Effect of Sintering Process on Densification of UN-30%U3Si2 Pellets

-

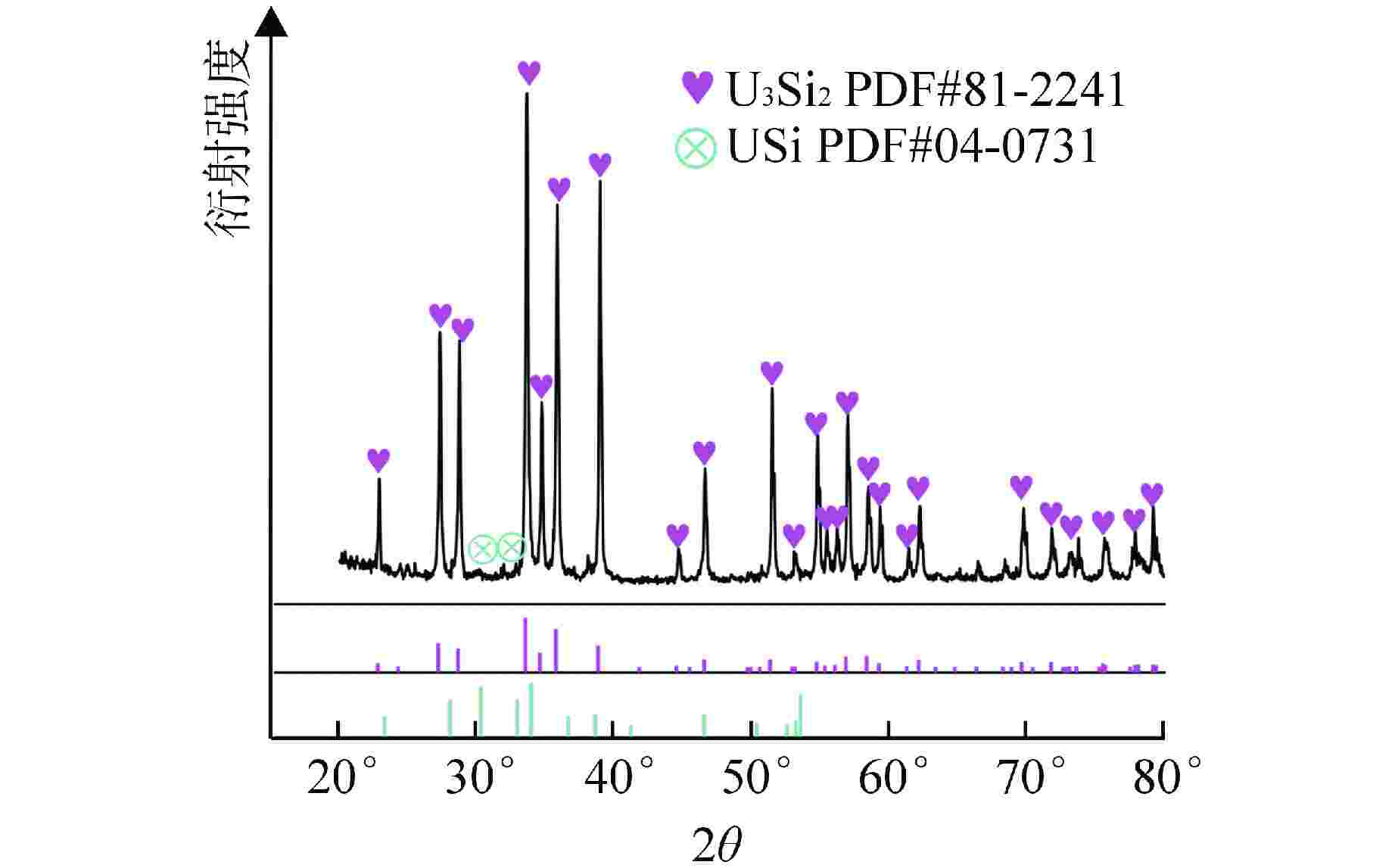

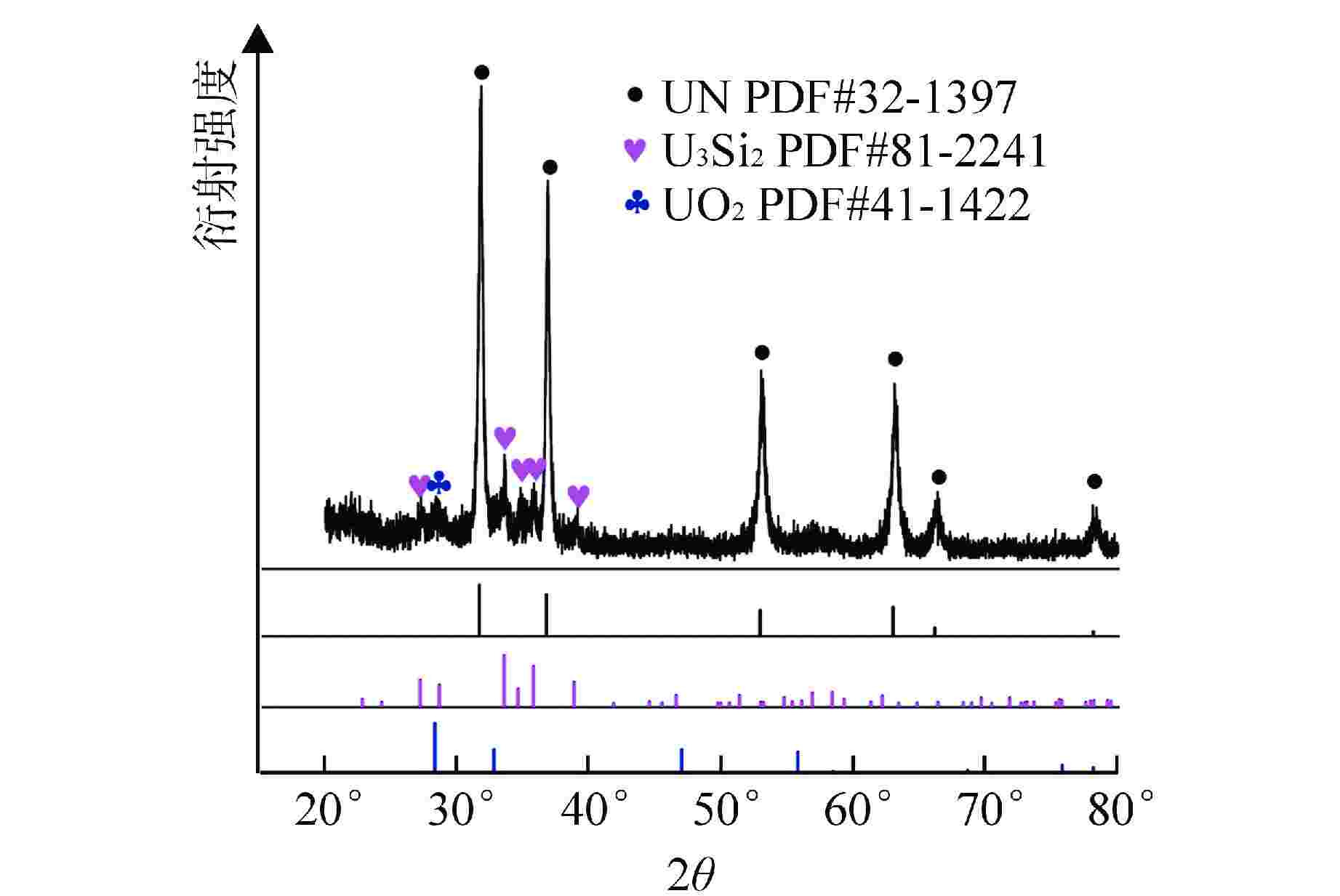

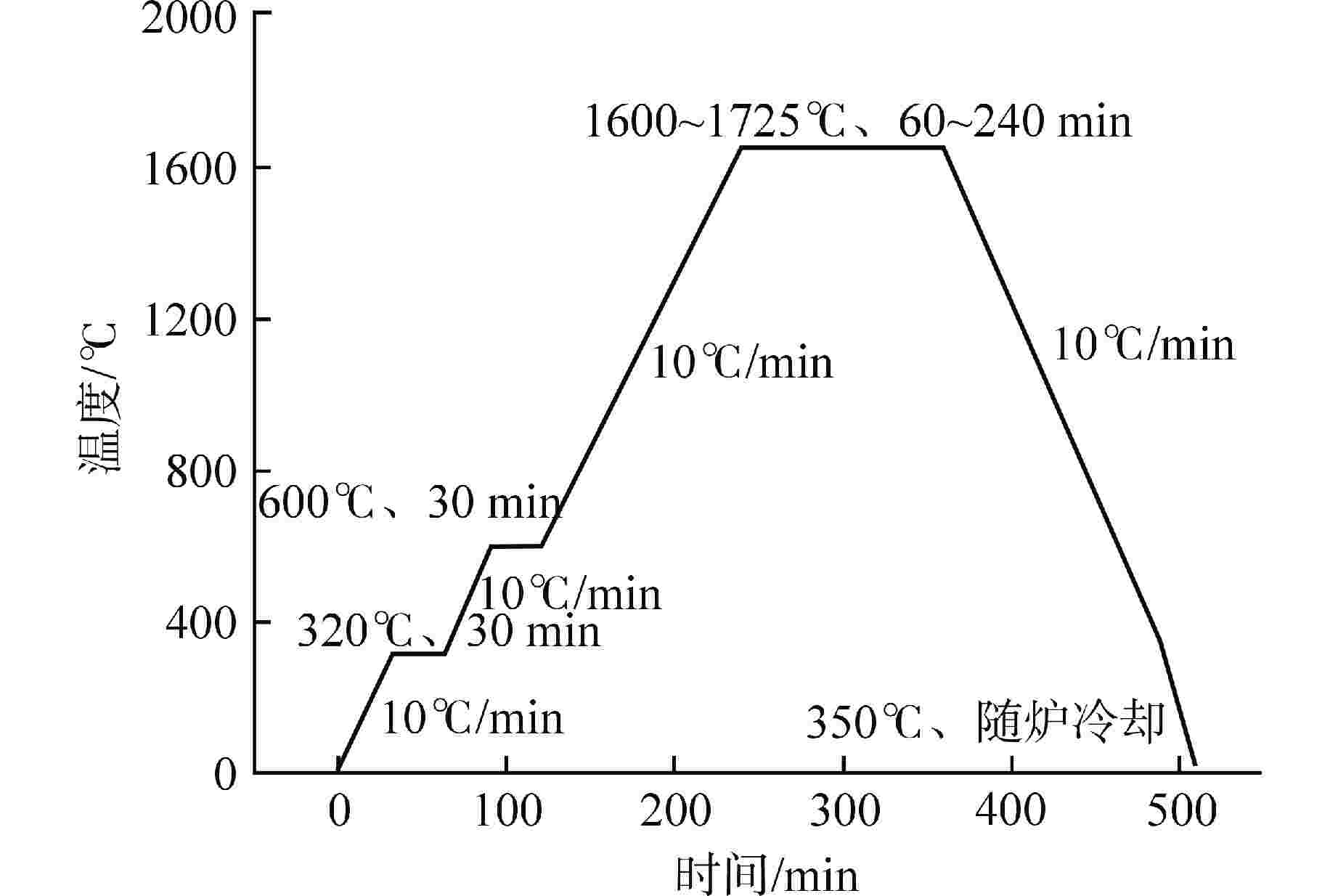

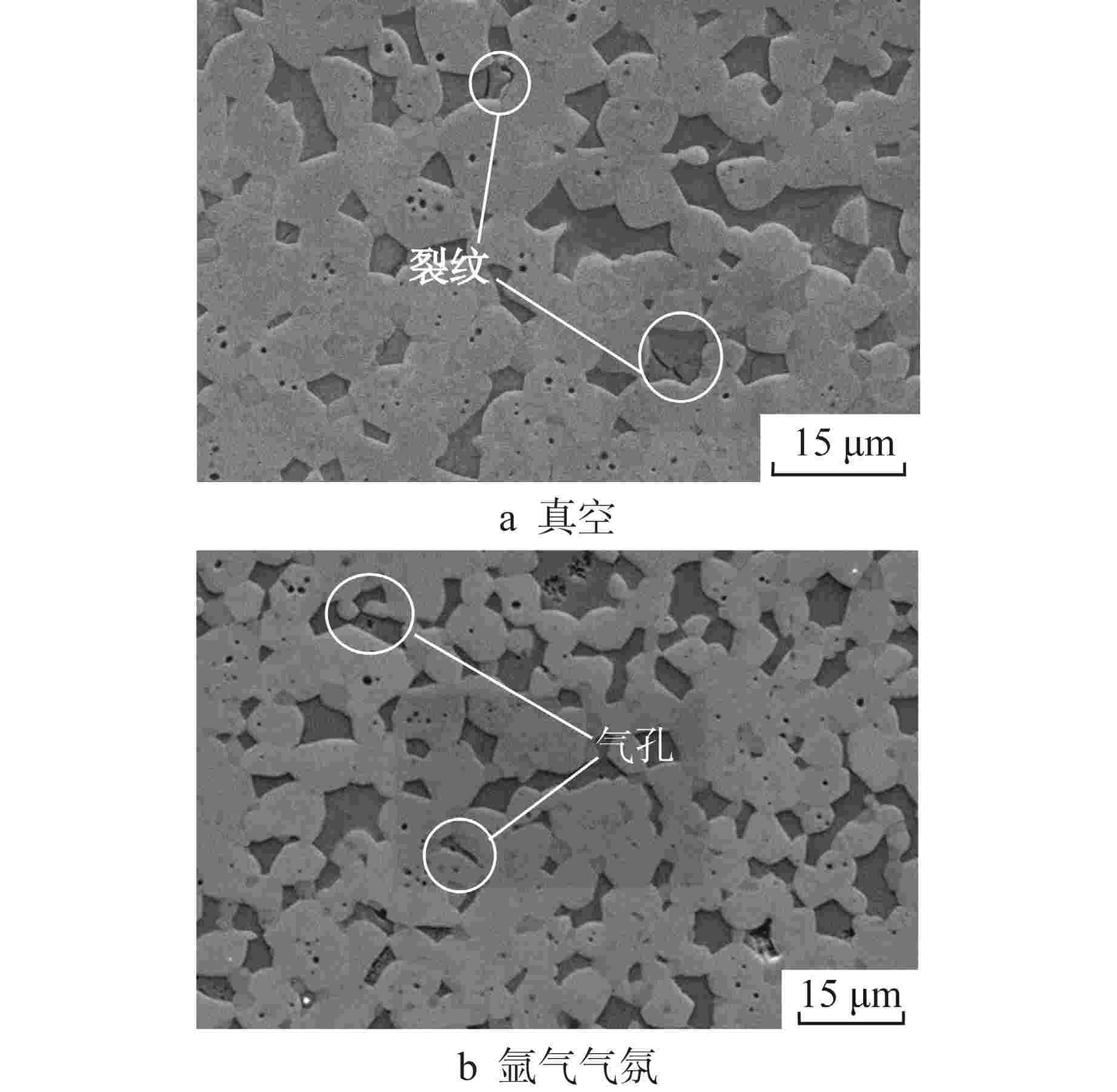

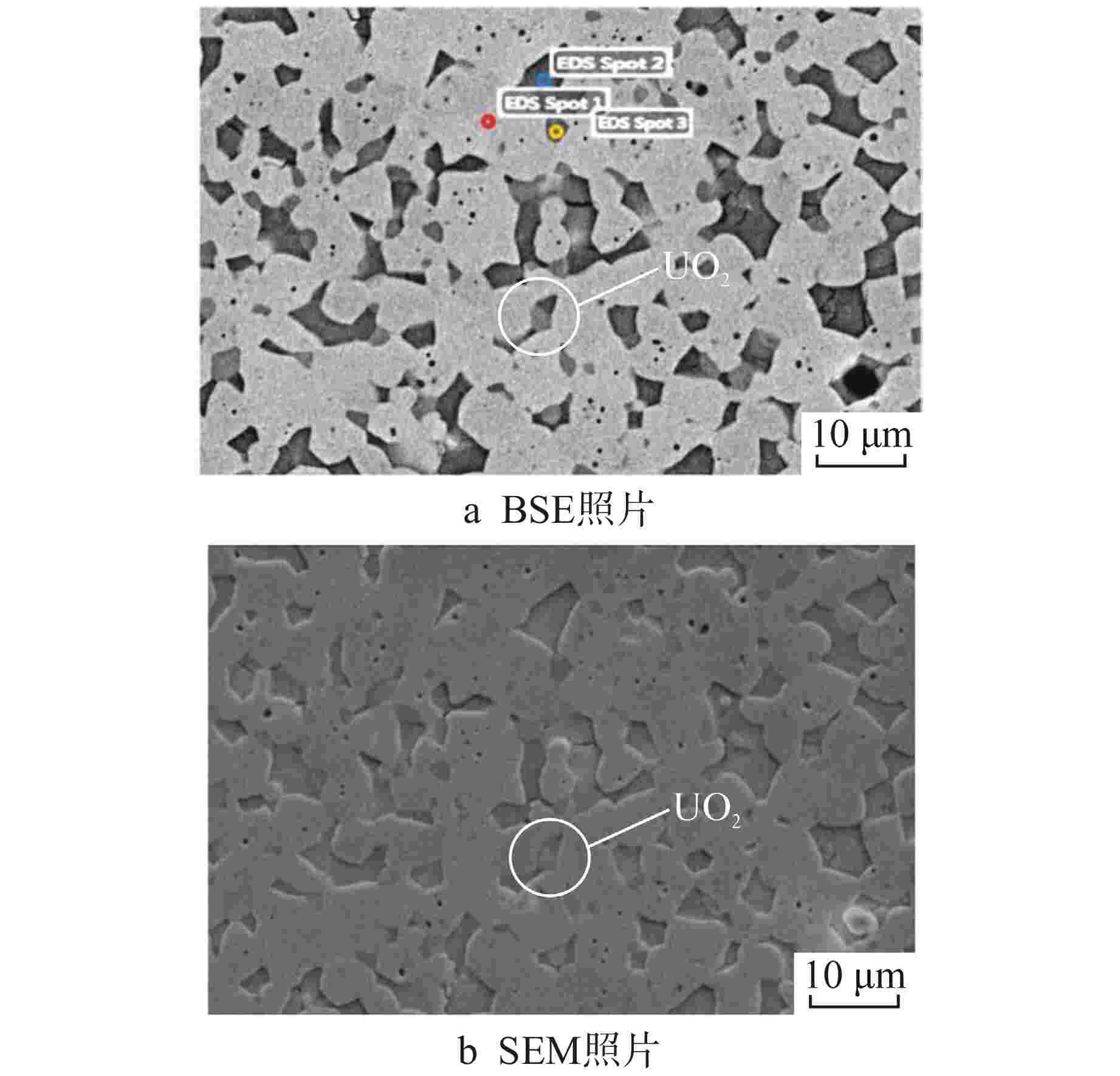

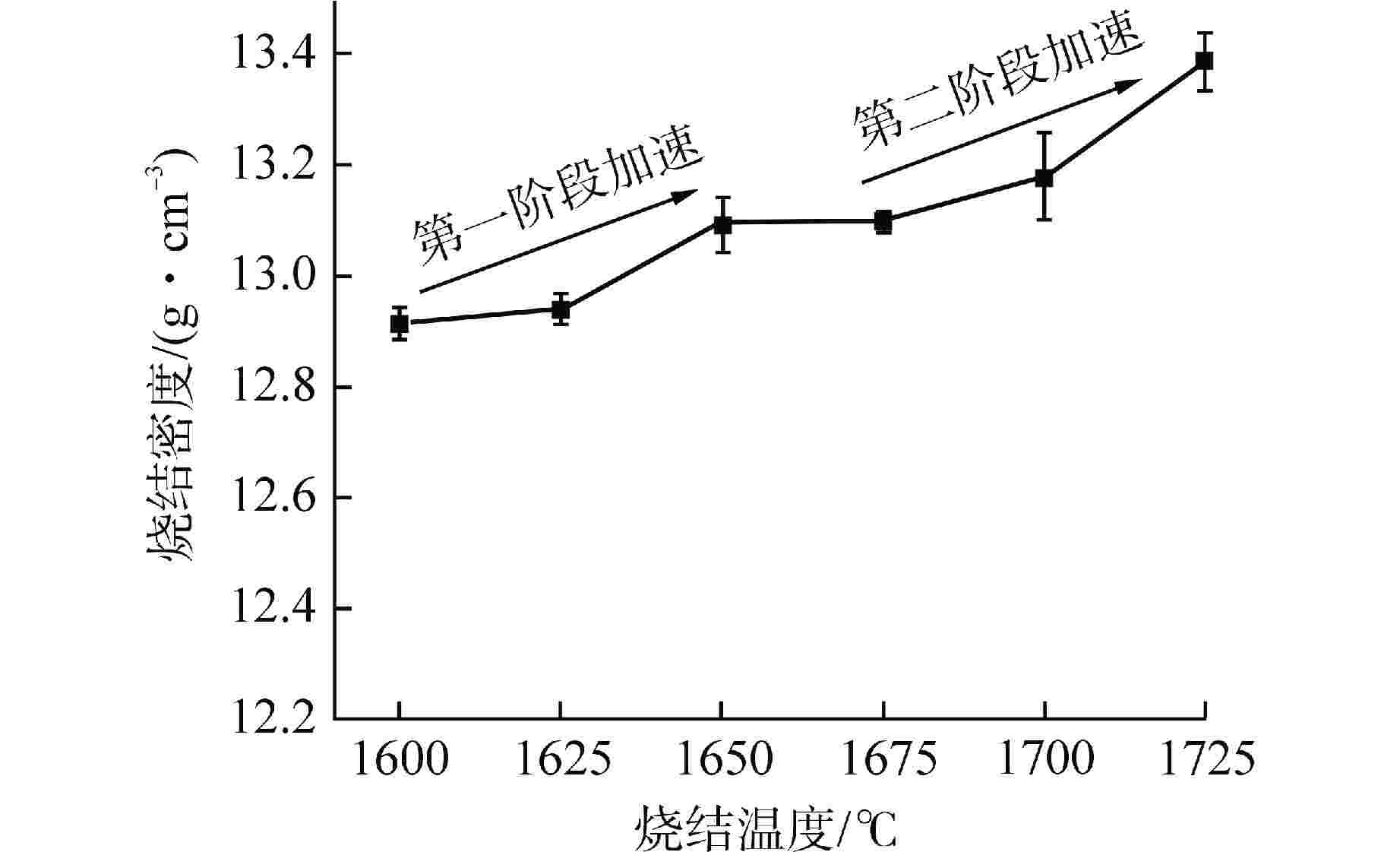

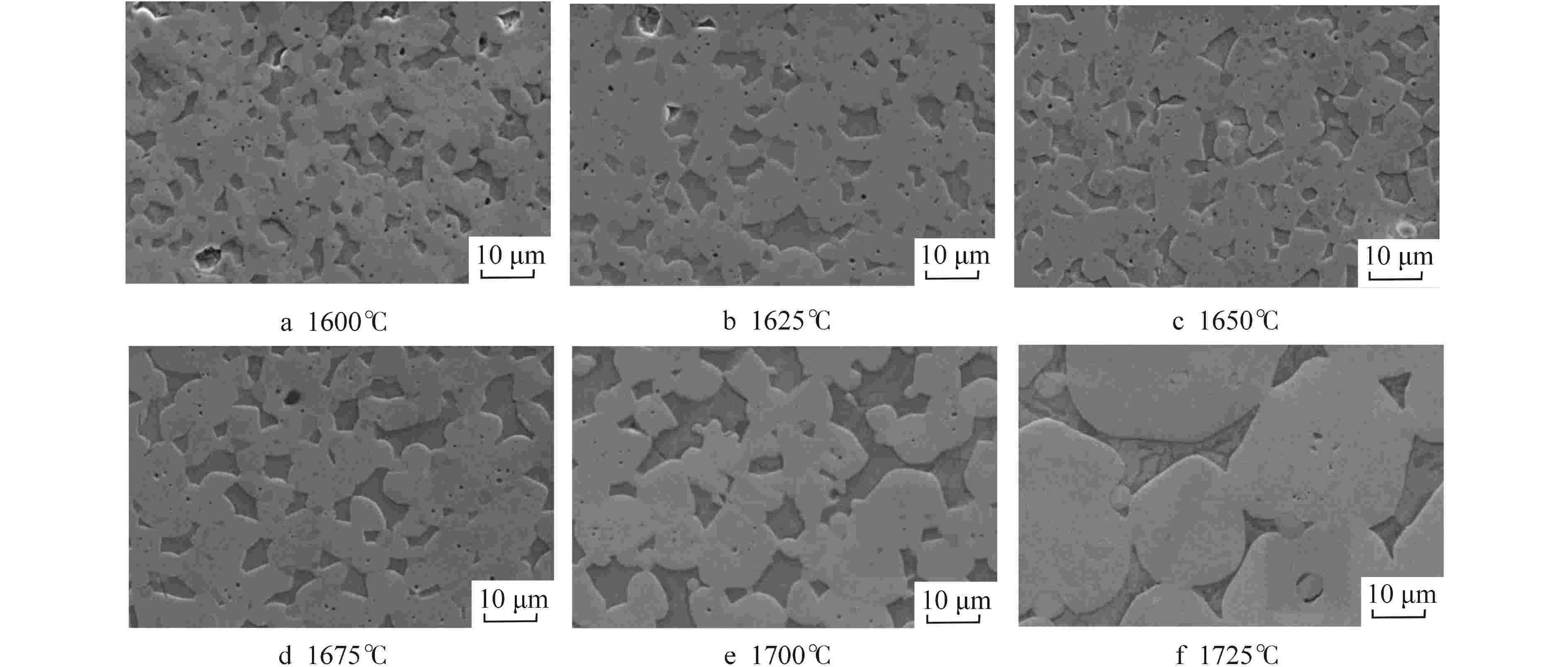

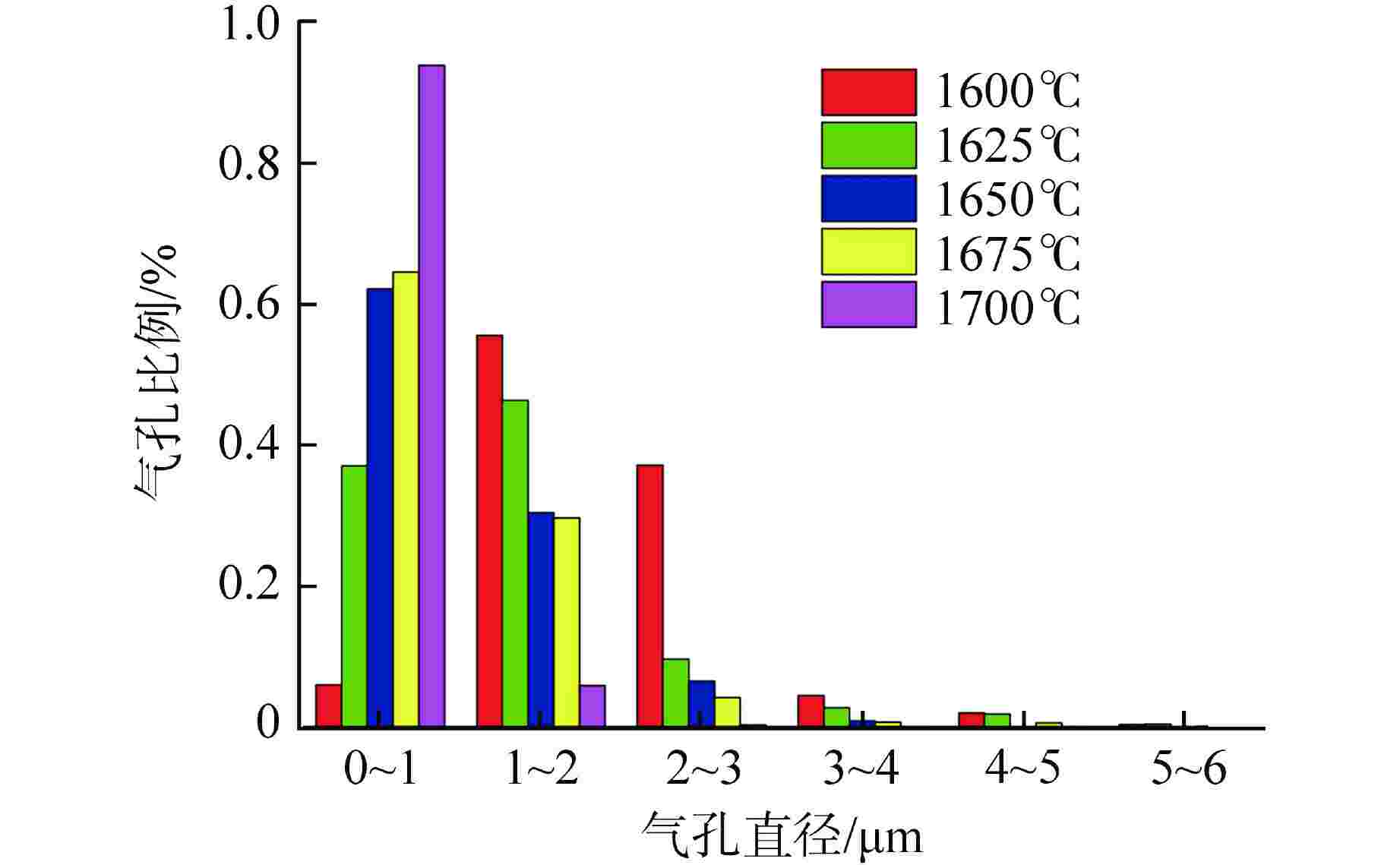

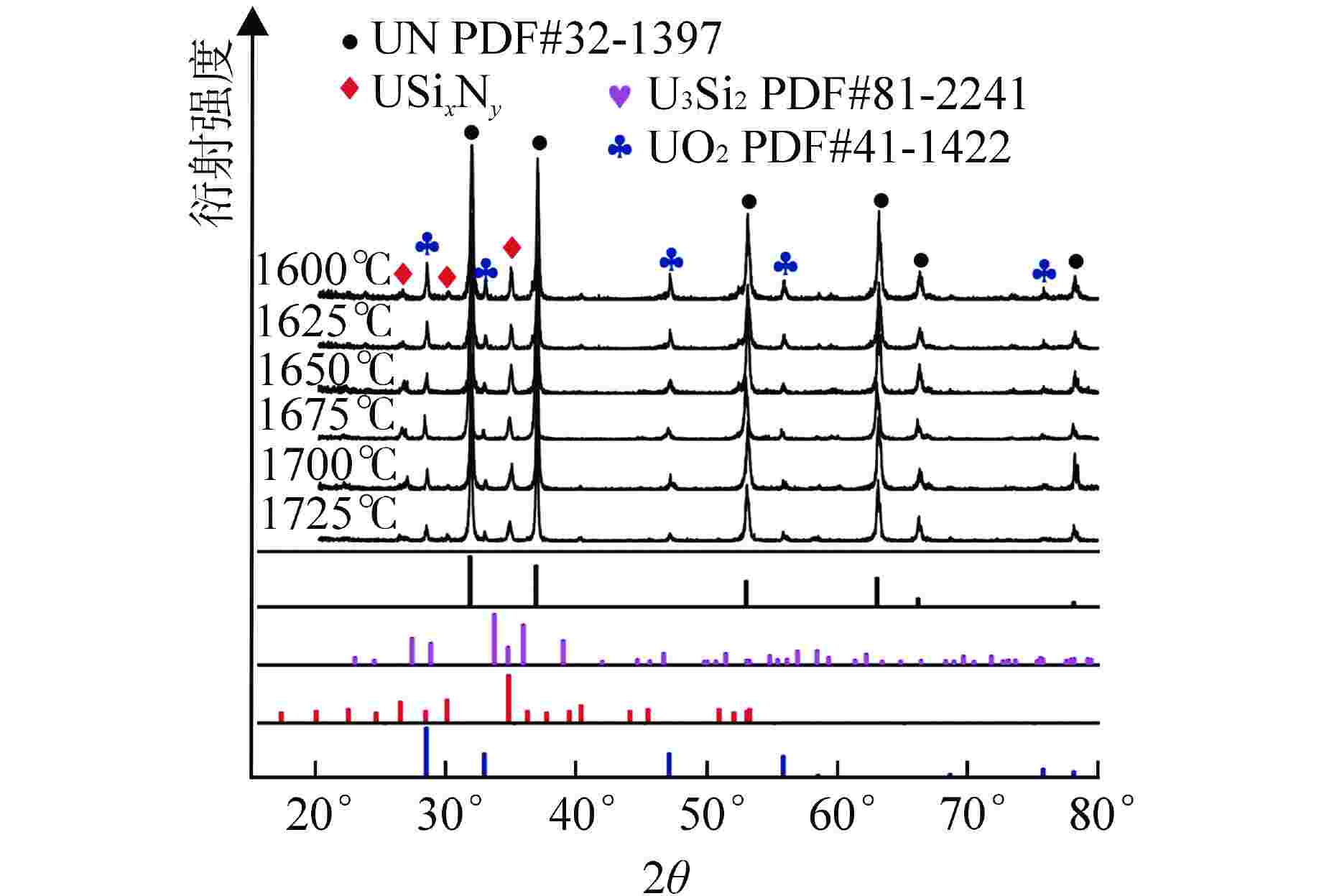

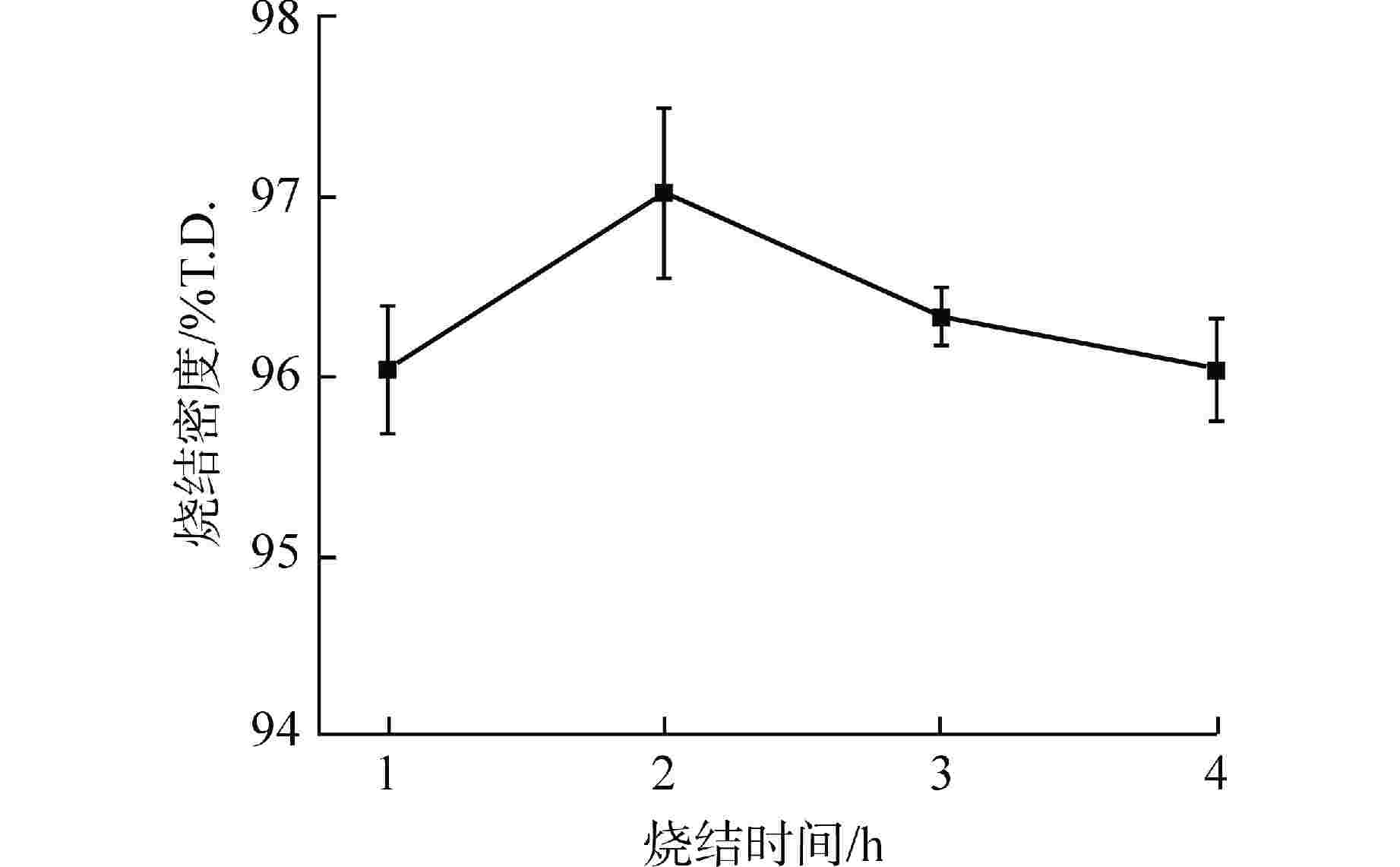

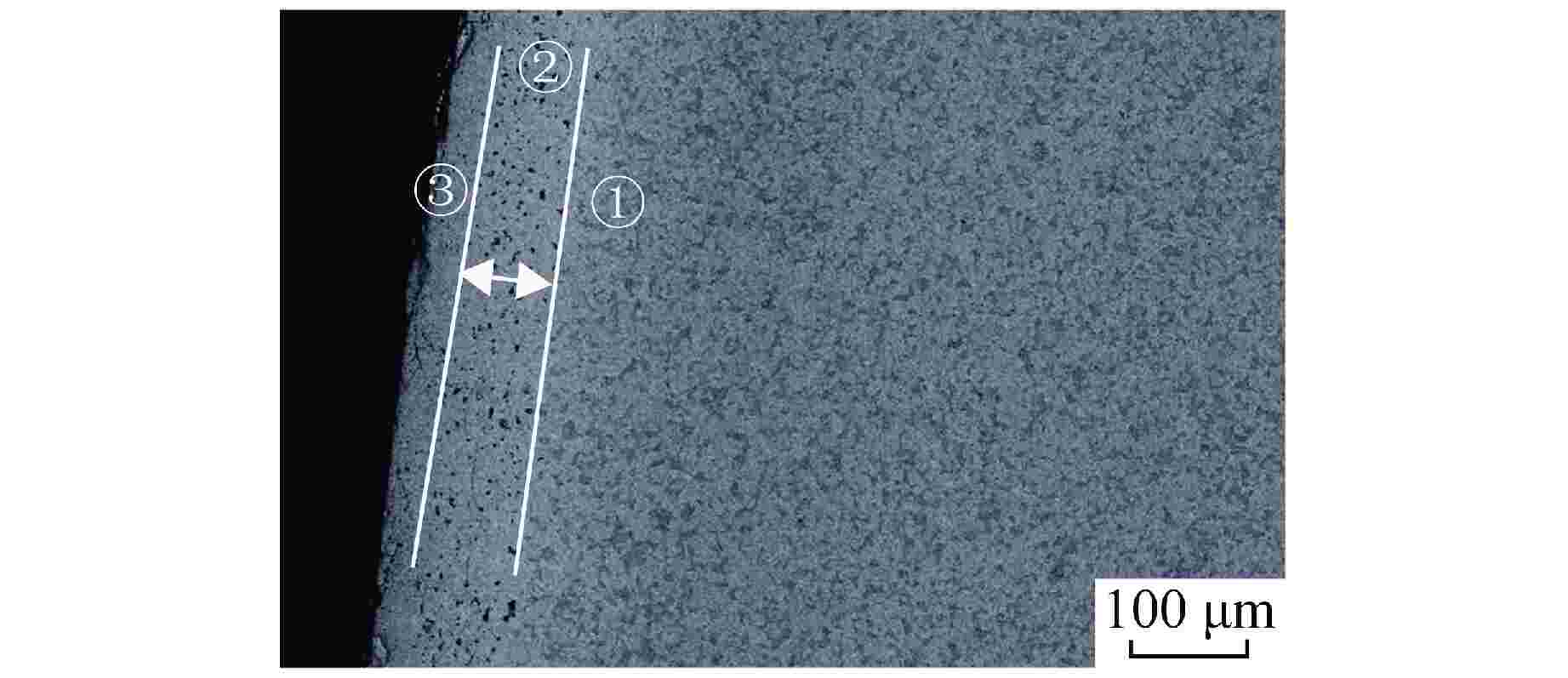

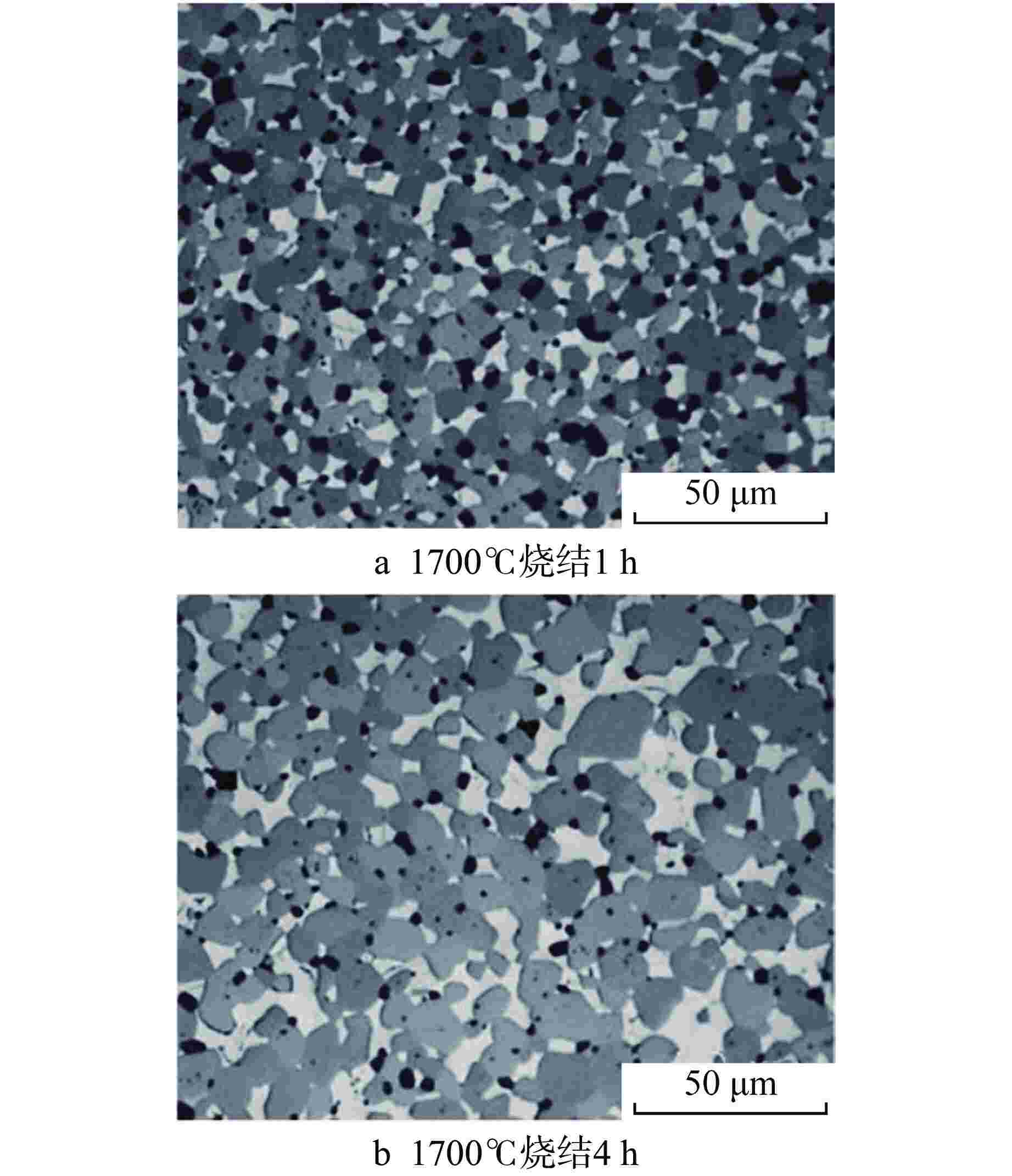

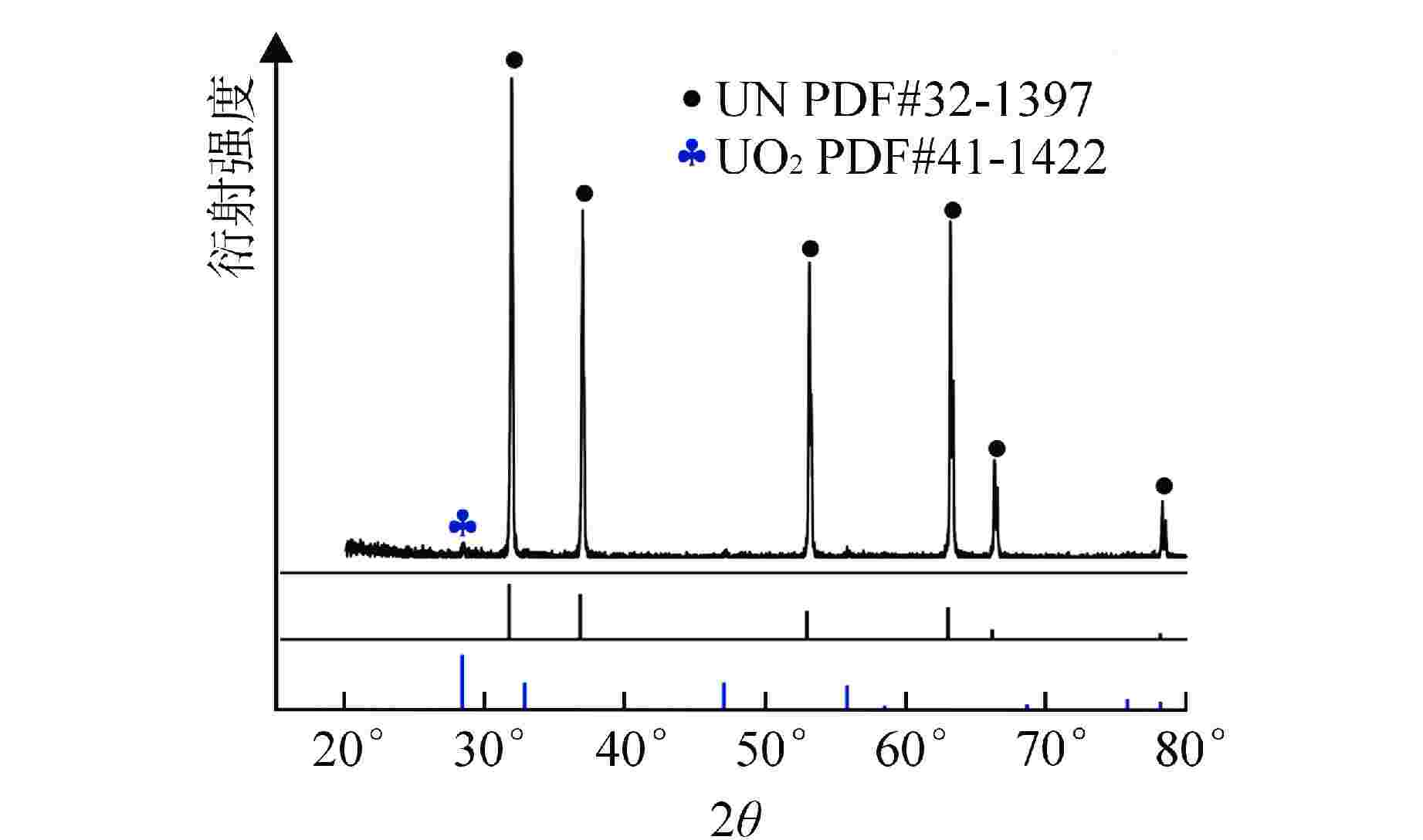

摘要: 本文基于粉末冶金技术制备了UN-30%U3Si2复合燃料芯块(U3Si2质量百分数为30%),研究了烧结气氛、烧结温度、烧结时间等烧结工艺对芯块烧结密度的影响规律,主要通过芯块的化学成分、物相组成以及微观组织变化等方面进行致密化过程分析。结果表明,UN-30%U3Si2复合燃料芯块真空烧结相比氩气气氛烧结更有利于致密化;随着烧结温度(1600~1675℃)升高,致密度逐渐增加,最高可达97%T.D.(T.D.为理论密度);当烧结温度高于U3Si2熔点之后,随着温度上升,U3Si2相在高真空条件下会烧损挥发,并且N元素有向U3Si2相扩散的趋势,形成未知USixNy相;烧结温度的升高或者烧结时间的延长,均有利于U3Si2相对UN相形成包覆。

-

关键词:

- UN-30%U3Si2复合燃料 /

- 烧结工艺 /

- 致密化过程

Abstract: In this paper, UN-30%U3Si2 composite fuel pellets with 30wt.%U3Si2 content were prepared based on powder metallurgy technology. The influence of sintering atmosphere, sintering temperature, sintering time and other sintering processes on the sintering density of pellets was studied. The densification process was analyzed mainly through the chemical composition, phase composition and microstructure changes of pellets. The results show that vacuum sintering of UN-30%U3Si2 composite fuel pellets is more favorable to densification than argon atmosphere sintering. With the increase of sintering temperature (1600~1675°C), the density increases gradually, up to 97%T.D. When the sintering temperature is higher than the melting point of U3Si2, with the increase of temperature, the U3Si2 phase suffers losses and volatilization during the high vacuum sintering process, and the N element tends to diffuse to the U3Si2 phase, forming the unknown USixNy phase. The increase of sintering temperature or the extension of sintering time is conducive to the formation of coating of U3Si2 relative to UN phase.-

Key words:

- UN-30%U3Si2 composite fuel /

- Sintering process /

- Densification process

-

表 1 真空、氩气气氛烧结UN-30%U3Si2复合芯块的元素含量(1650℃)

Table 1. Elemental Content of Sintered UN-30%U3Si2 Composite Pellets in Vacuum and Argon Atmosphere (1650°C)

烧结条件 元素质量百分数/% U N Si C O 真空 92.09 4.80 2.10 0.16 0.81 氩气 92.33 4.20 2.06 0.22 1.00 点 元素质量百分数/% U N Si O EDS Spot 1 84.14 12.73 0 3.13 EDS Spot 2 75.19 3.74 16.16 4.91 EDS Spot 3 82.34 9.96 0 7.70 表 3 不同烧结温度下UN-30%U3Si2复合芯块的Si、U含量

Table 3. Si and U Contents of UN-30%U3Si2 Composite Pellets at Different Sintering Temperatures

元素 质量百分数/% 1600℃ 1625℃ 1650℃ 1675℃ 1700℃ 1725℃ Si 2.22 2.17 2.18 2.10 1.81 0.97 U 92.06 92.33 91.17 92.09 92.47 93.17 表 4 1700℃烧结不同时间UN-30%U3Si2复合芯块的Si、U含量

Table 4. Si and U Contents of 30%U3Si2 Composite Pellets Sintered at 1700°C for Different Time

元素 质量百分数/% 1 h 2 h 3 h 4 h Si 1.90 1.81 1.95 2.00 U 91.22 92.47 92.23 92.50 -

[1] 张喜燕. UO2-锆合金化学反应条件下的包壳水侧氧化动力学[J]. 核科学与工程,1994, 14(3): 262-265. [2] ZINKLE S J, TERRANI K A, GEHIN J C, et al. Accident tolerant fuels for LWRs: A perspective[J]. Journal of Nuclear Materials, 2014, 448(1-3): 374-379. doi: 10.1016/j.jnucmat.2013.12.005 [3] KOO Y H, YANG J H, PARK J Y, et al. KAERI’s development of LWR accident-tolerant fuel[J]. Nuclear Technology, 2014, 186(2): 295-304. doi: 10.13182/NT13-89 [4] KIM D J, KIM K S, KIM D S, et al. Development status of microcell UO2 pellet for accident-tolerant fuel[J]. Nuclear Engineering and Technology, 2018, 50(2): 253-258. doi: 10.1016/j.net.2017.12.008 [5] ZHOU W, ZHOU W Z. Enhanced thermal conductivity accident tolerant fuels for improved reactor safety – A comprehensive review[J]. Annals of Nuclear Energy, 2018, 119: 66-86. doi: 10.1016/j.anucene.2018.04.040 [6] 陆永洪,贾代坤,粟丹科,等. 真空烧结U3Si2燃料芯块的微观组织与导热性能[J]. 粉末冶金材料科学与工程,2022, 27(4): 436-441. [7] MATTHEWS R B, CHIDESTER K M, HOTH C W, et al. Fabrication and testing of uranium nitride fuel for space power reactors[J]. Journal of Nuclear Materials, 1988, 151(3): 345. [8] YAPICI H, İPEK O, ÖZCEYHAN V, et al. Analysis of the rejuvenation performance of hybrid blankets by using uranium fuels (UN, UC, UO2, U3Si2) and different coolants for various volume fraction[J]. Annals of Nuclear Energy, 2000, 27(4): 279-294. doi: 10.1016/S0306-4549(99)00058-4 [9] GONZALES A, WATKINS J K, WAGNER A R, et al. Challenges and opportunities to alloyed and composite fuel architectures to mitigate high uranium density fuel oxidation: uranium silicide[J]. Journal of Nuclear Materials, 2021, 553: 153026. doi: 10.1016/j.jnucmat.2021.153026 [10] WOOD E S, WHITE J T, GROTE C J, et al. U3Si2 behavior in H2O: Part I, flowing steam and the effect of hydrogen[J]. Journal of Nuclear Materials, 2018, 501: 404-412. doi: 10.1016/j.jnucmat.2018.01.002 [11] REST J. A model for fission-gas-bubble behavior in amorphous uranium silicide compounds[J]. Journal of Nuclear Materials, 2004, 325(2-3): 107-117. doi: 10.1016/j.jnucmat.2003.11.008 [12] KIM Y S, HOFMAN G L, REST J, et al. Temperature and dose dependence of fission-gas-bubble swelling in U3Si2[J]. Journal of Nuclear Materials, 2009, 389(3): 443-449. doi: 10.1016/j.jnucmat.2009.02.037 [13] XIONG Q W, QIAN L B, SONG G L, et al. Realistic performance assessment of FeCrAl-UN/U3Si2 accident tolerant fuel under loss-of-coolant accident scenario[J]. Reliability Engineering & System Safety, 2024, 243: 109847. [14] HARP J M, LESSING P A, HOGGAN R E. Uranium silicide pellet fabrication by powder metallurgy for accident tolerant fuel evaluation and irradiation[J]. Journal of Nuclear Materials, 2015, 466: 728-738. doi: 10.1016/j.jnucmat.2015.06.027 [15] JOHNSON K D, RAFTERY A M, LOPES D A, et al. Fabrication and microstructural analysis of UN-U3Si2 composites for accident tolerant fuel applications[J]. Journal of Nuclear Materials, 2016, 477: 18-23. doi: 10.1016/j.jnucmat.2016.05.004 [16] JOHNSON K D, WALLENIUS J, JOLKKONEN M, et al. Spark plasma sintering and porosity studies of uranium nitride[J]. Journal of Nuclear Materials, 2016, 473: 13-17. doi: 10.1016/j.jnucmat.2016.01.037 [17] GONG B W, KARDOULAKI E, YANG K, et al. UN and U3Si2 composites densified by spark plasma sintering for accident-tolerant fuels[J]. Ceramics International, 2022, 48(8): 10762-10769. doi: 10.1016/j.ceramint.2021.12.292 -

下载:

下载: