Research on Fault Pattern Recognition Model of Nuclear Power Plant Water Pump Based on Frequency-Domain Data Attention Mechanism

-

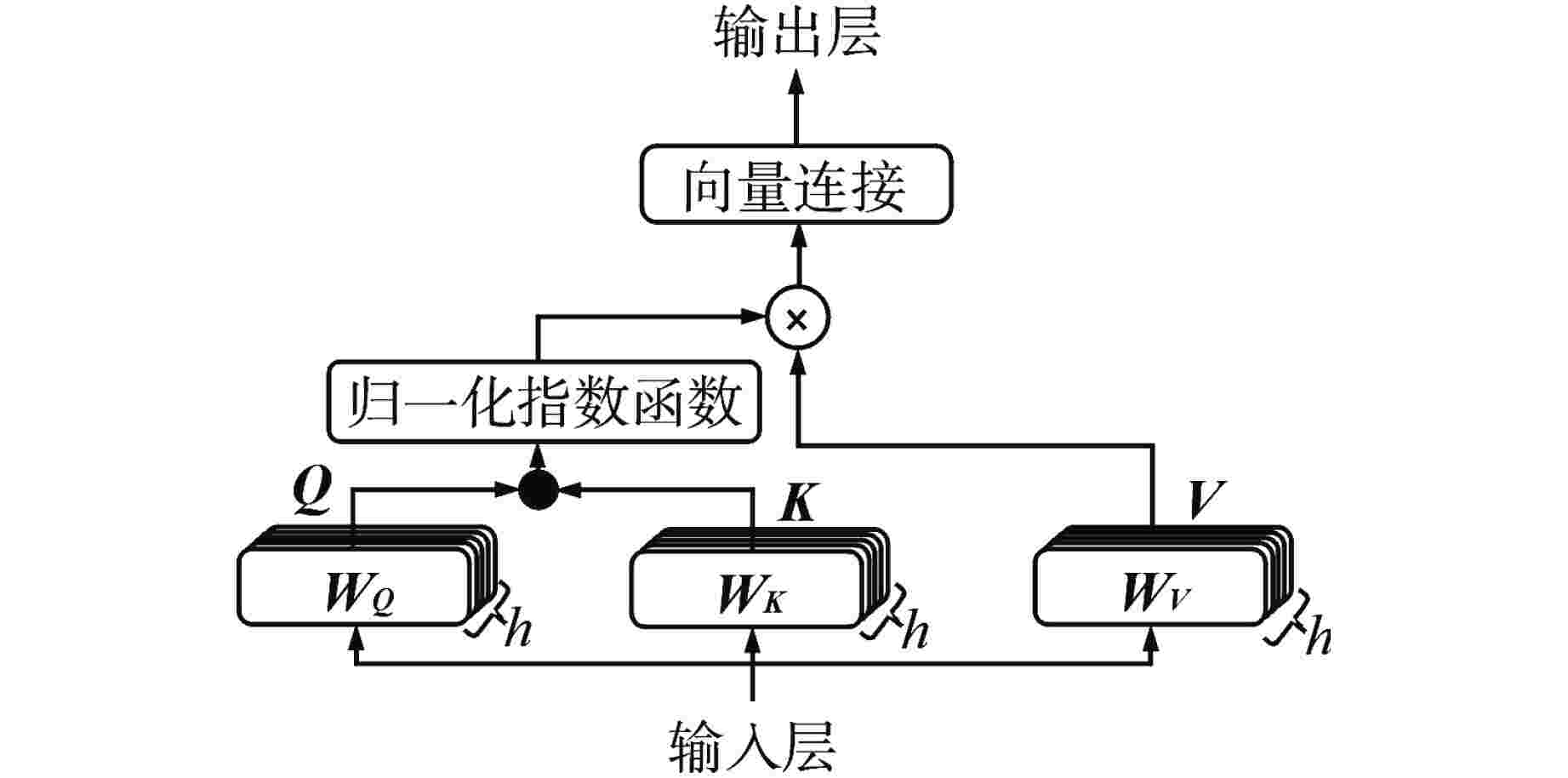

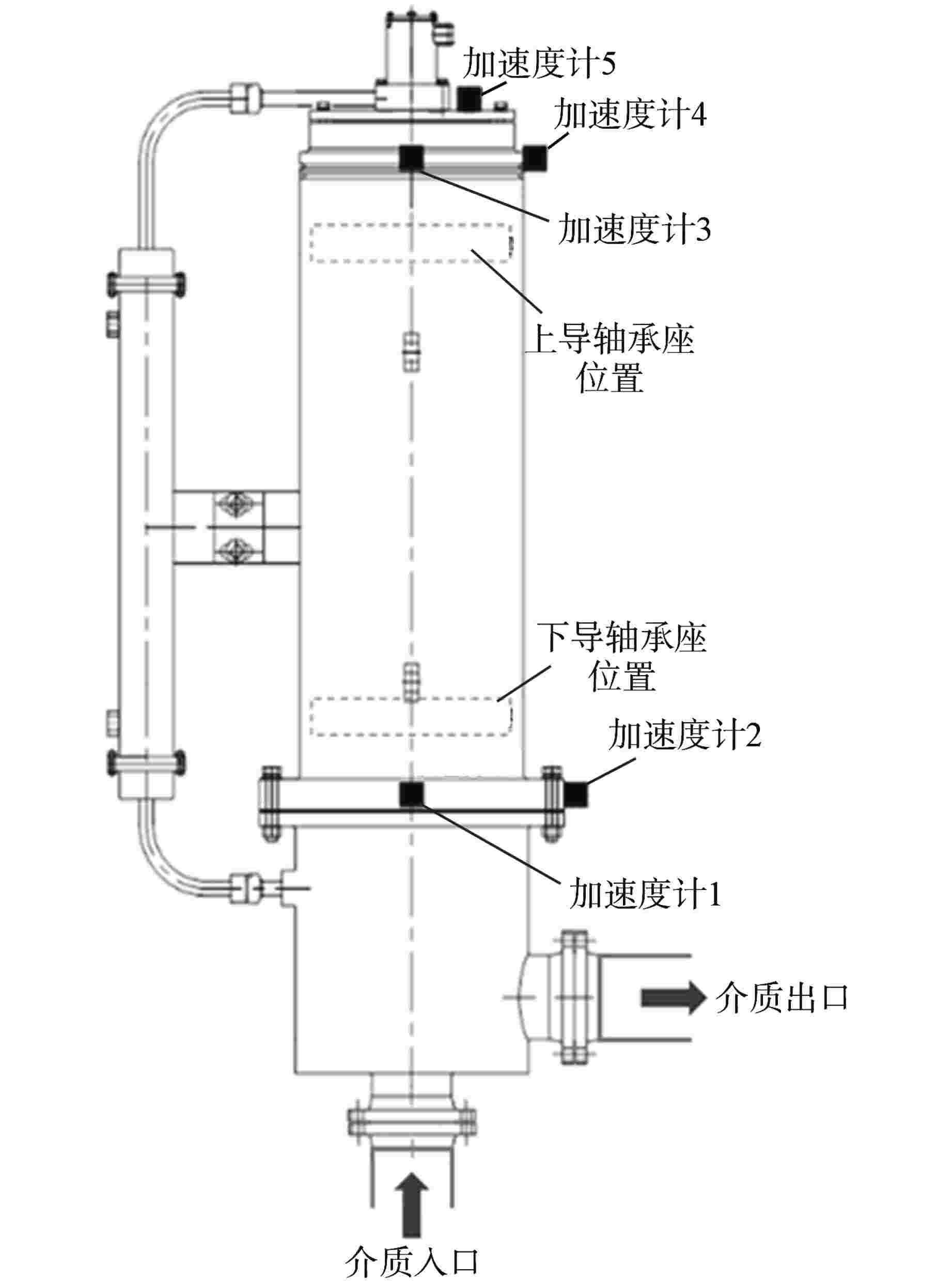

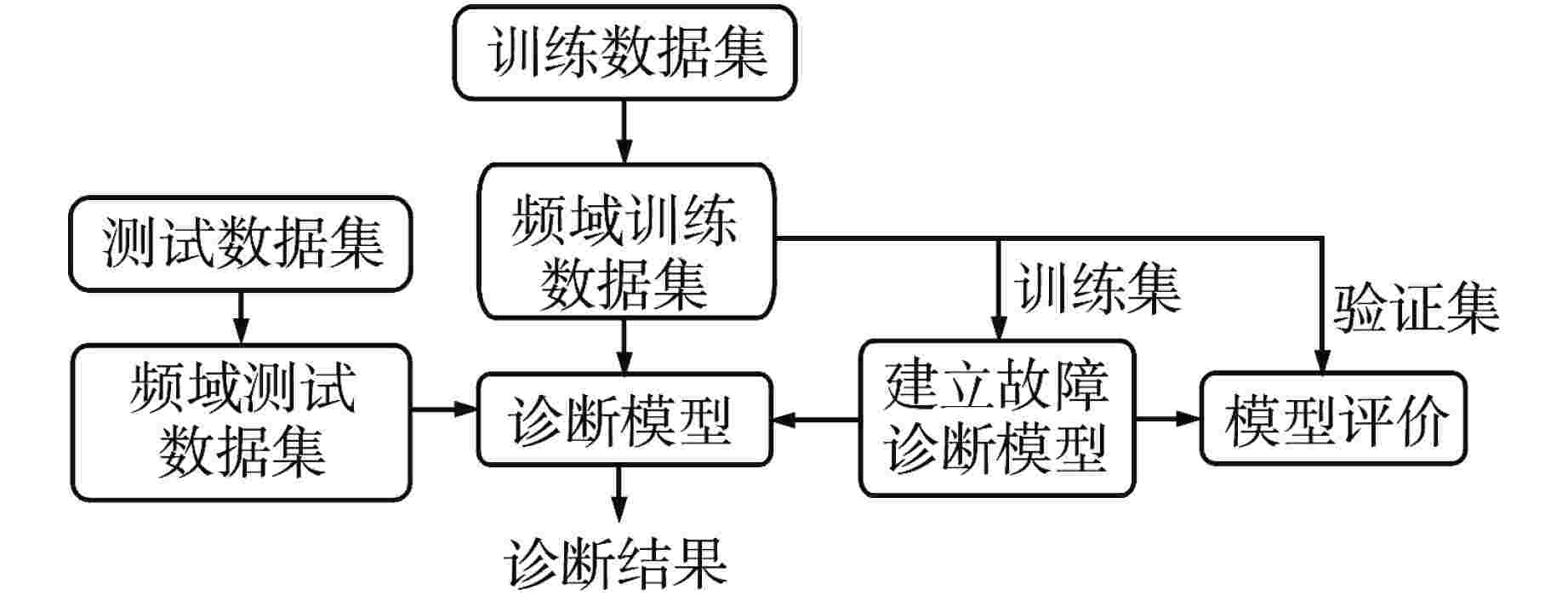

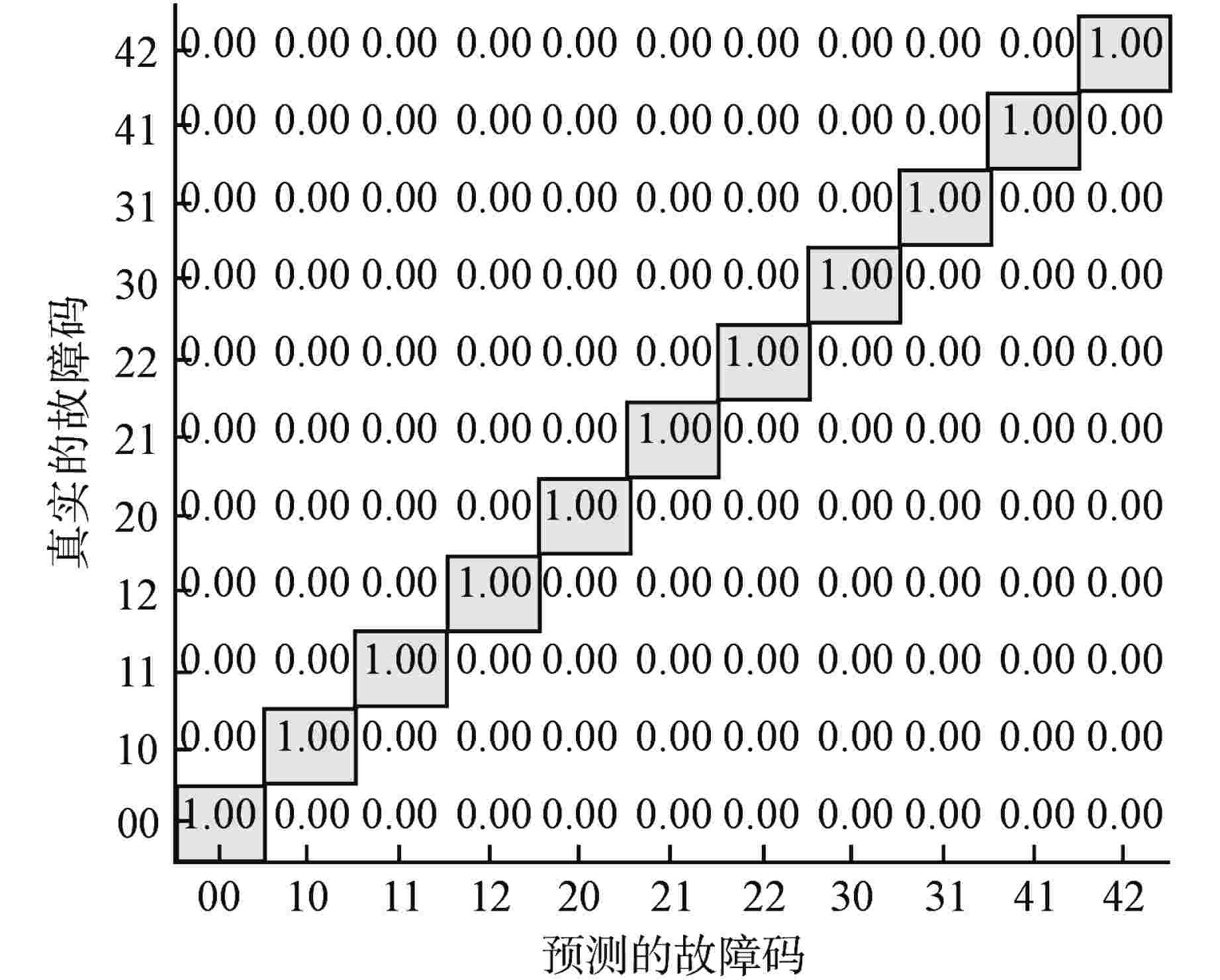

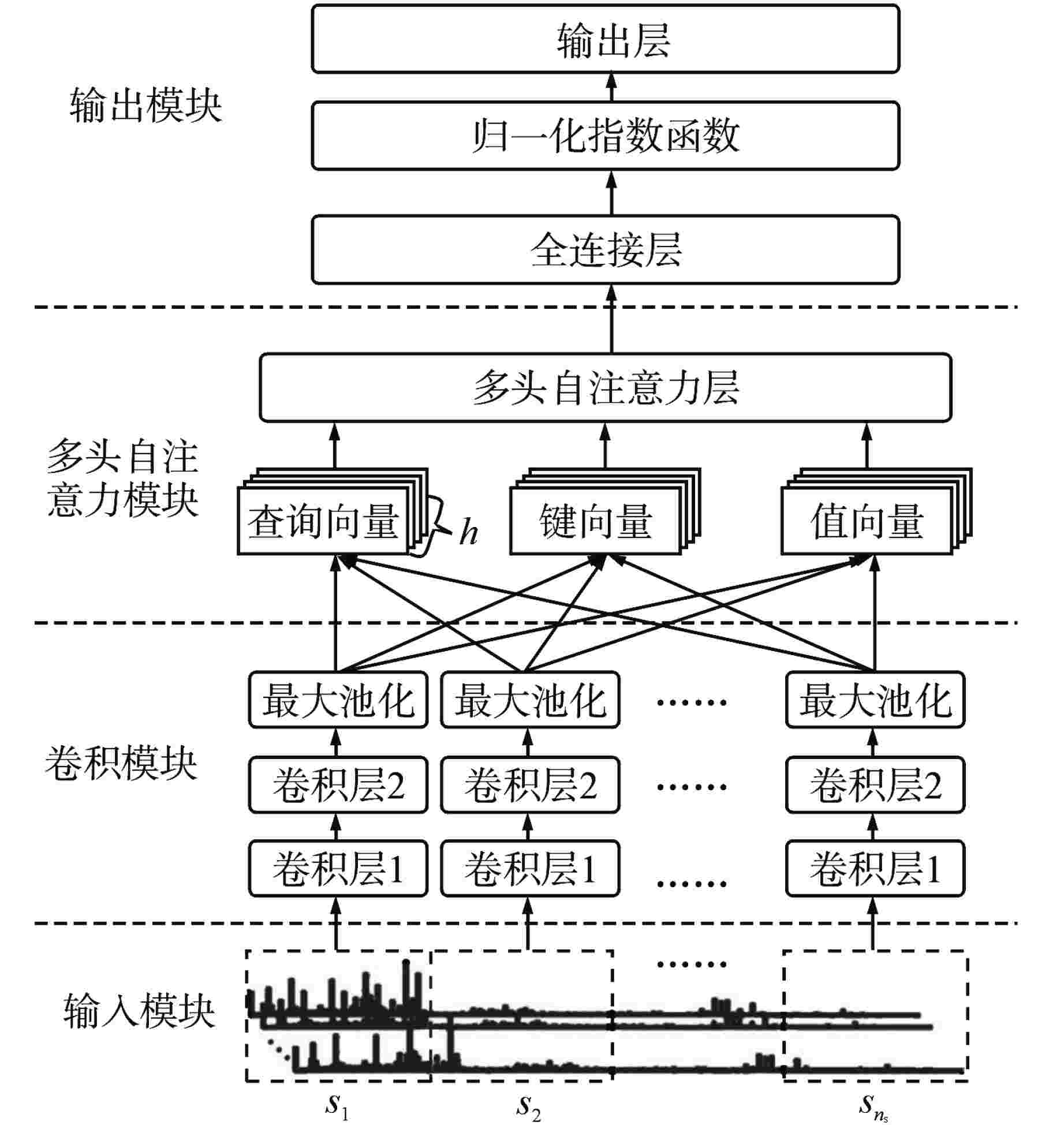

摘要: 针对核电厂水泵共性的异常振动、转子部件摩擦与磨损等故障模式,利用水泵最容易获取的泵壳加速度信号的频域数据为输入,提出了一种结合卷积神经网络和注意力网络的频域数据注意力机制方法,并建立了核电厂水泵故障模式识别模型。研究结果表明:相对于传统方法,利用频域数据作为输入、基于频域数据注意力网络算法建立的水泵故障模式识别模型输入的数据长度更短,能够有效提升模型训练的效率,该故障模式识别模型在测试集上的故障模式识别准确率达到100%,优于其他基于深度学习算法建立的故障诊断模型,证明了本文提出方法的优势。Abstract: In view of the common fault modes of nuclear power plant pump, such as abnormal vibration, friction and abrasion of rotor parts, etc., this paper uses frequency domain data of the acceleration signal on pump shell which is easiest to be obtained as input, proposes a new method for frequency-domain data attention mechanism which combines convolutional neural network and attention network, and establishes the recognition model of fault mode of nuclear power plant water pump. The results show that: Compared with the traditional methods, the water pump fault pattern recognition model based on frequency domain data as input and based on frequency domain data attention network algorithm has a shorter input data length and can effectively improve the efficiency of model training. The fault pattern recognition accuracy of the fault pattern recognition model on the test set is 100%, which is better than other fault diagnosis models based on deep learning algorithm, which proves the advantages of the method proposed in this paper.

-

表 1 水泵故障模拟试验的故障类型、故障程度及数据条数

Table 1. Fault Type, Degree and Data Number of Pump Fault Simulation Test

编号 故障码 故障类型 故障程度 数据条数 0 00 正常 3680 1 10 导轴承磨损 轻度 3720 2 11 导轴承磨损 中度 3870 3 12 导轴承磨损 重度 3820 4 20 止推轴承磨损 轻度 3760 5 21 止推轴承磨损 中度 4020 6 22 止推轴承磨损 重度 3700 7 30 口环刮磨 中度 3770 8 31 口环刮磨 重度 3660 9 41 转子偏心 中度 3740 10 42 转子偏心 重度 3720 注:空白表示无此项 表 2 频域数据注意力机制模型相关超参数

Table 2. Related Hyper-Parameter of Frequency Domain Data Attention Mechanism Model

所属部分 超参数名 超参数值 输入层 数据段数目ns 50 输入层 截段后每个数据段长度ls 500 卷积模块 卷积1核长度/通道数 5/32 卷积模块 卷积2核长度/通道数 3/1 卷积模块 池化长度lp 2 多头自注意力网络 h/$ {d_{{K_i}}} $/$ {d_{{V_i}}} $ 2/50/30 表 3 各个模型在时域数据集和频域数据集上的训练信息

Table 3. Training Information of Each Model on Time-Domain Dataset and Frequency-Domain Dataset

-

[1] XIA M, LI T, XU L, et al. Fault diagnosis for rotating machinery using multiple sensors and convolutional neural networks[J]. IEEE/ASME Transactions on Mechatronics, 2018, 23(1): 101-110. doi: 10.1109/TMECH.2017.2728371 [2] ZHAO M H, ZHONG S S, FU X Y, et al. Deep residual shrinkage networks for fault diagnosis[J]. IEEE Transactions on Industrial Informatics, 2020, 16(7): 4681-4690. doi: 10.1109/TII.2019.2943898 [3] SIMONYAN K, ZISSERMAN A. Very deep convolutional networks for large-scale image recognition[C]//3rd International Conference on Learning Representations. San Diego, CA, USA: ICLR, 2015: 1-14. [4] ZHANG W, PENG G L, LI C H, et al. A new deep learning model for fault diagnosis with good anti-noise and domain adaptation ability on raw vibration signals[J]. Sensors, 2017, 17(2): 425. doi: 10.3390/s17020425 [5] VAN DER MAATEN L, HINTON G. Visualizing data using t-SNE[J]. Journal of Machine Learning Research, 2008, 9(86): 2579-2605. [6] LI X, ZHANG W, DING Q. Understanding and improving deep learning-based rolling bearing fault diagnosis with attention mechanism[J]. Signal Processing, 2019(161): 136-154. doi: 10.1016/j.sigpro.2019.03.019 [7] YANG Z B, ZHANG J P, ZHAO Z B, et al. Interpreting network knowledge with attention mechanism for bearing fault diagnosis[J]. Applied Soft Computing Journal, 2020(97): 106829. doi: 10.1016/j.asoc.2020.106829 [8] VASWANI A, SHAZEER N, PARMAR N, et al. Attention is all you need[C]//Proceedings of the 31st International Conference on Neural Information Processing Systems. Long Beach, CA, USA: NIPS, 2017: 5998-6008. -

下载:

下载: