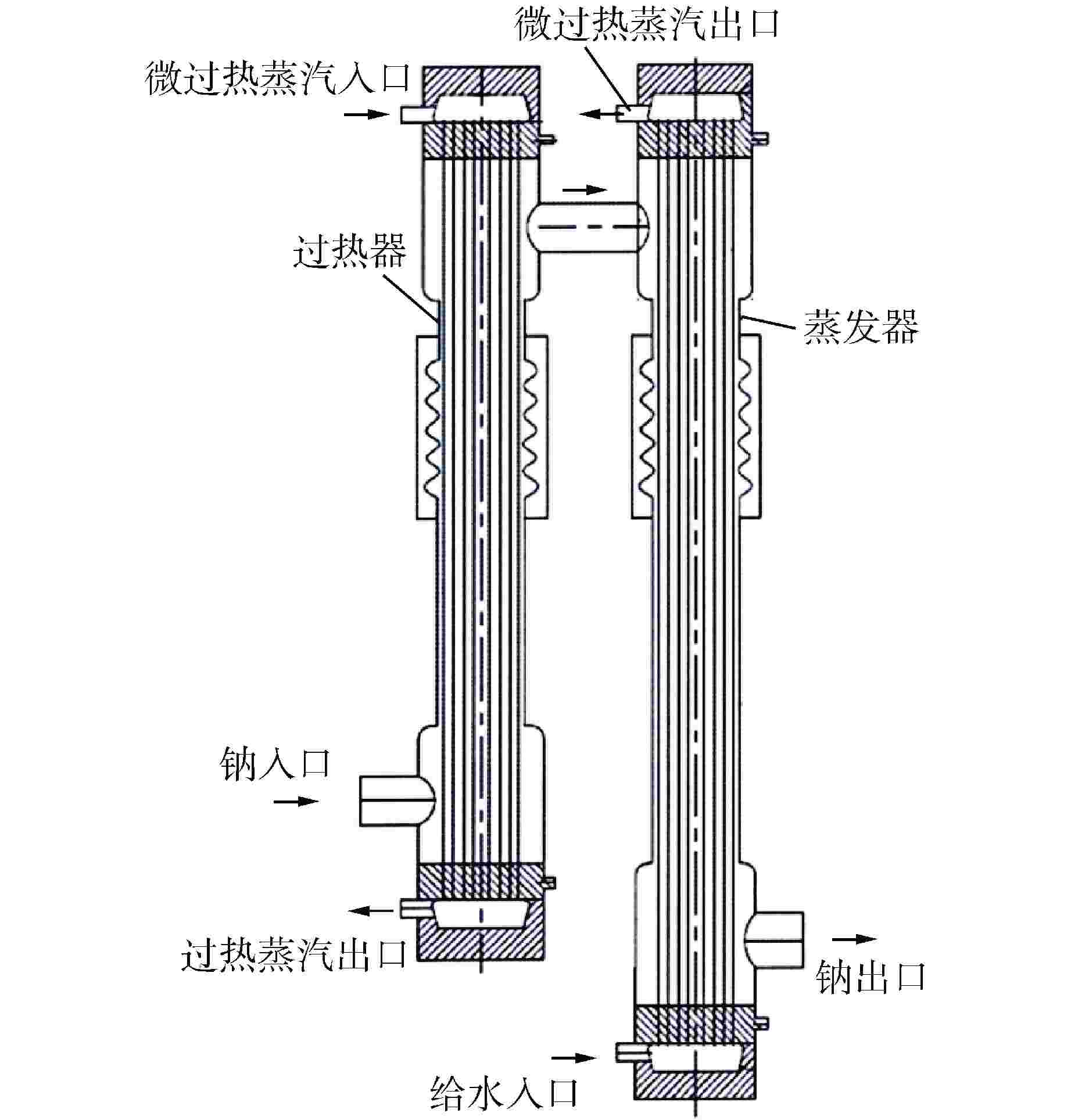

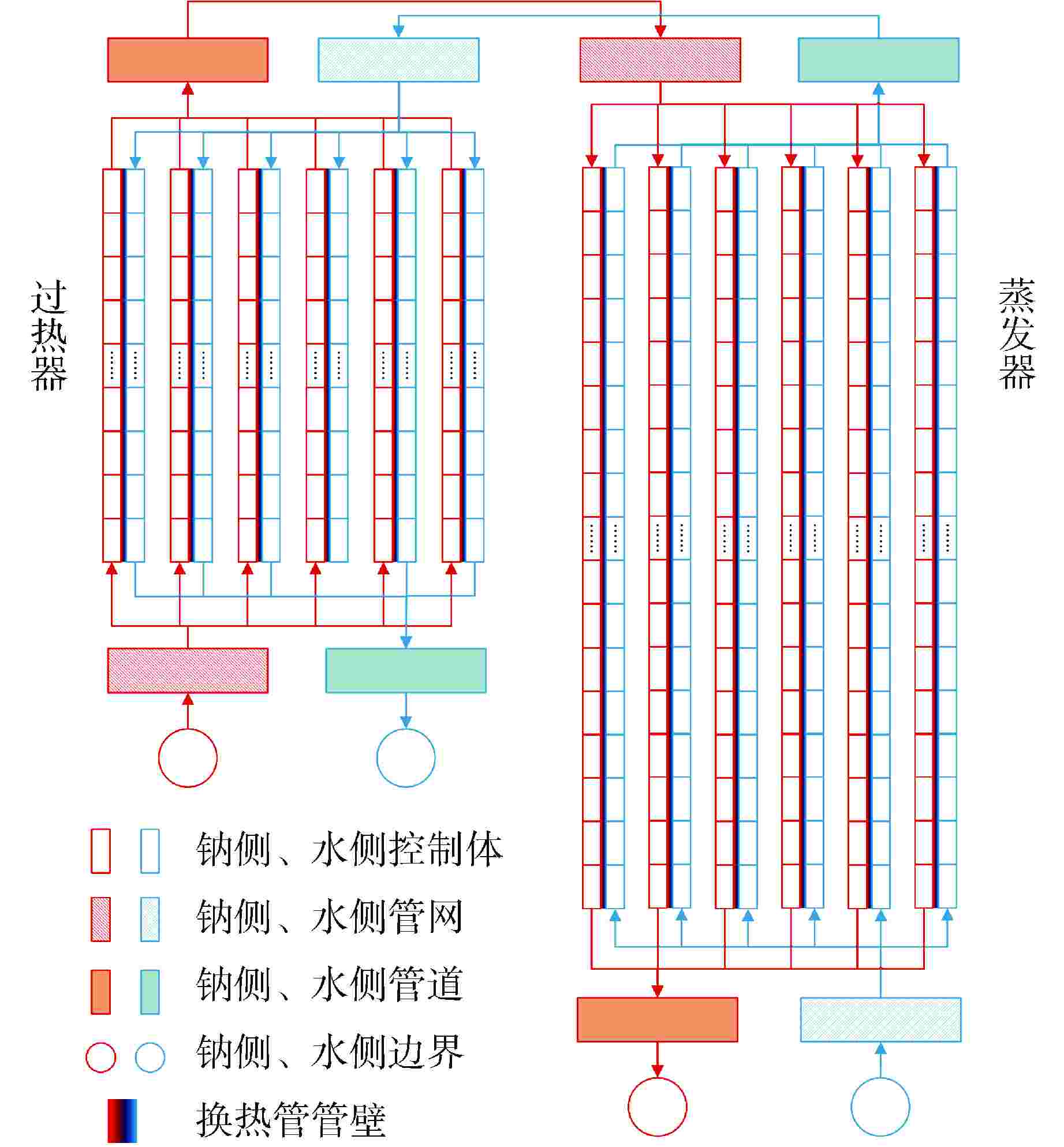

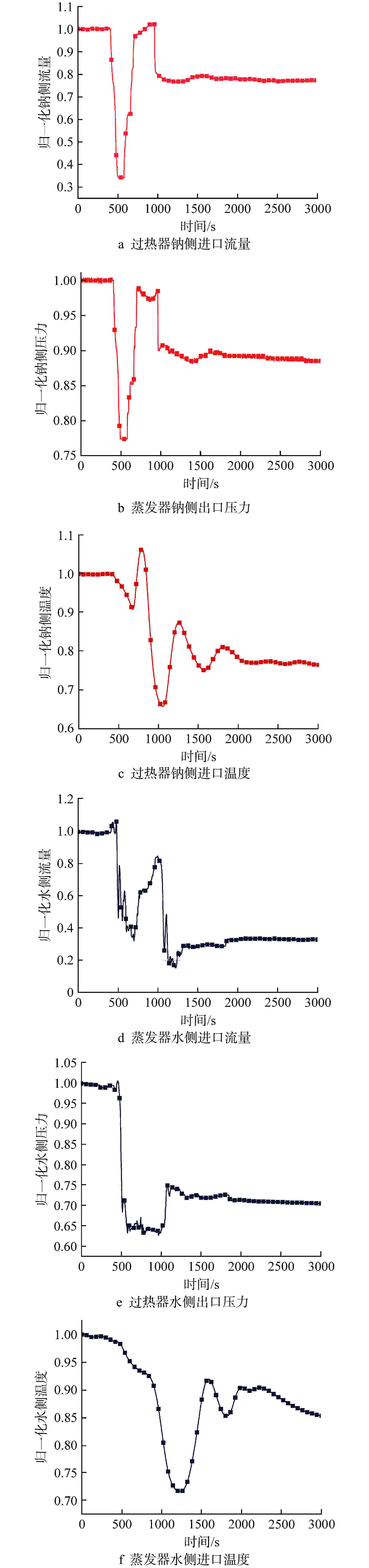

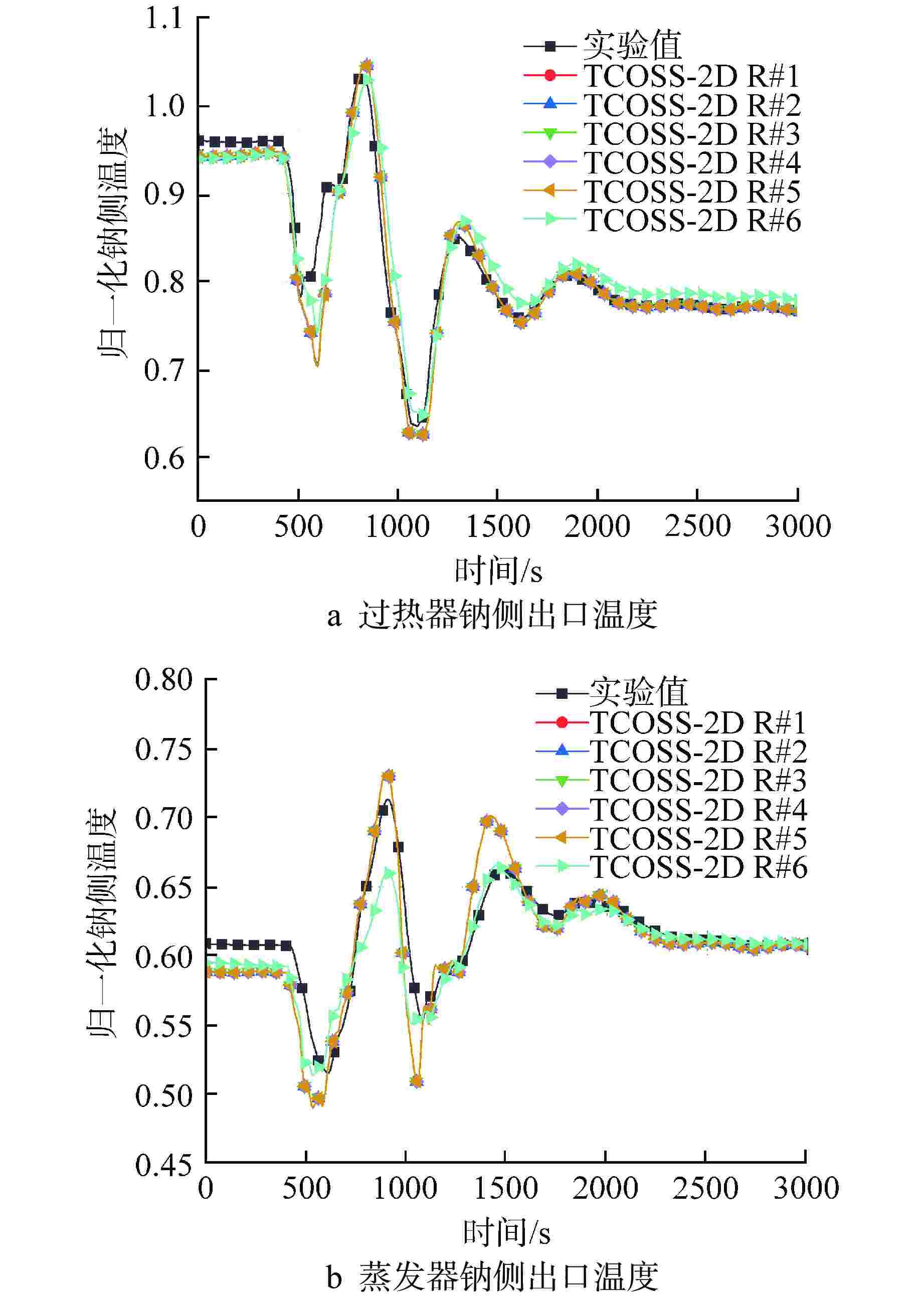

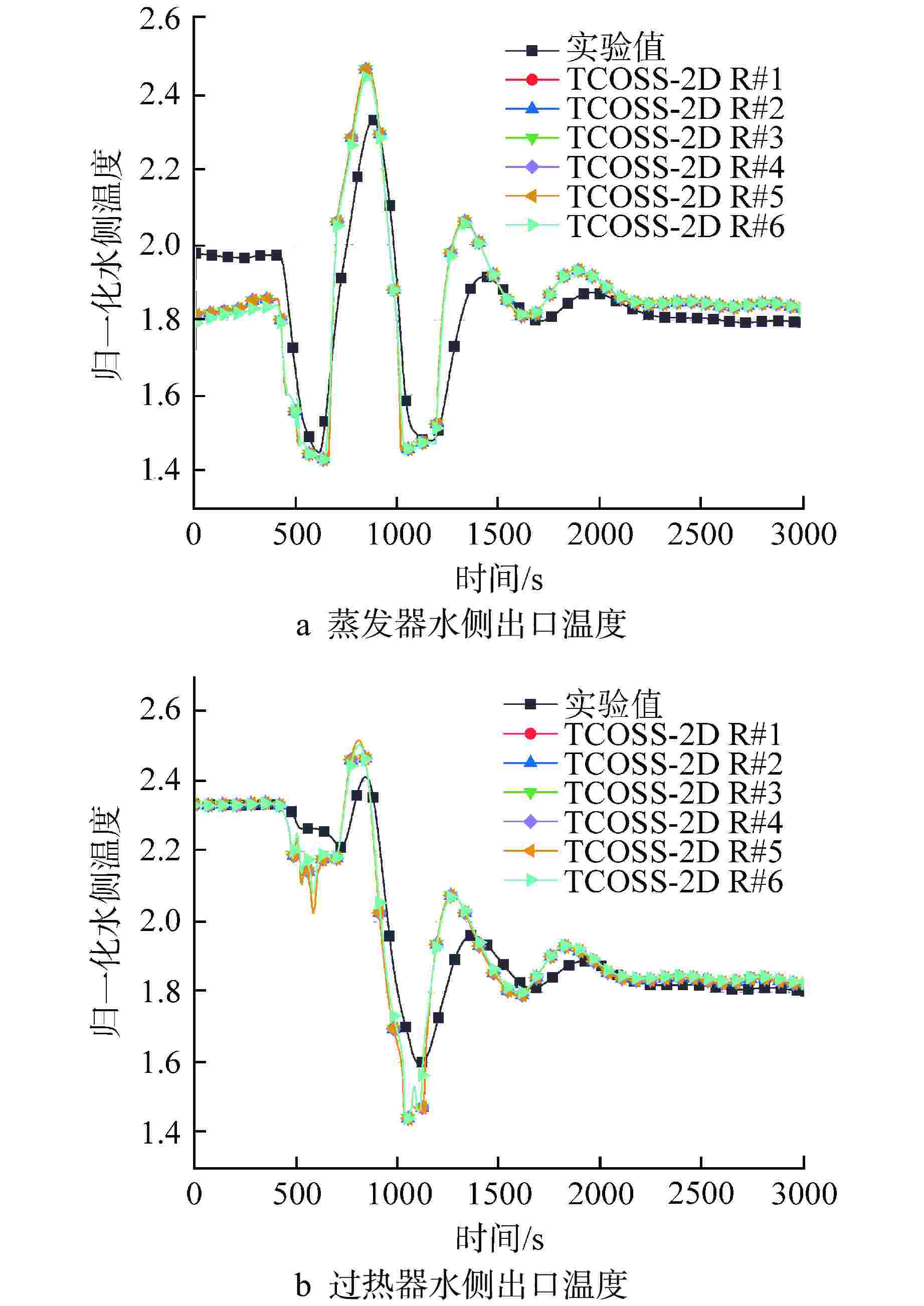

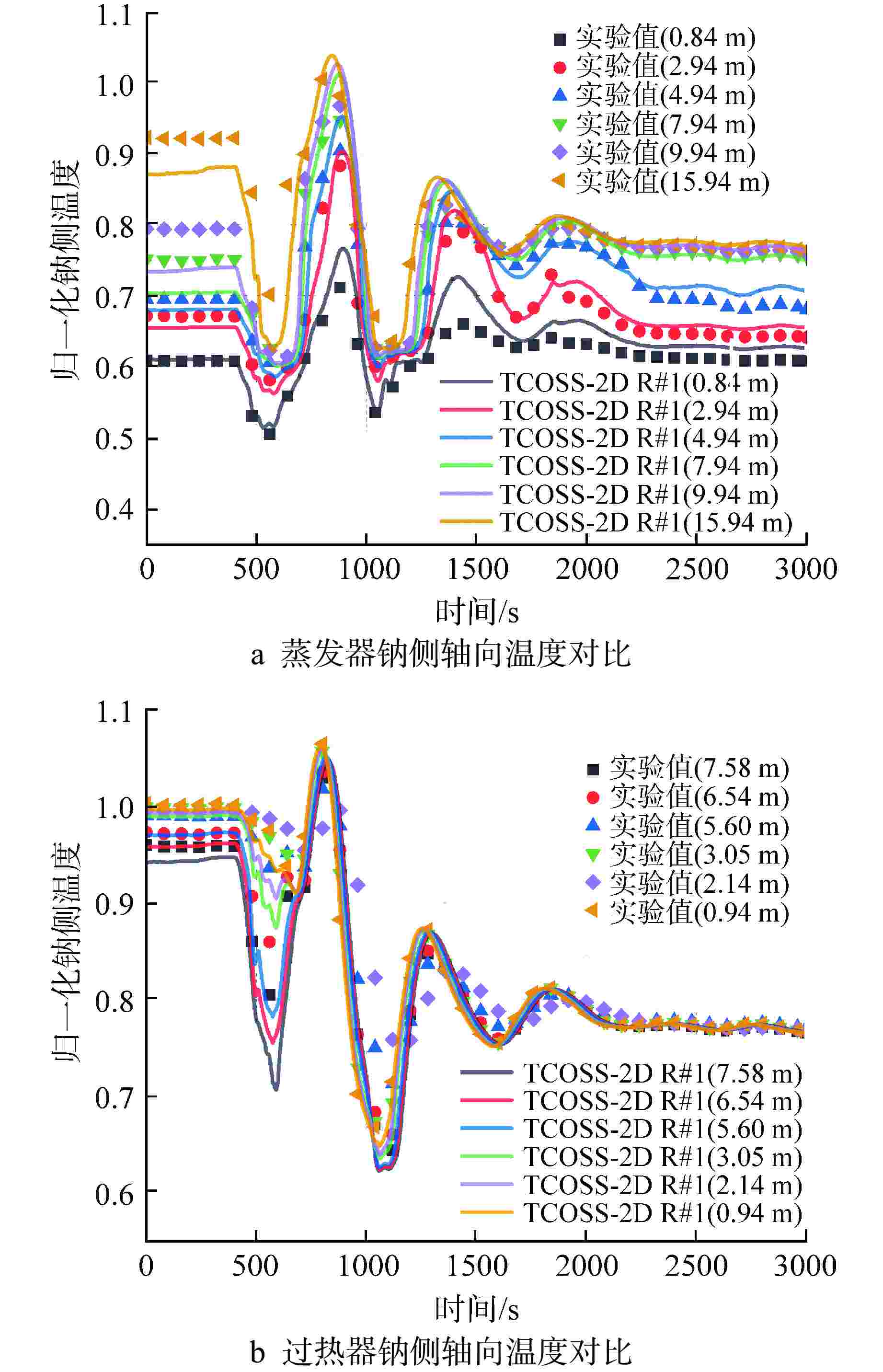

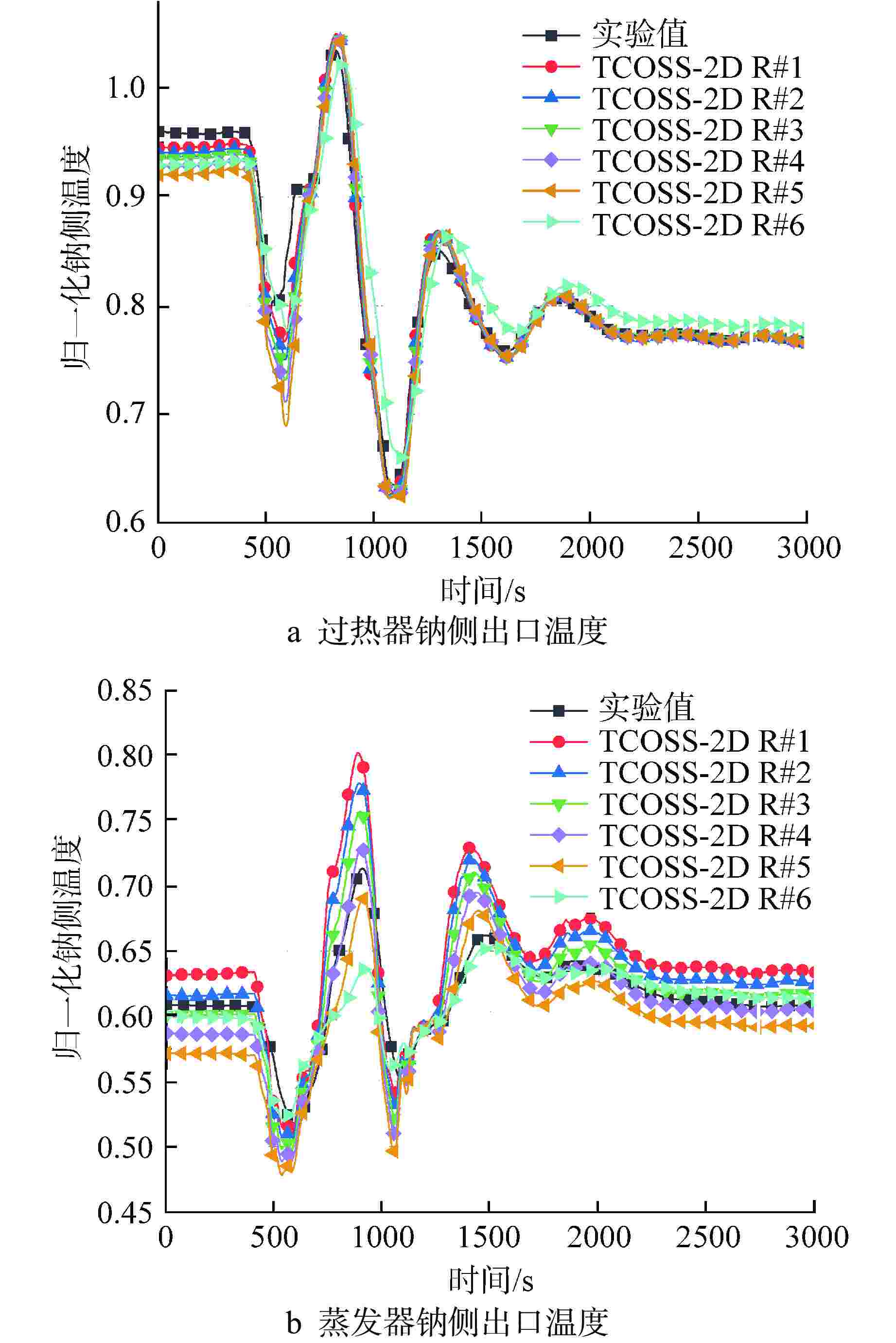

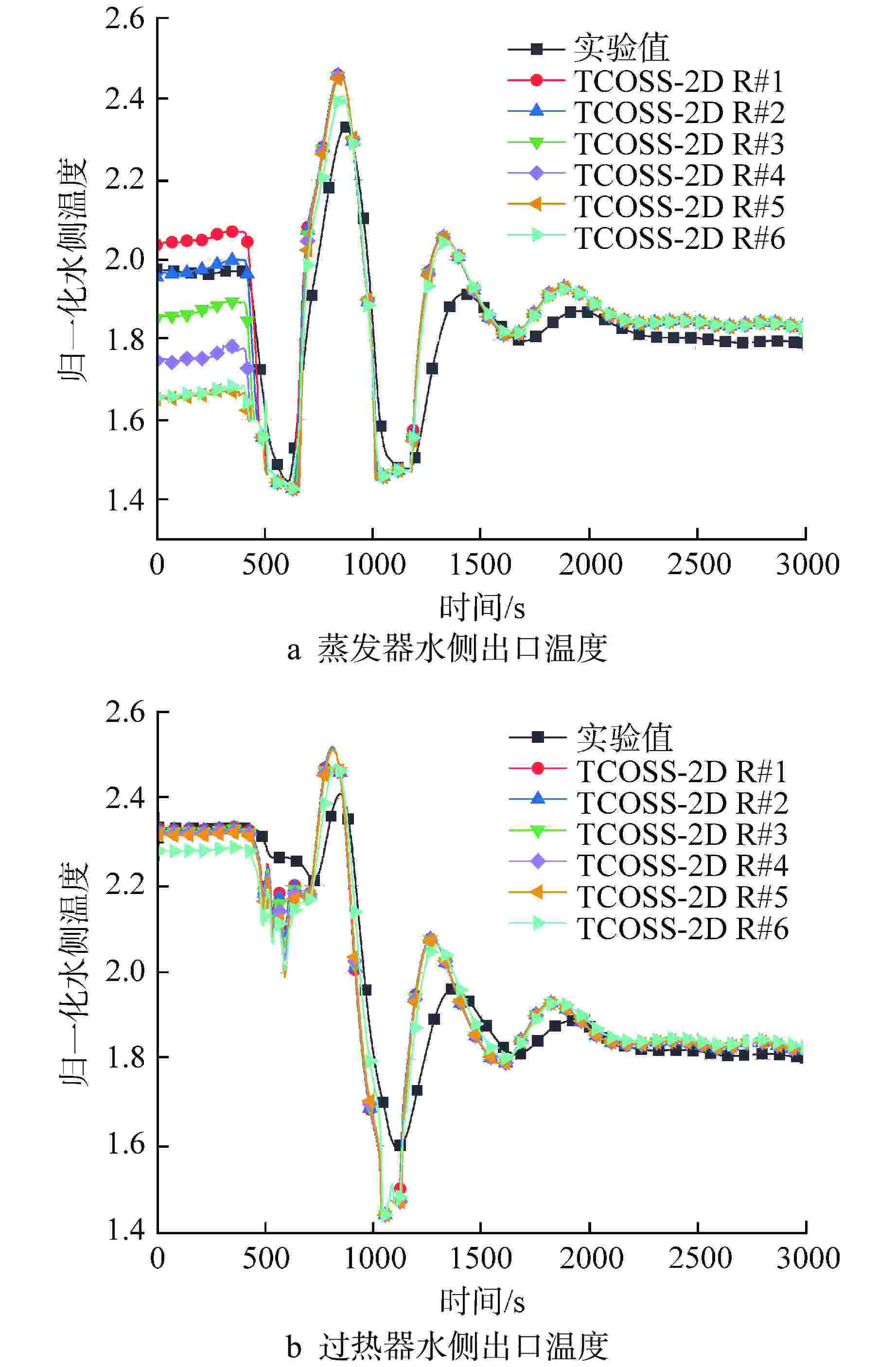

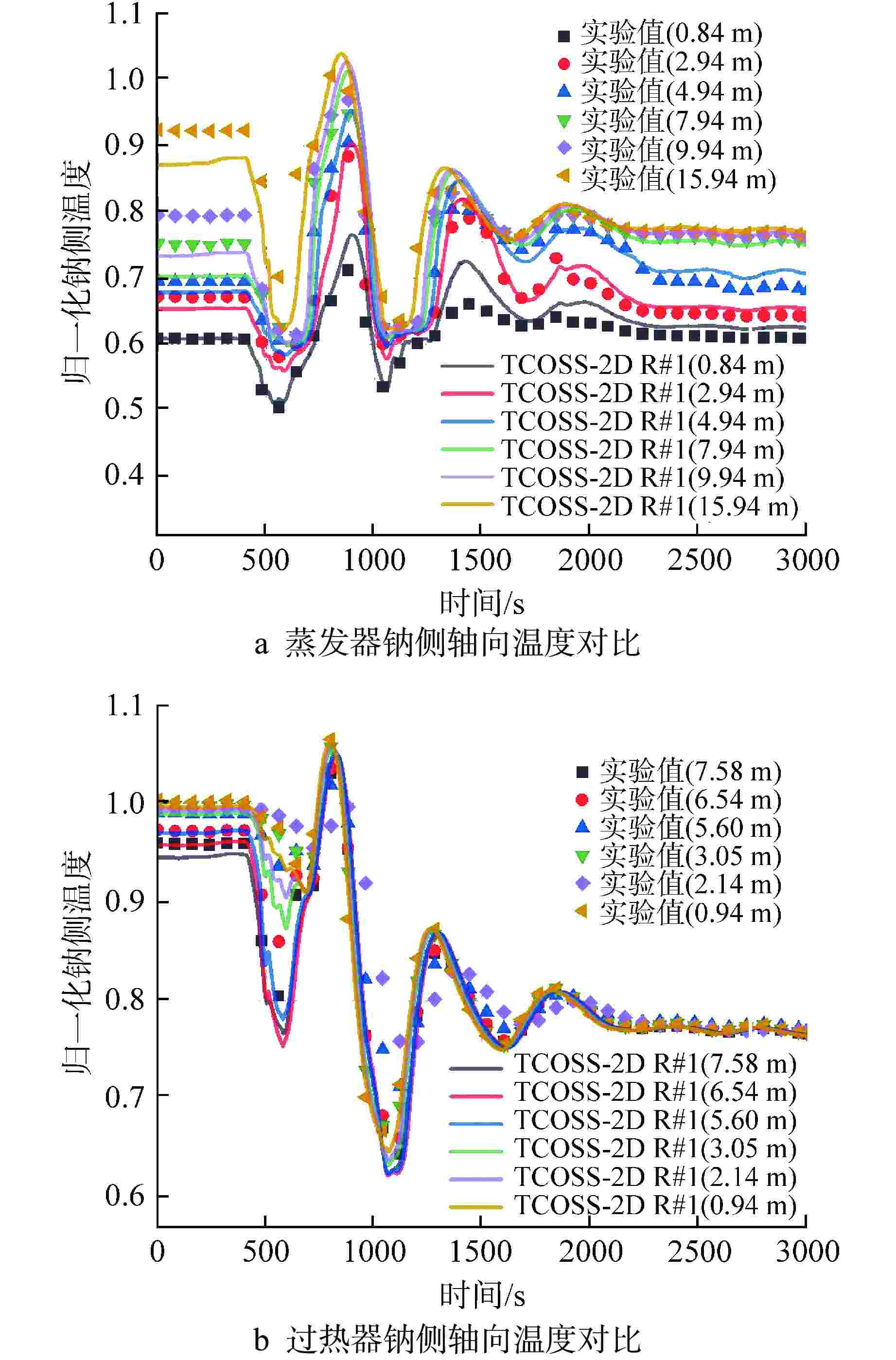

摘要: 钠-水直流蒸汽发生器是钠冷快堆的重要设备,传统的蒸汽发生器一维热工水力系统分析程序无法考虑径向热工水力参数分布,不适用于疲劳和热应力分析。为了计算蒸汽发生器的径向热工水力参数分布,采用管网、管道和蒸汽发生器部件相结合的方法开发了TCOSS-2D程序。首先,利用TCOSS-2D对中国示范快堆(CFR600)蒸汽发生器原型样机进行了径向多层建模和热工水力计算,结果表明程序计算的瞬态响应变化趋势与实验符合良好,验证了程序的径向热工水力计算能力;其次,考虑了钠-水直流蒸汽发生器钠侧径向不均匀流量分配,结果表明钠侧径向不均匀流量分配对蒸发器径向温度差异影响大于过热器,瞬态变化过程中钠侧的非均匀流量分配对水侧的不均匀性影响相对较小。因此,本研究开发的钠-水直流蒸汽发生器数值模型能够用于其径向热工水力特性的分析。

-

关键词:

- TCOSS-2D /

- 钠-水直流蒸汽发生器 /

- 径向热工水力 /

- 程序验证

Abstract: The sodium heated once-through steam generator is the critical equipment of a sodium-cooled fast reactor. The traditional one-dimensional thermal-hydraulic system analysis code cannot take into account the radial thermal-hydraulic parameter distributions of the steam generator, and therefore is not applicable to fatigue and thermal stress analyses. In order to calculate the radial thermal-hydraulic parameter distribution of the steam generator, the TCOSS-2D code was developed adopting a combination of pipe network, pipeline and steam generator. Firstly, radial multilayer modeling and thermal-hydraulic calculations were carried out on the steam generator prototype of the Chinese demonstration fast reactor (CFR600) using TCOSS-2D, and the results showed that the transient response trend calculated by the code was in good agreement with the experiment, so the radial thermal hydraulic calculation capability of the code was validated. Secondly, the radial non-uniform flow distribution on the sodium side of the sodium heated once-through steam generator was considered and compared. The results show that the radial non-uniform sodium-side flow distribution has a greater effect on the radial temperature difference of the evaporator than the superheater, while the non-uniform flow distribution of the sodium-side of the transient process has a relatively small effect on the non-uniformity of the water-side. Therefore, the numerical model of sodium heated once-through steam generator developed in this study can be utilized for the analysis of its radial thermal-hydraulic characteristics. -

表 1 蒸汽发生器原型样机主要设计参数

Table 1. Major Design Parameters of Prototype Steam Generator

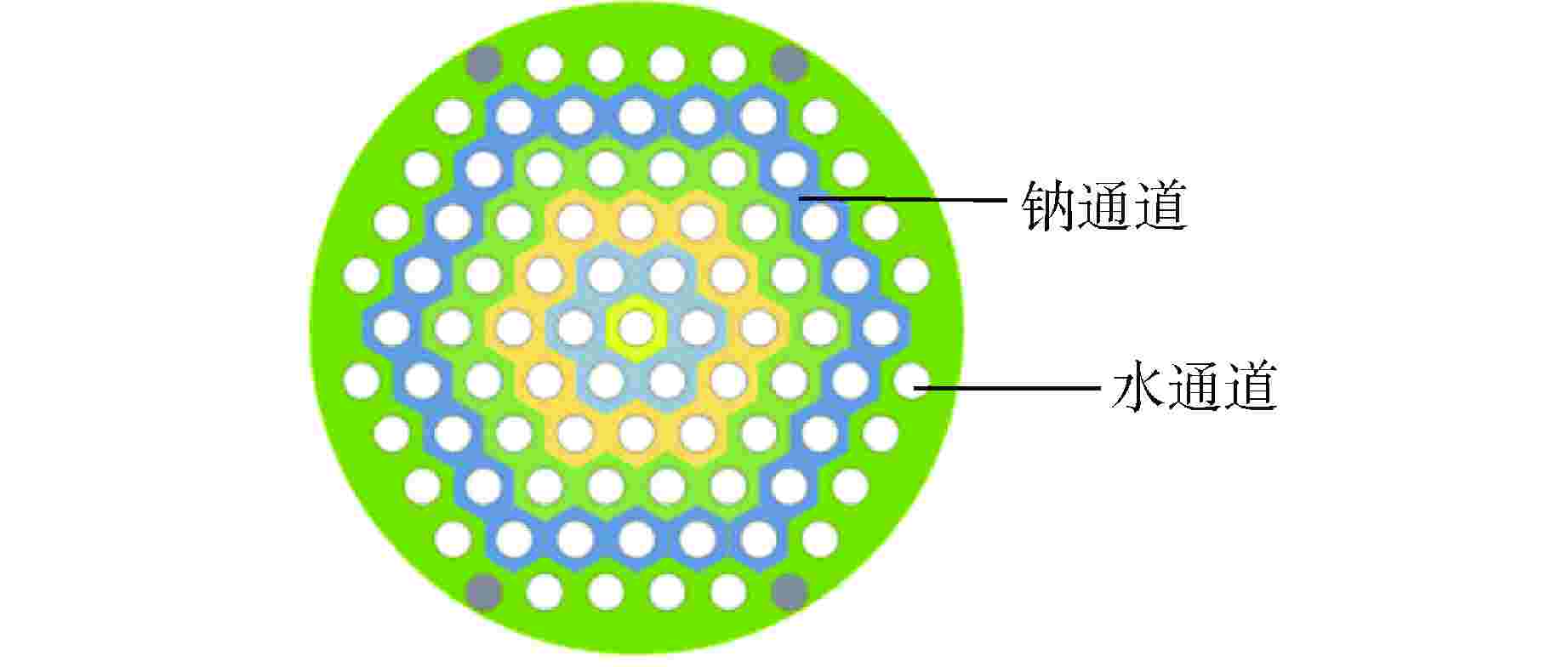

参数名 数值及方式 蒸汽发生器功率/MW 20 传热管布置方式 正三角形 蒸发器传热管长度/m 17.884 过热器传热管长度/m 8.034 蒸发器传热管根数 85 过热器传热管根数 73 壳程设计压力/MPa 2.5 管程设计压力/MPa 17 蒸发器壳程设计温度/℃ 490 蒸发器管程设计温度/℃ 450 过热器壳程设计温度/℃ 510 过热器管程设计温度/℃ 500 -

[1] 张福民,李继涛,申江坤,等. 浅谈第四代堆-钠冷快堆(SFR)的技术状况[J]. 中国设备工程,2023(7): 125-127. [2] YOON J, KIM J P, KIM H Y, et al. Development of a computer code, ONCESG, for the thermal-hydraulic design of a once-through steam generator[J]. Journal of Nuclear Science and Technology, 2000, 37(5): 445-454. doi: 10.1080/18811248.2000.9714917 [3] TZANOS C P. A movable boundary model for once-through steam generator analysis[J]. Nuclear Technology, 1988, 82(1): 5-17. doi: 10.13182/NT88-A34113 [4] ABDALLA M A. A four-region, moving-boundary model of a once-through, helical-coil steam generator[J]. Annals of Nuclear Energy, 1994, 21(9): 541-562. doi: 10.1016/0306-4549(94)90078-7 [5] 袁媛. 螺旋管式直流蒸汽发生器建模与仿真研究[D]. 哈尔滨: 哈尔滨工程大学,2014. [6] 黄晓津,冯元琨,郭人俊. HTR-10螺旋管直流蒸汽发生器实时动态模型[J]. 清华大学学报: 自然科学版,2000, 40(6): 88-90. [7] 朱景艳,张志俭,郭赟. 套管式直流蒸汽发生器动态实时仿真研究[J]. 原子能科学技术,2011, 45(8): 937-942. [8] XU R S, ZHANG D L, TIAN W X, et al. Development of thermal hydraulic design code for SFR steam generators[J]. Nuclear Engineering and Design, 2019, 348: 46-55. doi: 10.1016/j.nucengdes.2019.04.009 [9] XU R S, ZHANG D L, TIAN W X, et al. Thermal-hydraulic analysis code development for sodium heated once-through steam generator[J]. Annals of Nuclear Energy, 2019, 127: 385-394. doi: 10.1016/j.anucene.2018.12.027 [10] XU R S, SONG P, ZHANG D L, et al. Numerical analysis on flow instability of parallel channels in steam generator for sodium‐cooled fast reactor[J]. International Journal of Energy Research, 2021, 45(8): 11943-11956. doi: 10.1002/er.5933 [11] 肖常志,杨红义,张大林,等. 快堆钠-水蒸汽发生器热工水力稳态综合性能研究[J]. 原子能科学技术,2024, 58(2): 328-336. [12] WANG B, FENG Z Y, CHEN Y C, et al. Optimization and improvement of sodium heated once-through steam generator transient analysis code based on the JFNK algorithm[J]. Energies, 2023, 16(1): 482. doi: 10.3390/en16010482 [13] COLEBROOK C F, WHITE C M. Experiments with fluid friction in roughened pipes[J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 1937, 161(906): 367-381. [14] MIKITYUK K. Heat transfer to liquid metal: review of data and correlations for tube bundles[J]. Nuclear Engineering and Design, 2009, 239(4): 680-687. doi: 10.1016/j.nucengdes.2008.12.014 [15] SIEDER E N, TATE G E. Heat Transfer and pressure drop of liquids in tubes[J]. Industrial & Engineering Chemistry, 1936, 28(12): 1429-1435. [16] CHEN J C. Correlation for boiling heat transfer to saturated fluids in convective flow[J]. Industrial & Engineering Chemistry Process Design and Development, 1966, 5(3): 322-329. [17] THORN J R S, WALKER W M, FALLON T A, et al. Paper 6: boiling in sub-cooled water during flow up heated tubes or annuli[J]. Proceedings of the Institution of Mechanical Engineers, Conference Proceedings, 1965, 180(3): 226-246. doi: 10.1243/PIME_CONF_1965_180_117_02 -

下载:

下载: