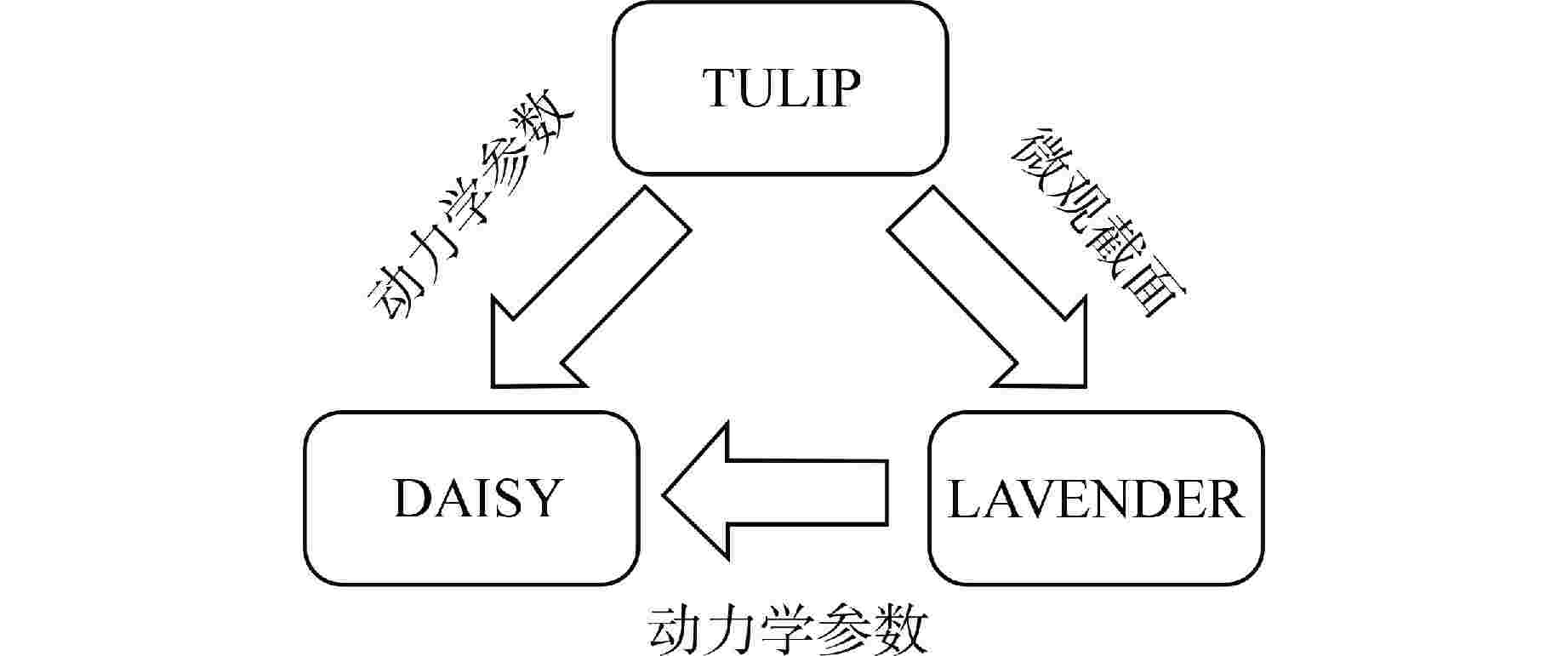

Research on the Application of SARAX in the Design of Marine Heat Pipe Reactor

-

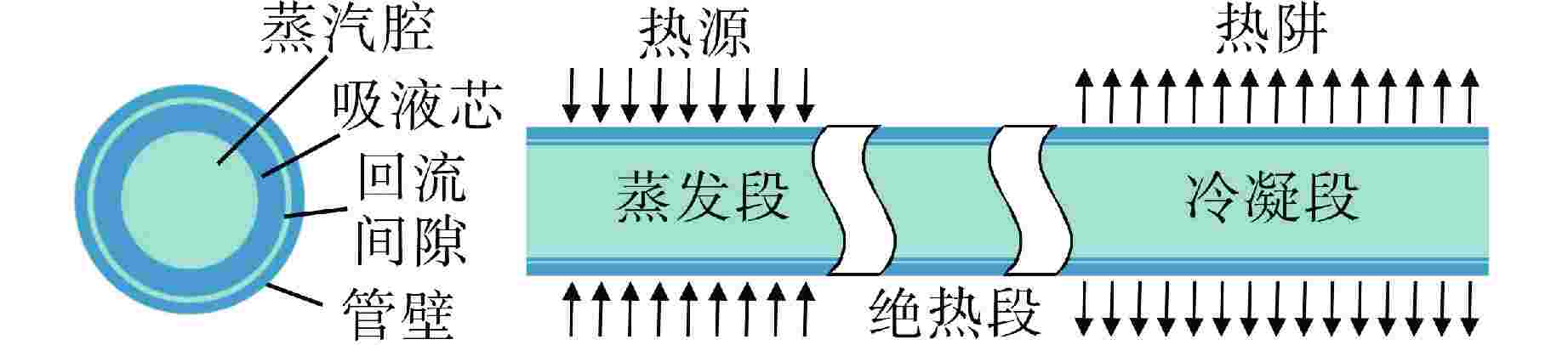

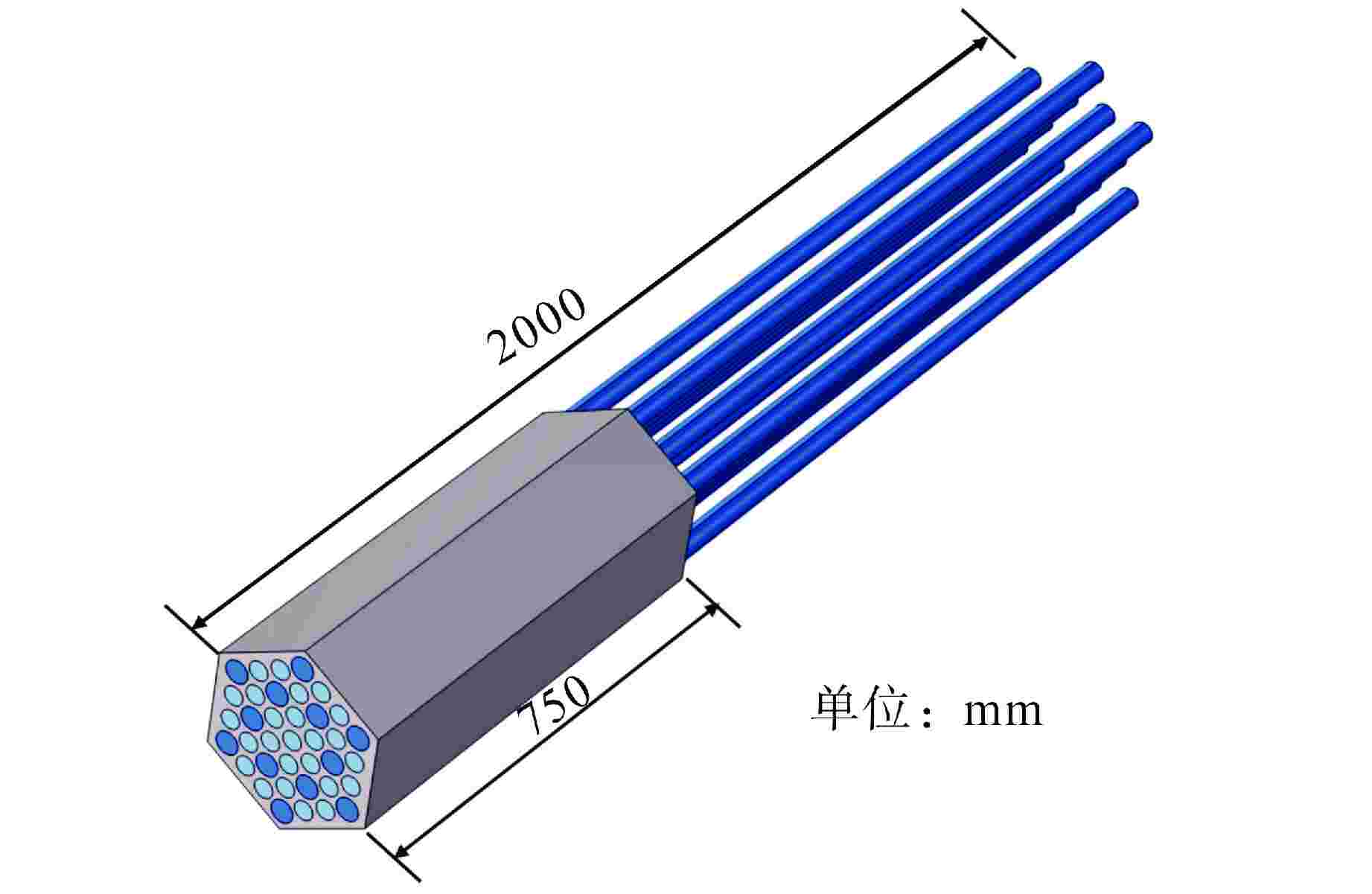

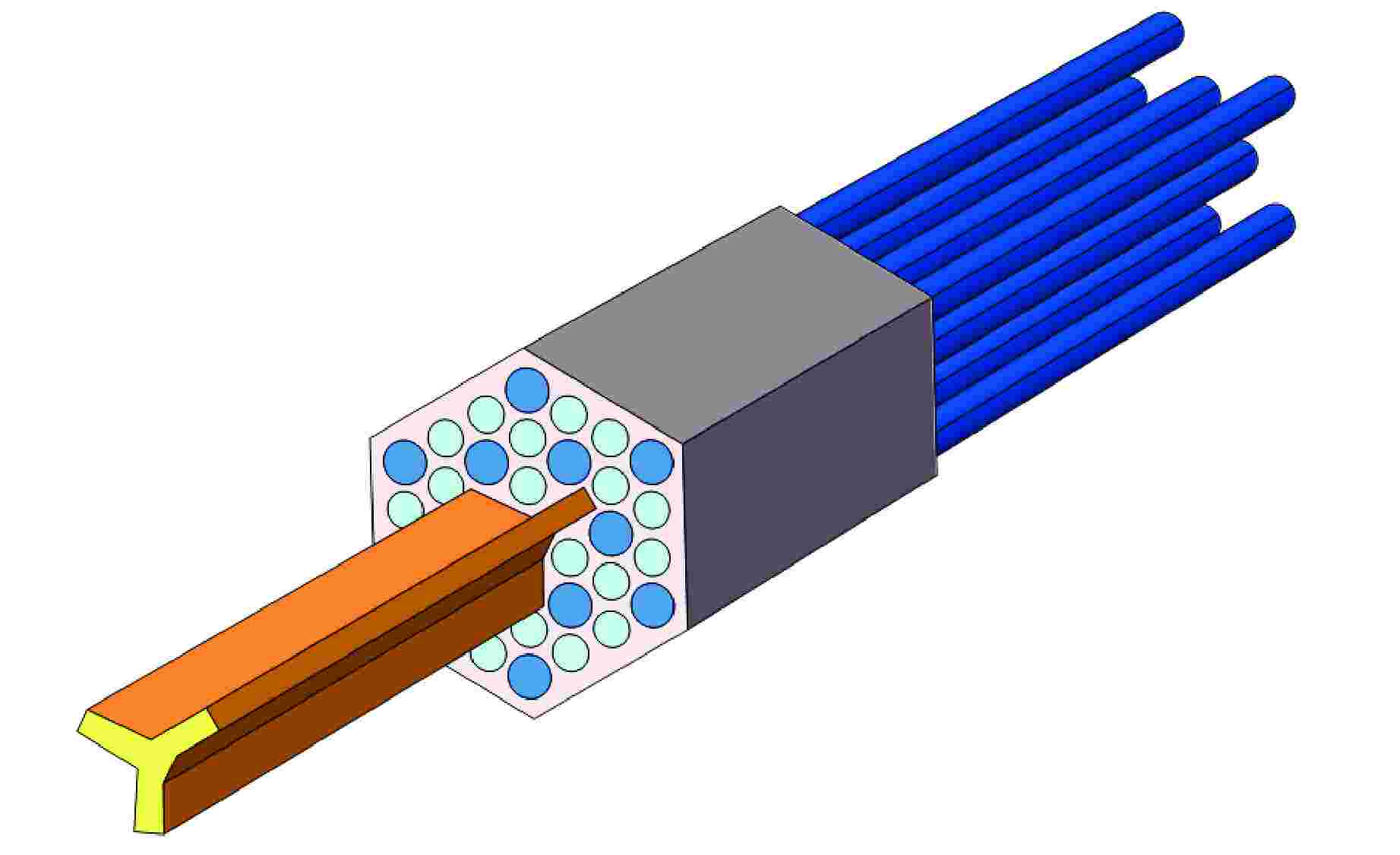

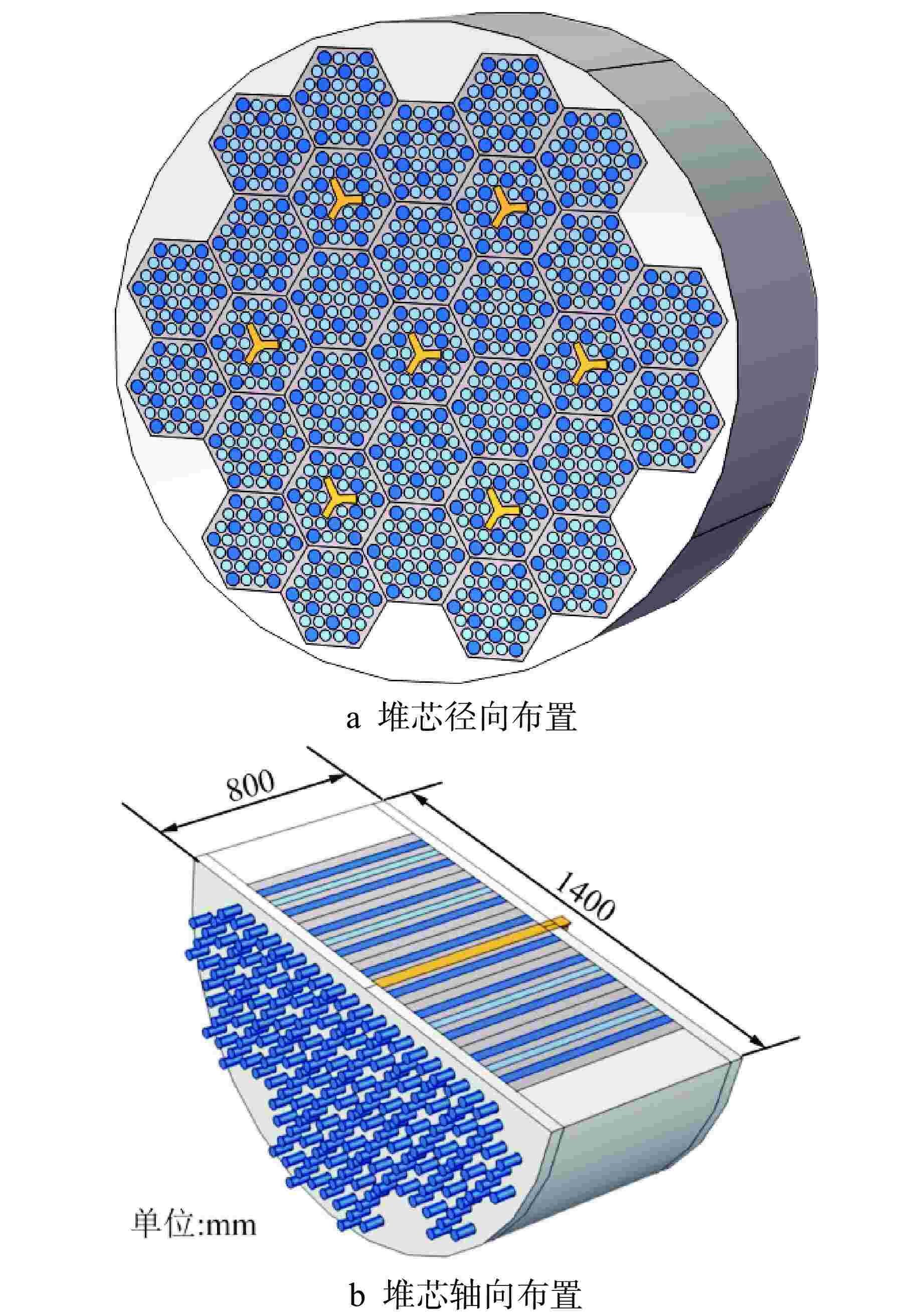

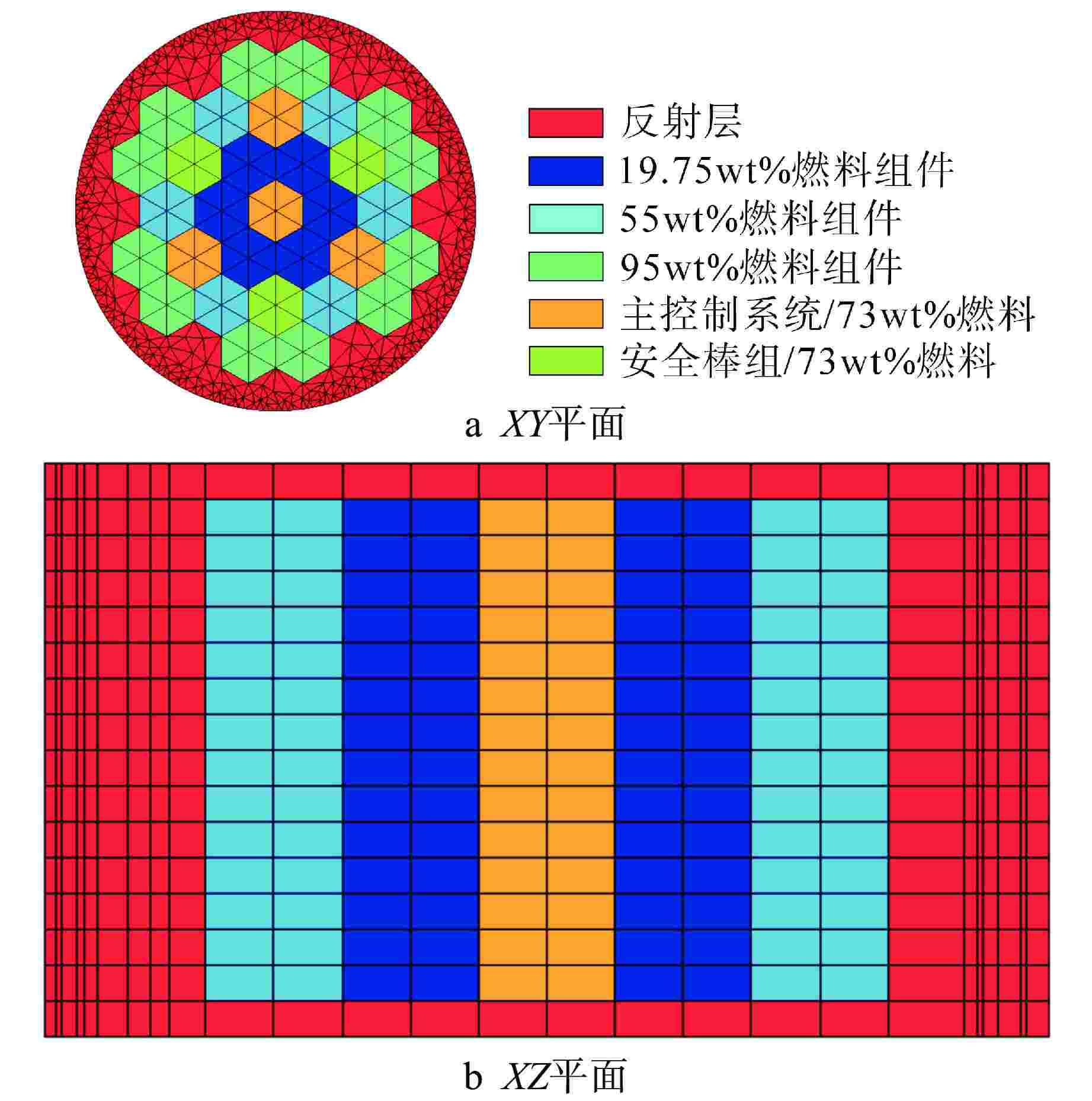

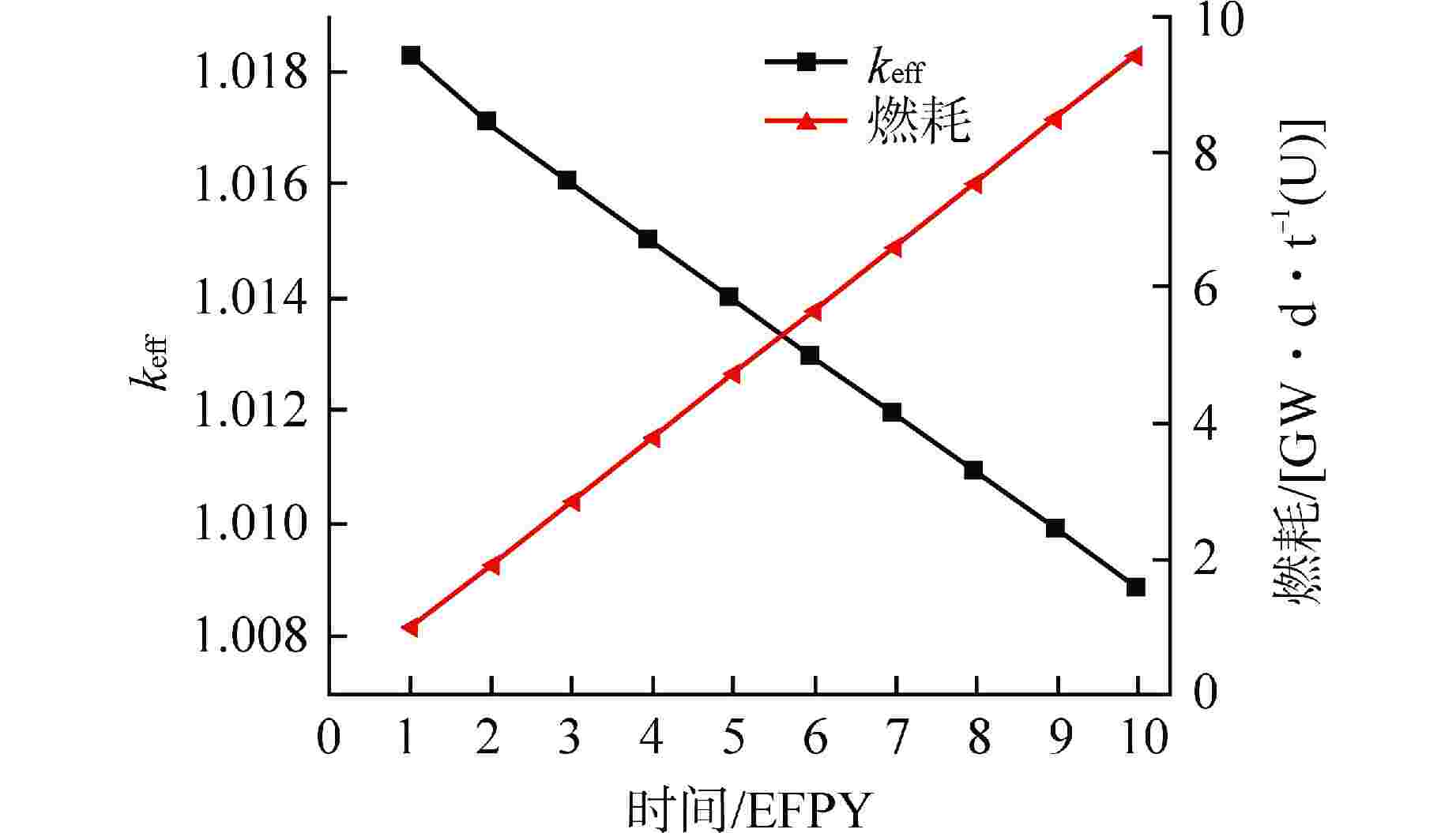

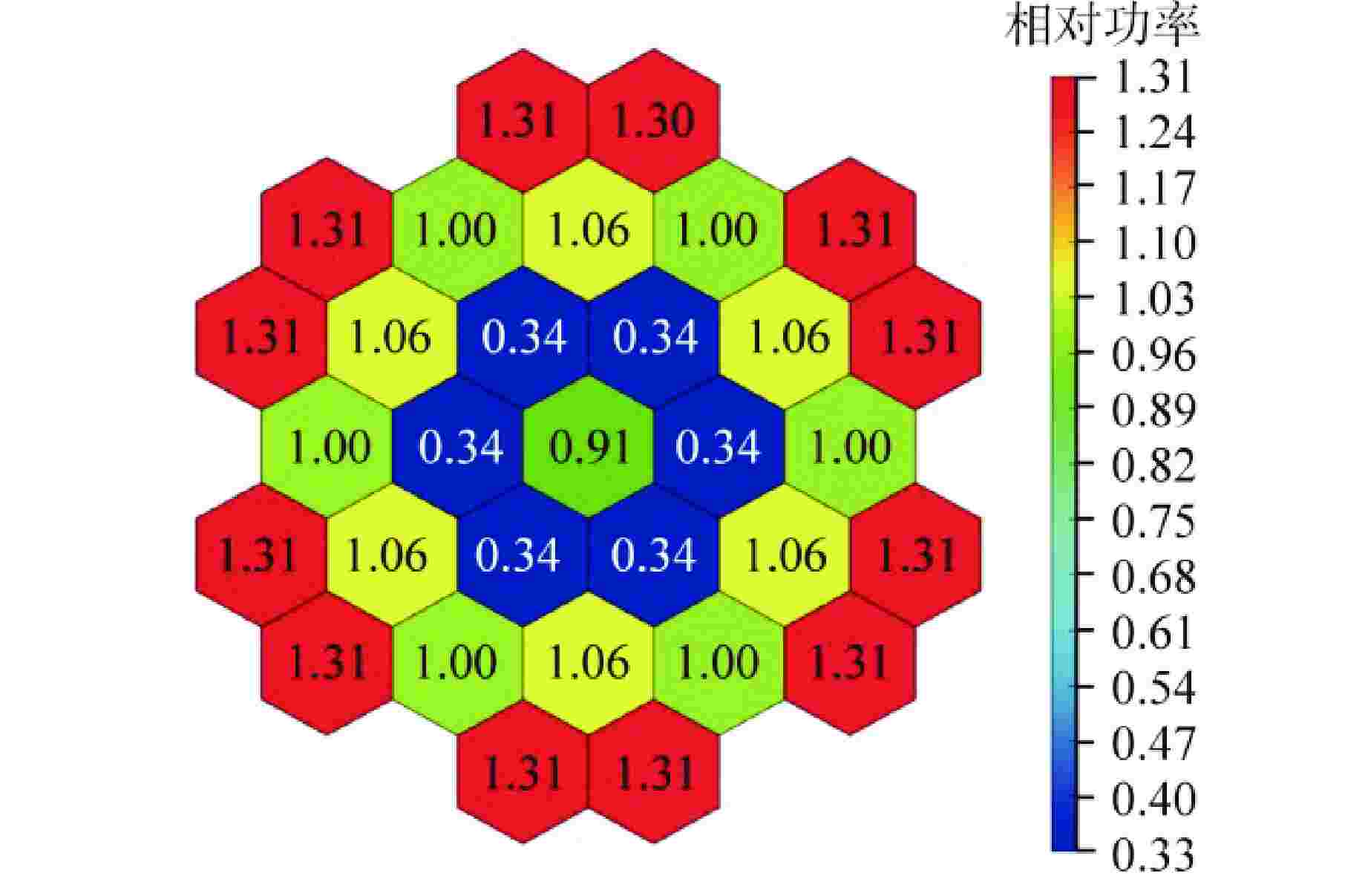

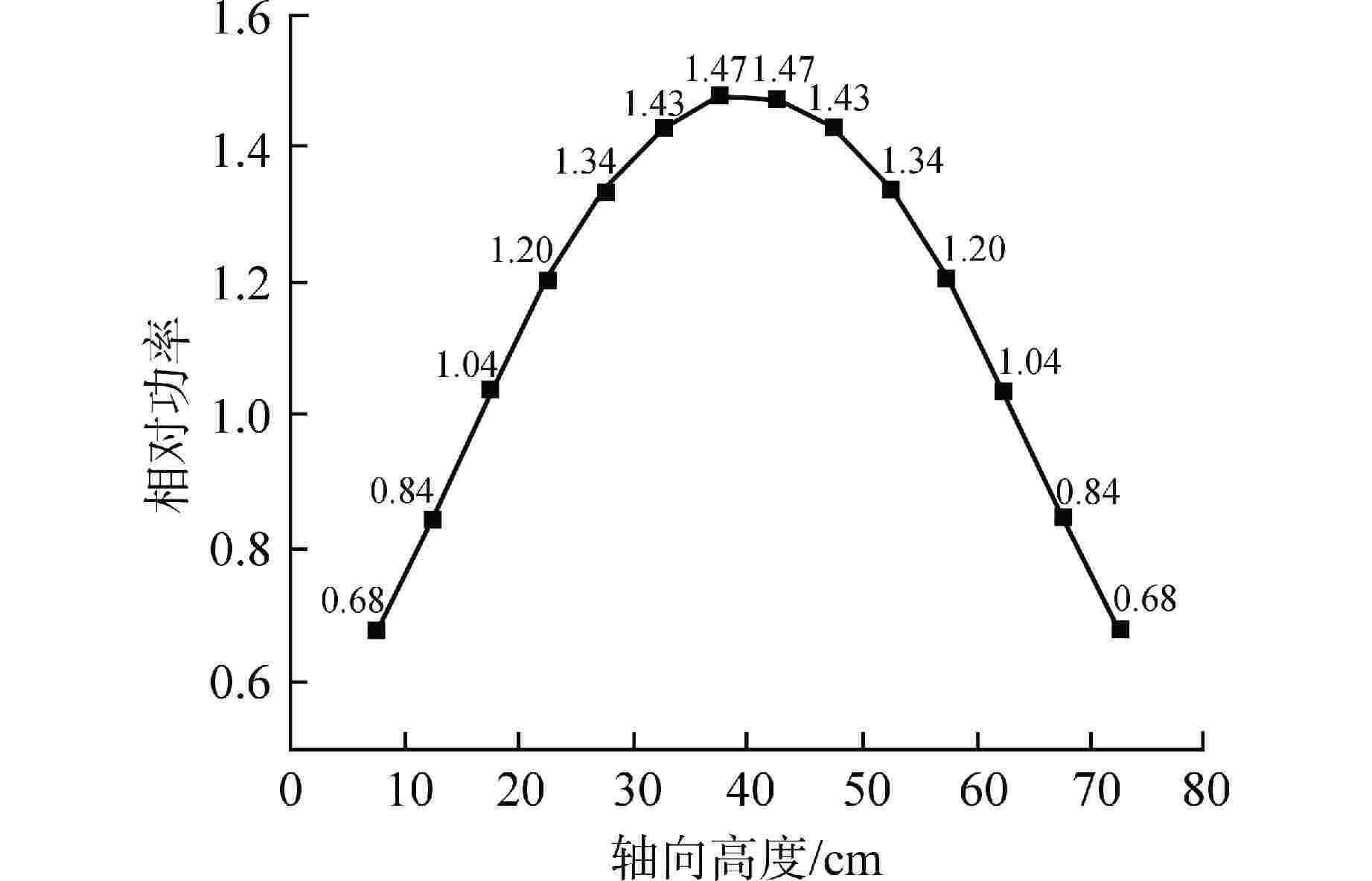

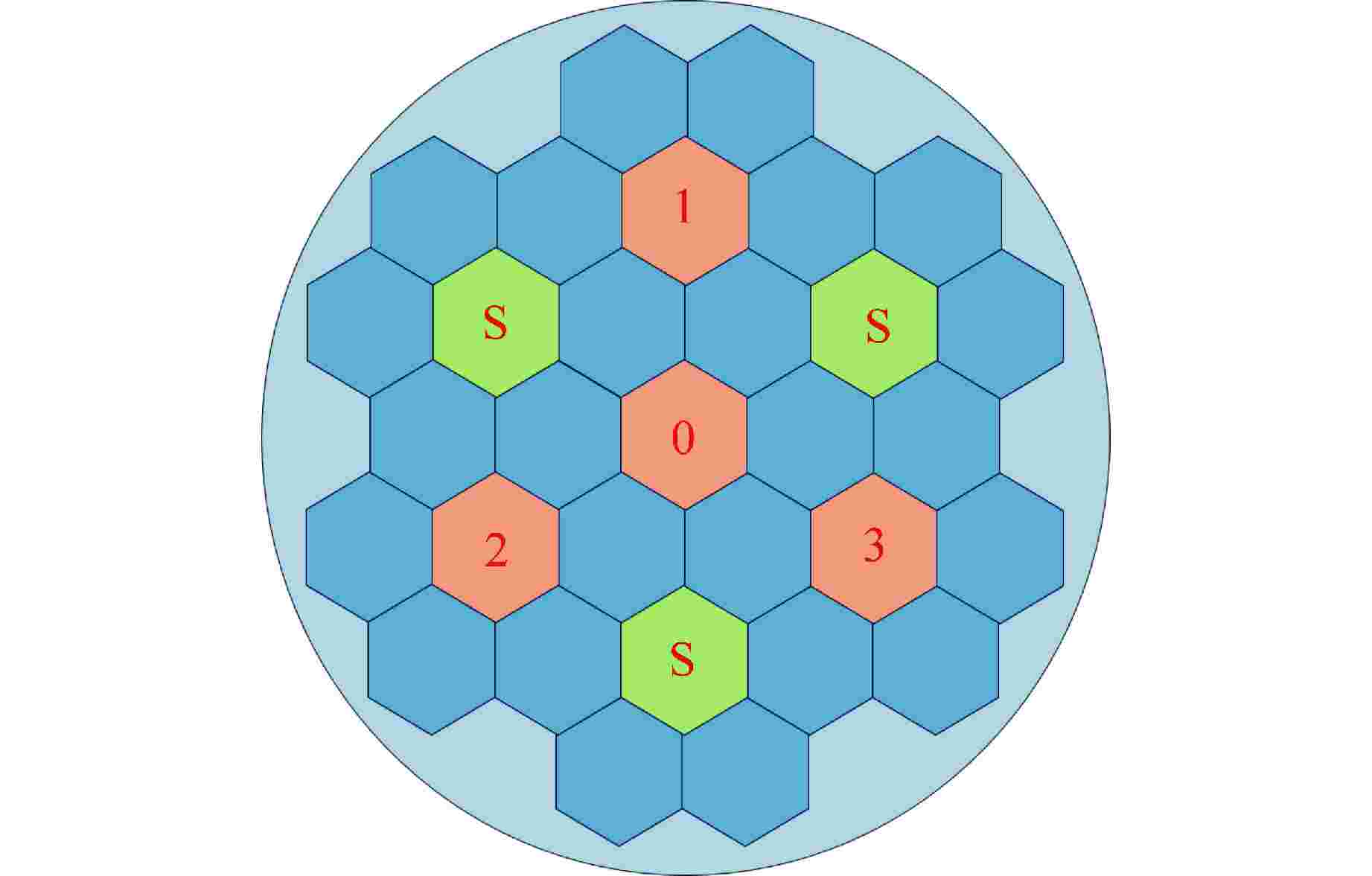

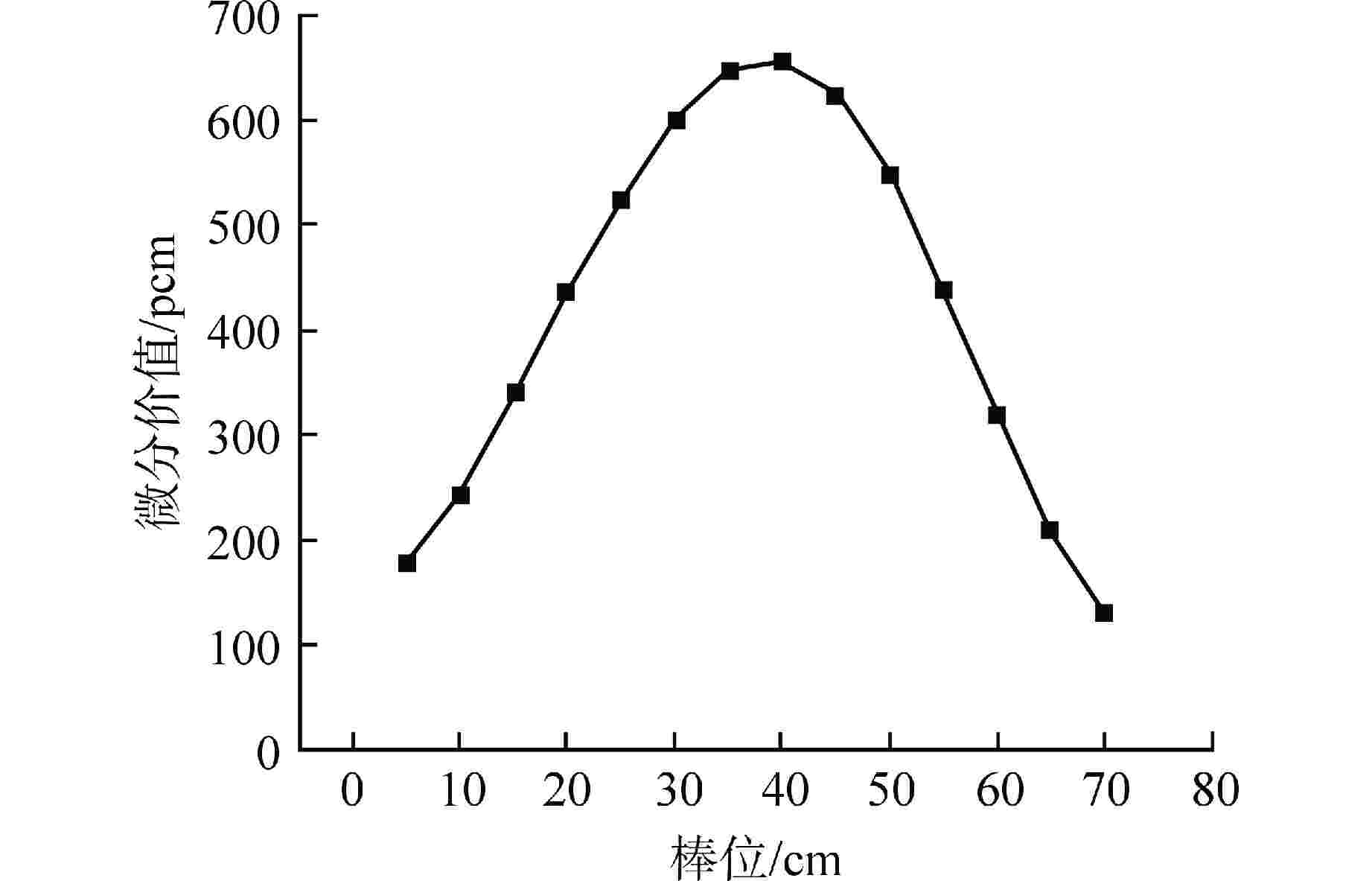

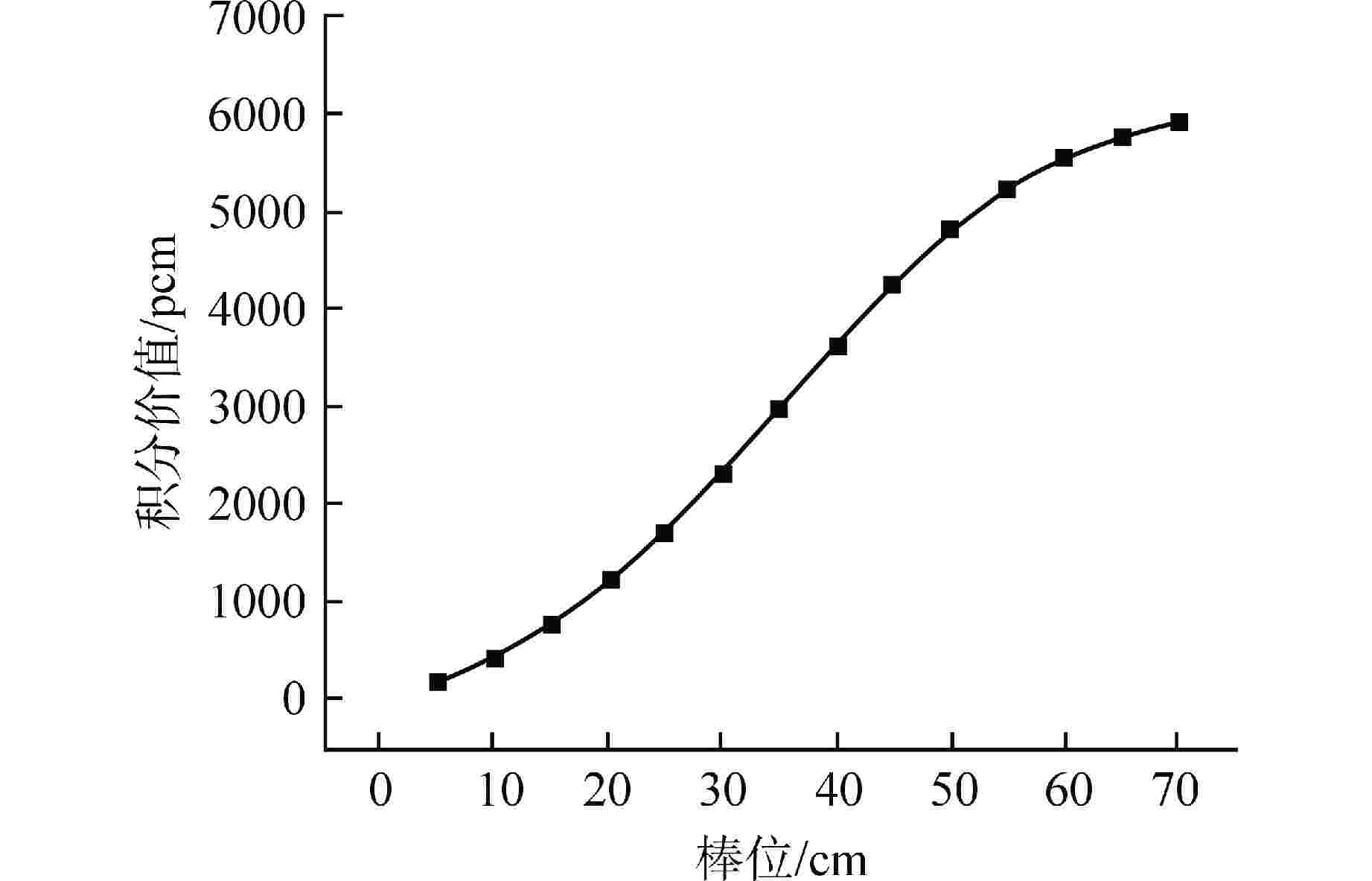

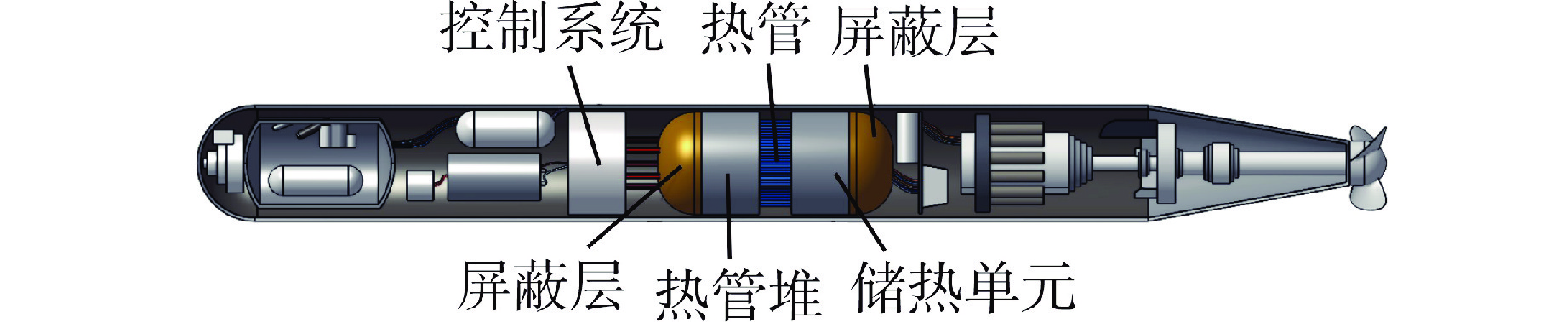

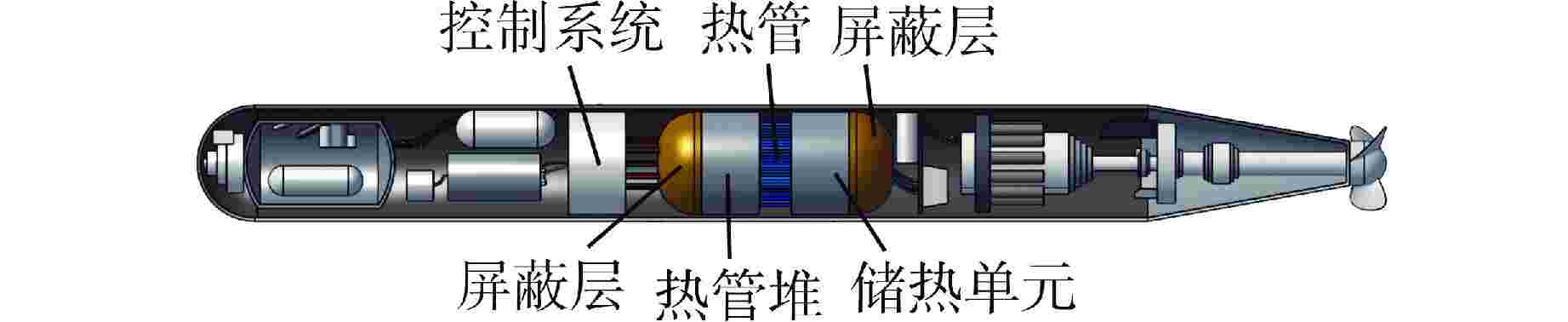

摘要: 随着热管堆技术的逐步成熟,其在水下无人潜航器(UUV)上的应用潜力不断提升。本文针对水下平台对小型化、长寿命、高可靠性核动力系统的需求,提出了一种适用于核动力潜航器的兆瓦级热管堆,设计寿期为10 a。基于SARAX程序对该堆型进行中子学分析,内容包括燃耗趋势、功率分布、反应性系数及控制棒价值等关键参数。计算结果表明,该反应堆具备良好的中子学性能和均匀的功率分布,10 a寿期内燃料的平均燃耗深度为9.455 GW·d/t(U);堆芯径向相对功率峰出现在最外圈燃料组件;补偿棒在寿期内的反应性补偿量小于2000pcm(1pcm=10−5);单根控制棒价值不超过1β,满足反应堆体积小、重量轻、控制安全的设计目标。该堆型有望为UUV提供稳定、持续的水下动力支持,以提升其续航能力与任务执行能力。

-

关键词:

- 无人潜航器(UUV) /

- 热管堆 /

- 中子学

Abstract: With the gradual maturation of heat pipe reactor technology, its potential application in unmanned underwater vehicles (UUVs) is constantly developing. In response to the stringent requirements of underwater platforms for compactness, extended operational lifetime, and high nuclear power system reliability, this paper proposes a megawatt-class heat pipe reactor specifically designed for nuclear-powered UUV, with a design lifetime of 10 years. A comprehensive neutronic analysis was conducted using SARAX, covering critical parameters such as fuel burnup trend, power distribution, reactivity coefficients, and control rod worth. The simulation results demonstrate that the proposed reactor exhibits favorable neutronic characteristics along with a well-balanced power distribution. Over its 10-year lifetime, the reactor achieves an average fuel burnup of 9.455 GW·d/t(U); the radial relative power peak of the core occurs in the outermost fuel assembly; the reactivity compensation of shim rods during the lifetime is less than 2000pcm (pcm=10−5); the worth of a single control rod does not exceed 1 β. These outcomes confirm that the reactor fulfills the design criteria of compactness, lightweight construction, and safe reactivity control. The proposed reactor is expected to provide a stable and continuous power supply for UUVs, thereby significantly enhancing their underwater endurance and mission execution capabilities.-

Key words:

- Submersible /

- Heat pipe reactor /

- Neutronics

-

表 1 候选燃料性能

Table 1. Properties of Candidate Fuels

参数 UO2 UN UC U-10Mo 密度/

(g·cm−3)10.96 14.31 13.60 16.90 熔点/ K 3138 3120 2670~2800 1387 热导率/

(W·m−1·K−1)2.1

(1273.5 K)15.8

(1000 K)18.8

(1000 K)37.5

(1073 K)热膨胀系数/

10−6K12.83 9.90 12.80 热导率为括号中特定温度下参数值。 表 2 常用固体慢化材料物理性能

Table 2. Physical Properties of Commonly-used Solid Moderating Materials

慢化材料种类 密度/

(g·cm−3)中子慢化

能力宏观吸收

截面/cm−1慢化比 氢密度/

cm−3石墨(C) 1.70 0.065 3.3×10−4 200 铍(Be) 1.84 0.16 1.23×10−3 130 氧化铍(BeO) 3.00 0.12 7.4×10−4 163 氢化锆(ZrH2) 5.62 1.45 3.0×10−2 49 7.3×10²² 氢化钇(YH2) 4.30 1.20 4.8×10−2 25 5.8×10²² 氢化钛(TiH2) 3.78 1.85 2.9×10−1 6.3 9.1×10²² 表 3 燃料组件主要材料参数

Table 3. Main Material Parameters of Fuel Assembly

元件 参数名 参数值 燃料 燃料棒数目/根 25 UO2富集度/% 19.75/55/95/73 可燃毒物丰度/% 60/30/60/19.75 密度/(g·cm−3) 10.42 基体 材料种类 SiC 密度/(g·cm−3) 3.2 包壳 材料种类 不锈钢 密度/(g·cm−3) 7.98 表 4 热管堆堆芯参数

Table 4. Core Parameters for Heat Pipe Reactor

参数名 参数值 燃料组件数/个 31 UO2富集度/% 19.75/55/95/73 燃料棒数目/根 747 热管数目/根 372 反射层材料 Be 可燃毒物材料 B4C 控制棒吸收体材料 B4C 活性区高度/mm 700 活性区等效直径/mm 1110 反应堆堆芯高度/mm 800 反射层外径/mm 1400 表 5 热管堆的多普勒系数

Table 5. Doppler Coefficient for Heat Pipe Reactor

参数名 参数值 反应性变化/pcm −22.871 多普勒系数/ (pcm·K−1) −0.0254 表 6 热管堆的安全棒价值

Table 6. Safety Rod Value of Heat Pipe Reactor

工况类型 keff 价值/pcm 安全棒全提 1.01835 安全棒全插 0.96916 4919 -

[1] 伍赛特. 核动力装置应用于民用商船的可行性分析研究[J]. 中国水运,2018, 18(10): 97-98. [2] GIBSON M A, MASON L S, BOWMAN C, et al. Kilopower, NASA's small fission power system for science and human exploration[C]//Proceedings of the 12th International Energy Conversion Engineering Conference. Cleveland: AIAA, 2014. [3] 余红星,马誉高,张卓华,等. 热管冷却反应堆的兴起和发展[J]. 核动力工程,2019, 40(4): 1-8. [4] POSTON D I. The heatpipe-operated mars exploration reactor (HOMER)[J]. AIP Conference Proceedings, 2001, 552(1): 797-804. [5] EL-GENK M S, TOURNIER J P. "SAIRS"—scalable amtec integrated reactor space power system[J]. Progress in Nuclear Energy, 2004, 45(1): 25-69. doi: 10.1016/j.pnucene.2004.08.002 [6] EL-GENK M S, TOURNIER J M. Conceptual design of HP-STMCs space reactor power system for 110 kWe[J]. AIP Conference Proceedings, 2004, 699(1): 658-672. [7] LEVINSKY A, VAN WYK J J, ARAFAT Y, et al. Westinghouse eVinciTM reactor for off-grid markets[C]//American Nuclear Society Winter Meeting 2018. Orlando:American Nuclear Society, 2018. [8] DU X N, TAO Y S, ZHENG Y Q, et al. Reactor core design of UPR-s: a nuclear reactor for silence thermoelectric system NUSTER[J]. Nuclear Engineering and Design, 2021, 383: 111404. [9] WU Y Q, ZHENG Y Q, TAO Y S, et al. The low-enriched uranium core design of a MW heat pipe cooled reactor[J]. Nuclear Engineering and Design, 2023, 404: 112195. doi: 10.1016/j.nucengdes.2023.112195 [10] ZHENG Y Q, DU X N, XU Z T, et al. SARAX: a new code for fast reactor analysis part I: methods[J]. Nuclear Engineering and Design, 2018, 340: 421-430. [11] ZHENG Y Q, QIAO L, ZHAI Z A, et al. SARAX: a new code for fast reactor analysis part II: verification, validation and uncertainty quantification[J]. Nuclear Engineering and Design, 2018, 331: 41-53. doi: 10.1016/j.nucengdes.2018.02.033 [12] DU X N, ZHENG Y Q, WANG Y P, et al. Validation of SARAX code system using the SFR operational tests[J]. Annals of Nuclear Energy, 2020, 147: 107744. [13] DU X N, CAO L Z, ZHENG Y Q, et al. A hybrid method to generate few-group cross sections for fast reactor analysis[J]. Journal of Nuclear Science and Technology, 2018, 55(8): 931-944. [14] ZHOU S C, WU H C, CAO L Z, et al. LAVENDER: a steady-state core analysis code for design studies of accelerator driven subcritical reactors[J]. Nuclear Engineering and Design, 2014, 278: 434-444. doi: 10.1016/j.nucengdes.2014.07.027 [15] TOSHI S. Japan’s experimental fast reactor JOYO MK-I core: sodium-cooled uranium-plutonium mixed oxide fueled fast core surrounded by UO2 blanket[Z]. USA: Argonne National Lab (ANL), 2006. [16] ISHIKAWA M. ZPPR17A experiment: a 650 MWe-class sodium-cooled mox-fueled FBR axial heterogeneous core mock-up critical experiment with central internal blanket zone[Z]. USA: Argonne National Lab (ANL), 2006. [17] PONOMAREV A, MIKITYUK K, ZHANG L, et al. Superphénix benchmark Part I: results of static neutronics[J]. Journal of Nuclear Engineering and Radiation Science, 2022, 8(1): 011320. doi: 10.1115/1.4051449 [18] 苏著亭,杨继材,柯国土. 空间核动力[M]. 上海: 上海交通大学出版社,2016: 214. [19] 洪兵. 锂热管冷却空间反应堆堆芯物理特性研究[D]. 合肥: 中国科学技术大学,2018. [20] EL-GENK M S, TOURNIER J M. A review of refractory metal alloys and mechanically alloyed-oxide dispersion strengthened steels for space nuclear power systems[J]. Journal of Nuclear Materials, 2005, 340(1): 93-112. doi: 10.1016/j.jnucmat.2004.10.118 [21] 杨文斗. 反应堆材料学[M]. 北京: 原子能出版社,2000: 305. [22] TIAN Z X, ZHANG J R, WANG C L, et al. Experimental evaluation on heat transfer limits of sodium heat pipe with screen mesh for nuclear reactor system[J]. Applied Thermal Engineering, 2022, 209: 118296. doi: 10.1016/j.applthermaleng.2022.118296 [23] 吴宏春. 核反应堆物理[M]. 北京: 原子能出版社,2014: 104. -

下载:

下载: