Numerical Investigation on Thermal Hydraulics of Helical Coil Tube Once Through Steam Generator for LBE Fast Reactor

-

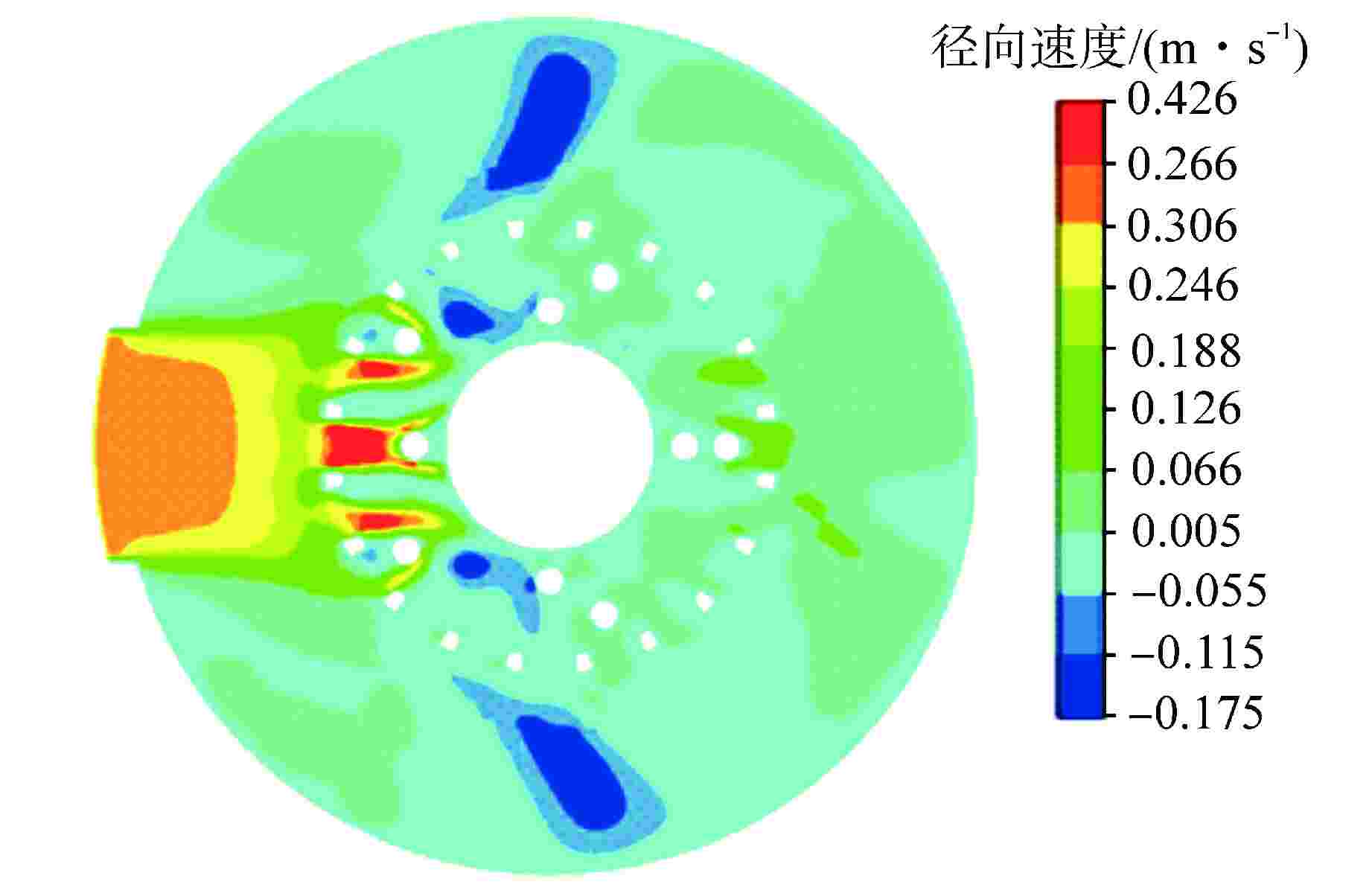

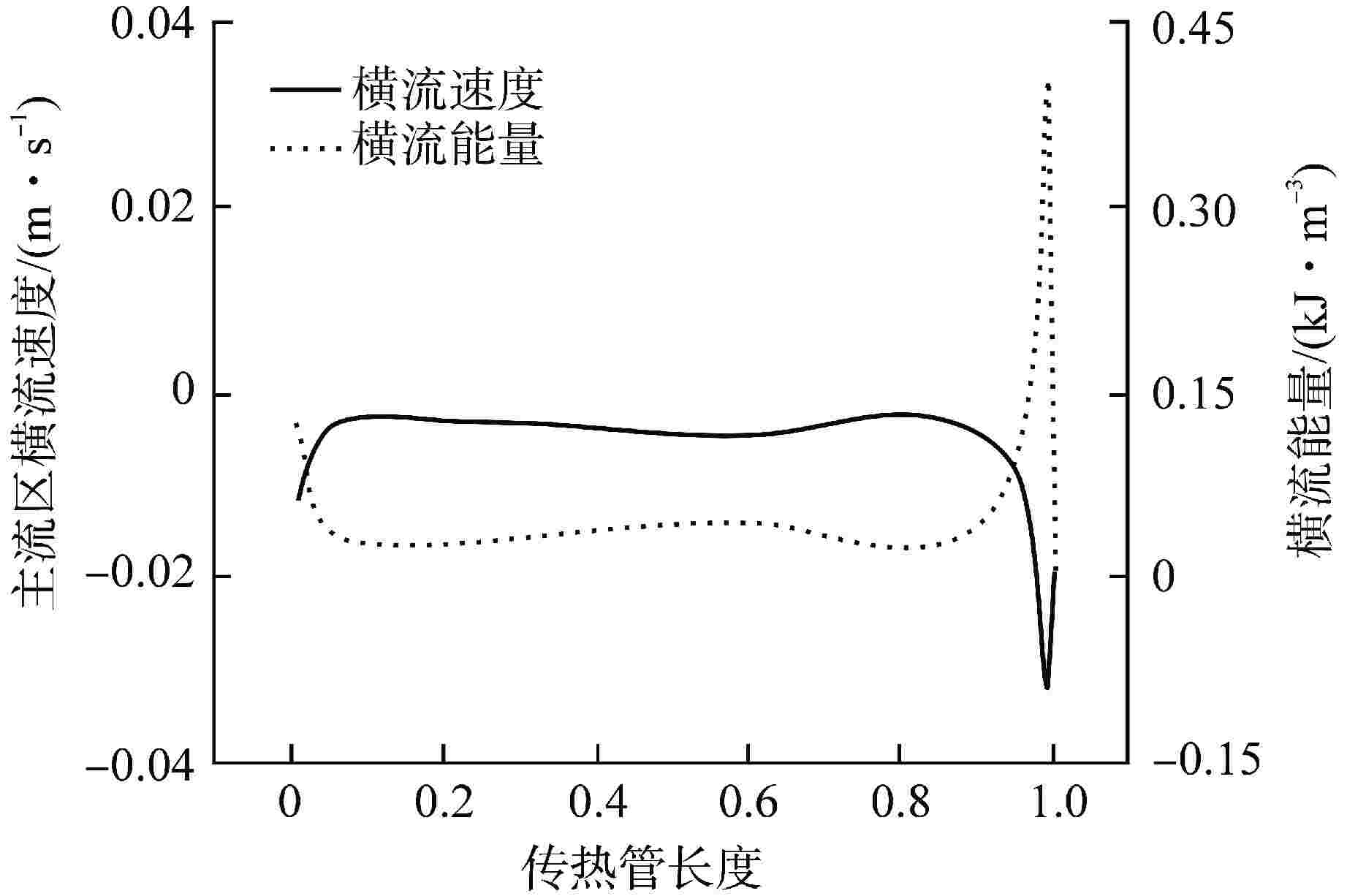

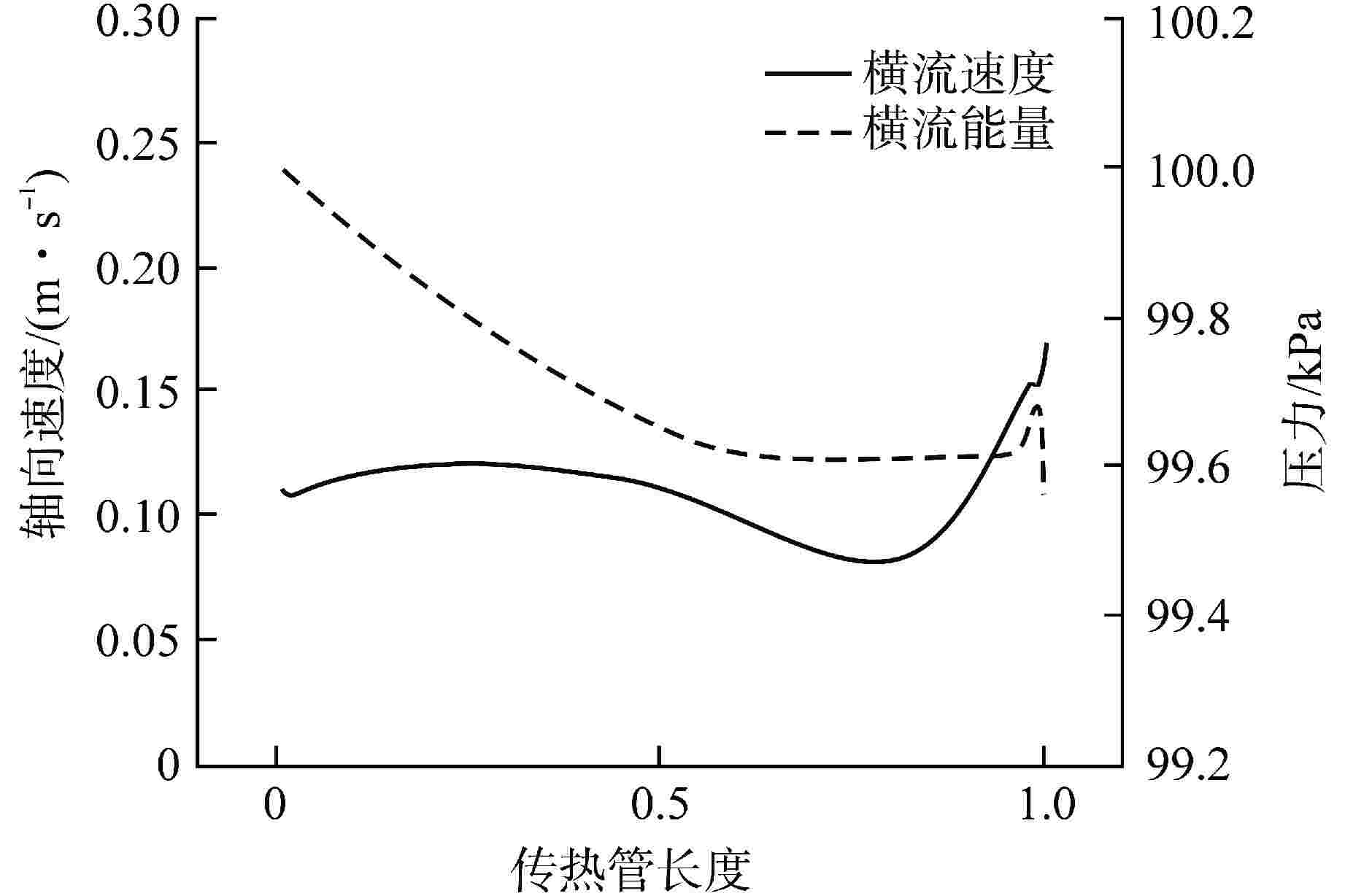

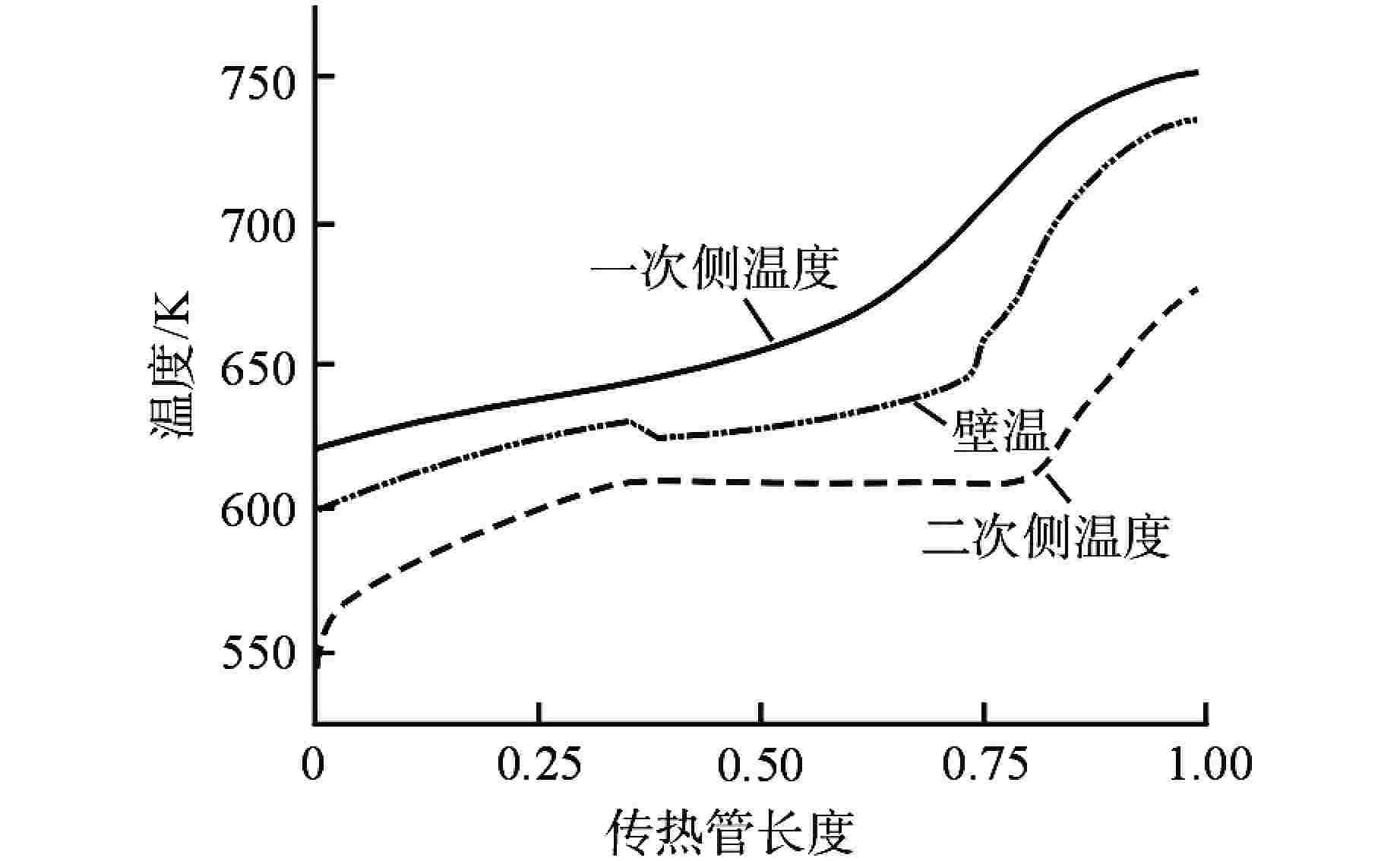

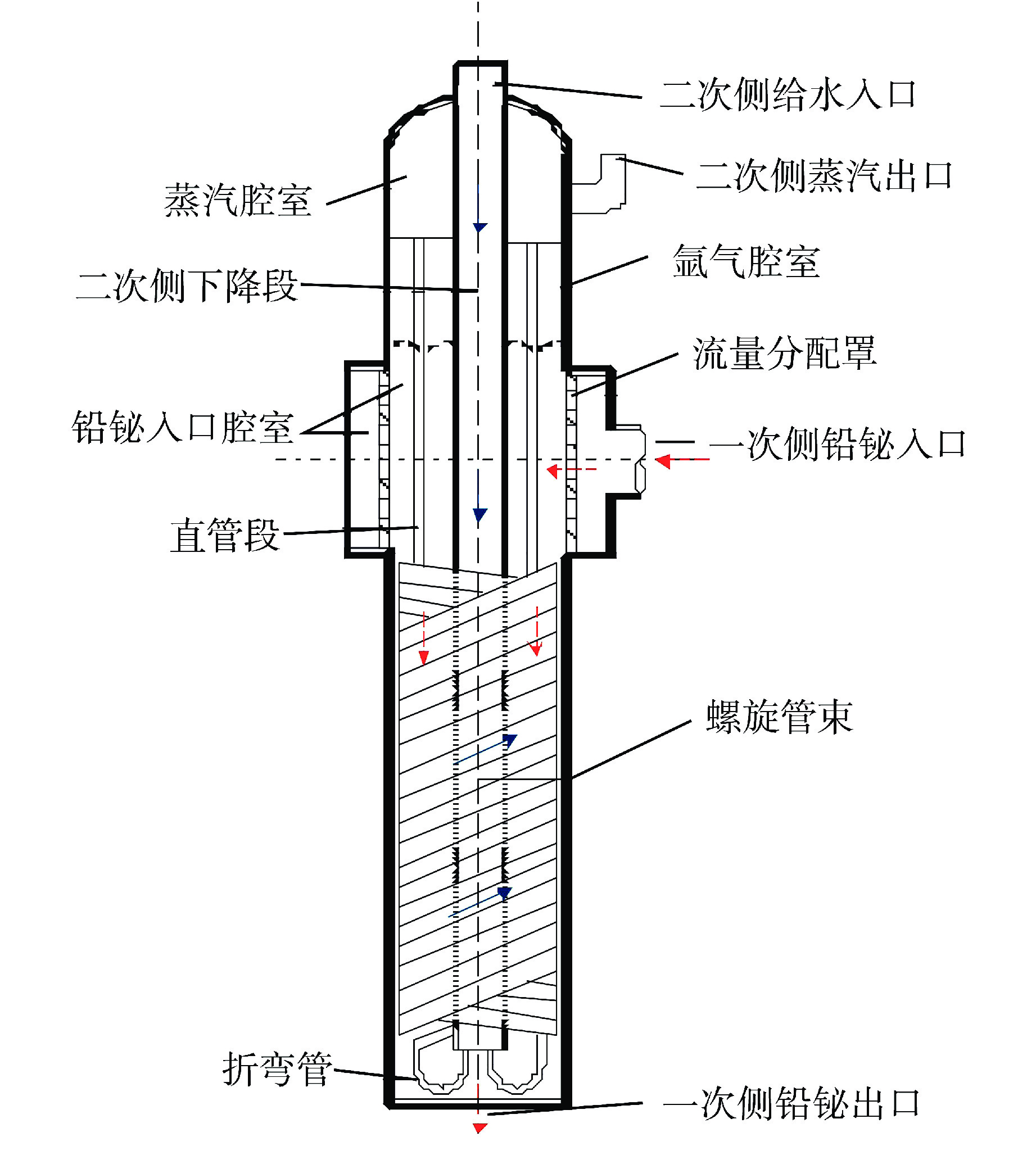

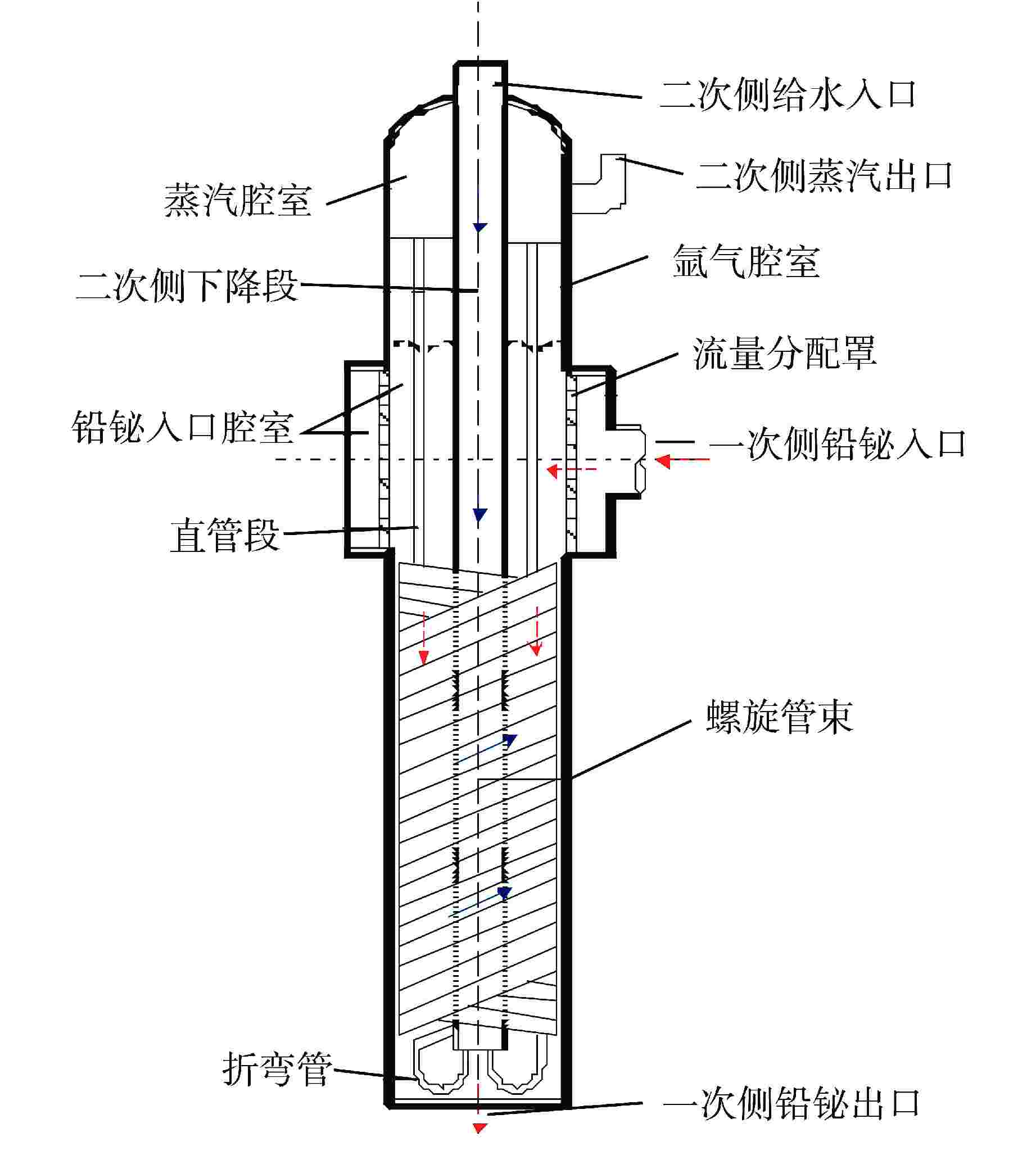

摘要: 本研究以铅铋快堆螺旋管直流蒸汽发生器(HOTSG)设计结构为研究对象,采用精细网格与多孔介质相结合的物理建模方法,通过一次侧三维湍流计算与二次侧用户自定义函数(UDF)分区传热计算相耦合的手段,在FLUENT求解器中开展了蒸汽发生器的热工水力特性数值分析研究。研究表明:铅铋入口附近的流量分配孔和腔室对应的直管段区域出现铅铋流速峰值,径向最大速度为0.431 m/s;入口腔室至管束区位置受到阻力突变的影响,压力、横流速度、轴向速度变化较大;热工参数变化符合流动与传热机理,临界热流密度(CHF)点附近一二次侧温差最大为109.61 K,此处最大热流密度为323.55 kW/m2。该研究将为铅铋快堆HOTSG结构设计、流致振动及安全评价提供重要的参考。

-

关键词:

- 铅铋快堆 /

- 螺旋管直流蒸汽发生器(HOTSG) /

- 数值分析 /

- 多孔介质 /

- 热工水力

Abstract: The design of Lead and Bismuth Eutectic (LBE) cooled fast reactor helical coil tube steam generator is modeled in this study. Physical modeling method is developed with the combination of fine grid blocks and porous medium. Through the coupling the primary three-dimensional turbulence calculation and the secondary side heat transfer based on UDF (User Defined Function) method, a numerical analysis of the thermal hydraulic characteristics of the steam generator is carried out in the FLUENT solver. The results show that: a. the flow distribution holes near LBE inlet and the straight tubes in the chamber have peaks in the flow rate of LBE, and the maximum radial velocity is 0.431 m/s, b. when LBE flows from the inlet chamber into the tube bundle, the pressure, cross flow and axial flow rates change rapidly because of resistance mutation, and c. the changing process of thermal hydraulic parameters confirms to the qualitative mechanism analysis results of flow and heat transfer. The maximum temperature difference between primary and secondary sides near the Critical Heat Flux (CHF) point is 109.61 K, and the maximum heat flux is 323.55 kW/m2. This study will provide an important reference for HOTSG structure design, fluid-induced vibration and safety evaluation of lead-bismuth fast reactor. -

表 1 网格数量和质量表

Table 1. Number and Quality of HOTSG Meshes

部件 网格数量/万 网格质量 铅铋入口腔室 298.31 0.79 流量分配罩 205.24 0.871 氩气腔室 286.68 0.83 管束区 50.84 0.795 二次侧下降段 49.19 0.945 蒸汽腔室 17.99 0.904 直管段 450.8 0.917 总计 1359.05 0.385 除0.385为最小正交质量外,其余质量均为平均质量。 表 2 HOTSG额定工况参数

Table 2. Full Power State Parameters of HOTSG

参数 数值 一次侧压力/MPa 0.1 一次侧入口温度/℃ 480 一次侧入口流量/(kg·s −1) 26.55 二次侧压力/MPa 14 二次侧入口温度/℃ 270 二次侧入口流量/(kg·s −1) 0.289 管束区高度/m 0.7 管束区内/外壳径/m 0.081/0.162 表 3 控制方程离散方法

Table 3. Discretization Methods of Governing Equations

离散项 离散格式 重力 基于最小二乘单元 压力 体强制加权 动量 二阶迎风格式 能量 二阶迎风格式 湍动能 二阶迎风格式 比耗散率 二阶迎风格式 -

[1] CIONCOLINI A, SANTINI L. Two-phase pressure drop prediction in helically coiled steam generators for nuclear power applications[J]. International Journal of Heat & Mass Transfer, 2016(100): 825-834. [2] WANG M, ZHENG M, CHAO M, et al. Experimental and CFD estimation of single-phase heat transfer in helically coiled tubes[J]. Progress in Nuclear Energy, 2019(112): 185-190. doi: 10.1016/j.pnucene.2018.12.015 [3] DEHBI A, BADREDDINE H. CFD prediction of mixing in a steam generator mock-up: Comparison between full geometry and porous medium approaches[J]. Annals of Nuclear Energy, 2013(58): 178-187. doi: 10.1016/j.anucene.2013.03.019 [4] 王弘扬,阮神辉,文青龙,等. 基于多孔介质模型的快堆蒸汽发生器热工水力特性数值研究[J]. 核动力工程,2019, 40(05): 51-55. [5] 丁雪友, 文青龙, 阮神辉, 等. 铅铋快堆螺旋管直流蒸汽发生器热工水力模型研究[C]. 第十六届全国反应堆热工流体学术会议暨中核核反应堆热工水力技术重点实验室2019年学术年会论文集, 2019: 196-206. [6] FLUENT A. Theory guide[Z]. Ansys Inc, 2015. [7] PATIL L T, PATWARDHAN A W, PADMAKUMAR G, et al. Distribution of liquid sodium in the inlet plenum of steam generator in a Fast Breeder Reactor[J]. Nuclear Engineering and Design, 2010, 240(4): 850-859. doi: 10.1016/j.nucengdes.2009.12.004 [8] ERGUN S. Fluid flow through packed columns[J]. Chem. Eng. Prog., 1952(48): 89-94. [9] KIRILLOV P L, USHAKOV P A. Heat transfer to liquid metals: specific features, methods of investigation, and main relationships[J]. Thermal Engineering, 2001, 48(1): 50-59. [10] 吴鸽平,吴埃敏, 田文喜,等. 双面加热环形窄缝通道内流动沸腾干涸点实验研究[J]. 核动力工程,2003, 24(6): 526-530. doi: 10.3969/j.issn.0258-0926.2003.06.008 [11] SOBOLEV V. Thermophysical properties of lead and lead–bismuth eutectic[J]. Journal of nuclear materials, 2007, 362(2-3): 235-247. doi: 10.1016/j.jnucmat.2007.01.144 -

下载:

下载: