Study on Evaluation Method for Creep Performance of New Zirconium Alloy Cladding

-

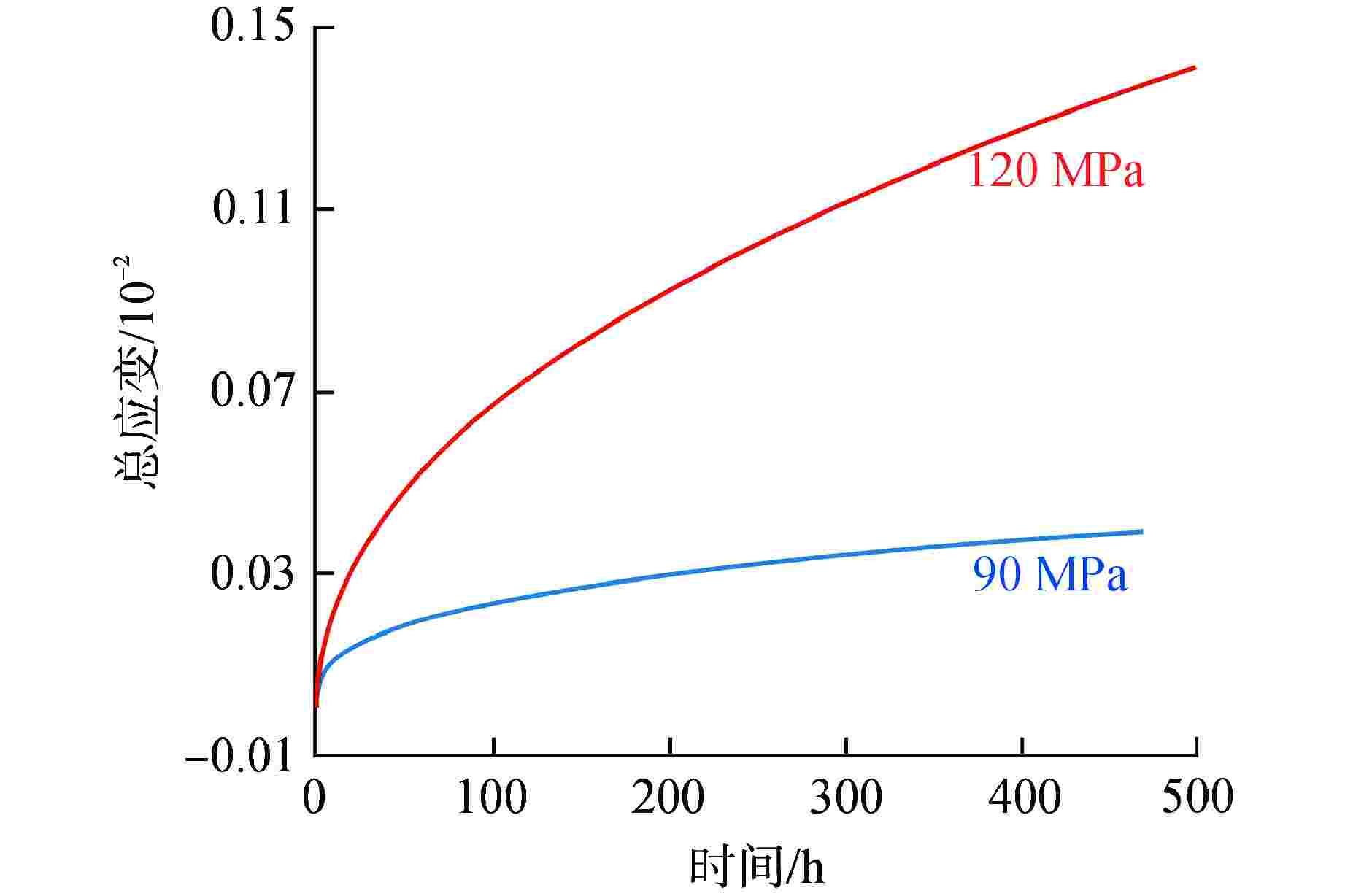

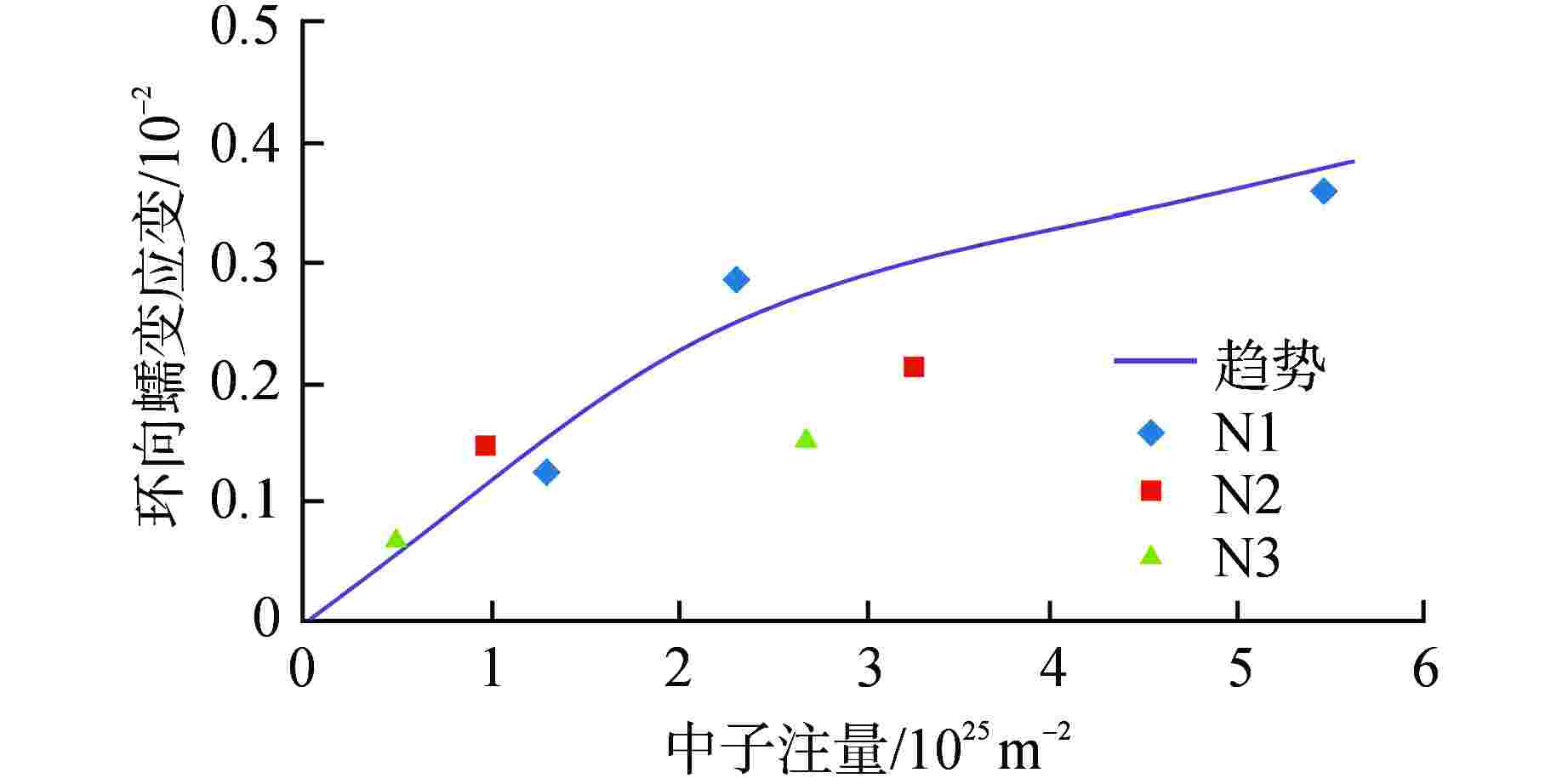

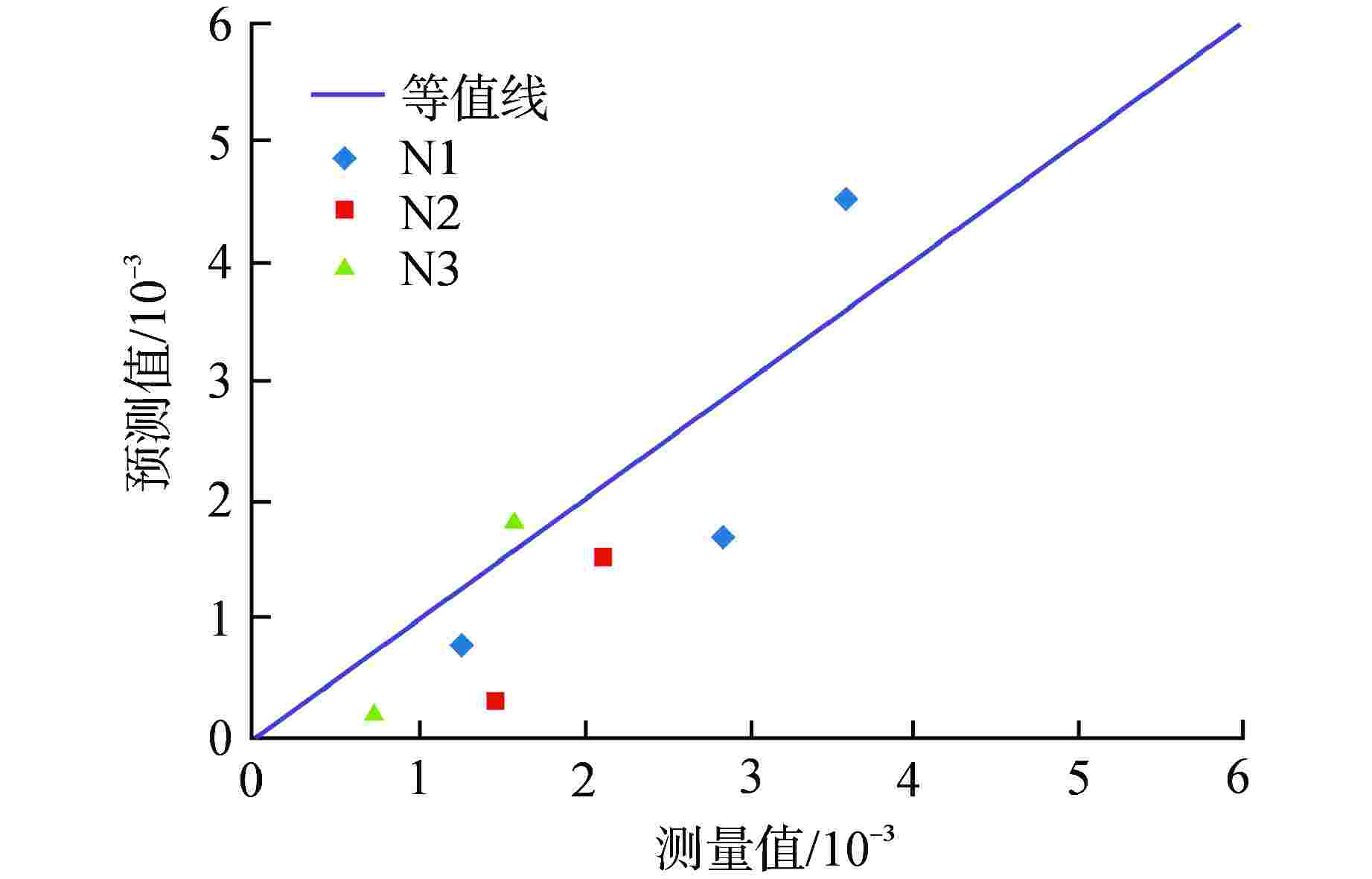

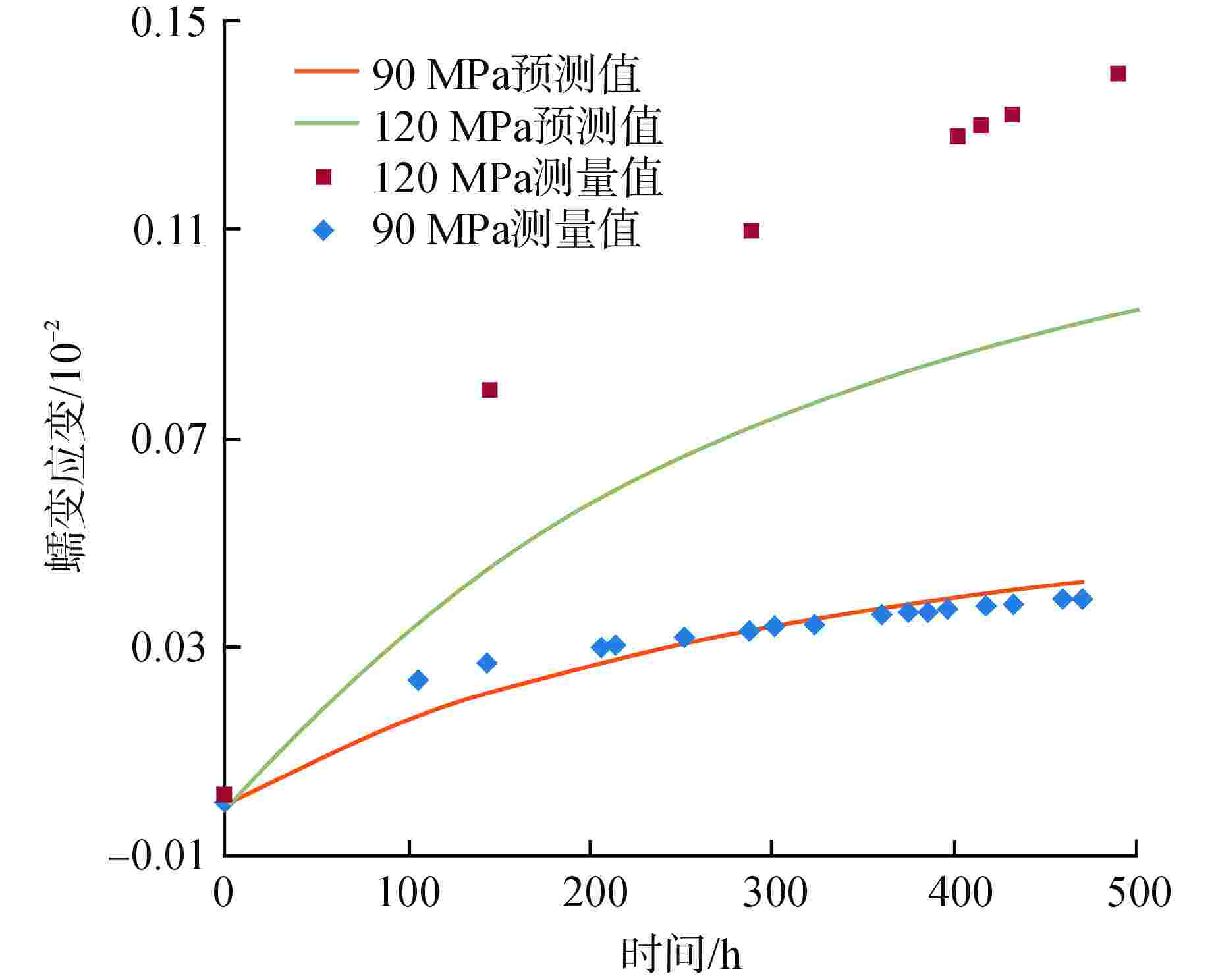

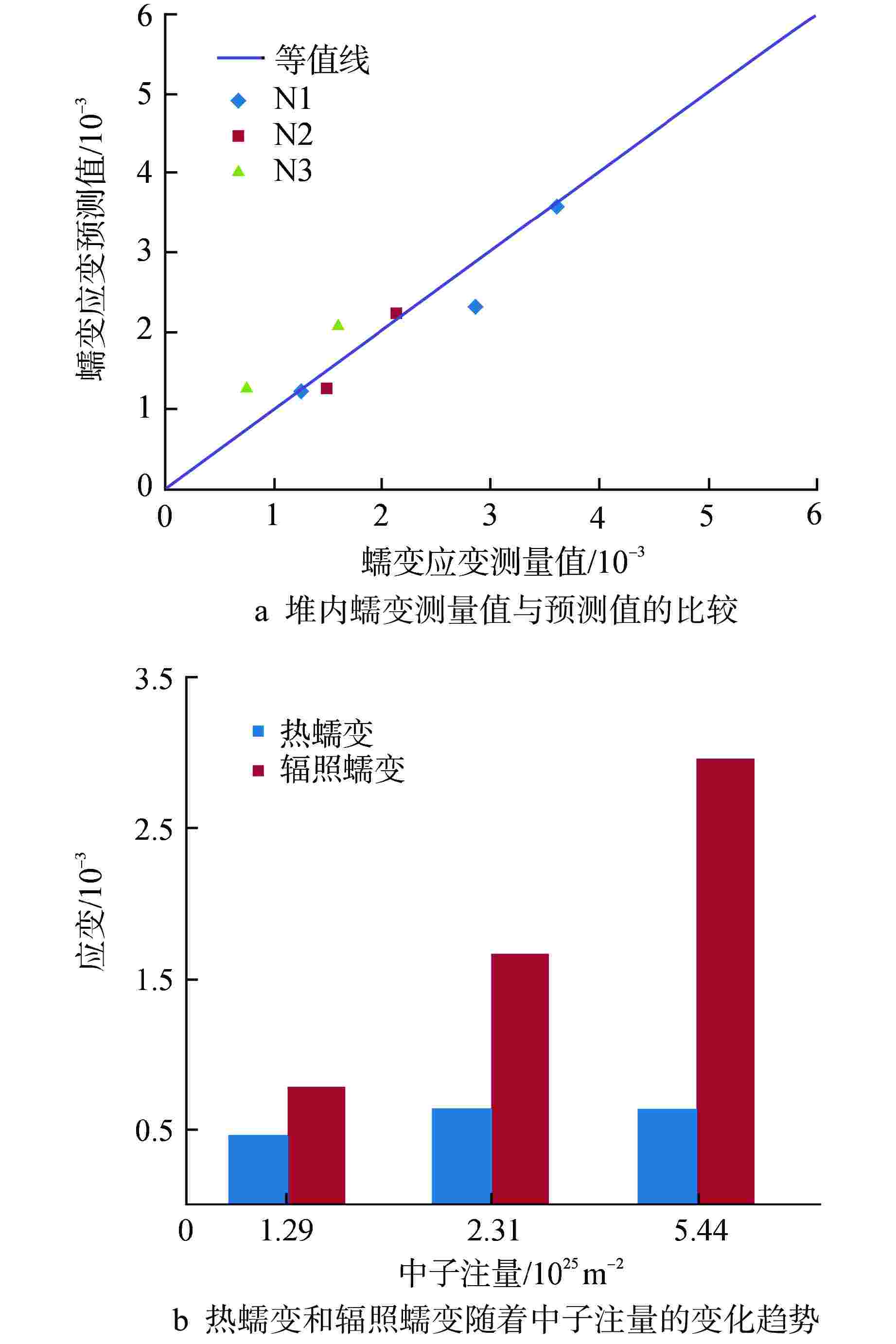

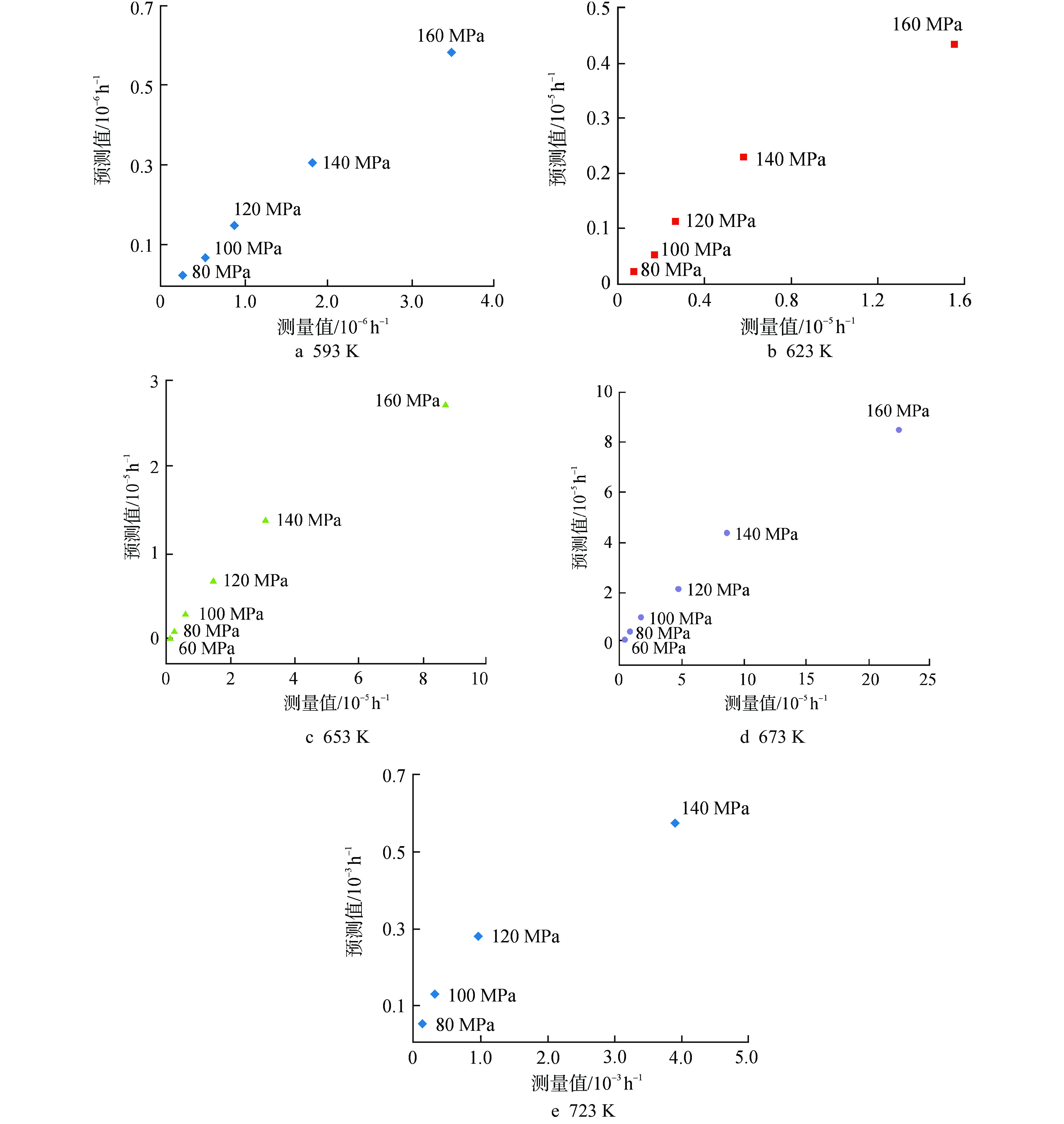

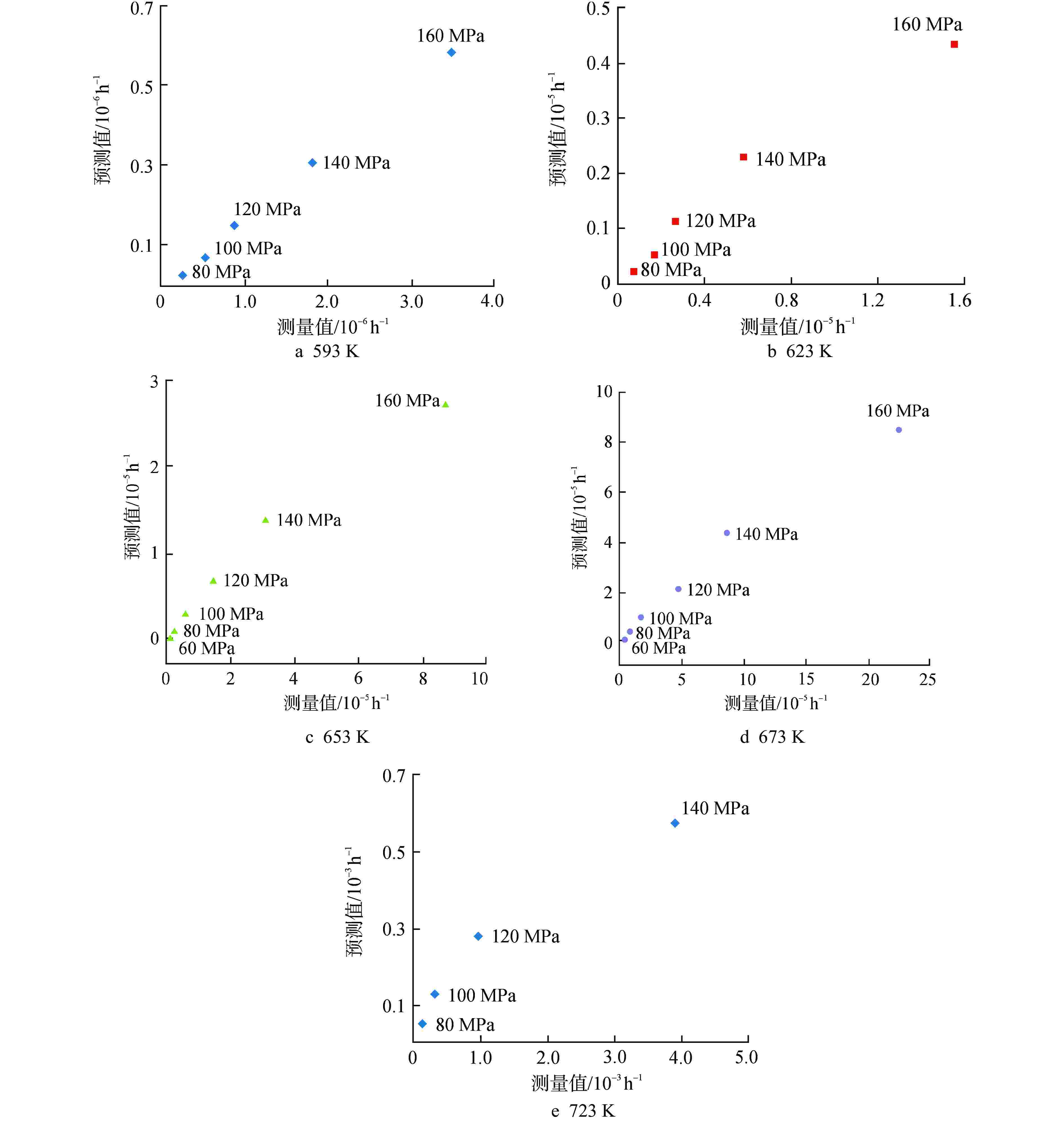

摘要: 为建立可用于新型锆合金的蠕变模型,本文根据新型锆合金的蠕变试验数据,研究了新型锆合金包壳管在温度为593~673 K、应力在60~160 MPa条件下的堆内外蠕变行为,采用锆合金经典蠕变模型对新型锆合金包壳蠕变性能进行了预测研究,从蠕变行为本构方程出发,研究并建立了新型锆合金包壳蠕变的初步评价方法,并进行了初步验证。验证结果表明:预测值和测量值符合较好,最大相对偏差在25%以内,模型符合锆合金堆内蠕变行为的变化。本研究建立了新型锆合金包壳蠕变模型,表达了其堆内蠕变规律,为新型锆合金的堆内行为的预测提供了支持。Abstract: In order to establish a creep model for new zirconium alloy, based on the data from creep test, the creep behavior of the new zirconium alloy cladding tubes at the temperature of 593-673K and the stress of 60-160 MPa was investigated. The classical zirconium alloy creep model was used to predict the creep behavior of the new zirconium alloy clad tube. Based on the constitutive equation of creep behavior, a preliminary evaluation method of creep of new zirconium alloy cladding tube was studied and established, and the preliminary verification was carried out. The verification results show that the predicted values are in good agreement with the measured values, and the maximum relative deviation is whithin 25%. The model is in agreement with the change of creep behavior of zirconium alloy in reactor. In this study, a new zirconium alloy cladding creep model is established, and the model is in agreement with the change of the in-core creep behavior of the zirconium alloy, which provides support for the prediction of the new zirconium alloy's in-reactor behavior.

-

Key words:

- New zirconium alloy /

- Creep /

- Evaluaton method /

- Verification

-

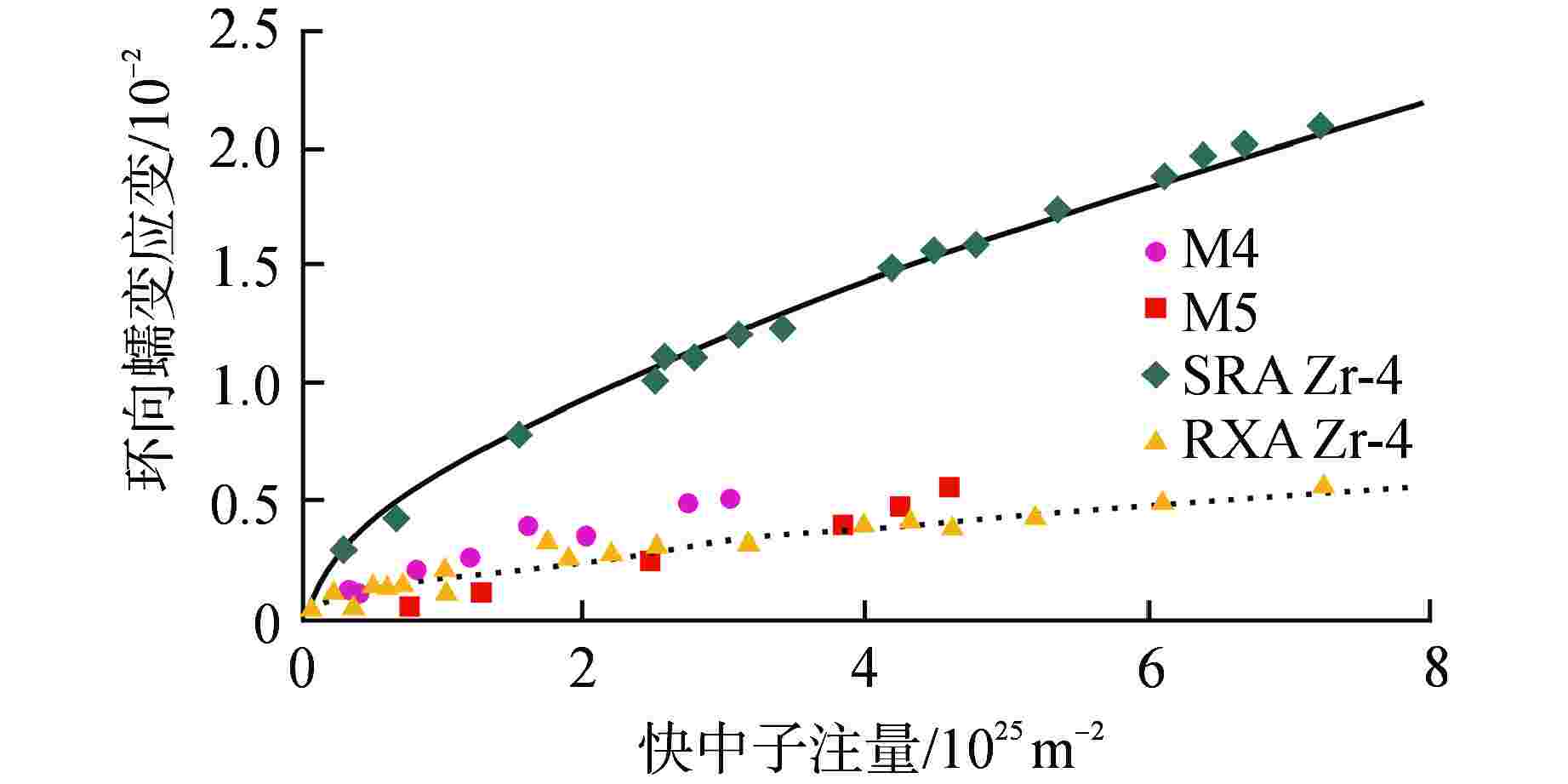

图 3 Zr-4等合金堆内蠕变行为[4]

Figure 3. In-core Creep Behavior of Zircaloy-4

表 1 弹性模量随温度的变化

Table 1. Change of Elastic Modulus with Temperature

温度/K 593 623 653 673 723 弹性模量/GPa 90.884 87.045 84.966 83.58 80.115 表 2 稳态蠕变速率计算值与测量值的比较(内压蠕变试验)

Table 2. Comparison of Measured and Predicted Steady-state Creep Rates (Internal Pressure Creep Test)

试验条件 稳态蠕变速率/10−6 h−1 预测值 计算值 623 K、90 MPa 0.383 0.365 623 K、120 MPa 0.958 1.230 -

[1] 彭继华,李文芳,BECHADE J L,等. 织构对先进锆合金蠕变性能各向异性的影响[J]. 稀有金属,2008, 32(1): 1-6. [2] 王朋飞,赵文金,陈乐,等. N36锆合金包壳管的高温蠕变行为[J]. 稀有金属材料与工程,2015, 44(5): 1149-1153. [3] GEELHOOD K J, LUSCHER W G. FRAPCON-3.5: a computer code for the calculation of steady-state, thermal-mechanical behavior of oxide fuel rods for high burnup: NUREG/CR-7022[R]. Richland: U. S. Nuclear Regulatory Commission, 2014: 2.30-2.31. [4] SONIAK A, L’HULLIER N, MARDON J P, et al. Irradiation Creep behavior of Zr-base alloys[C]//Zirconium in the Nuclear Industry: 13th International Symposium. Annecy: ASTM, 2002: 837-862. [5] ITO K, KAMIMURA K, TSUKUDA Y, et al. Evaluation of irradiation effect on spent fuel cladding creep properties[C]//Proceedings of the 2004 International Meeting on LWR Fuel Performance. Orlando, FL: American Nuclear Society, 2004: 1117. [6] GAROFALO F. Fundamentals of creep and creep-rupture in metals[M]. New York: The Macmillan Co., 1965: 17. -

下载:

下载: