Analysis of Start-up Characteristics of Heat Pipe Reactor

-

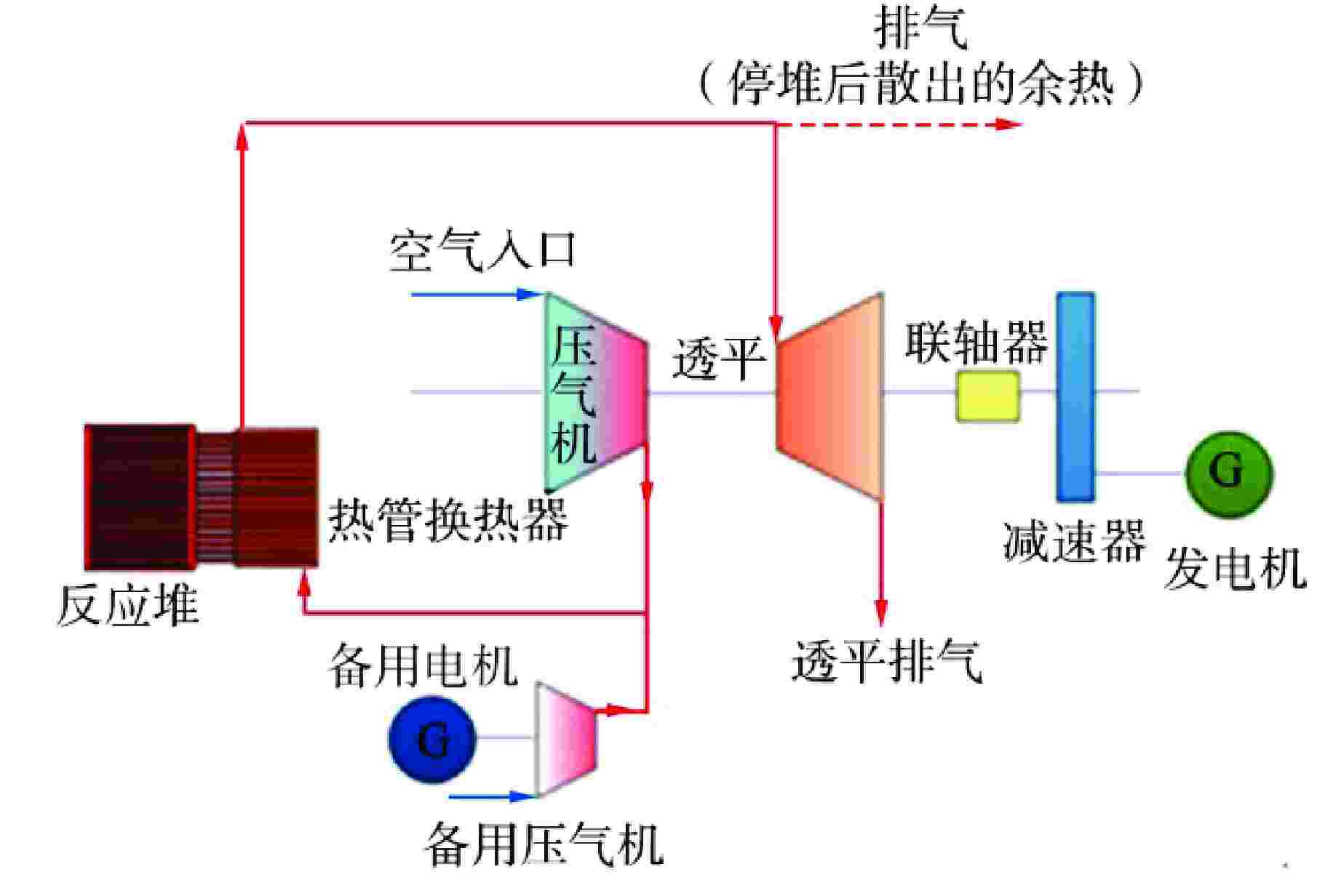

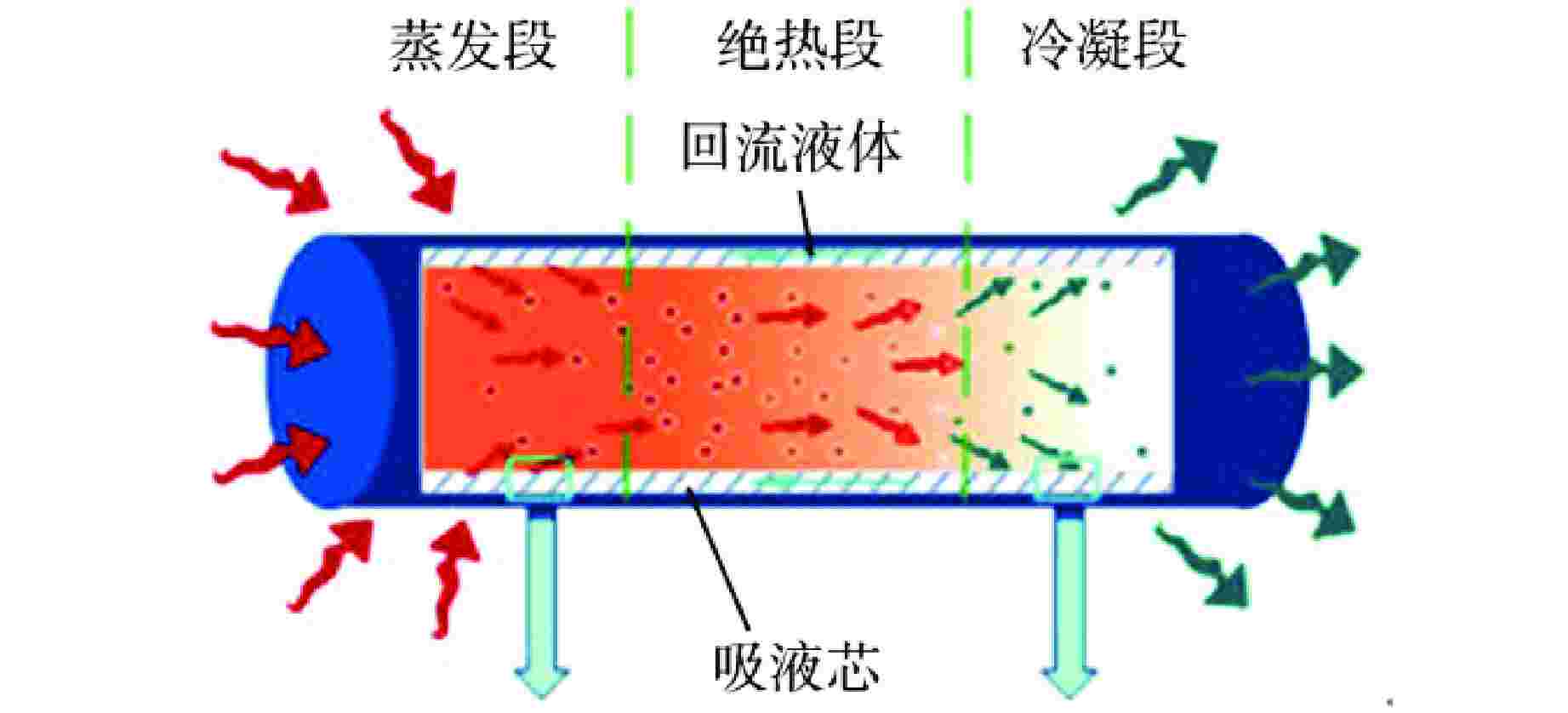

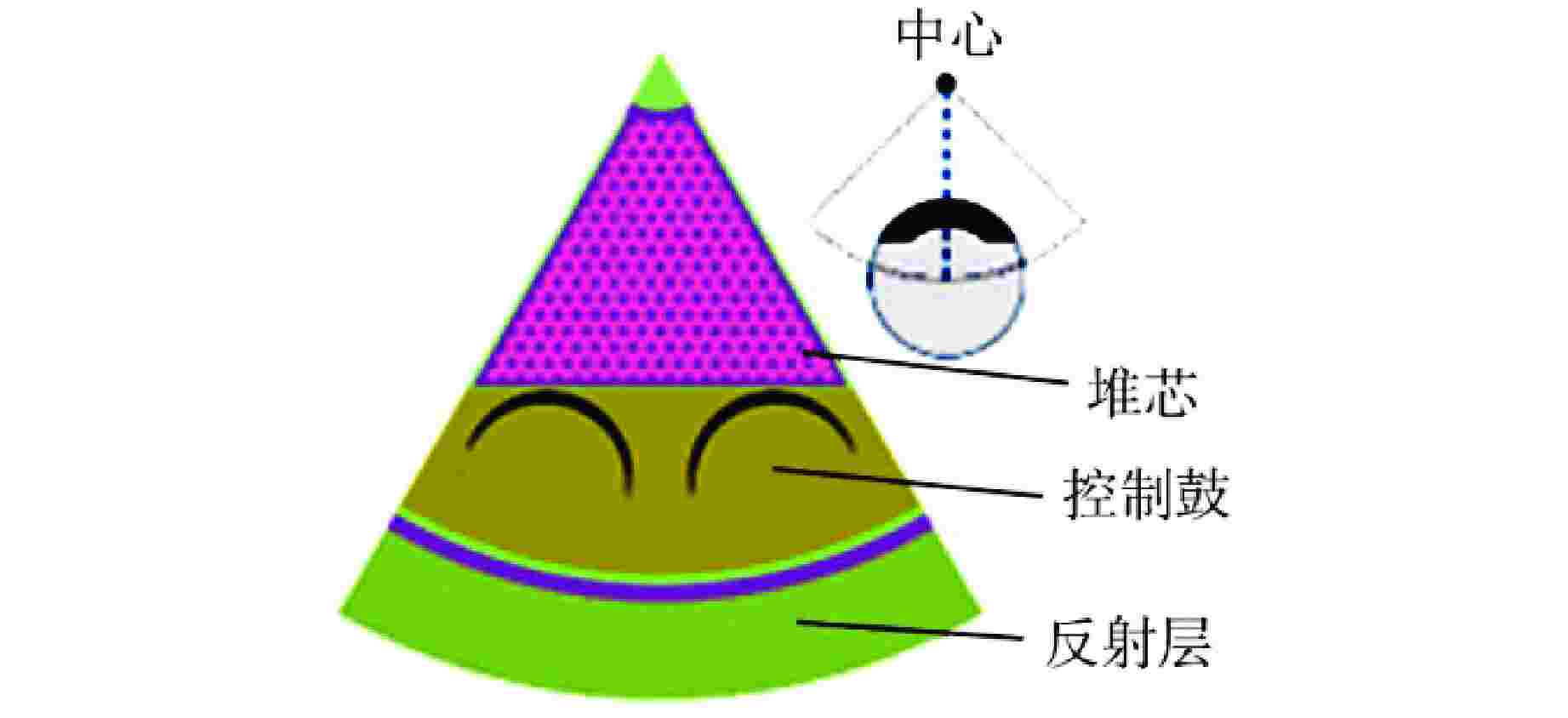

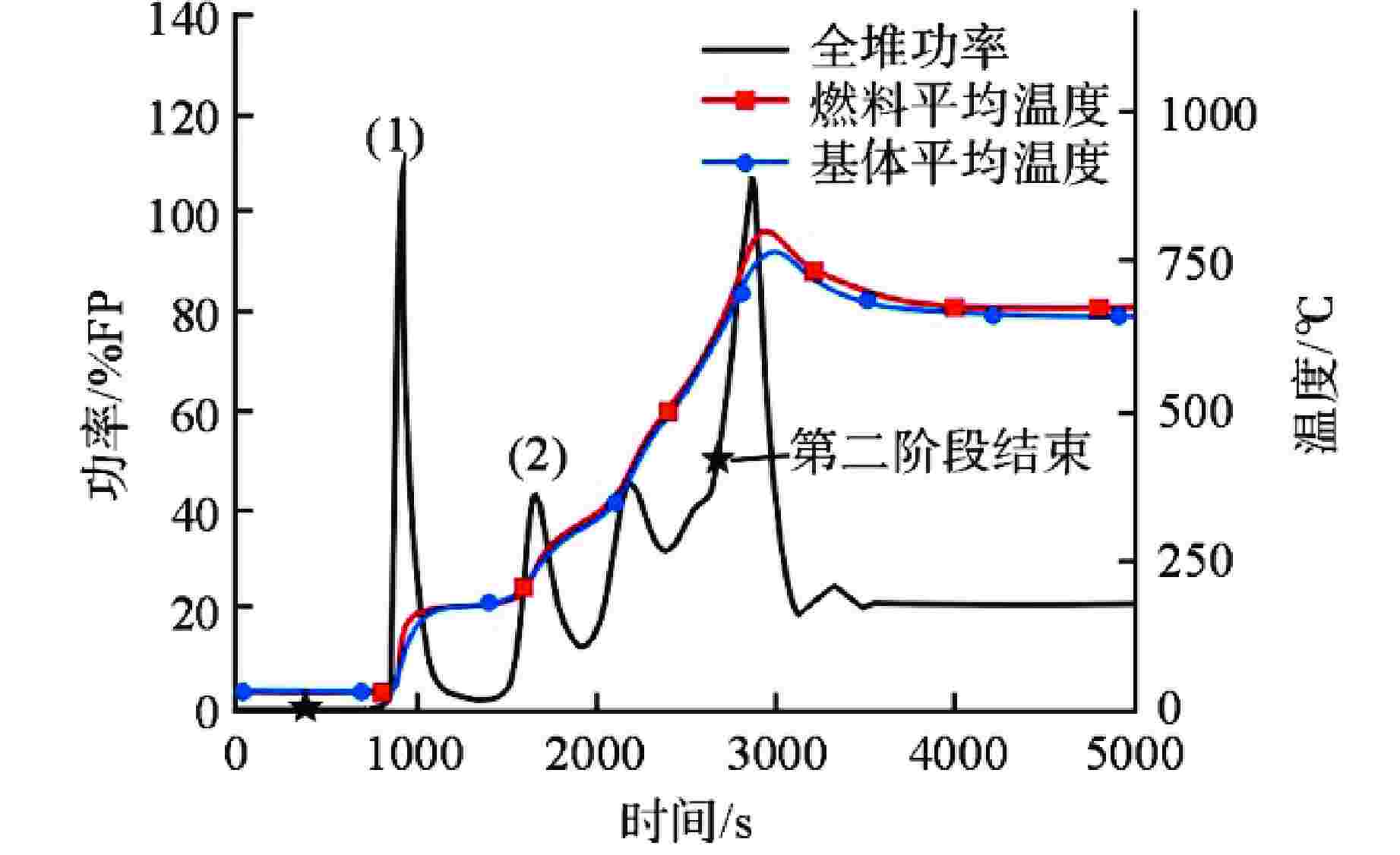

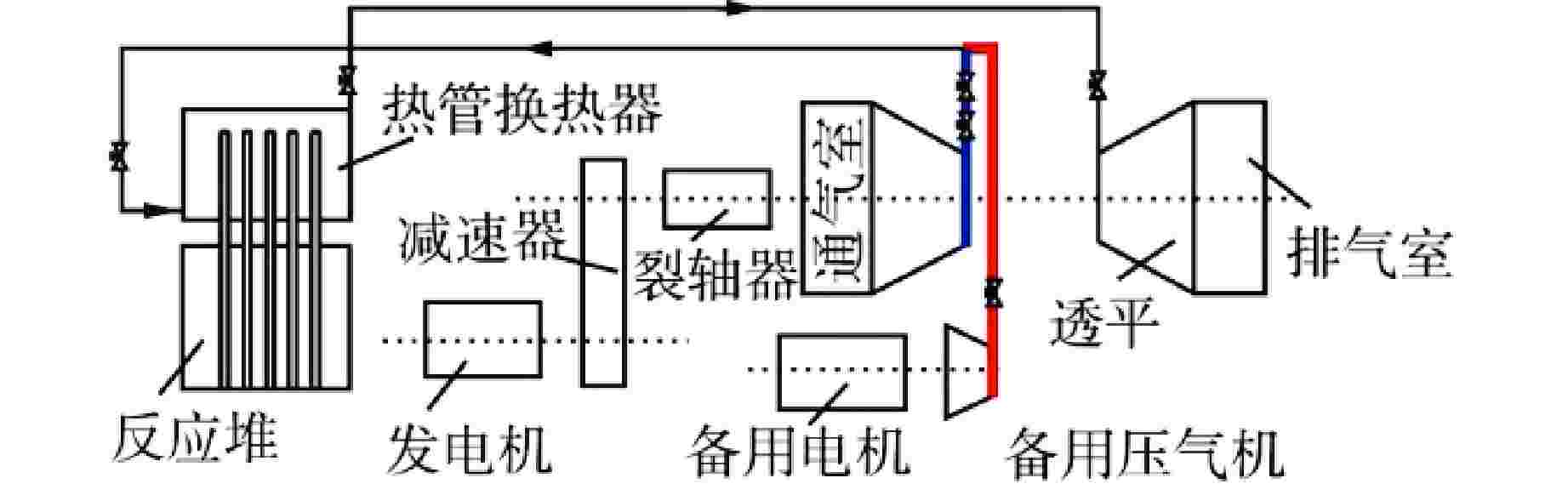

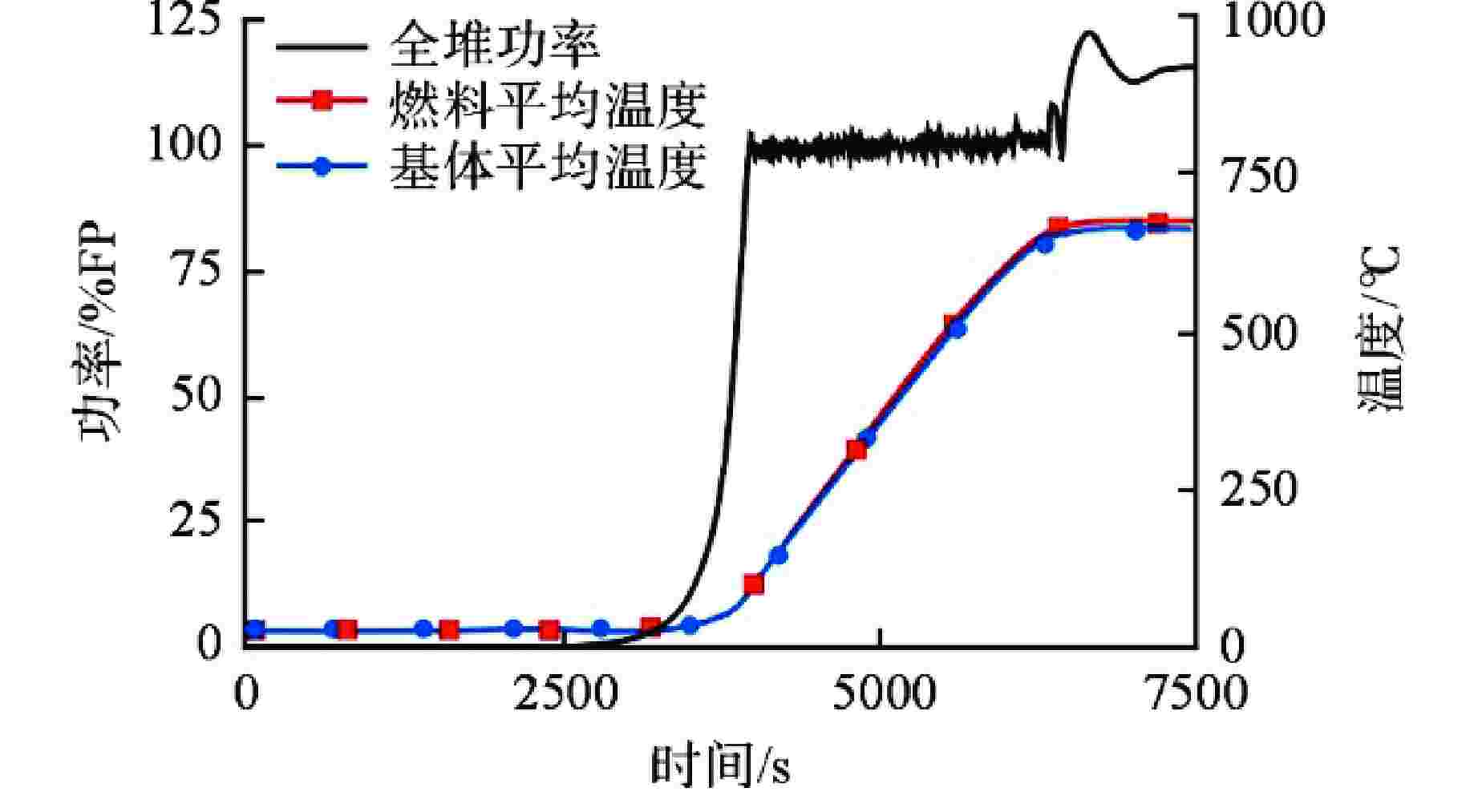

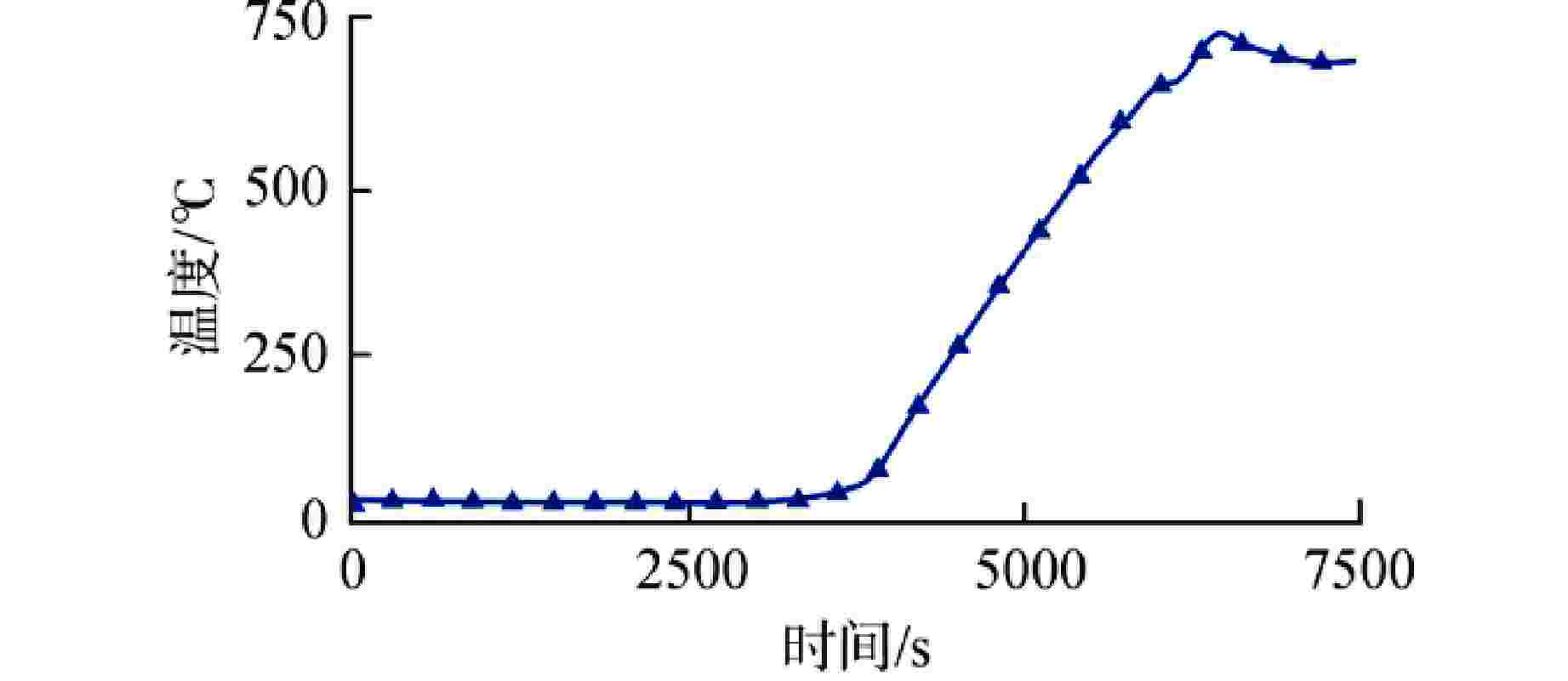

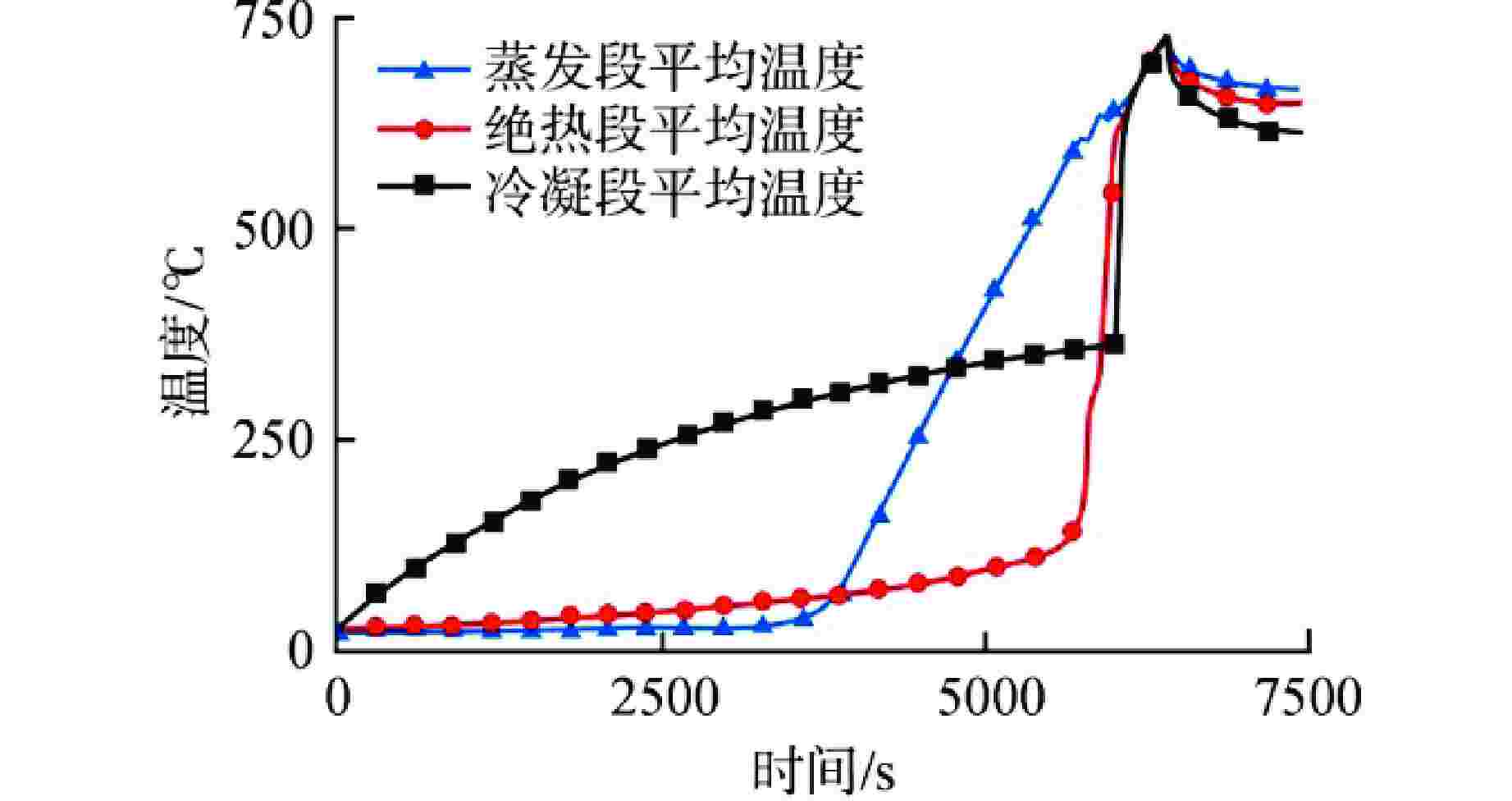

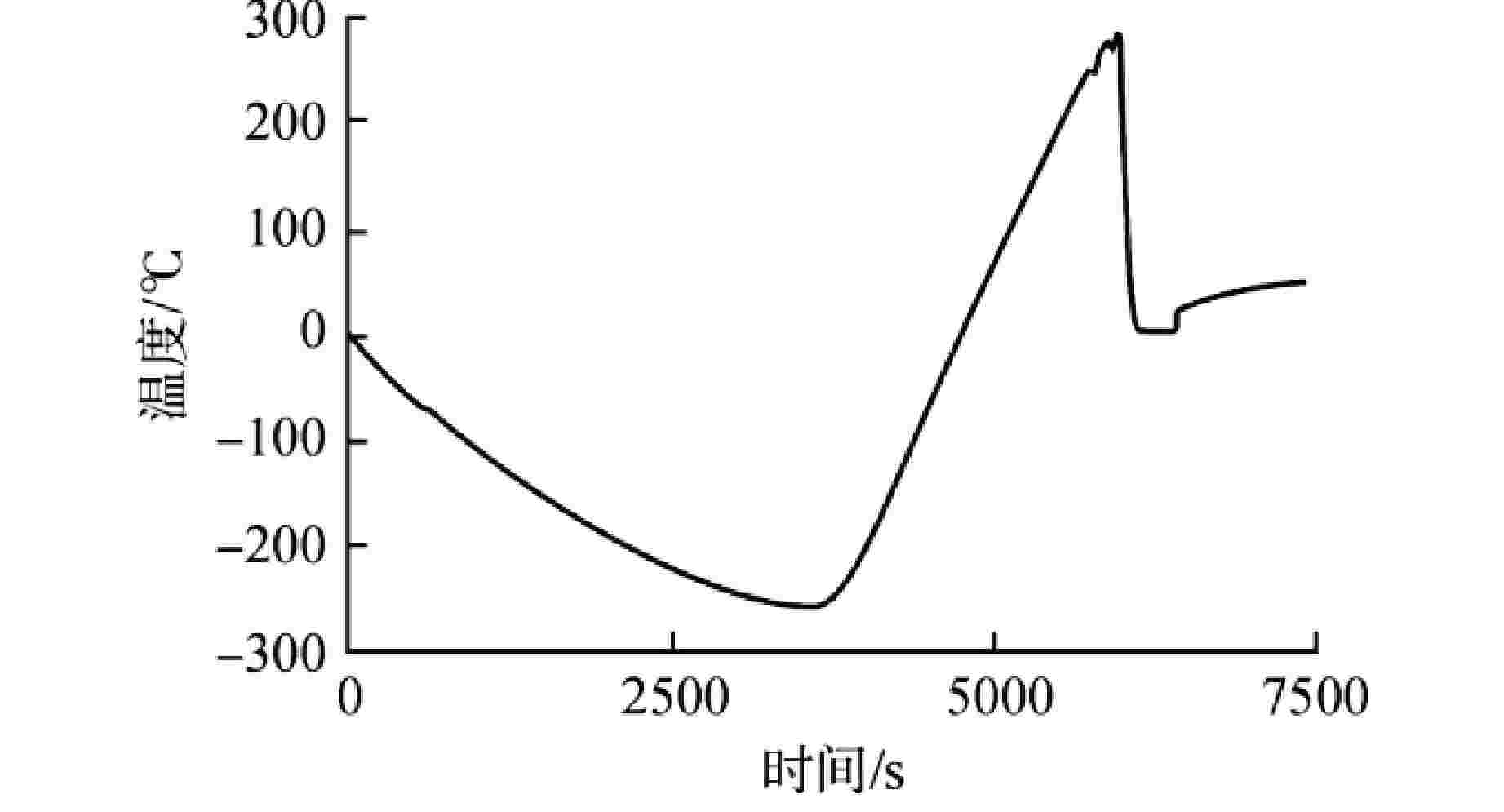

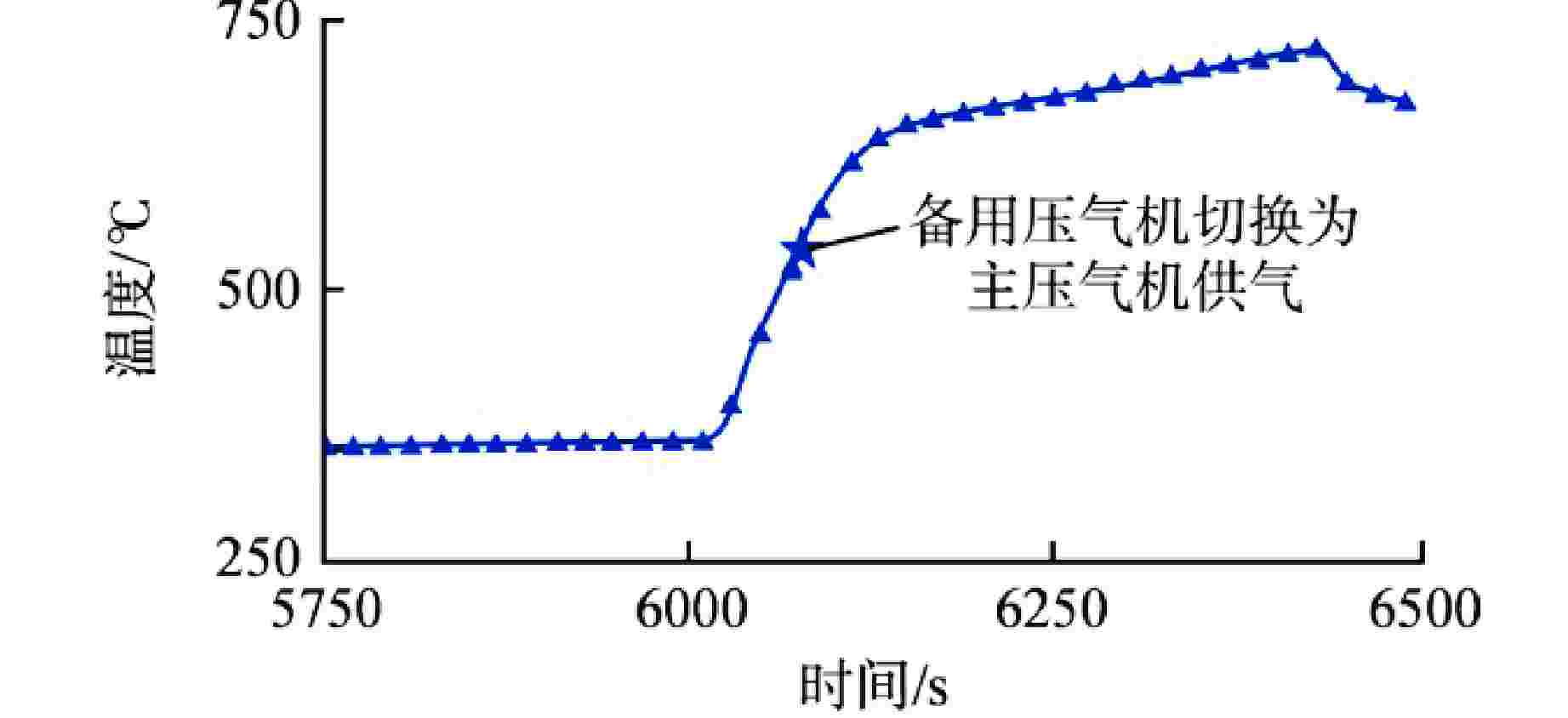

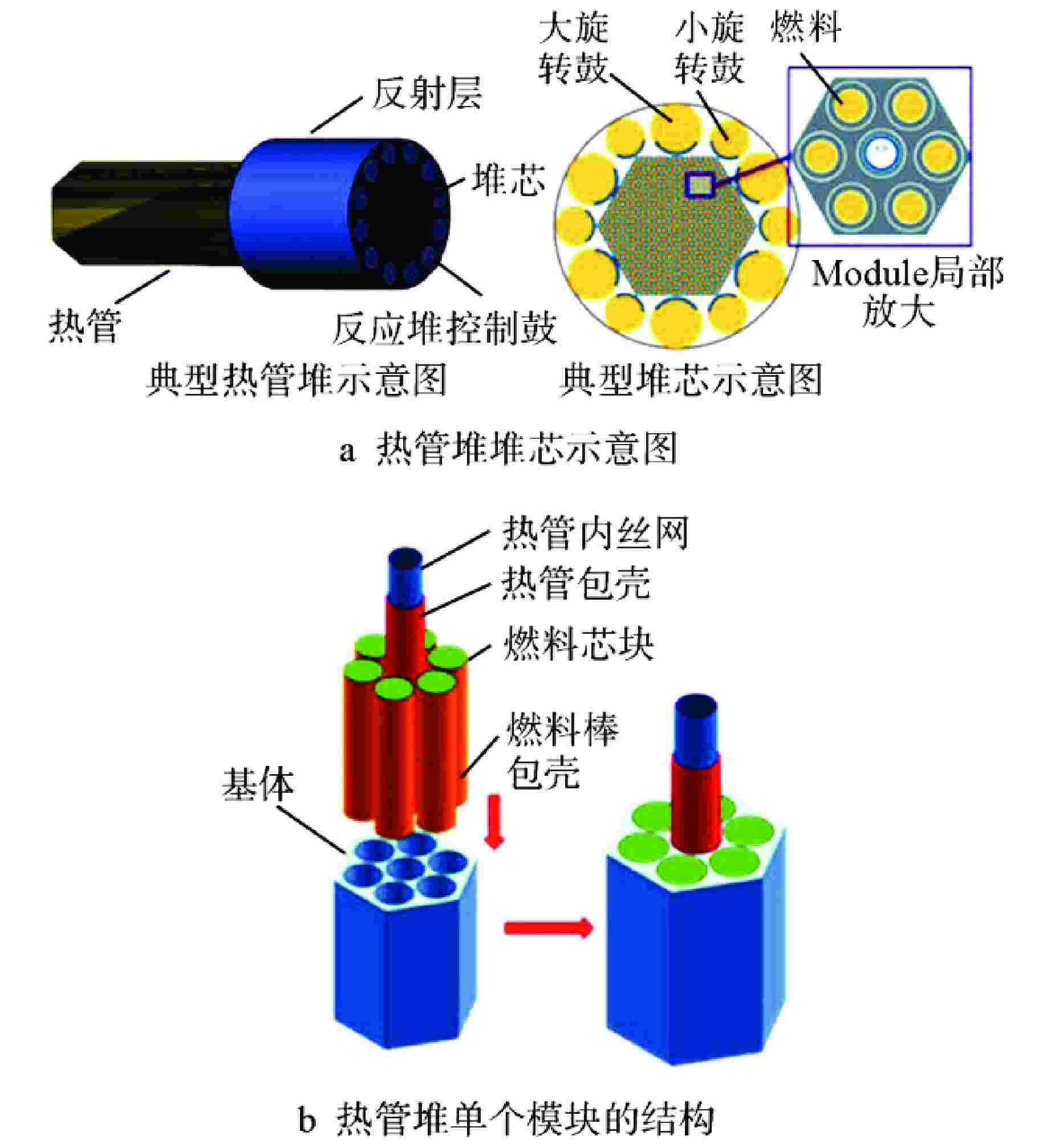

摘要: 热管反应堆在中子能谱、燃料及堆芯结构、温度反馈系数、反应性控制方式、冷却剂等方面与压水堆存在较大的不同,导致其启堆过程中堆芯可能出现较大的功率峰值并导致热管两端出现较大的温差。针对上述问题,以陆地热管反应堆为研究对象,提出了“蛙跳式”启堆控制策略,通过理论分析的方法提出了策略的控制整定值;在系统设计改进方面,提出了增加空气预热器用于热管完全启动前热管冷凝段预热的方案;并采用数值计算的方法对前述方案的应用效果进行了分析和验证。计算结果表明,提出的启堆控制策略和系统设计改进方案减小了启堆过程中堆芯功率的波动幅度,减小了热管启动过程中热管蒸发段和冷凝段的温差,并相应降低了热管热应力,提高了热管运行的可靠性。其研究成果为控制鼓的设计提供了输入,也为反应堆保护与控制系统相关监测参数的设定和热管堆气体冷却系统的设计方案提供了参考。

-

关键词:

- 热管反应堆(HPR) /

- 启堆 /

- 控制策略 /

- 热管冷凝段预热

Abstract: The heat pipe reactor differs significantly from the pressurized water reactor in terms of neutron energy spectrum, fuel and core structure, temperature feedback coefficient, reactivity control method, and coolant, which may lead to a large power peak in the core and temperature difference at both ends of the heat pipe during startup. In response to these issues, this paper focuses on the land-based heat pipe reactor and proposes a “leapfrog” startup control strategy. The control set values of the strategy are determined through theoretical analysis. In terms of system design improvement, a scheme is proposed to add an air preheater for preheating the condensation section of the heat pipe before the heat pipe is completely started. The application effect of the aforementioned scheme is analyzed and verified using numerical calculations. The results show that the startup control strategy and system design improvement proposed in this paper reduce the fluctuation amplitude of core power during startup, decrease the temperature difference between the evaporation and condensation sections of the of heat pipe during startup, and correspondingly reduce the thermal stress of the heat pipe, thereby improving the reliability of heat pipe operation. The research findings of this paper provide input for drum control design and serve as a reference for setting monitoring parameters related to reactor protection and control systems. The relevant research findings of this paper can also provide reference for the design of gas-cooled systems in heat pipe reactors. -

-

[1] 余红星,马誉高,张卓华,等. 热管冷却反应堆的兴起和发展[J]. 核动力工程,2019, 40(4): 1-8. [2] YAN B H, WANG C, LI L G. The technology of micro heat pipe cooled reactor: a review[J]. Annals of Nuclear Energy, 2020, 135: 106948. doi: 10.1016/j.anucene.2019.106948 [3] 马誉高,杨小燕,刘余,等. MW级热管冷却反应堆反馈特性及启堆过程研究[J]. 原子能科学技术,2021, 55(S2): 213-220. [4] 屈伸,曹良志,郑琪,等. 热管堆高温数据库的制作及堆芯初步物理计算[J]. 现代应用物理,2017, 8(4): 041202. [5] 唐思邈,王成龙,苏光辉,等. 小型核电源传热及热电特性实验研究[J]. 核动力工程,2019, 40(4): 200-202. [6] 张一帆,屈伸,曹良志,等. 空间核反应堆安全分析[J]. 上海航天,2019, 36(6): 121-125. [7] 孙浩,王成龙,刘逍,等. 水下航行器微型核电源堆芯设计[J]. 原子能科学技术,2018, 52(4): 646-651. [8] MCCLURE P R, POSTON D I, DASARI V R, et al. Design of megawatt power level heat pipe reactors: LA-UR-15-28840[R]. Los Alamos: Los Alamos National Laboratory, 2015. [9] ARAFAT Y, VAN WYK J. eVinci micro reactor[J]. Nuclear Plant Journal, 2019,37(2): 34-37. [10] YAO C Z, HU G, XIE J C, et al. A scheme of lunar surface nuclear reactor power[J]. Science & Technology Review, 2015, 33(12): 19-23. [11] 钟睿诚,马誉高,邓坚,等. 热管堆多反馈效应下的启堆特性研究[J]. 核动力工程,2021, 42(S2): 104-108. [12] MA Y G, TIAN C Q, YU H X, et al. Transient heat pipe failure accident analysis of a megawatt heat pipe cooled reactor[J]. Progress in Nuclear Energy, 2021, 140: 103904. doi: 10.1016/j.pnucene.2021.103904 [13] MA Y G, LIU J S, YU H X, et al. Coupled irradiation-thermal-mechanical analysis of the solid-state core in a heat pipe cooled reactor[J]. Nuclear Engineering and Technology, 2022, 54(6): 2094-2106. doi: 10.1016/j.net.2022.01.002 [14] 姚仲鹏,王新国. 车辆冷却传热[M]. 北京: 北京理工大学出版社,2001: 194-217. [15] 杨世铭,陶文铨. 传热学[M]. 第四版. 北京: 高等教育出版社,2006: 248-249. -

下载:

下载: