Design and Optimization of Electromagnetic Ultrasonic Longitudinal Guided Wave Transducer for Heat Exchange Tube of Stream Generator

-

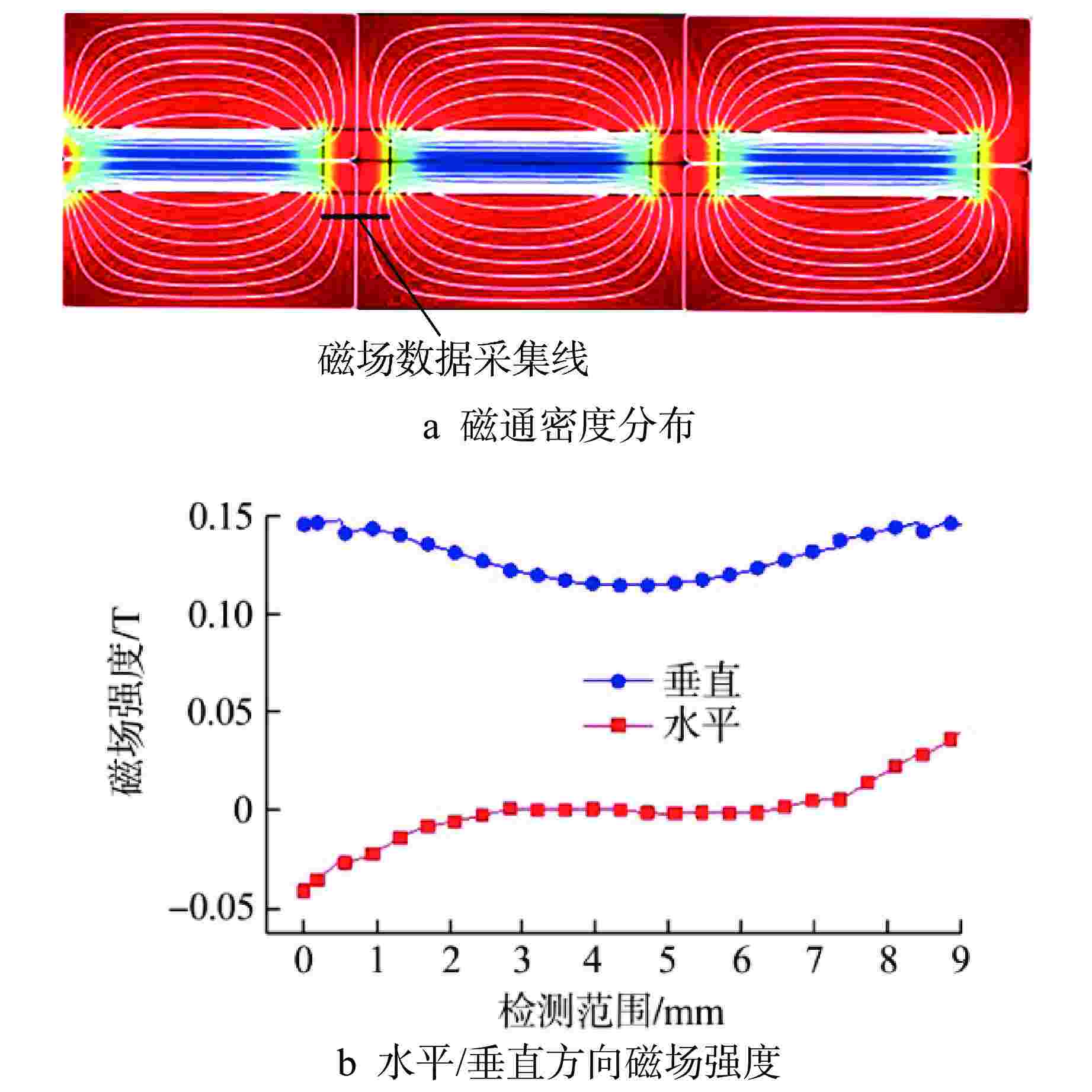

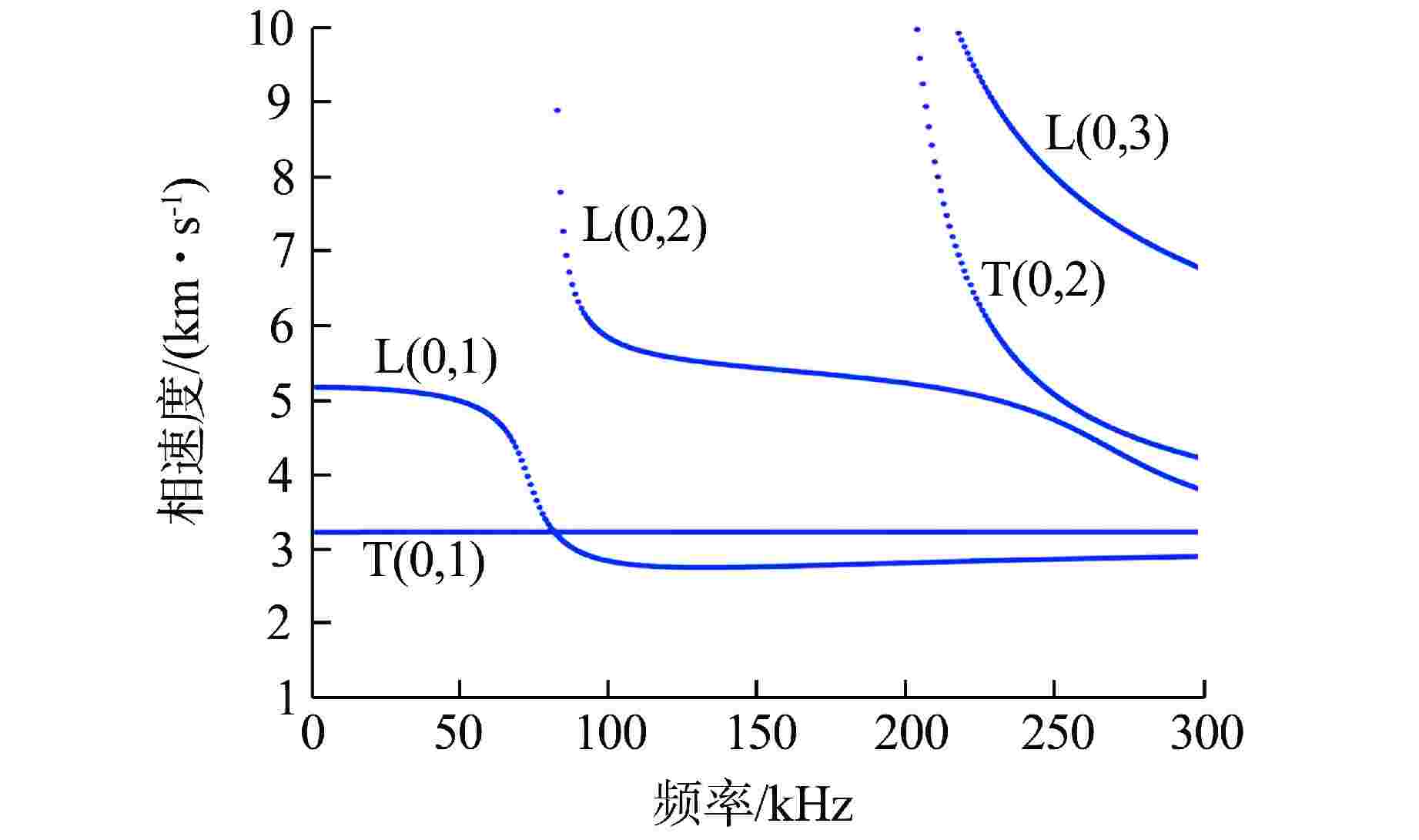

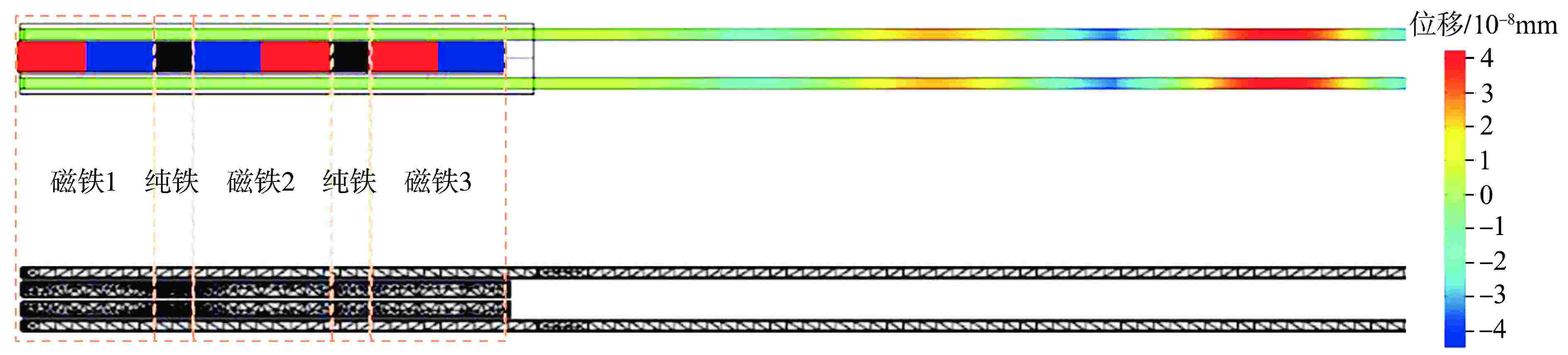

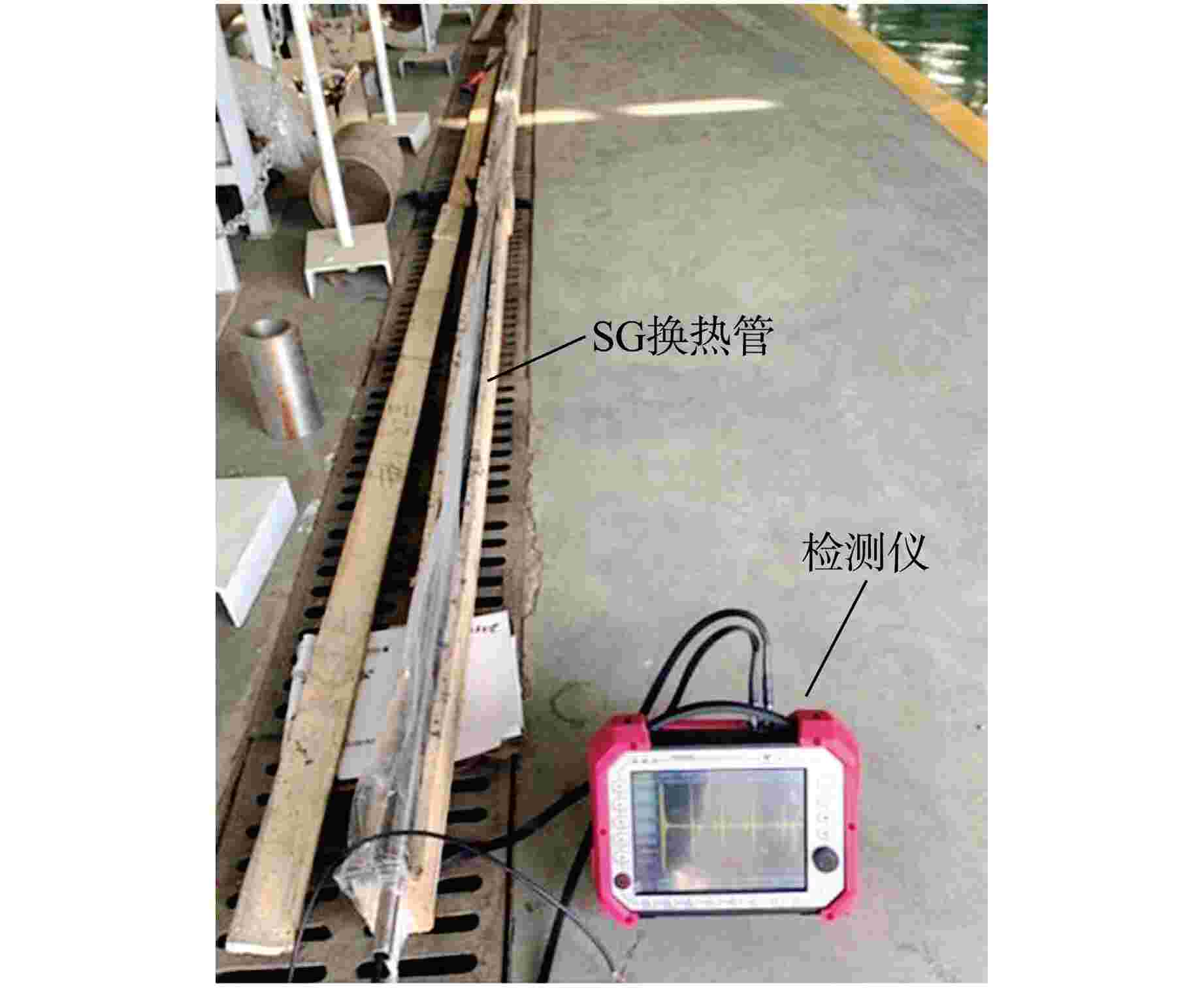

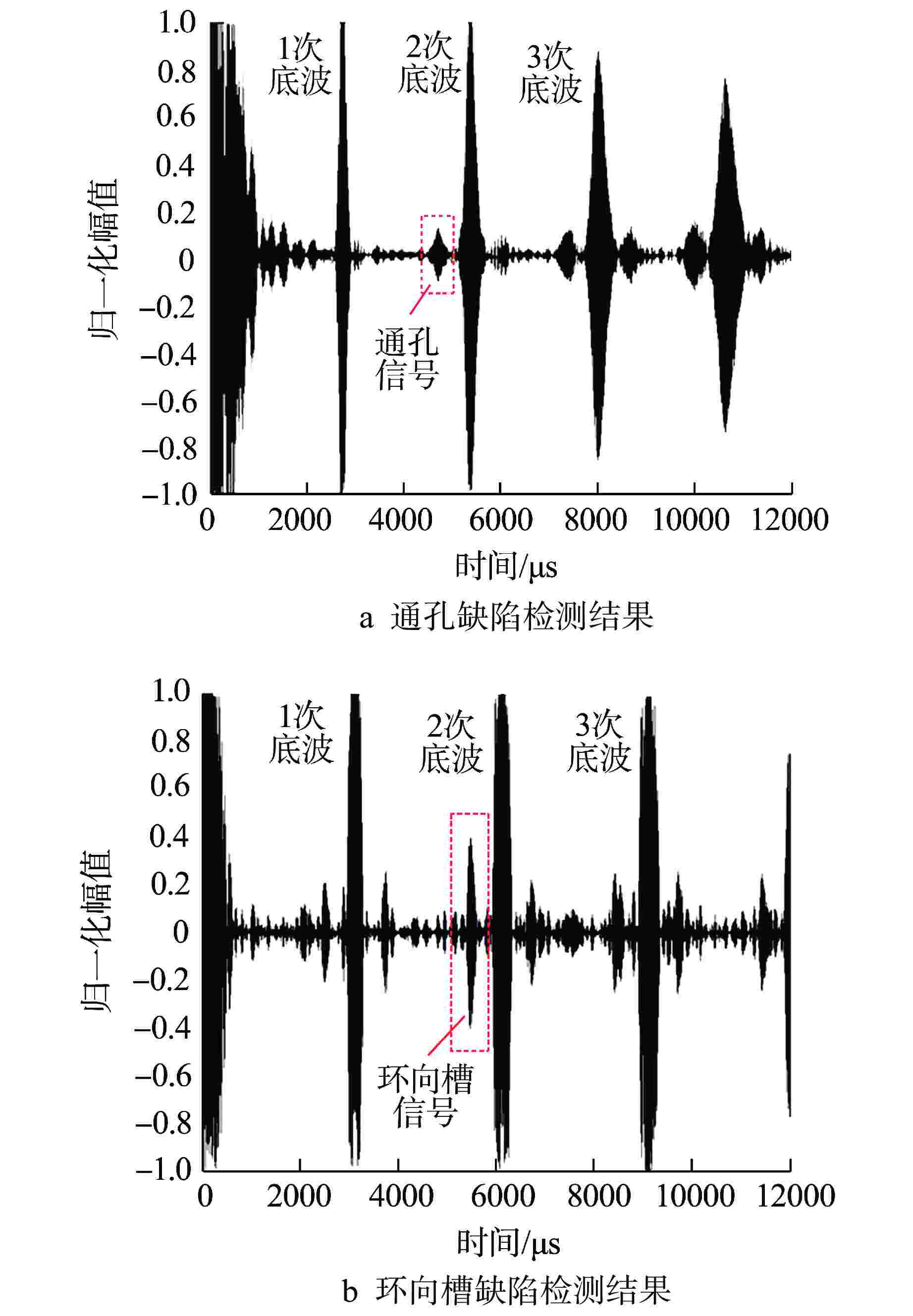

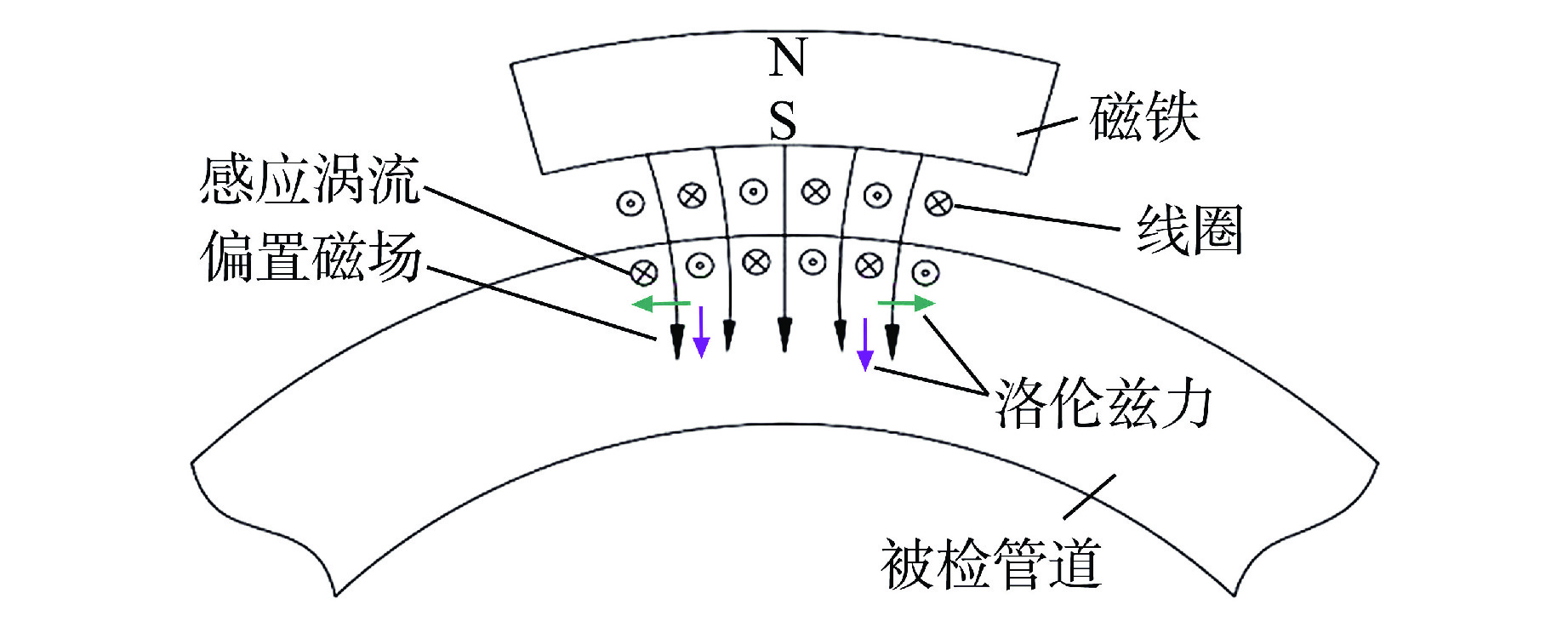

摘要: 高温气冷堆蒸汽发生器换热管特殊的螺旋结构导致传统外置型电磁超声导波换能器难以进行有效检测。本文针对蒸汽发生器不锈钢换热管的缺陷检测,开发了一种新型内置型电磁超声纵向导波换能器,建立了有限元多物理场耦合模型,研究了换能器铁磁结构的静态磁场分布,并对换能器激励出的纵向导波进行了时域仿真。结果表明:采用挤压聚磁的换能器结构可保证线圈附近的垂直方向磁场远大于水平方向磁场,能高效地在管道内部激励单一模式的纵向导波;优化后的探头可检测直径为5 mm的通孔缺陷和长×宽×深为20 mm×1.5 mm×1.2 mm的环向槽缺陷。因此,新型电磁超声纵向导波换能器可有效激励纵向导波,并有望应用于高温气冷堆蒸汽发生器换热管的在役缺陷检测。Abstract: The special spiral structure of the heat exchange tube of the steam generator of the high-temperature gas-cooled reactor makes it difficult for the traditional external electromagnetic ultrasonic guided wave transducer to be effectively detected. Aiming at the defect detection of stainless steel heat exchange tube of stream generator, a new built-in electromagnetic ultrasonic longitudinal guided wave transducer is developed, a finite element multi physical field coupling model is established, the static magnetic field distribution of ferromagnetic structure of the transducer is studied, and the longitudinal guided wave excited by the transducer is simulated in time domain. The results show that: the use of the squeezed magnetization transducer structure can ensure that the vertical magnetic field near the coil is much larger than the horizontal magnetic field, and can efficiently excite a single mode of longitudinal guided waves inside the tube. The optimized probe can detect through-hole defects with a diameter of 5mm and circular groove defects with a length × width × depth of 20 mm×1.5 mm×1.2 mm. Therefore, the new electromagnetic ultrasonic longitudinal guided wave transducer can effectively excite the longitudinal guided wave, and is expected to be applied to the in-service defect detection of the heat exchange tube of the steam generator of the high-temperature gas-cooled reactor.

-

表 1 铁磁结构材料物理性能参数

Table 1. Physical Property Parameters of Ferromagnetic Structural Materials

材料 电导率/(S·m−1) 相对磁导率 磁铁 7.1429×105 1.05 纯铁 4.032×106 4 000 表 2 管道有限元模型相关参数

Table 2. Relevant Parameters of Tube Finite Element Model

材质 杨氏模量/

GPa泊松比 密度/

(kg·m−3)内径/

mm外径/

mm长度/

mm不锈钢 200 0.03 7850 13 19 6000 -

[1] 张贵泉,姚洪猛,孙雅萍,等. 高温高压水化学环境T22材质均匀腐蚀行为研究[J]. 热力发电,2020, 49(9): 93-97. [2] 李晓伟,吴莘馨,张作义,等. 高温气冷堆示范工程螺旋管式直流蒸汽发生器工程验证试验[J]. 清华大学学报:自然科学版,2021, 61(4): 329-337. [3] 张作义,吴宗鑫,王大中,等. 我国高温气冷堆发展战略研究[J]. 中国工程科学,2019, 21(1): 12-19. [4] 陶钰,吕坤勇,彭磊,等. 基于TMR传感器阵列的蒸汽发生器换热管检测探头设计[J]. 仪表技术与传感器,2020(5): 37-41,47. doi: 10.3969/j.issn.1002-1841.2020.05.009 [5] 宋飞,刘锋,赵广森,等. 某电厂高压加热器换热管开裂泄漏原因分析[J]. 中国电力,2014, 47(5): 20-24. [6] 刘丽艳,王一鹏,朱勇,等. 蒸汽发生器U形管湍流抖振及微动磨损研究[J]. 振动与冲击,2021, 40(8): 35-40. doi: 10.13465/j.cnki.jvs.2021.08.005 [7] 吴斌,孟凡江,和广庆,等. 核用传热管表面划伤致应力腐蚀失效问题及研究进展[J]. 腐蚀与防护,2020, 41(9): 1-9,15. doi: 10.11973/fsyfh-202009001 [8] 陶于春,李平仁,任尚坤,等. 基于概率论的核电传热管无损检测能力评估[J]. 测试技术学报,2020, 34(2): 93-98. doi: 10.3969/j.issn.1671-7449.2020.02.001 [9] 殷松涛,王宁宁,王海军,等. 压水堆核电厂管道泄漏特性数值模拟研究[J]. 核动力工程,2021, 42(3): 32-36. [10] 王浩,石勇军,高俊,等. AP1000机组蒸汽发生器传热管役前检查[J]. 中国电力,2015, 48(10): 6-11. [11] 佟海山,李明达,周德强,等. 蒸汽发生器传热管缺陷涡流无损检测方法研究[J]. 机械研究与应用,2020, 33(5): 180-185,188. [12] 唐博,汪双印,唐岚,等. 机器视觉在核电站蒸发器涡流检测中的应用[J]. 无损检测,2018, 40(10): 26-28,44. doi: 10.11973/wsjc201810006 [13] CUI W, ZHANG Y H, FENG Z M, et al. Magnetic leakage internal detection device and series-parallel detection method for small diameter ferromagnetic spiral heat exchanger tubes[J]. Tehnički Vjesnik, 2020, 27(3): 933-940. [14] 肖雄. 换热管内旋转超声检测技术[J]. 压力容器,2013, 30(9): 60-64. doi: 10.3969/j.issn.1001-4837.2013.09.009 [15] 杨炯,雷春辉,马先宏. 核电厂蒸汽发生器传热管氦气检漏系统研究[J]. 核动力工程,2021, 42(6): 219-224. [16] KWUN H, CRANE J F, KIM S Y, et al. A torsional mode guided wave probe for long range, in bore testing of heat exchanger tubing[J]. Materials Evaluation, 2005, 63(4): 430-433. [17] ALLEYNE D N, VOGT T, CAWLEY P. The choice of torsional or longitudinal excitation in guided wave pipe inspection[J]. Insight:Non-Destructive Testing and Condition Monitoring, 2009, 51(7): 373-377. doi: 10.1784/insi.2009.51.7.373 [18] 栗霞飞,刘飞,赵满全,等. 基于超声导波检测管道缺陷的数值模拟[J]. 声学技术,2019, 38(2): 164-169. [19] 李洪刚,彭国平,张在东,等. MsS导波技术在不锈钢换热管束中的应用[J]. 无损探伤,2016, 40(2): 32-34. [20] 萨辉. 高压加热器钢管超声导波检测试验研究[J]. 无损探伤,2019, 43(6): 44-46. -

下载:

下载: