Numerical Study on Dryout Critical Boiling in Vertical Circular Tube under Rolling Conditions

-

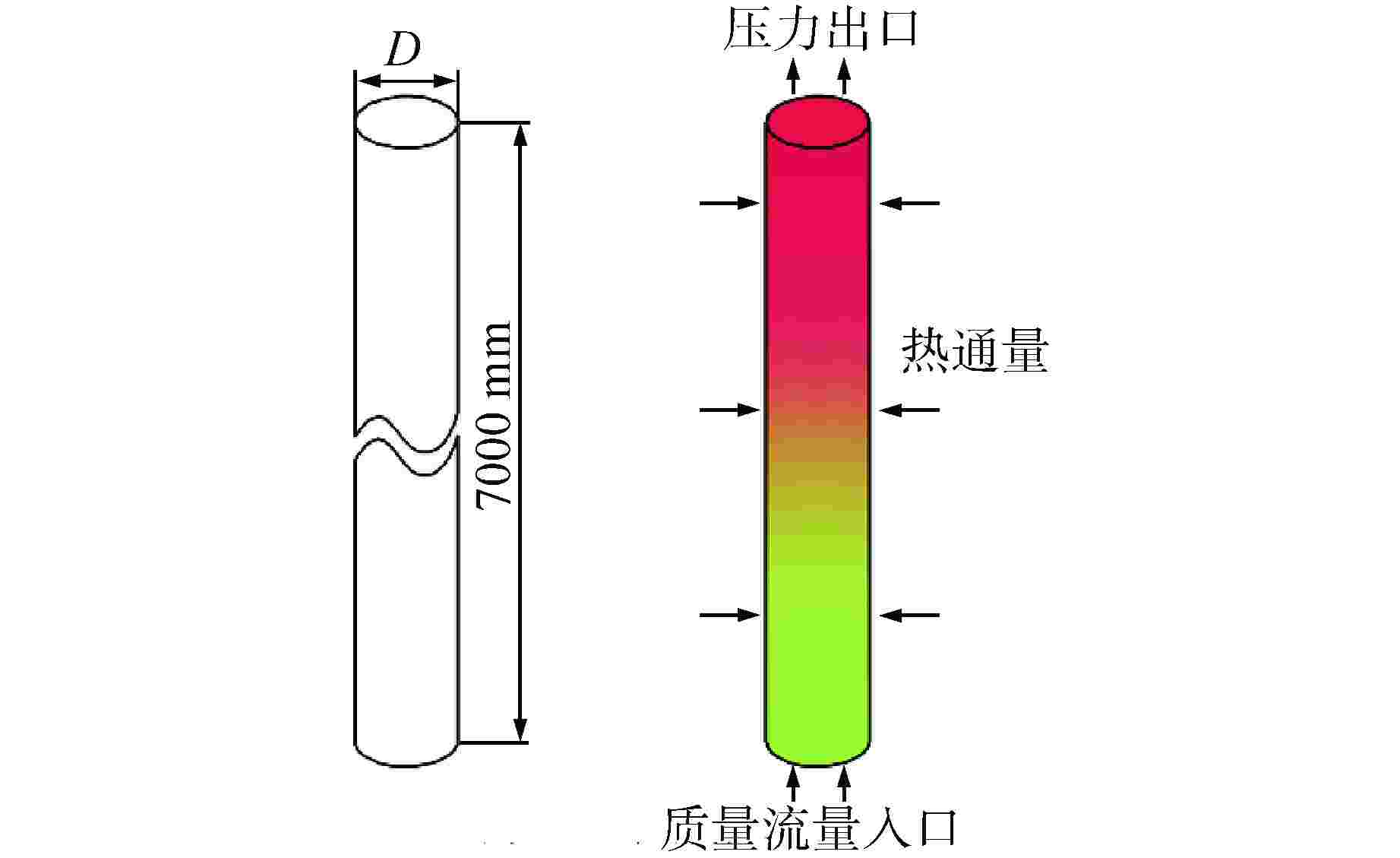

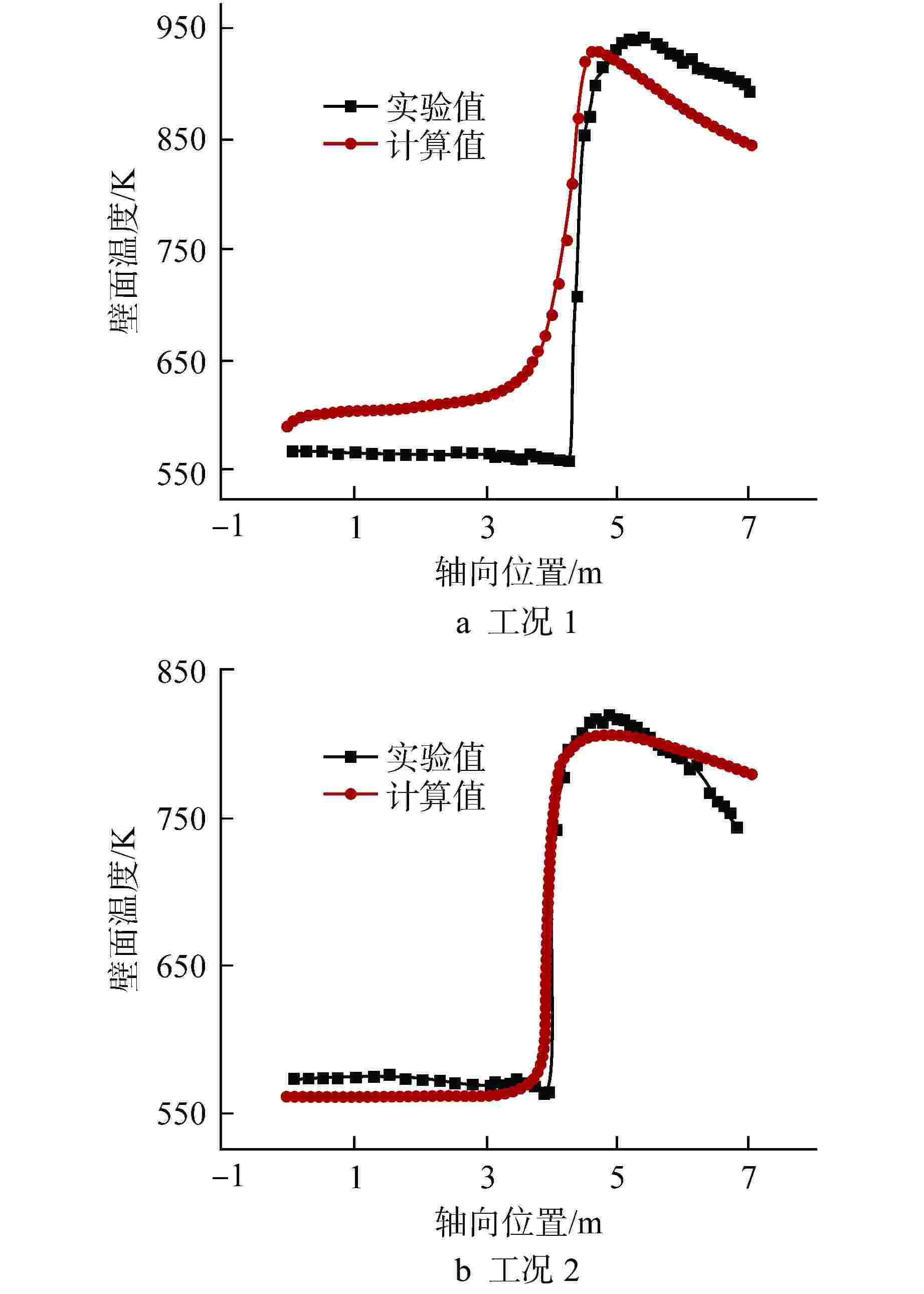

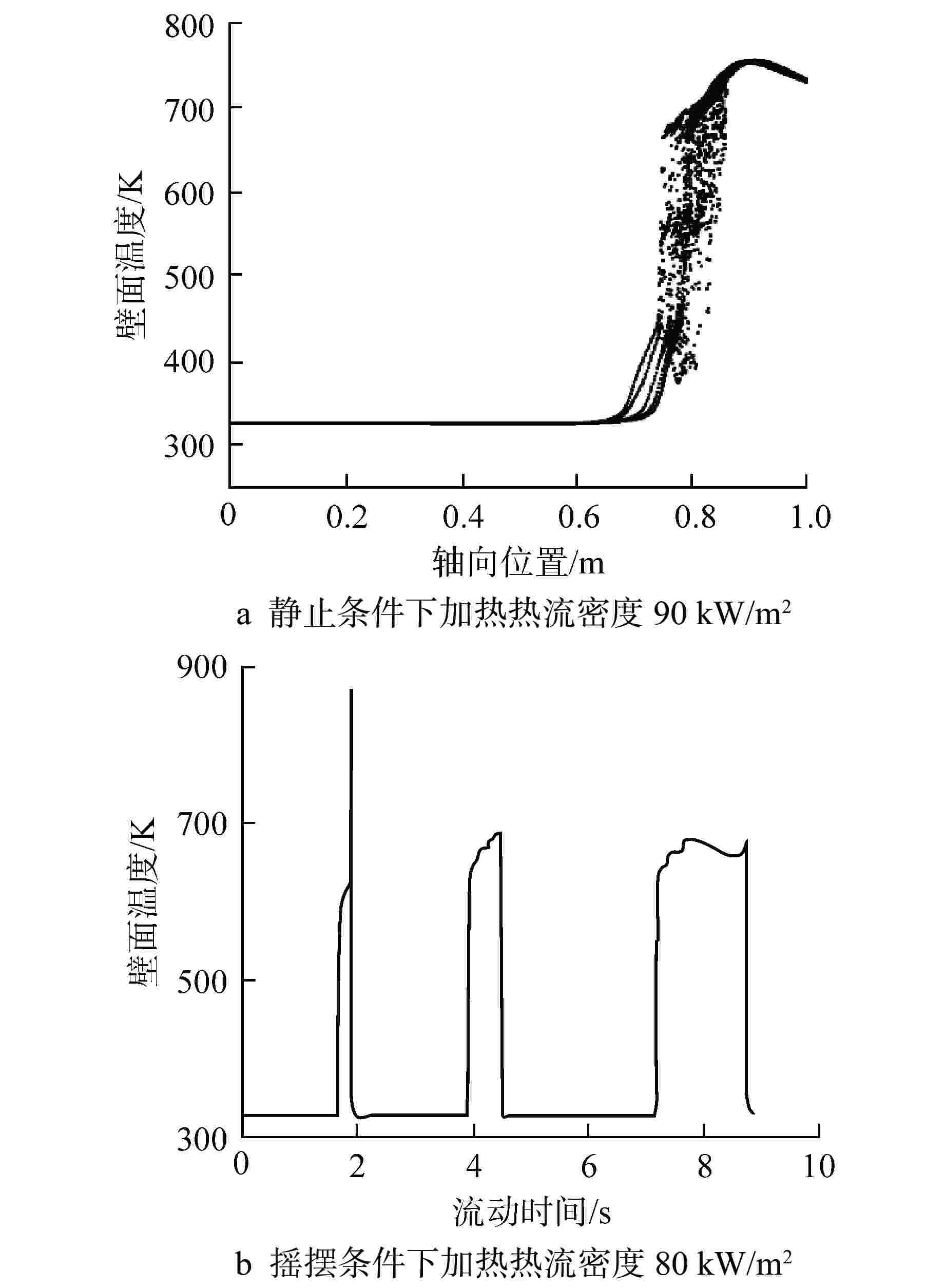

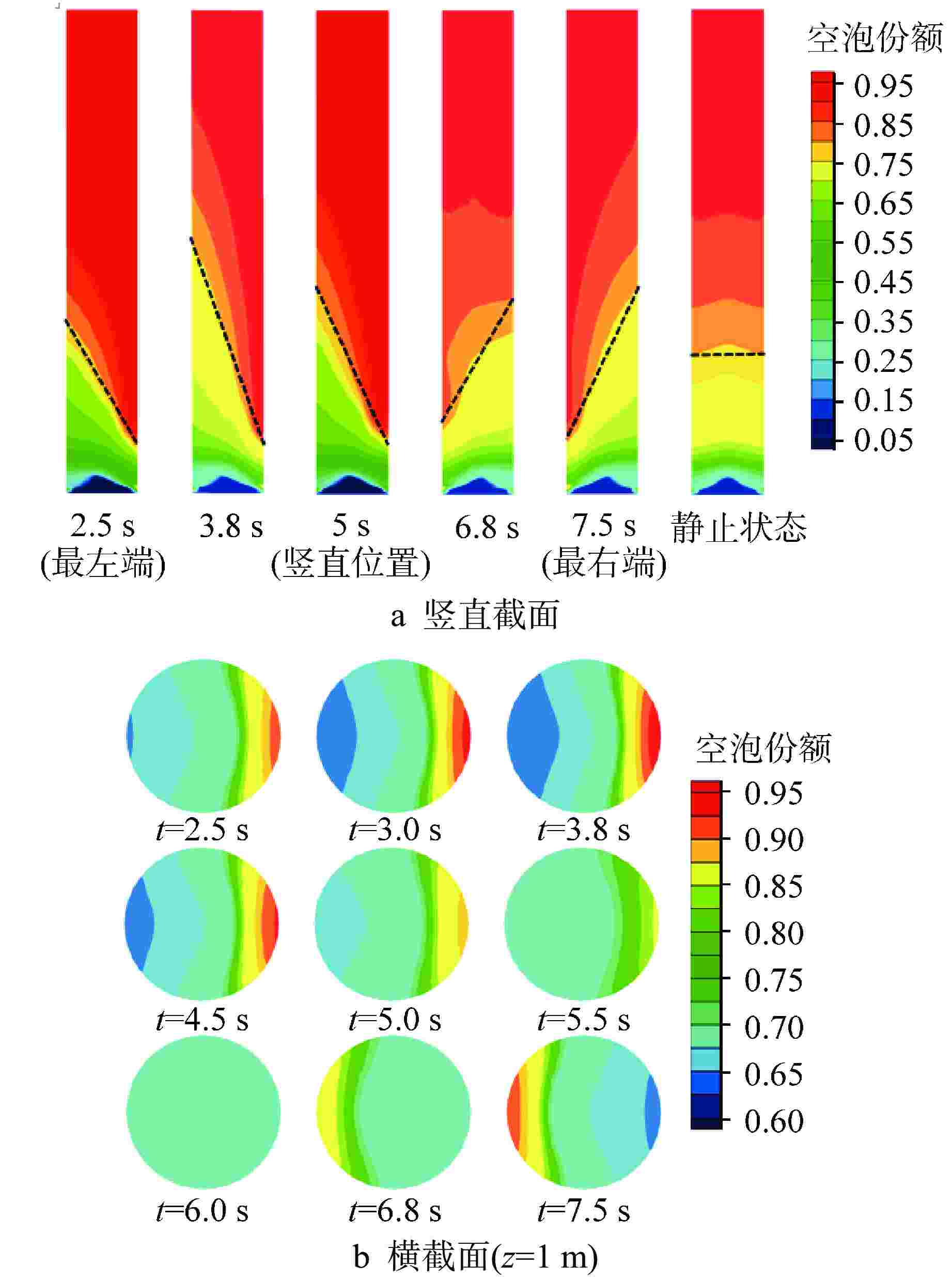

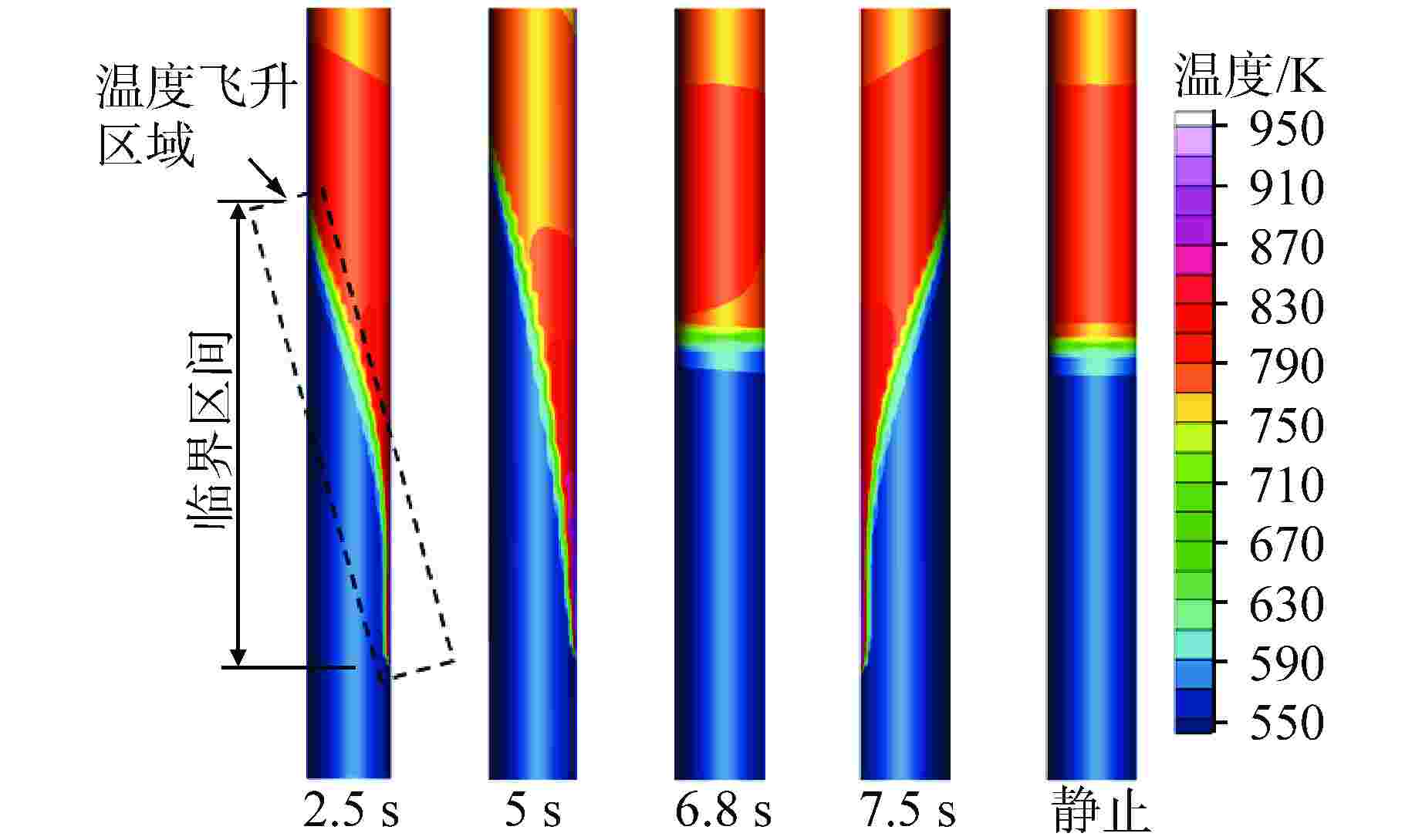

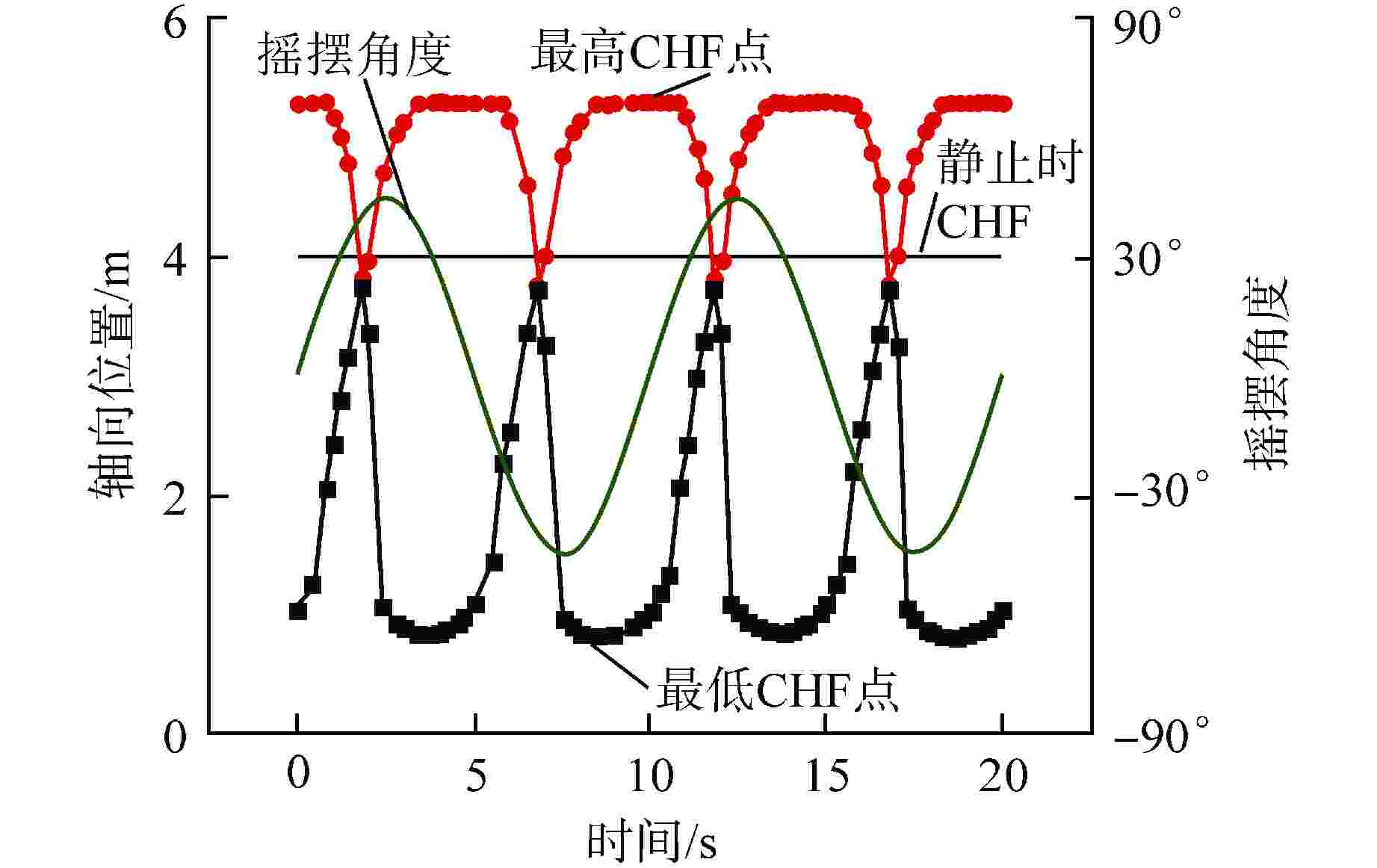

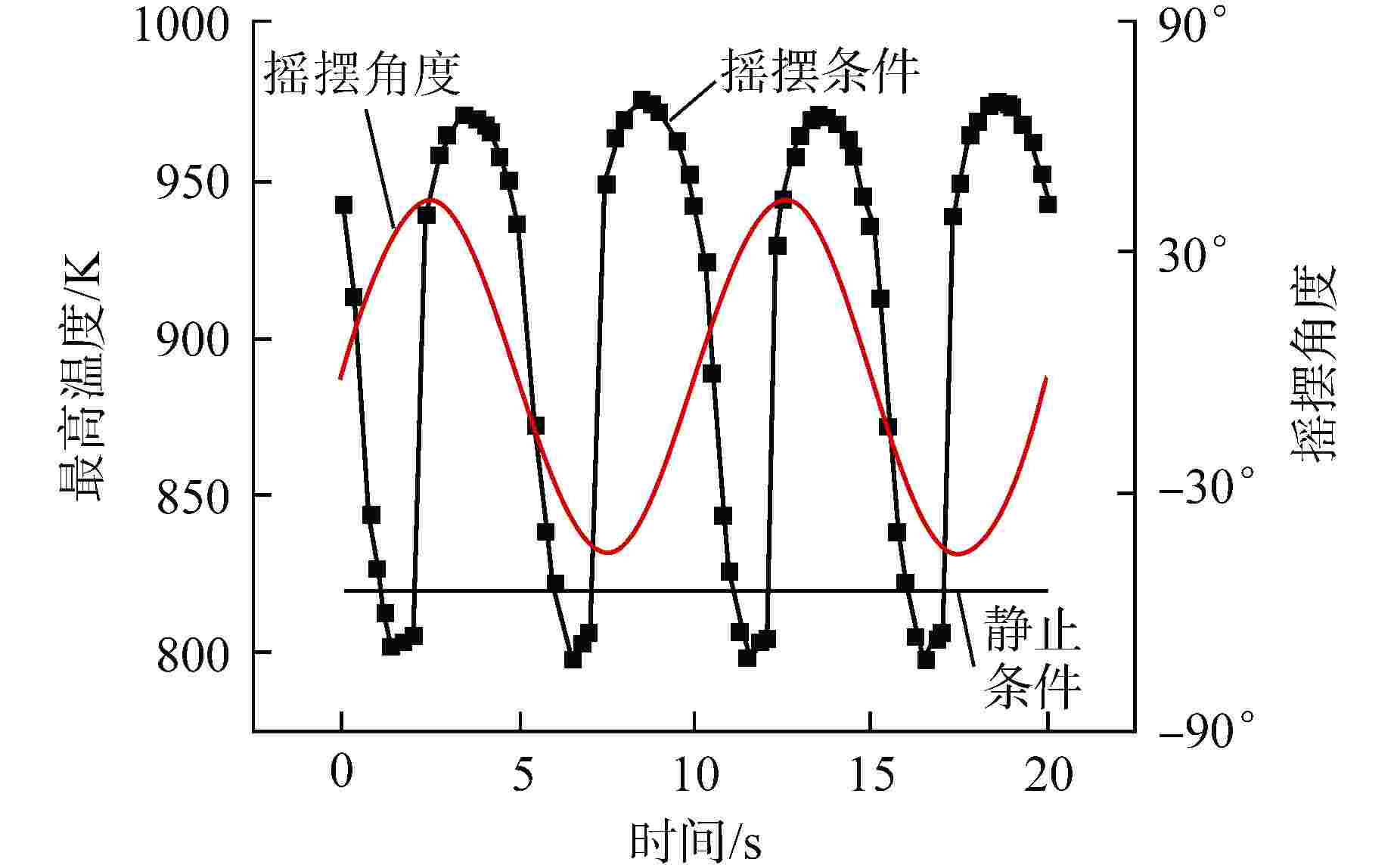

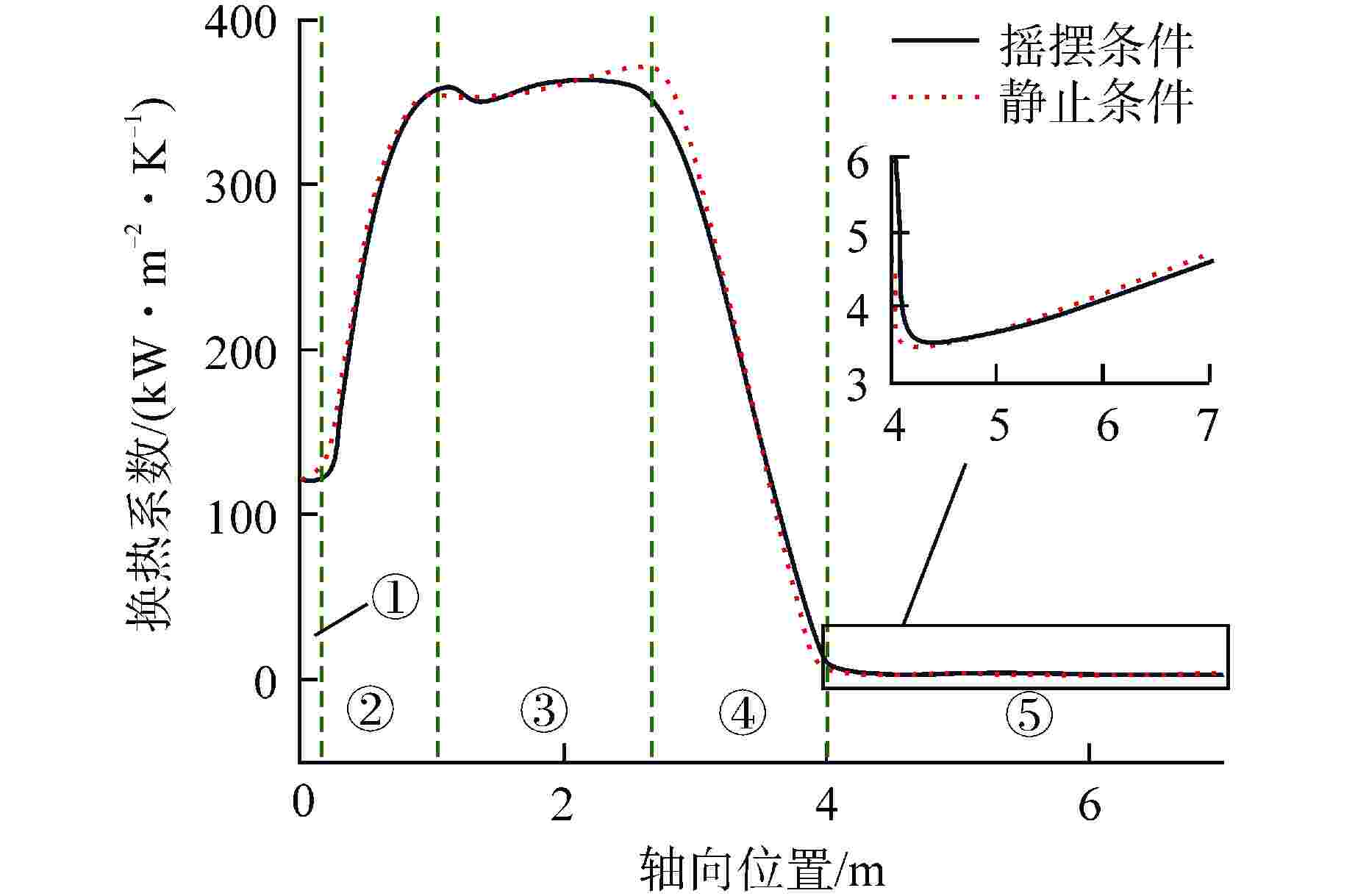

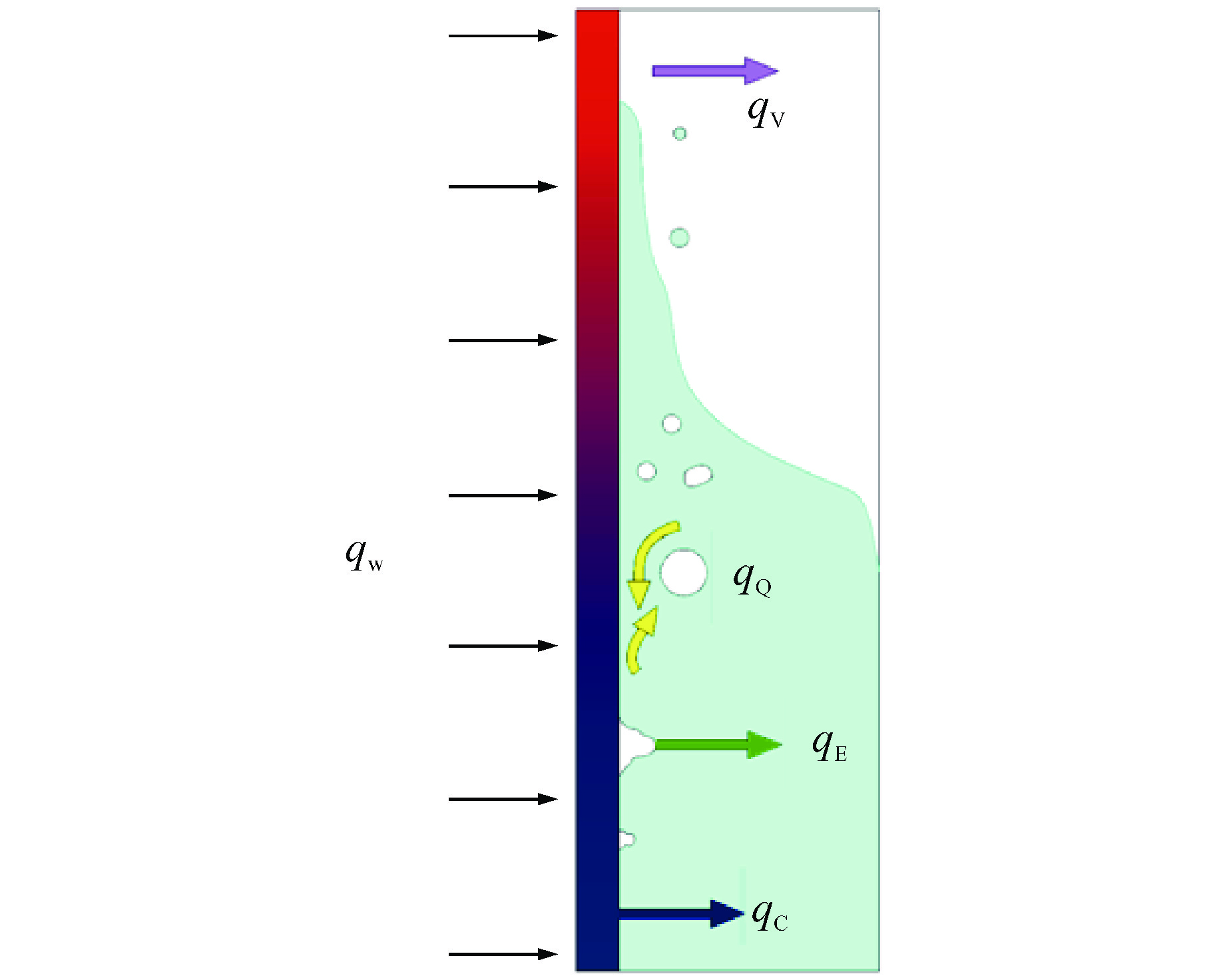

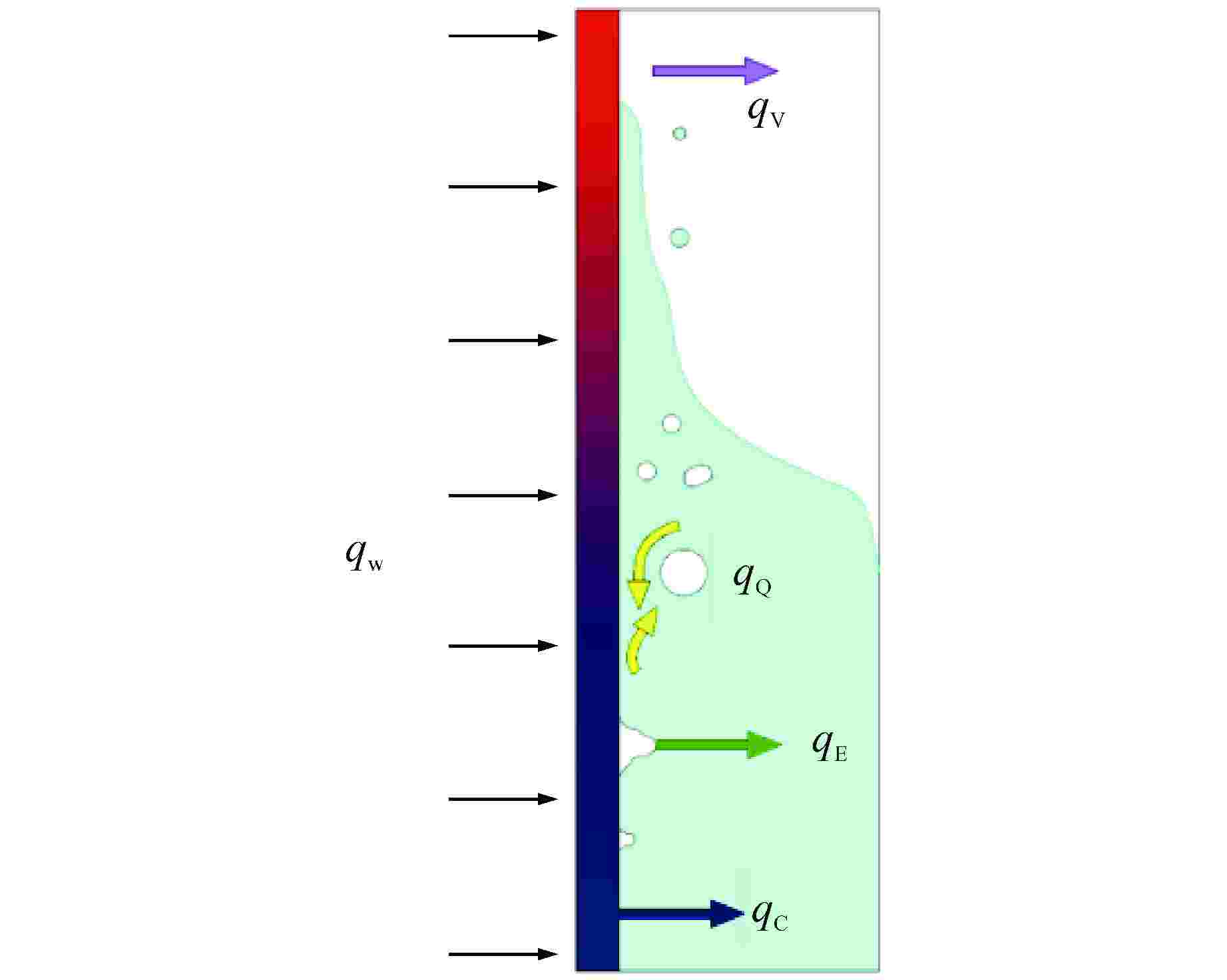

摘要: 针对摇摆条件下竖直圆管内干涸型临界热流密度(Dryout CHF)进行了三维数值计算,研究了摇摆条件下竖直圆管内相态分布特性、圆管内临界热流密度(CHF)的位置以及最高壁面温度,同时对管壁沿程换热系数特性进行了分析。结果表明:在摇摆条件下,圆管内相分布呈现周期性变化,CHF的位置也会发生周期性变化;同时发现摇摆运动会导致壁面最高温度更高,因此摇摆条件会使沸腾临界现象更严重。随着流型转变和沸腾传热机制的变化,管壁换热系数沿流动方向也会显著变化。本研究可以为摇摆条件下Dryout CHF的数值预测提供参考。

-

关键词:

- 干涸型临界热流密度(Dryout CHF) /

- 摇摆条件 /

- 壁面温度 /

- 换热系数

Abstract: The three-dimensional numerical calculation of the dryout critical heat flux (Dryout CHF) in a circular tube under rolling conditions is carried out. The phase distribution characteristics, the location of critical heat flux (CHF) and the maximum wall temperature in the circular tube under rolling condition are studied, and the characteristics of heat transfer coefficient along the tube wall are analyzed. The results show that under the rolling condition, the phase distribution in the circular tube changes periodically, and the position of CHF also changes periodically; At the same time, it is found that the rolling motion leads to a higher maximum wall temperature, so the rolling condition will make the boiling critical phenomenon more serious. With the change of flow pattern and boiling heat transfer mechanism, the wall heat transfer coefficient will also change significantly along the flow direction. This study can provide a reference for the numerical prediction of dryout CHF under rolling condition.-

Key words:

- Dryout CHF /

- Rolling conditions /

- Wall temperature /

- Heat transfer coefficient

-

表 1 沸腾子模型的选取

Table 1. Selection of Boiling Submodel

物理模型 模型选项 汽泡脱离直径 Tolubinsky-Kostanchuk 汽泡脱离频率 Cole 核化密度 Lemmert-Chawla 面积影响系数 Delvalle-Kenning 表 2 相间模型的选取

Table 2. Selection of Interphase Models

作用力模型 模型选项 曳力 Ishii模型 升力 Moraga模型 湍流耗散力 Burns-et-al模型 壁面润滑力 Antal-et-al模型 虚拟质量力系数 0.5 表 3 验证工况参数

Table 3. Verification Condition Parameters

参数 工况1 工况2 管径 D/mm 14.9 10 压力 p/MPa 7.01 7.02 质量流量 G/(kg·m−2·s−1) 1002 1495 实验测得的临界热流密度 QCHF/(kW·m−2) 863 797 进口温度 Tin/K 549 555 表 4 边界条件[2]

Table 4. Boundary Conditions

参数名 参数值 G/(kg·m−2·s−1) 285 进口比焓/(kJ·kg−1) 221.781 Tsat/K 322.607 Tin/K 289.013 θ0 40° t0/s 6 -

[1] 高璞珍,王兆祥,庞凤阁,等. 摇摆情况下水的自然循环临界热流密度实验研究[J]. 哈尔滨工程大学学报,1997, 18(6): 38-42. [2] HWANG J S, LEE Y G, PARK G C. Characteristics of critical heat flux under rolling condition for flow boiling in vertical tube[J]. Nuclear Engineering and Design, 2012, 252: 153-162. doi: 10.1016/j.nucengdes.2012.06.032 [3] TANJUNG E F, JO D. Visualization study on pool boiling critical heat flux under rolling motion[J]. International Journal of Heat and Mass Transfer, 2020, 153: 119620. doi: 10.1016/j.ijheatmasstransfer.2020.119620 [4] 徐海淞. 基于拉格朗日—欧拉法的环状流模拟及干涸型临界热流密度预测研究[D]. 上海: 上海交通大学, 2019. [5] 陈丽娟. 竖直加热管道内干涸型临界沸腾数值分析[D]. 哈尔滨: 哈尔滨工程大学, 2018. [6] DU D X, TIAN W X, SU G H, et al. Theoretical study on the characteristics of critical heat flux in vertical narrow rectangular channels[J]. Applied Thermal Engineering, 2012, 36: 21-31. doi: 10.1016/j.applthermaleng.2011.11.039 [7] GUI M Y, TIAN W X, WU D, et al. Development of a three-field mechanistic model for dryout prediction in annular flow[J]. Annals of Nuclear Energy, 2020, 135: 106978. doi: 10.1016/j.anucene.2019.106978 [8] GUI M Y, TIAN W X, WU D, et al. Study on CHF characteristics in narrow rectangular channel under complex motion condition[J]. Applied Thermal Engineering, 2020, 166: 114629. doi: 10.1016/j.applthermaleng.2019.114629 [9] 桂民洋,田文喜,吴迪,等. 棒束子通道CHF机理模型开发及初步验证[J]. 原子能科学技术,2021, 55(11): 1930-1938. doi: 10.7538/yzk.2021.youxian.0046 [10] PENG J, CHEN D Q, XU J J, et al. CFD simulation focusing on void distribution of subcooled flow boiling in circular tube under rolling condition[J]. International Journal of Heat and Mass Transfer, 2020, 156: 119790. doi: 10.1016/j.ijheatmasstransfer.2020.119790 [11] TENTNER A, LO S, IOILEV A, et al. Computational fluid dynamics modeling of two-phase flow topologies in a boiling water reactor fuel assembly[C]//Proceedings of the 16th International Conference on Nuclear Engineering. Orlando: ASME, 2008: 178-183. [12] RANZ W E, MARSHALL W R. Evaporation from drops[J]. Chemical Engineering Progress, 1952, 48(3): 141-146. [13] 魏列. 运动条件对自然循环系统驱动力特性的影响机制研究[D]. 重庆: 重庆大学, 2020. [14] BECKER K M, LING C H, HEDBERG S, et al. An experimental investigation of post dryout heat transfer[R]. Stockholm: Department of Nuclear Reactor Engineering Royal Institute of Technology Stockholm, 1983. [15] 史建新. 直管式直流蒸汽发生器蒸干及蒸干后传热数值模拟[D]. 哈尔滨: 哈尔滨工程大学, 2019. -

下载:

下载: