Marginal Research on IVR Capability of Alumina Nanofluid Enhanced Spherical Lower Head

-

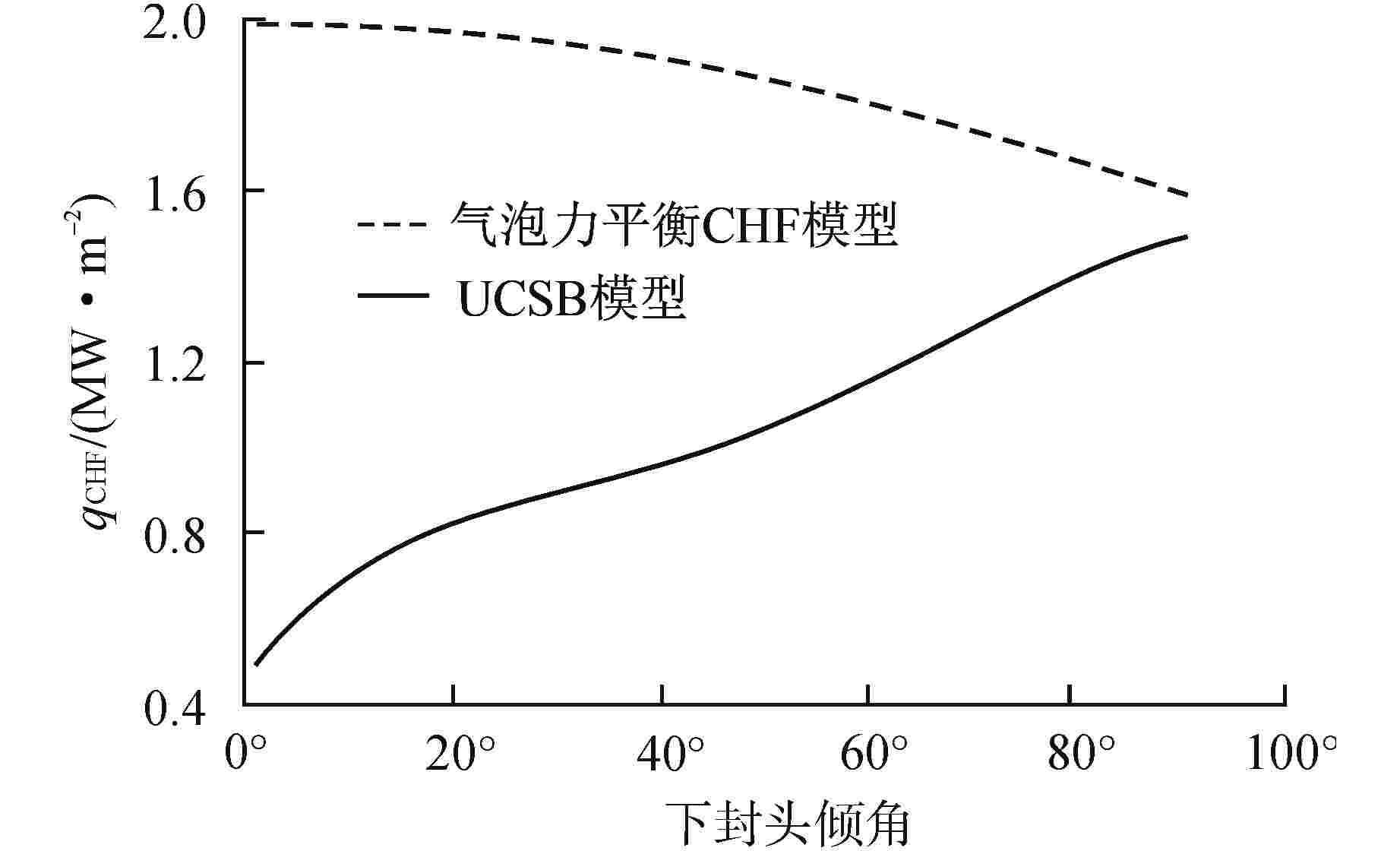

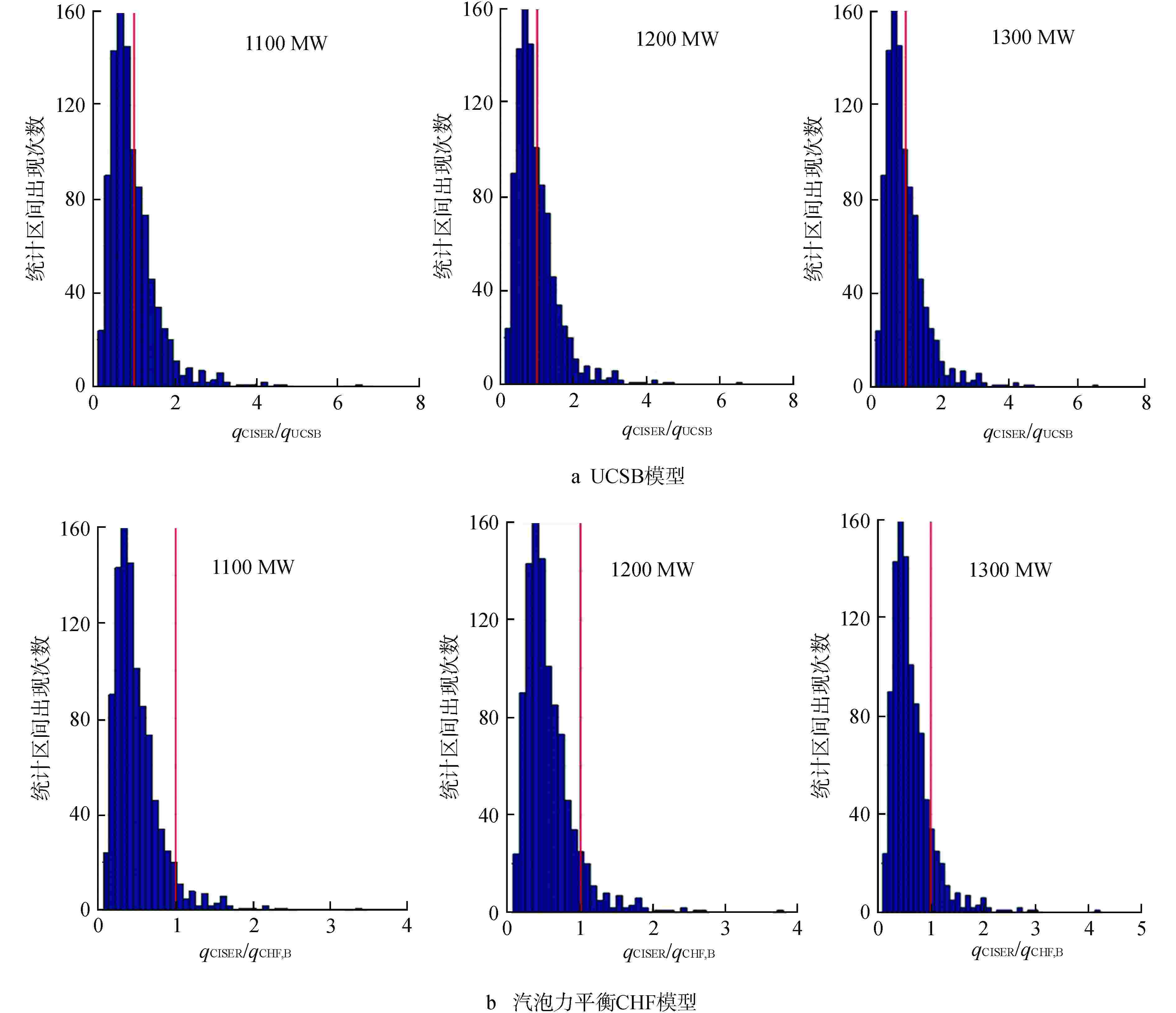

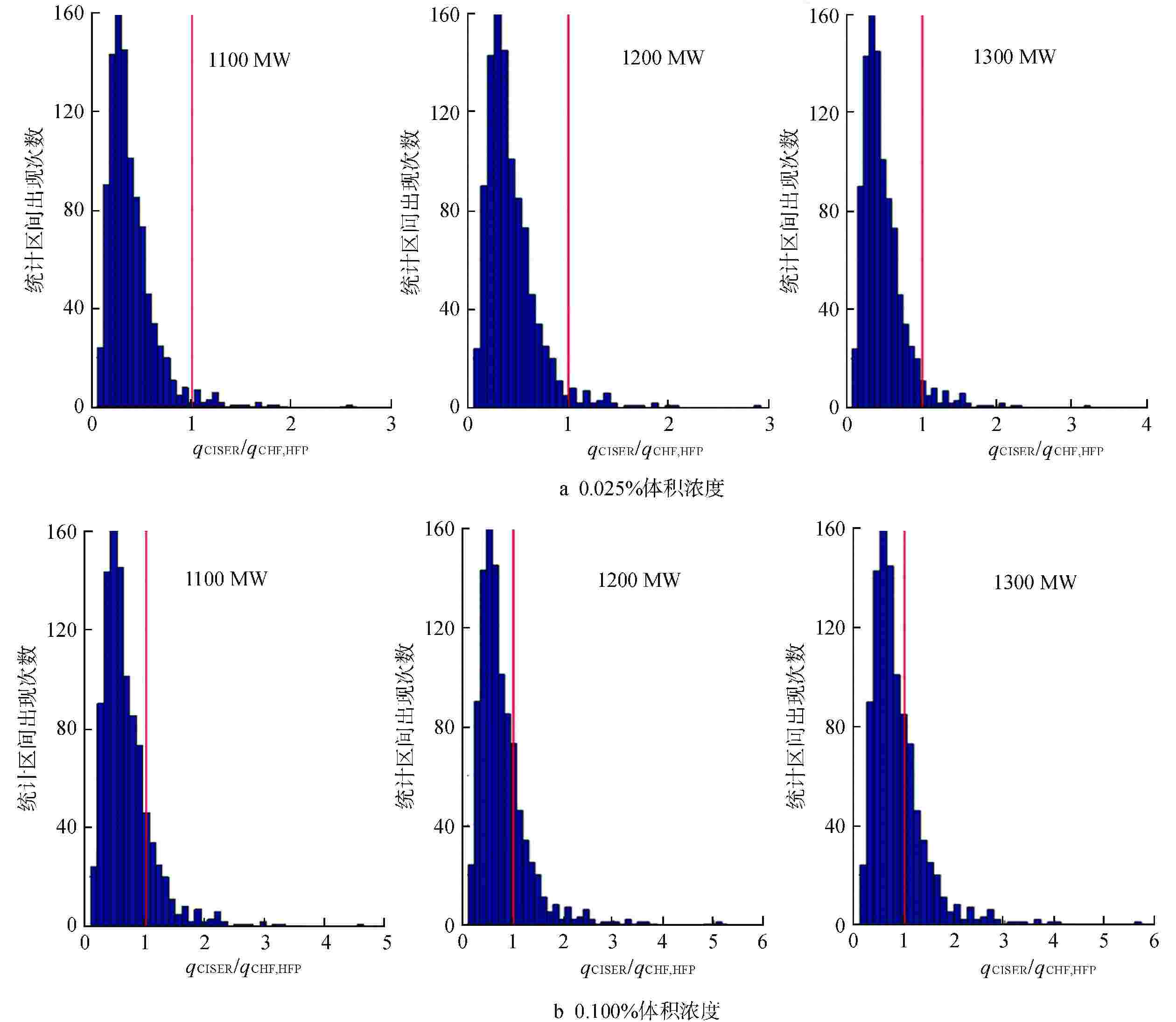

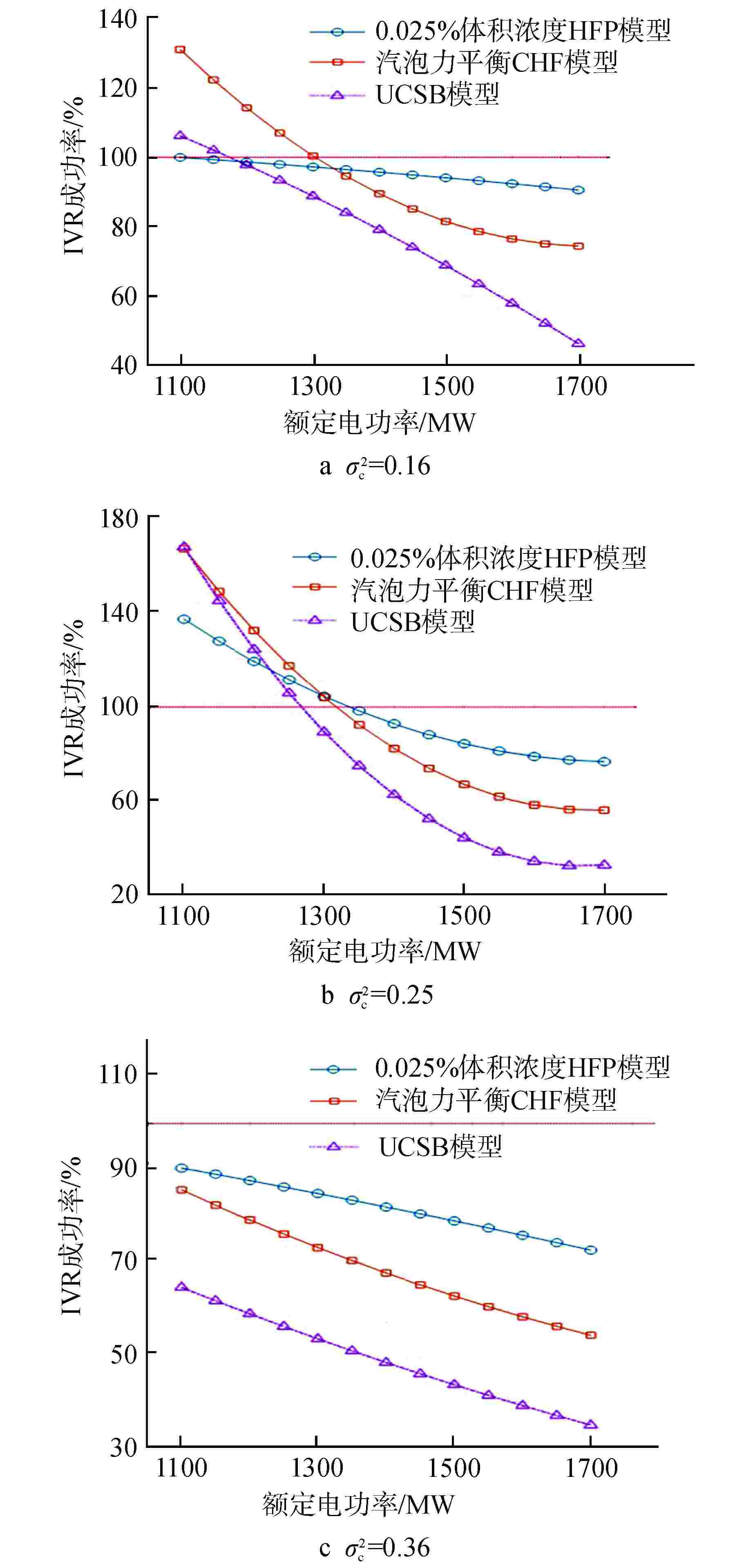

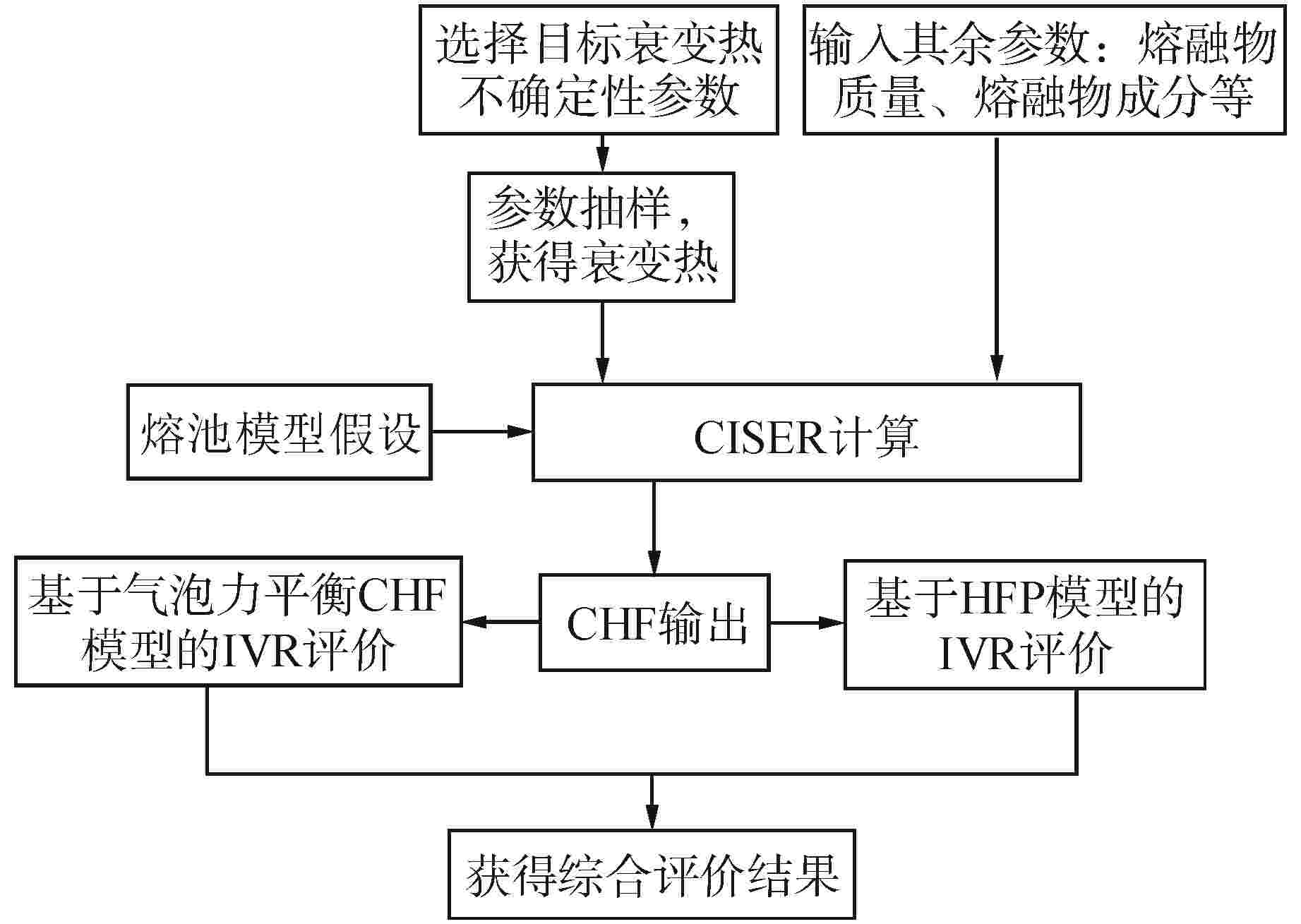

摘要: 为评价氧化铝纳米流体相对于纯水工质对球形下封头熔融物滞留(IVR)能力边际的拓展程度,采用基于气泡力平衡的氧化铝纳米流体临界热流密度(CHF)机理模型和壁面热通量拆分CHF模型计算球形下封头外表面纳米流体CHF。利用熔融物堆内滞留分析软件CISER开展衰变热分布抽样计算,得到下封头壁面CHF随倾角变化的随机分布,并将其与纳米流体CHF模型的理论值相比,以CHF比值小于1作为IVR成功准则,研判纳米流体对IVR能力边际拓展的影响程度。研究结果表明,若不对下封头内外传热构成采取任何优化措施,仅采用纳米流体替代纯水工质,压水堆核电厂的IVR能力边际能够拓展至1300 MW额定电功率水平。

-

关键词:

- 汽泡力平衡 /

- 热通量拆分 /

- 临界热流密度(CHF) /

- 熔融物堆内滞留(IVR) /

- 能力边际

Abstract: In order to evaluate the extent to which alumina nanofluids can extend the IVR capability of the spherical lower head relative to pure water working medium, in this paper, the critical heat flux (CHF) mechanism model of alumina nanofluid based on bubble force balance and the wall heat flux partitioning CHF model are used to calculate the CHF of nanofluid on the outer surface of spherical lower head. The decay heat distribution sampling calculation is carried out by using the IVR analysis software CISER, and the random distribution of CHF on the wall of the lower head with the inclination angle is obtained. Compared with the theoretical value of the nanofluid CHF model, the influence of nanofluid on the marginal expansion of IVR capability is studied and judged by taking the CHF ratio less than 1 as the IVR success criterion. The results show that if no optimization measures are taken for the internal and external heat transfer composition of the lower head and only nanofluid is used to replace pure water working medium, the IVR capability margin of PWR nuclear power plant can be expanded to 1300 MW rated power level. -

表 1 熔池初始参数

Table 1. Initial Parameter of Melting Pool

表 2 基于气泡力平衡CHF模型及UCSB模型的IVR结果

Table 2. IVR Results Based on the Bubble Force Balance Model and the UCSB Model

额定电功

率/MWIVR成功率/% UCSB纯水

模型气泡力平衡

CHF模型1100 80.2 94.6 1200 73.5 92.1 1300 67.8 88.2 1400 63.0 85.0 表 3 基于HFP模型的IVR结果

Table 3. IVR Results Based on HFP Model

额定电功

率/MWIVR成功率/% 0.025%体积

浓度0.100%体积

浓度1100 97.1 84.8 1200 96.2 78.9 1300 94.9 72.1 1400 93.2 66.3 -

[1] CILOGLU D, BOLUKBASI A. A comprehensive review on pool boiling of nanofluids[J]. Applied Thermal Engineering, 2015, 84: 45-63. doi: 10.1016/j.applthermaleng.2015.03.063 [2] KIM H D, KIM J, KIM M H. Experimental studies on CHF characteristics of nano-fluids at pool boiling[J]. International Journal of Multiphase Flow, 2007, 33(7): 691-706. doi: 10.1016/j.ijmultiphaseflow.2007.02.007 [3] 何晓强,余红星,江光明. 氧化铝纳米流体临界热流密度机理模型研究−物理模型[J]. 核动力工程,2018, 39(3): 162-165. [4] REMPE J L, KNUDSON D L, ALLISON C M, et al. Potential for AP600 in-vessel retention through ex-vessel flooding[R]. Washington: USDOE Assistant Secretary for Nuclear Energy, 1997. [5] 何晓强,余红星,王金雨,等. 氧化铝纳米流体临界热流密度机理模型验证[J]. 核动力工程,2019, 40(2): 6-9. [6] HAM J, CHO H. Theoretical analysis of pool boiling characteristics of Al2O3 nanofluid according to volume concentration and nanoparticle size[J]. Applied Thermal Engineering, 2016, 108: 158-171. doi: 10.1016/j.applthermaleng.2016.07.058 [7] 袁杨,李祥东,屠基元. 纳米流体沸腾模型中某些物理参数的理论探讨[J]. 清华大学学报:自然科学版,2015, 55(7): 815-820. [8] PHAM Q T, KIM T I, LEE S S, et al. Enhancement of critical heat flux using nano-fluids for invessel retention-external vessel cooling[J]. Applied Thermal Engineering, 2012, 35: 157-165. doi: 10.1016/j.applthermaleng.2011.10.017 -

下载:

下载: