Numerical Analysis of Influence of Positioning and Wrapping Wire Structure on Thermohydraulic Characteristics of Rod Bundle Channel

-

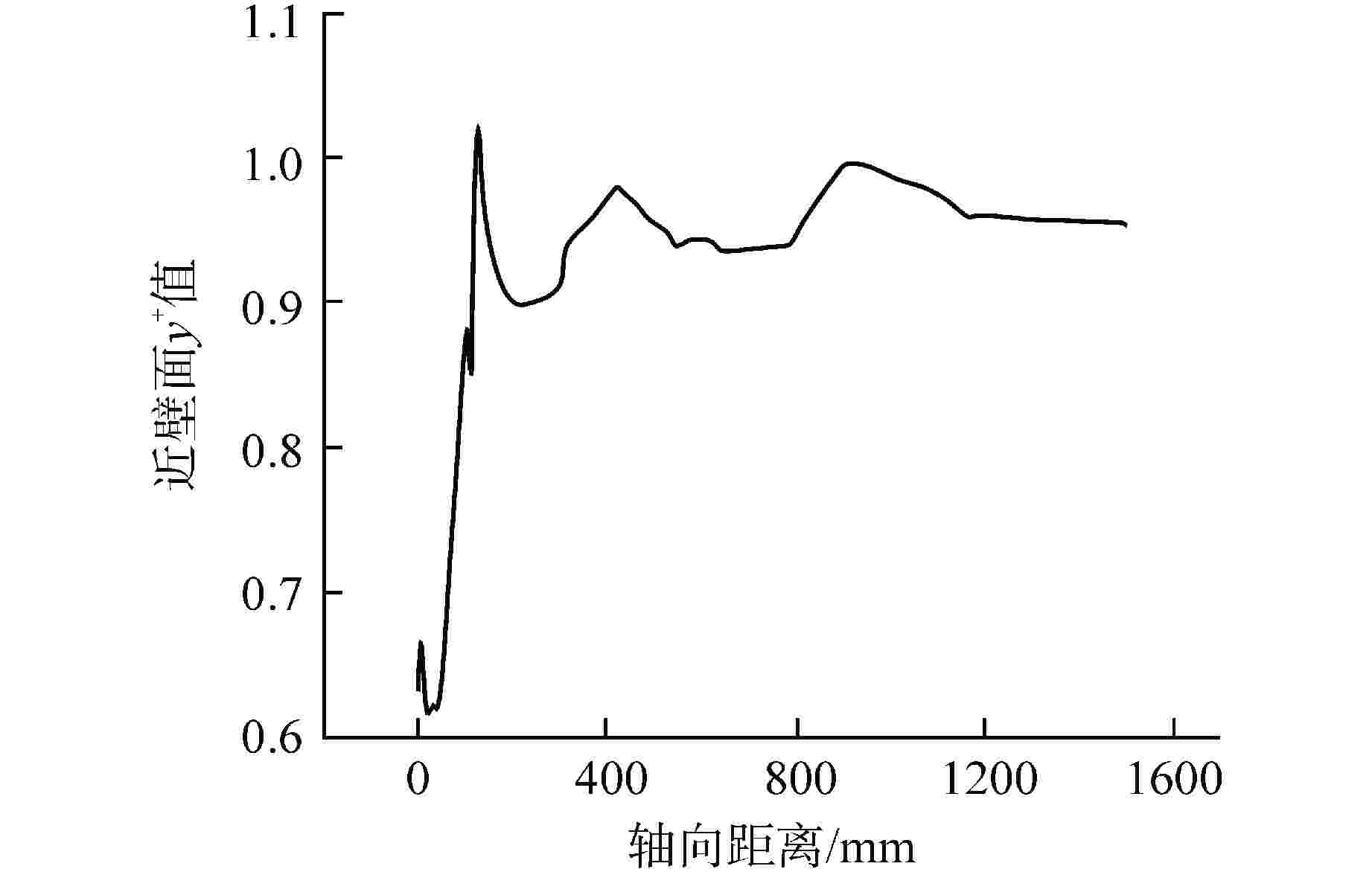

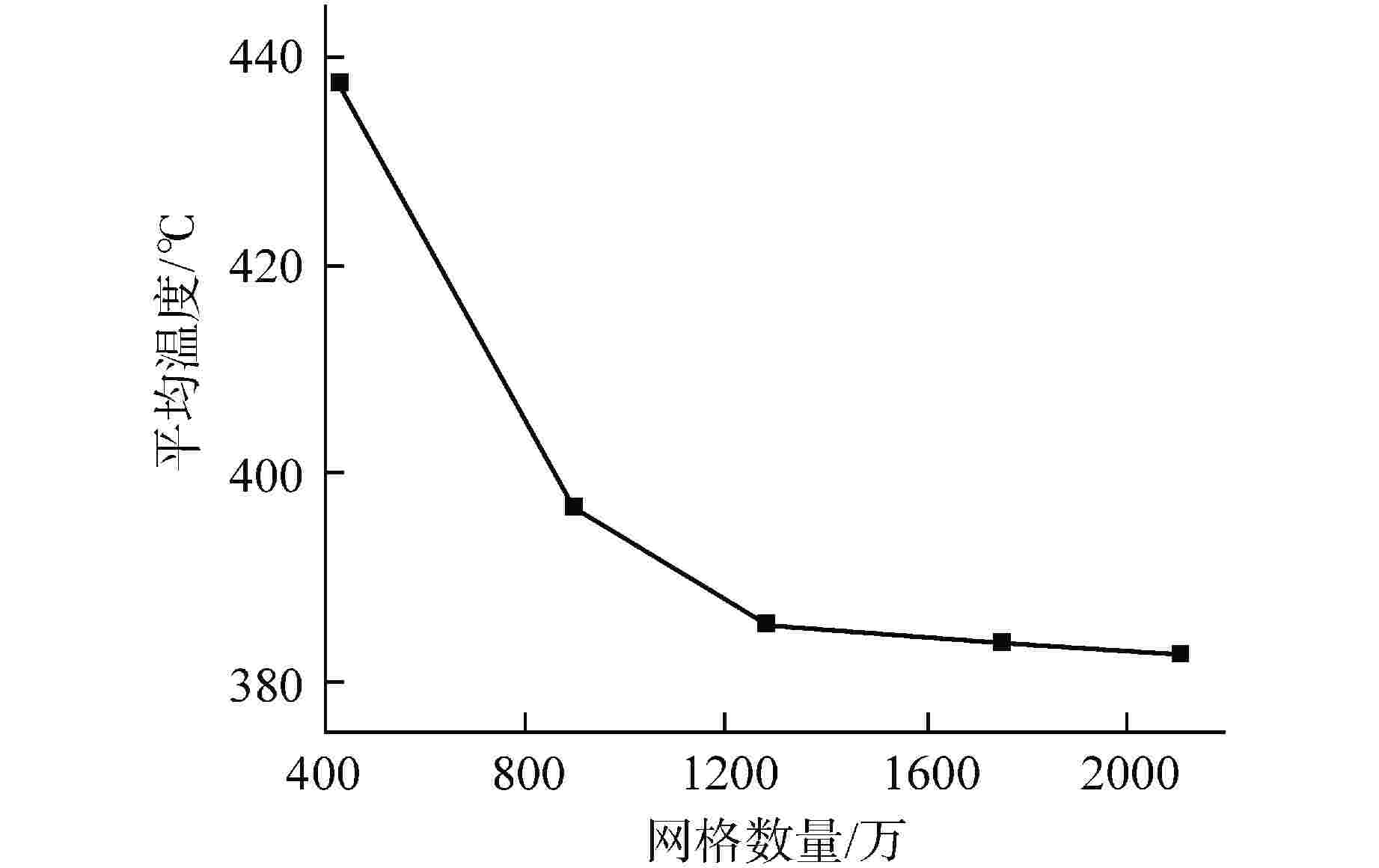

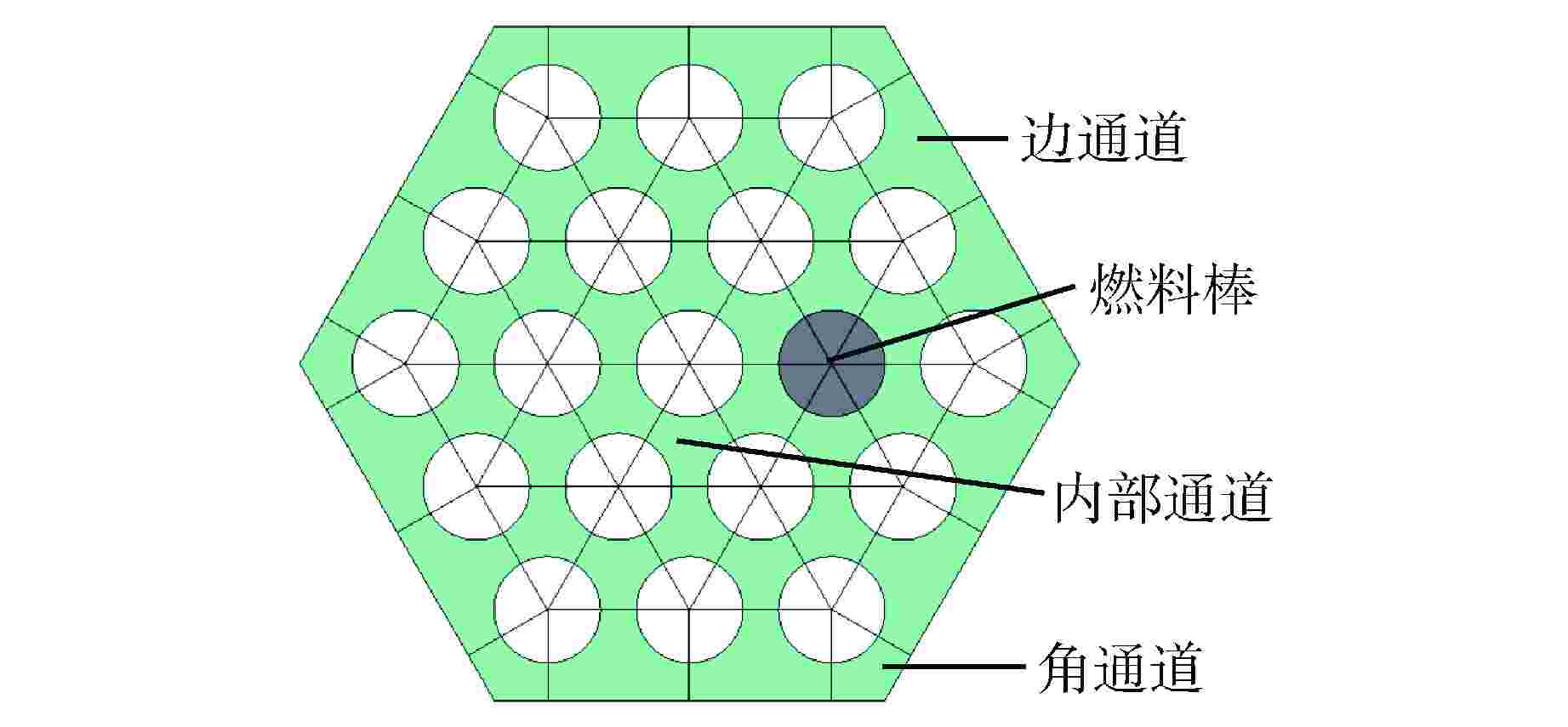

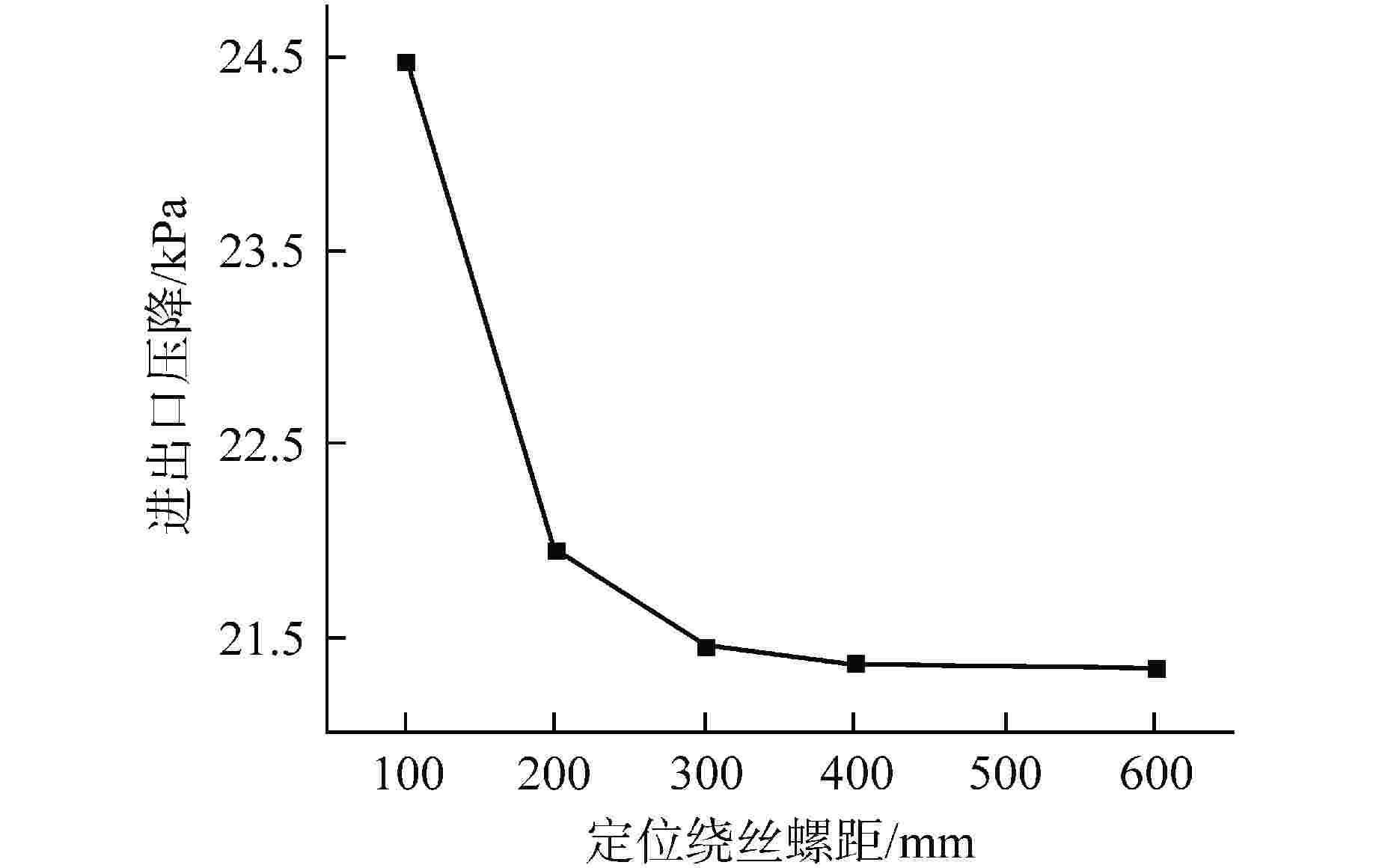

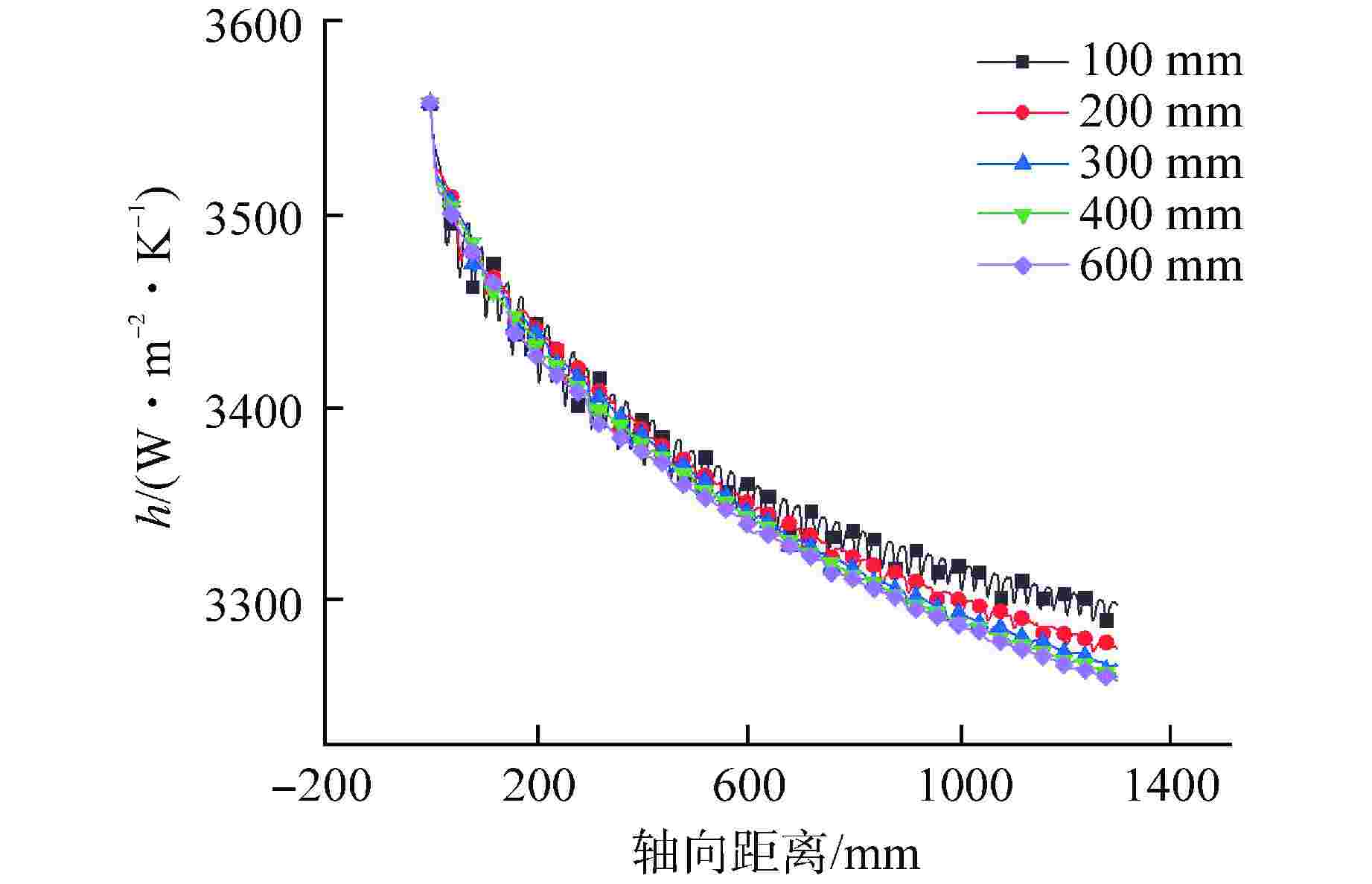

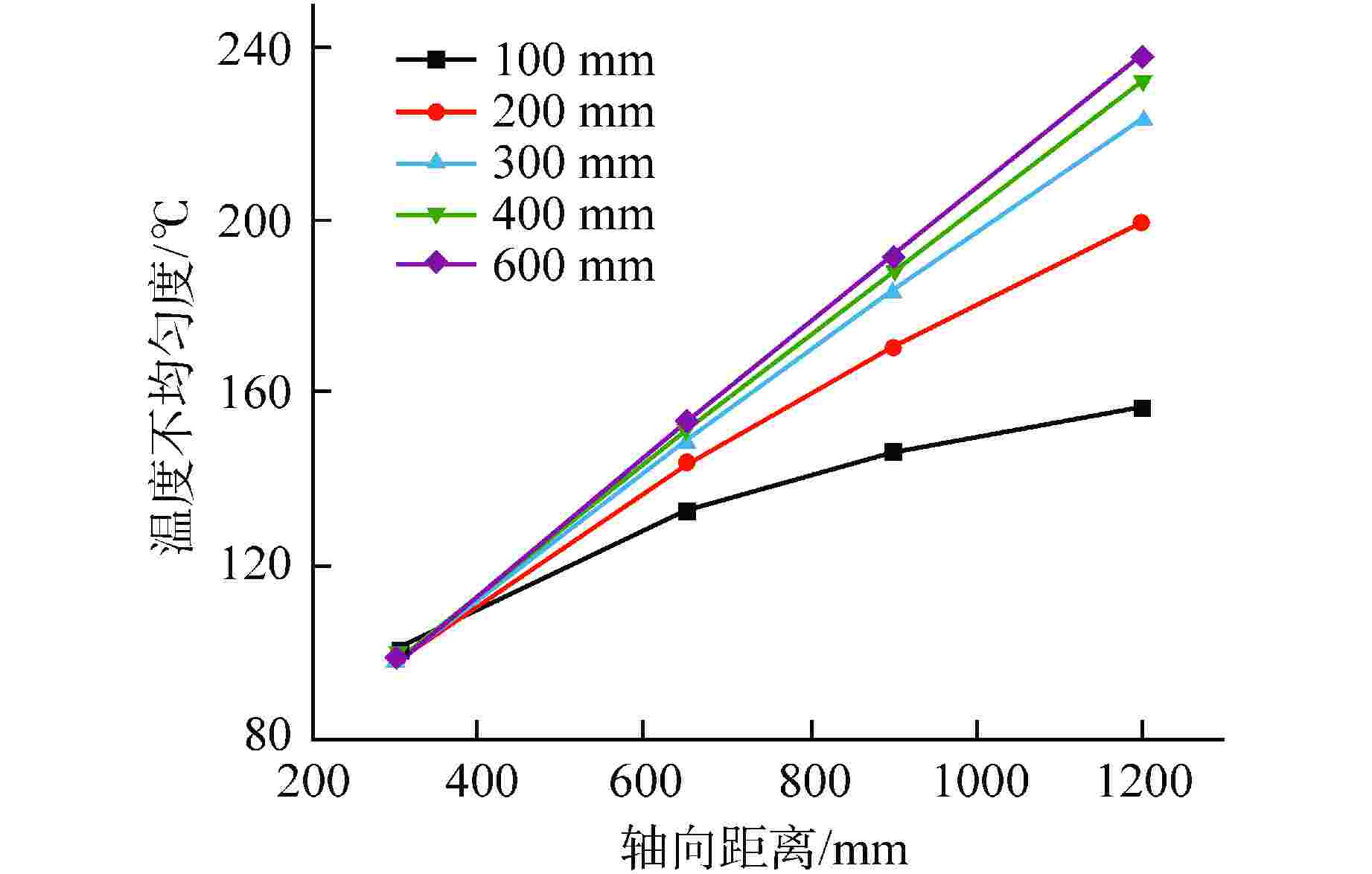

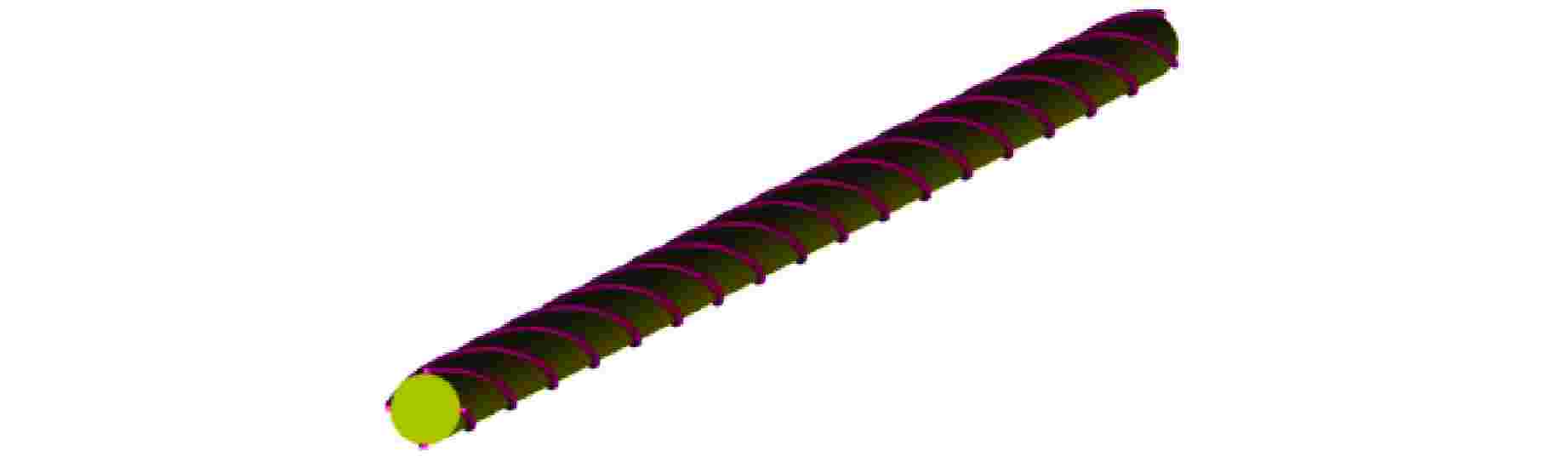

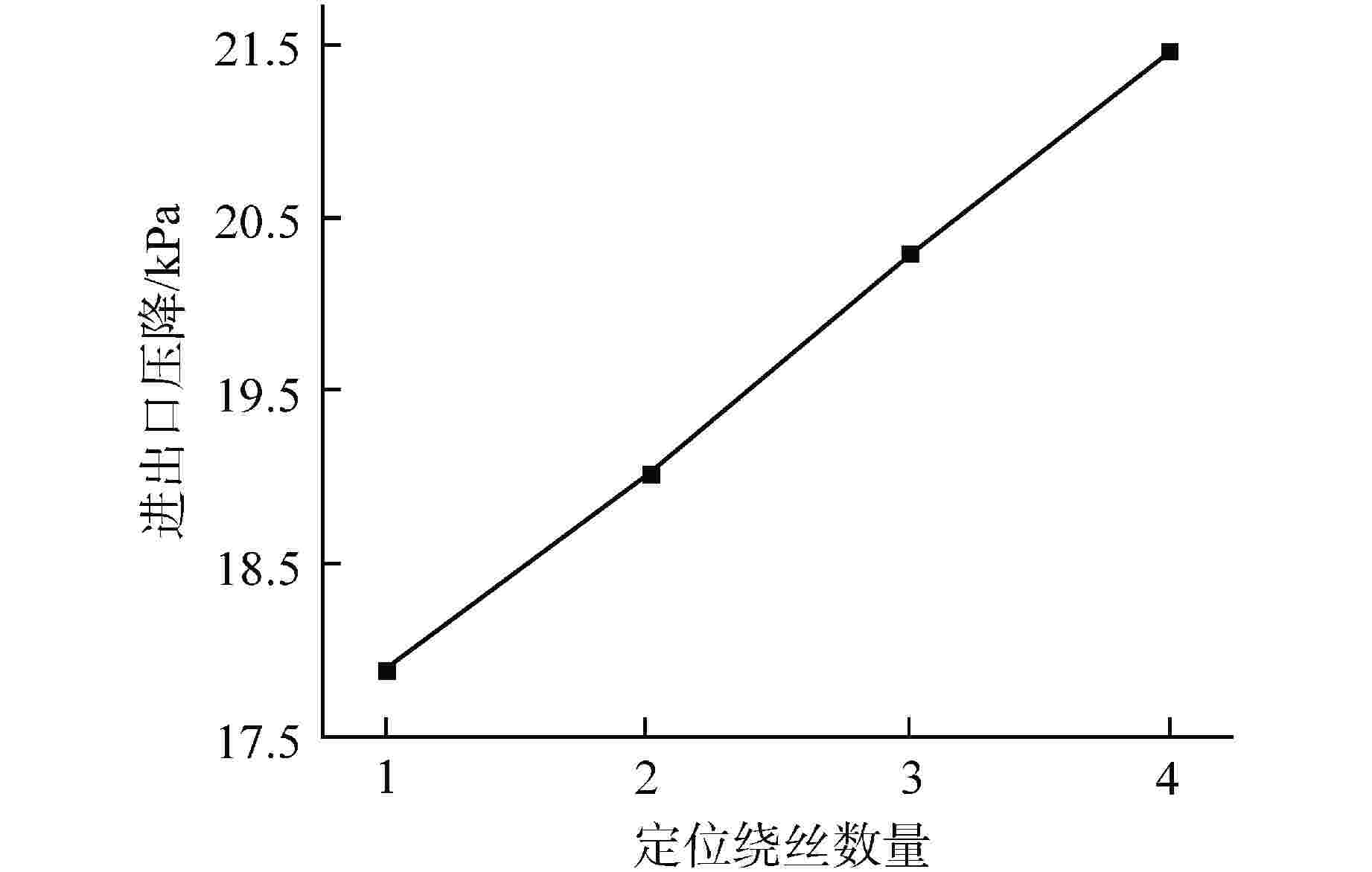

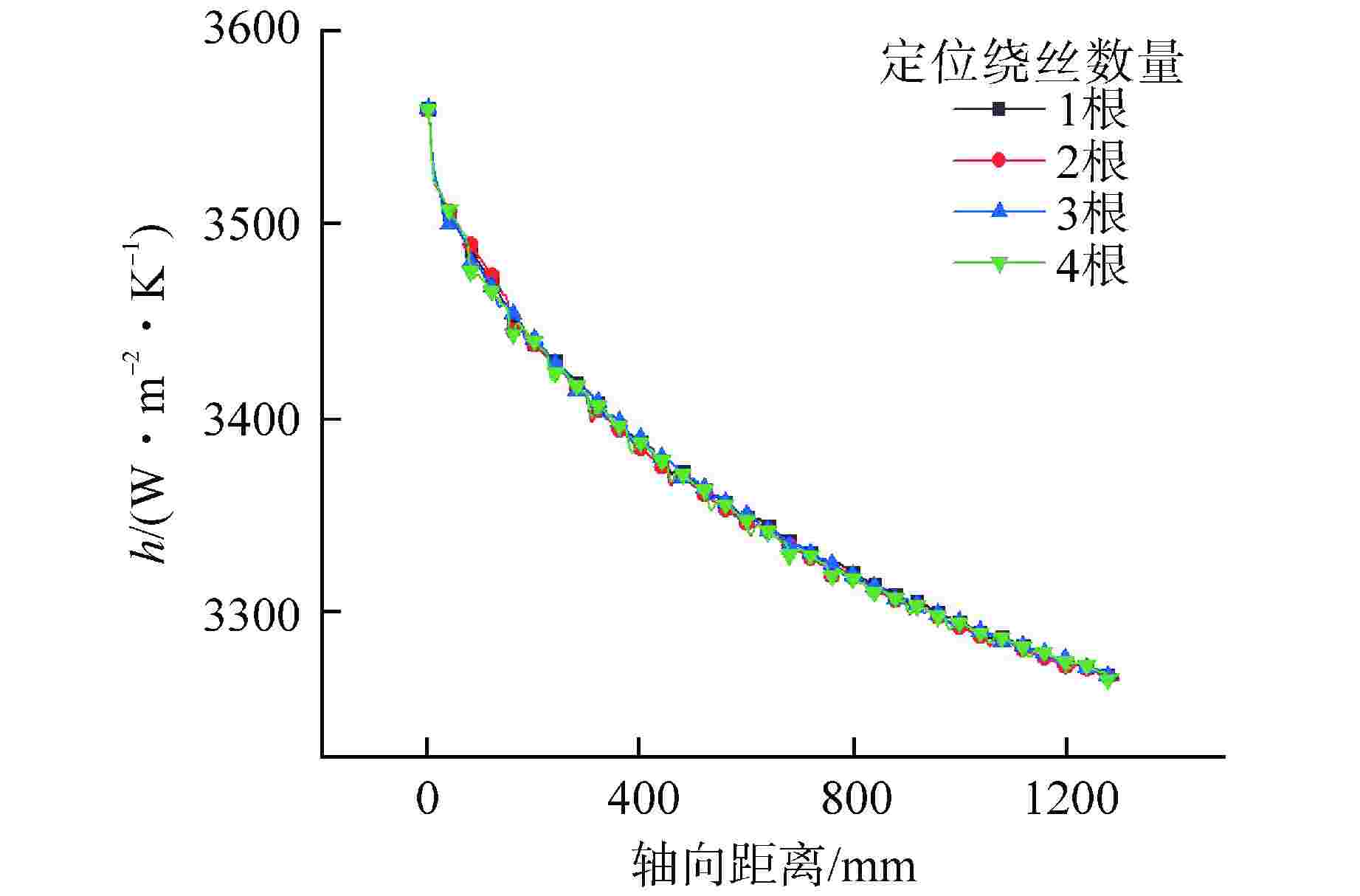

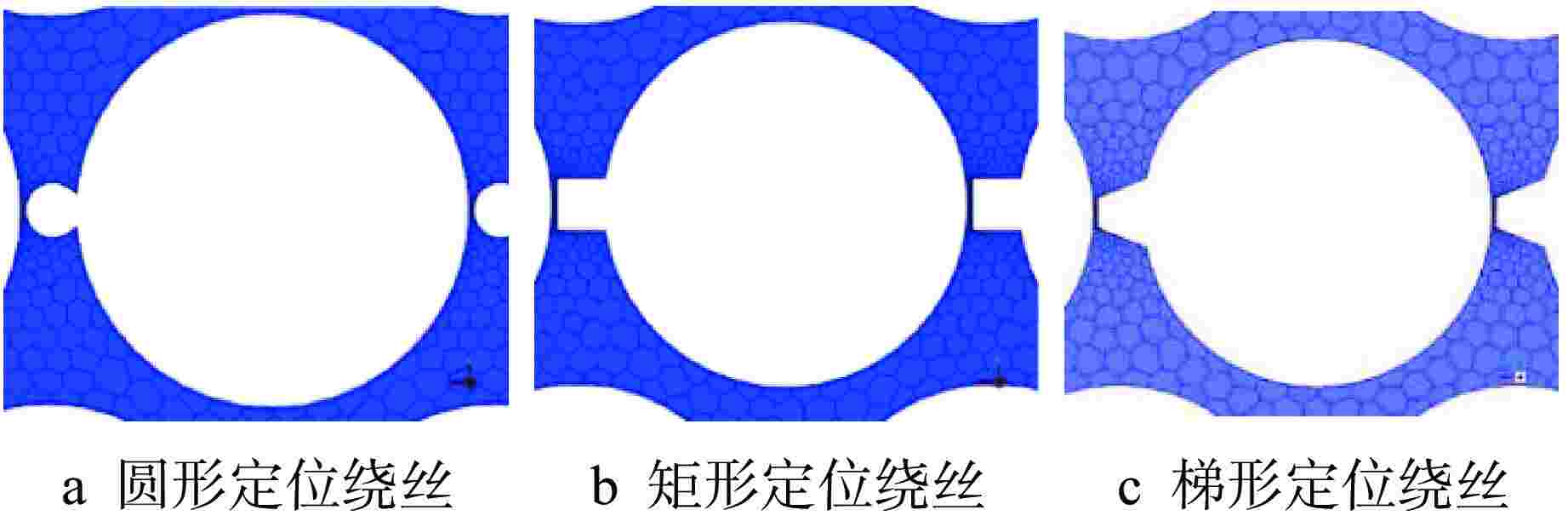

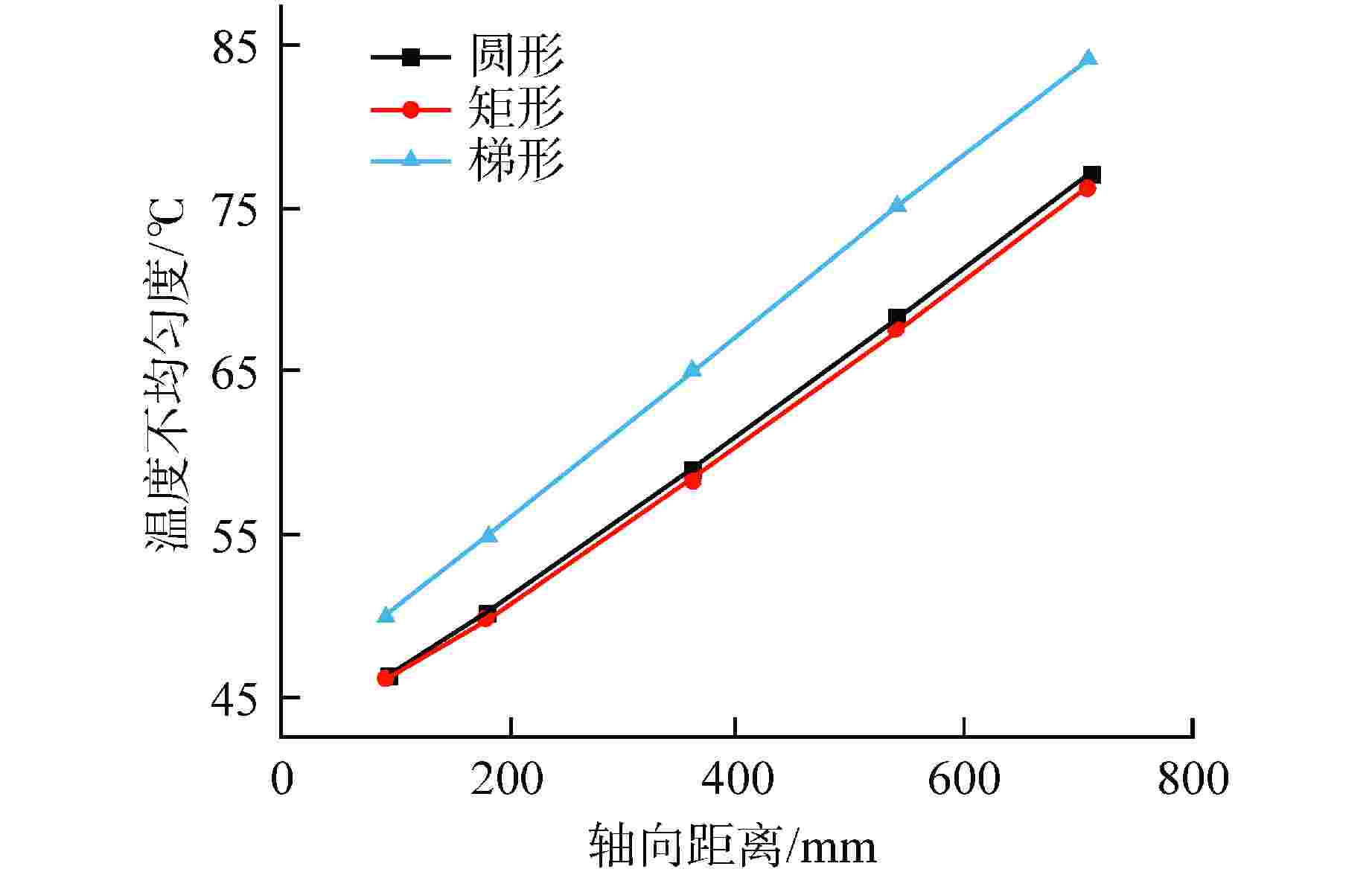

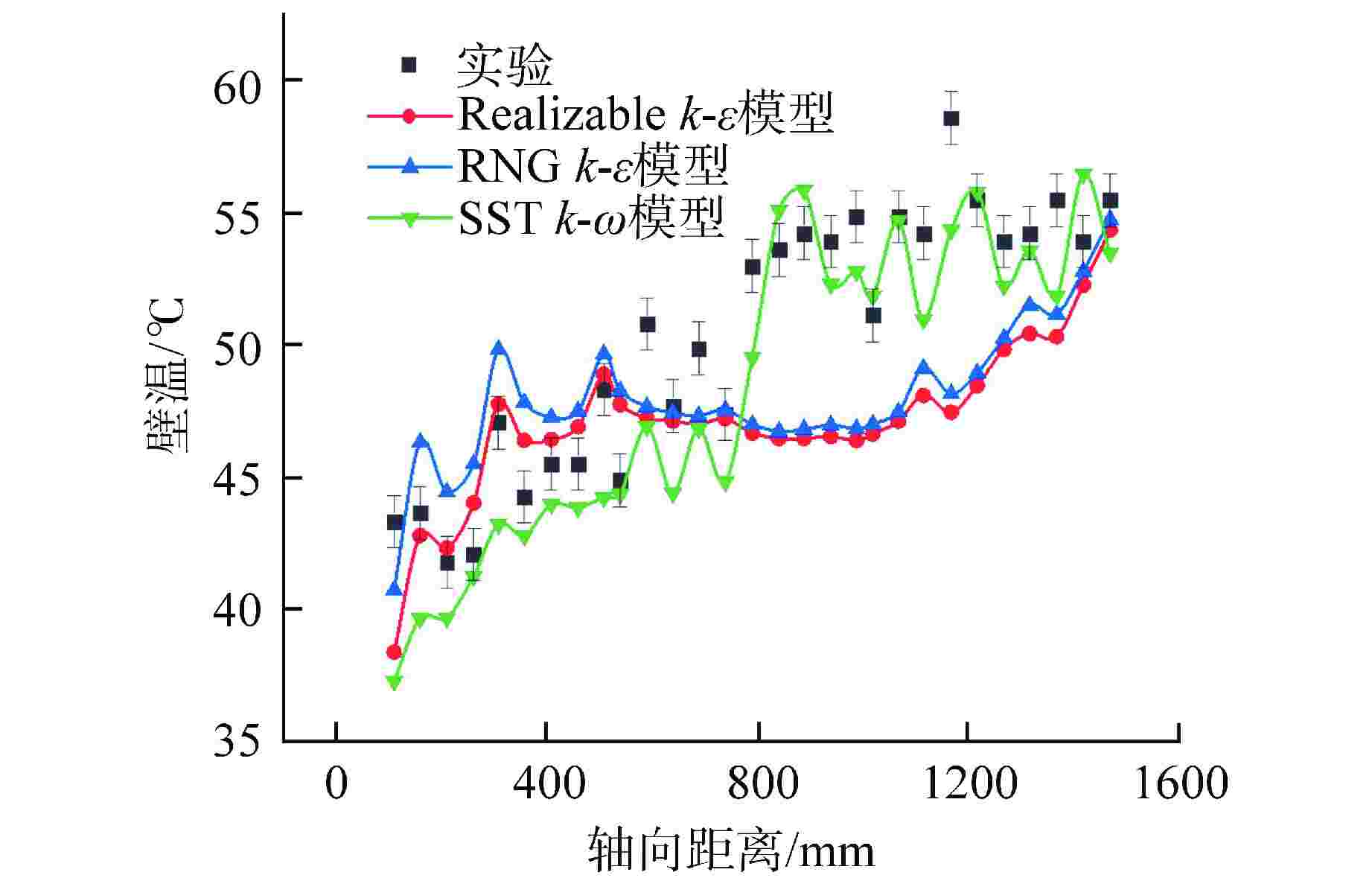

摘要: 定位绕丝设计广泛应用于金属快堆堆芯设计及气冷快堆堆芯设计中,本文基于三维精细化绕丝定位棒束通道网格模型模拟分析了定位绕丝螺距、定位绕丝数量及定位绕丝形状对超临界二氧化碳在棒束通道中流动换热的影响。模拟结果表明定位绕丝螺距比定位绕丝数量及定位绕丝形状对温场流场的影响更大,定位绕丝螺距小于200 mm时,进出口压降大幅增加,表面换热系数增加,温度不均匀度大幅降低;随着定位绕丝数量增加,进出口压降线性增加,表面换热系数变化不大;圆形定位绕丝可以以较小截面积达到与方形定位绕丝相似的效果,梯形定位绕丝对流场影响不如矩形定位绕丝。Abstract: The positioning and wrapping wire design is widely applied in the core design of metal cooled fast reactor and gas cooled fast reactor. In this paper, the effects of pitch, number and shape of positioning and wrapping wires on the flow and heat transfer of supercritical carbon dioxide in rod bundle channel are simulated and analyzed based on three-dimensional fine mesh model of wrapping wire positioning rod bundle channel. The simulation results show that positioning and wrapping wire pitch has a greater influence on the temperature field and flow field than the positioning and wrapping wire number and shape. When the positioning and wrapping wire pitch is less than 200 mm, pressure drop at the inlet and outlet increases significantly, surface heat transfer coefficient increases, and temperature non-uniformity decreases significantly and the temperature unevenness decreases greatly; with the increase in the number of the positioning and wrapping wires, pressure drop at the inlet and outlet increases linearly, but the surface heat transfer coefficient changes little; circular positioning and wrapping wire can achieve a similar effect to that of rectangular positioning and wrapping wire with a smaller cross-sectional area, and trapezoidal positioning and wrapping wire has less influence on flow field than rectangular positioning and wrapping wire.

-

表 1 不同形状绕丝定位棒束通道进出口压降

Table 1. Pressure Drop at Inlet and Outlet of Wrapping Wire Positioning Rod Bundle Channels with Different Shapes

参数名 参数值 圆形定位绕丝 矩形定位绕丝 梯形定位绕丝 归一化面积 0.78 1 1 进出口压降/Pa 31522.2 32152.2 29437.7 归一化进出口压降 0.98 1 0.91 -

[1] ETER A, GROENEVELD D, TAVOULARIS S. An experimental investigation of supercritical heat transfer in a three-rod bundle equipped with wire-wrap and grid spacers and cooled by carbon dioxide[J]. Nuclear Engineering and Design, 2016, 303: 173-191. doi: 10.1016/j.nucengdes.2016.04.002 [2] 李明刚,聂常华,徐长哲. 四根绕丝定位19棒束组件流动传热特性[J]. 工业技术创新,2021, 8(1): 115-122. doi: 10.14103/j.issn.2095-8412.2021.01.019 [3] 臧金光,闫晓,黄善仿,等. 含绕丝2×2棒束内超临界水传热特性数值研究[J]. 核动力工程,2014, 35(2): 33-36. [4] WANG X A, ZHANG D L, WANG M J, et al. Generating hexahedral mesh for wire-wrapped fuel assembly with RBF mesh deformation method[J]. Frontiers in Energy Research, 2021, 8: 616890. doi: 10.3389/fenrg.2020.616890 [5] 丛腾龙,王俊杰,肖瑶,等. 铅铋冷却绕丝燃料组件横流特性分析[J]. 原子能科学技术,2022, 56(12): 2725-2734. [6] 李虹锐,薛秀丽,周志伟. 绕丝棒束组件低流速时摩擦阻力实验研究[J]. 原子能科学技术,2021, 55(6): 1054-1059. doi: 10.7538/yzk.2020.youxian.0534 [7] WANG S Q, WANG H, ZANG J G, et al. Numerical simulation of the thermal-hydraulic characteristics of supercritical carbon dioxide in a wire-wrapped rod bundle[J]. Applied Thermal Engineering, 2021, 198: 117443. doi: 10.1016/j.applthermaleng.2021.117443 [8] MERZARI E, POINTER W D, SMITH J G, et al. Numerical simulation of the flow in wire-wrapped pin bundles: effect of pin-wire contact modeling[J]. Nuclear Engineering and Design, 2012, 253: 374-386. doi: 10.1016/j.nucengdes.2011.09.030 [9] SHAMS A, ROELOFS F, BAGLIETTO E, et al. High fidelity numerical simulations of an infinite wire-wrapped fuel assembly[J]. Nuclear Engineering and Design, 2018, 335: 441-459. doi: 10.1016/j.nucengdes.2018.06.012 [10] 郜冶,李小畅. 压水堆四通道模型全高度上的单相流数值模拟[J]. 哈尔滨工程大学学报,2013, 34(3): 292-297. [11] 王俊峰, 黄彦平. 一种超临界二氧化碳反应堆燃料组件: 中国, CN109273105B[P]. 2022-03-25. -

下载:

下载: