Research Progress on High Temperature Oxidation Behavior of Zirconium Cladding under LOCA Condition

-

摘要: 锆合金是被广泛地用于水冷动力堆反应的包壳材料。锆合金包壳在失水事故(LOCA)极端事故工况下的高温行为成为国内外学者研究和讨论的热点。本文综述了近年来国内外锆合金的高温氧化行为研究进展,详述了氧化动力学特征、氧化失稳现象和氧化转折机理,同时概述了近10 年中国核动力研究设计院(NPIC)的相关研究工作。本文报道的研究进展,尤其是对于转折机理的探讨,可为进一步提高国产化新型锆合金使用性能提供研发指导。Abstract: Zirconium alloy is a cladding material widely used in water-cooled power reactor. The high temperature behavior of zirconium alloy cladding under the extreme accident condition of loss of coolant accident (LOCA) has become a hot topic of research and being discussed at home and abroad. This paper summarizes the worldwide current research progress on high temperature oxidation behavior of zirconium alloy. The oxidation kinetics characteristics, breakaway oxidation behavior, and the oxidation transition mechanism are described in detail. Meanwhile, the research work of Nuclear Power Institute of China for nearly recent ten years has also been overviewed. The research progress reported in this paper, especially the discussion on the oxidation transition mechanism, will provide a theoretical guidance for developing domestic new zirconium alloys in the further.

-

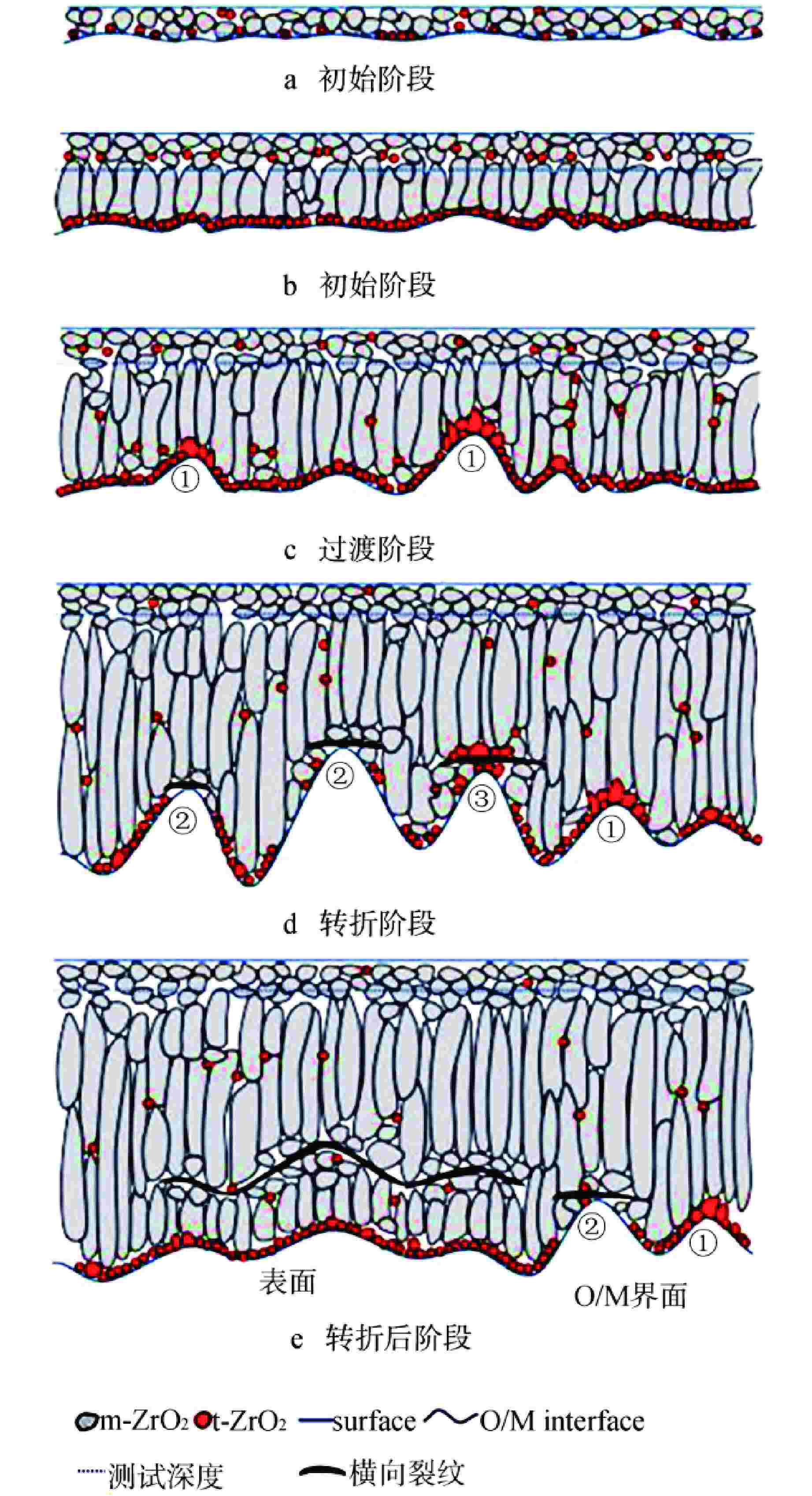

图 4 t→m相变诱发氧化失稳示意图[28]

①、②、③—O/M波纹状界面,代表不同反应阶段O/M附近晶粒组织特征不同;surface—氧化膜-腐蚀环境界面;O/M interface—氧化物/金属的内表面

Figure 4. Schematic Diagram of Mechanism of Oxidation Breakaway Induced by t→m Phase Transition

图 5 锆合金氧化膜/基体力学弯曲模型图[29]

w—Zr合金基底层的宽度;r—中性轴的初始曲率半径;$ \theta $—简化弯曲弯曲梁的挠度;h1—Zr合金的基体层的厚度;h2—氧化膜的厚度;x—锆合金氧化前的中心厚度;O—建立坐标系的圆点

Figure 5. Mechanical Bending Model of Zirconium Alloy Oxidation Film/Matrix

-

[1] SCHANZ G, ADROGUER B, VOLCHEK A. Advanced treatment of zircaloy cladding high-temperature oxidation in severe accident code calculations: Part I. Experimental database and basic modeling[J]. Nuclear Engineering and Design, 2004, 232(1): 75-84. doi: 10.1016/j.nucengdes.2004.02.013 [2] GROSSE M. Comparison of the high-temperature steam oxidation kinetics of advanced cladding materials[J]. Nuclear Technology, 2010, 170(1): 272-279. doi: 10.13182/NT10-A9464 [3] KIM H H, KIM J H, MOON J Y, et al. High-temperature oxidation behavior of zircaloy-4 and zirlo in steam ambient[J]. Journal of Materials Science & Technology, 2010, 26(9): 827-832. [4] ERBACHER F J, LEISTIKOW S. Zircaloy fuel cladding behavior in a loss-of-coolant accident: a review[J]. ASTM, 1987, 19(18): 451-487. [5] BAEK J H, PARK K B, JEONG Y H, Oxidation kinetics of Zircaloy-4 and Zr-1Nb-1Sn-0. 1Fe at temperatures of 700-1200℃[J]. Journal of Nuclear Materials, 2004, 335(3): 443-456. doi: 10.1016/j.jnucmat.2004.08.007 [6] STEINBRÜCK M, SCHAFFER S. High-temperature oxidation of zircaloy-4 in oxygen-nitrogen mixtures[J]. Oxidation of Metals, 2016, 85(3): 245-262. [7] LEISTIKOW S, SCHANZ G. Oxidation kinetics and related phenomena of Zircaloy-4 fuel cladding exposed to high temperature steam and hydrogen-steam mixtures under PWR accident conditions[J]. Nuclear Engineering and Design, 1987, 103(1): 65-84. doi: 10.1016/0029-5493(87)90286-X [8] STEINBRÜCK M, VÉR N, GROßE M. Oxidation of advanced zirconium cladding alloys in steam at temperatures in the range of 600–1200℃[J]. Oxidation of Metals, 2011, 76(3-4): 215-232. doi: 10.1007/s11085-011-9249-3 [9] 马树春,孙源珍,陈望春,等. PWR失水事故工况下燃料包壳与水蒸汽反应研究[J]. 原子能科学技术,1993, 27(4): 376-383. [10] 陈鹤鸣,马春来. 纯锆在400-850℃纯氧中的氧化[J]. 核科学与工程,1982, 2(1): 72-80. [11] 陈鹤呜,马春来,何晓蓓,等. 锆-4合金在高温水蒸汽中的氧化行为[J]. 中国腐蚀与防护学报,1991, 11(1): 99-104. [12] 金耀华,王正品,高巍,等. 热处理后Zr-4合金高温氧化行为研究[J]. 西安工业大学学报,2015, 35(4): 329-334. [13] 高巍,张娴,王正品,等. M5和Zirlo合金高温水蒸气氧化行为研究[J]. 西安工业大学学报,2016, 36(6): 473-480. [14] ZINO R, CHOSSON R, OLLIVIER M, et al. Parallel mechanism of growth of the oxide and α-Zr(O) layers on Zircaloy-4 oxidized in steam at high temperatures[J]. Corrosion Science, 2021, 179: 109178. doi: 10.1016/j.corsci.2020.109178 [15] BAEK J H, JEONG Y H. Breakaway phenomenon of Zr-based alloys during a high-temperature oxidation[J]. Journal of Nuclear Materials, 2008, 372(2-3): 152-159. doi: 10.1016/j.jnucmat.2007.02.011 [16] YAN Y, BURTSEVA T A, BILLONE M C. High-temperature steam-oxidation behavior of Zr-1Nb cladding alloy E110[J]. Journal of Nuclear Materials, 2009, 393(3): 433-448. doi: 10.1016/j.jnucmat.2009.06.029 [17] ELLIOTT R P. Constitution of binary alloys First supplement[M]. New York: McGraw-Hill, 1965: 140. [18] BILLONE M, YAN Y, BURTSEVA T, et al. Cladding embrittlement during postulated loss-of-coolant accidents[R]. Argonne: Argonne National Lab. , 2008. [19] KIM H G, KIM I H, JUNG Y I, et al. Properties of Zr Alloy cladding after simulated loca oxidation and water quenching[J]. Nuclear Engineering and Technology, 2010, 42(2): 193-202. doi: 10.5516/NET.2010.42.2.193 [20] BRACHET J C, VANDENBERGHE-MAILLOT V, PORTIER L, et al. Hydrogen content, preoxidation, and cooling scenario effects on post-quench microstructure and mechanical properties of zircaloy-4 and m5 alloys in LOCA conditions[J]. Journal of ASTM International, 2008, 5(5): 169. [21] LEISTIKOW S, SCHANZ G, ZUREK Z. Comparison of high temperature steam oxidation behavior of Zircaloy-4 versus austenitic and ferritic steels under light water reactor safety aspects: 3994[R]. Karlsruhe: Kernforschungszentrum Karlsruhe GmbH, 1985: 105. [22] KIM H G, KIM I H, CHOI B K, et al. A study of the breakaway oxidation behavior of zirconium cladding materials[J]. Journal of Nuclear Materials, 2011, 418(1-3): 186-197. doi: 10.1016/j.jnucmat.2011.06.039 [23] KIM H G, JEONG Y H, KIM K T. The effects of creep and hydride on spent fuel integrity during interim dry storage[J]. Nuclear Engineering and Technology, 2010, 42(3): 249-258. doi: 10.5516/NET.2010.42.3.249 [24] 邱军, 刘欣, 赵文金. N18合金高温氧化行为研究[R]. 成都: 中国核动力研究设计院科学技术年报, 2012. [25] 邱军, 赵文金, 苗志. 预氧化对N18锆合金高温氧化行为的影响[C]//中国核科学技术进展报告(第三卷)——中国核学会2013年学术年会论文集第4册(核材料分卷、同位素分离分卷、核化学与放射化学分卷). 哈尔滨: 中国核学会, 2013. [26] 邱军,赵文金,GUILBERT T,等. 3种锆合金的高温氧化行为[J]. 金属学报,2011, 47(9): 1216-1220. [27] 刘彦章,邱军,刘欣,等. N18锆合金在600~1200℃蒸汽中的氧化行为研究[J]. 核动力工程,2010, 31(2): 85-88. [28] 廖京京. Zr-Sn-Nb锆合金高温水腐蚀反应动力学转折机理研究[D]. 成都: 中国核动力研究设计院, 2020. [29] 张君松,吕俊男,龙冲生,等. 锆合金氧化膜的内应力计算[J]. 核动力工程,2021, 42(4): 101-104. -

下载:

下载: