Numerical Study on Heat Transfer Characteristics of a Scaled Model for Horizontal Dry Storage System of Spent Fuel

-

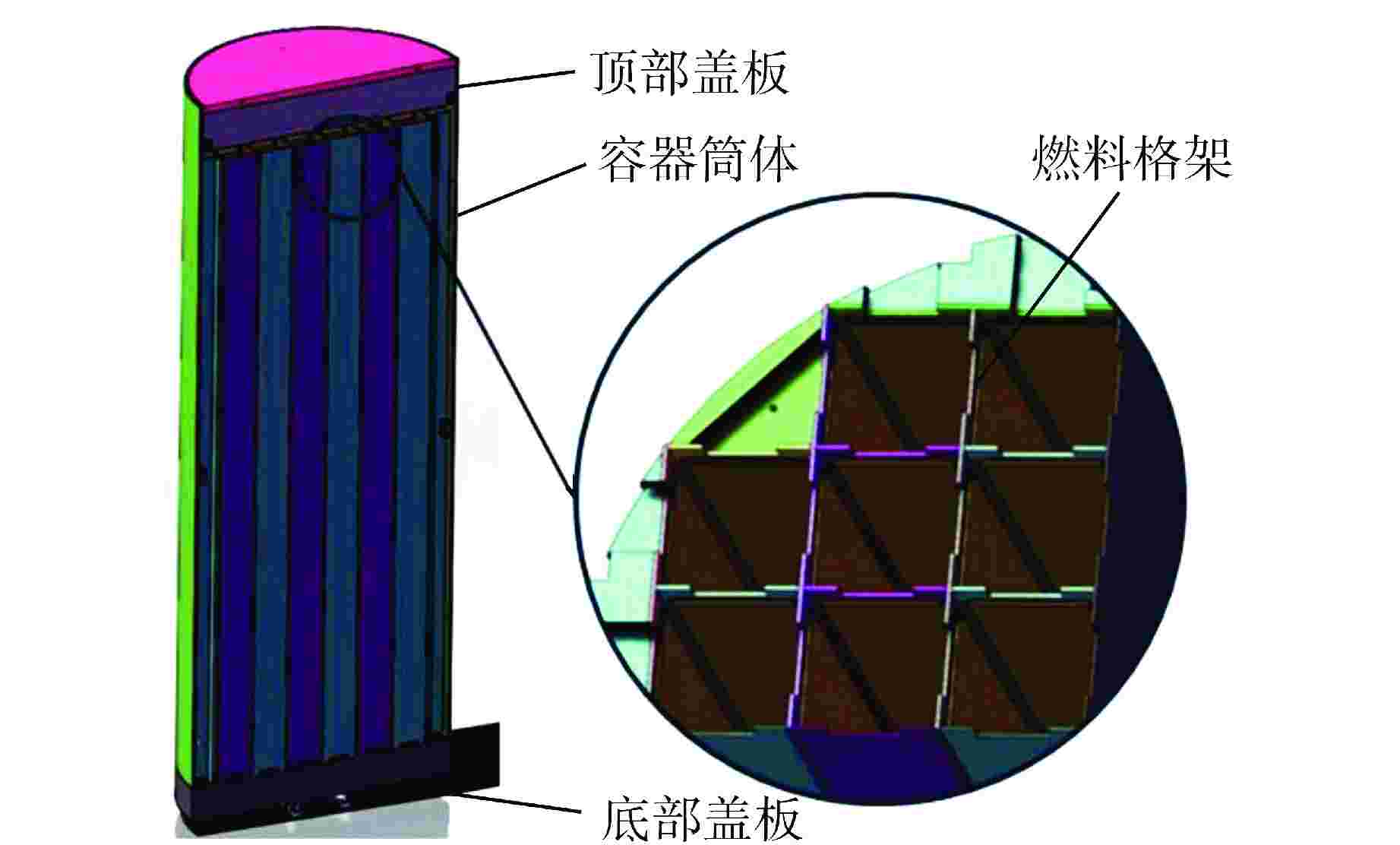

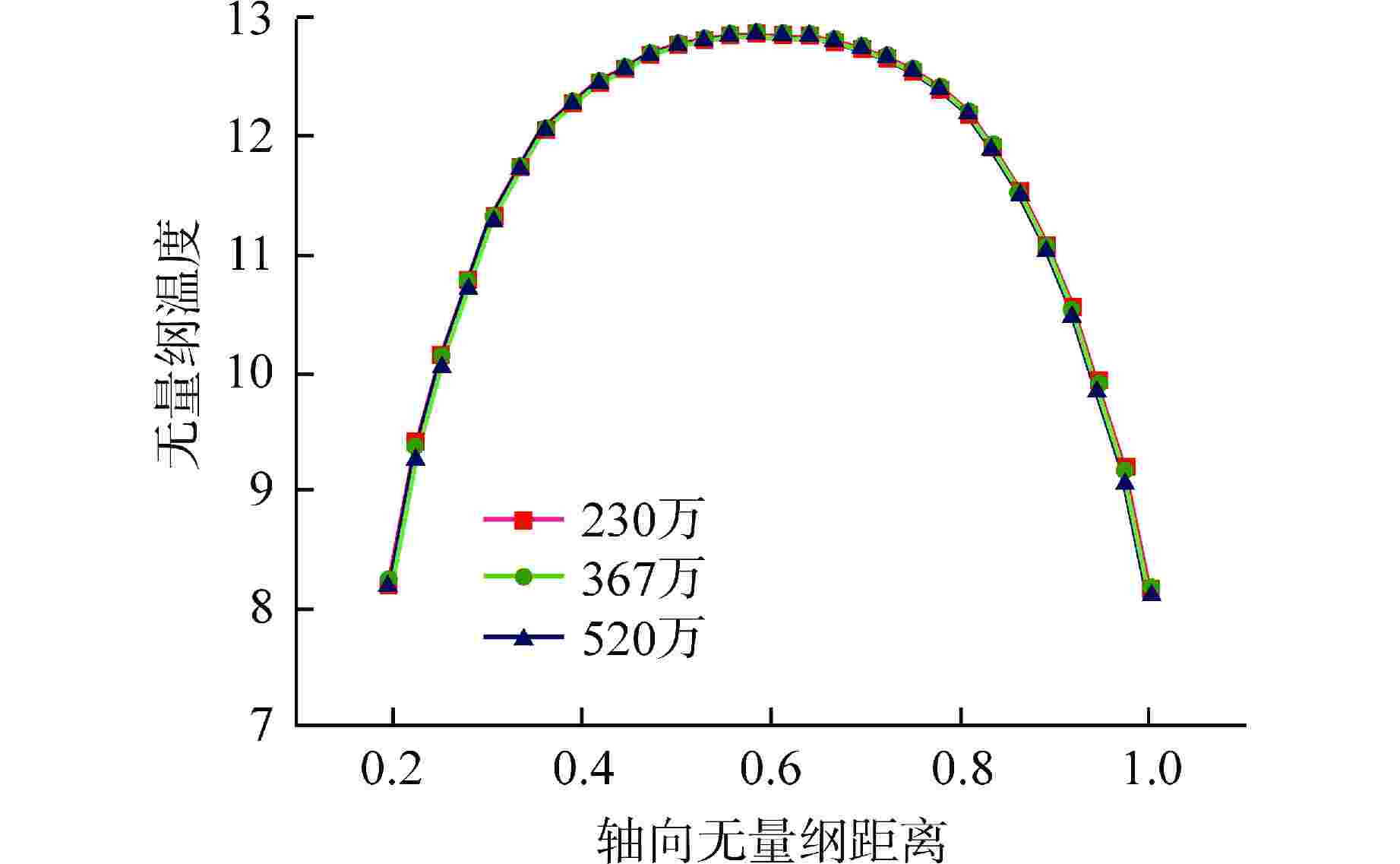

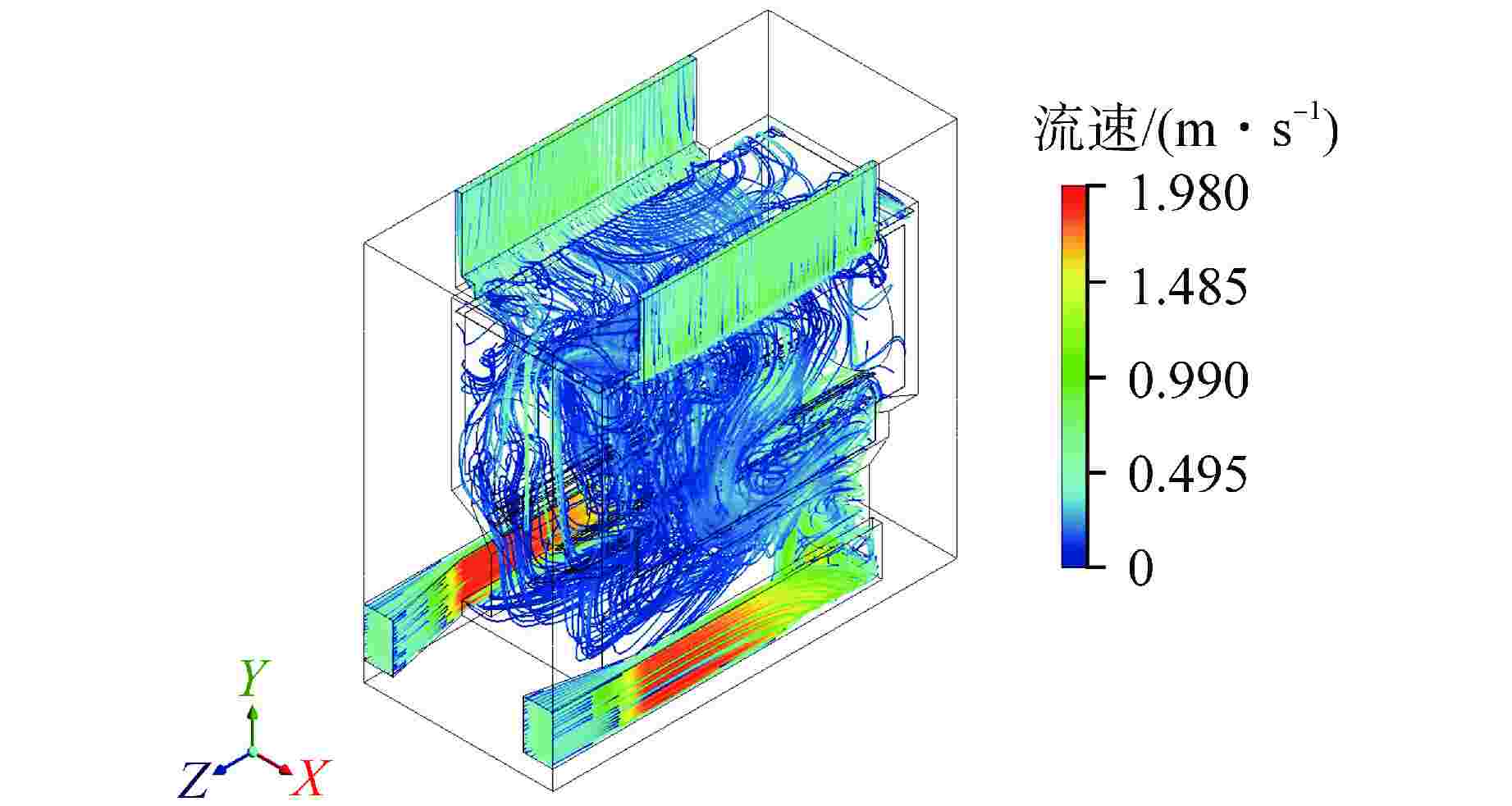

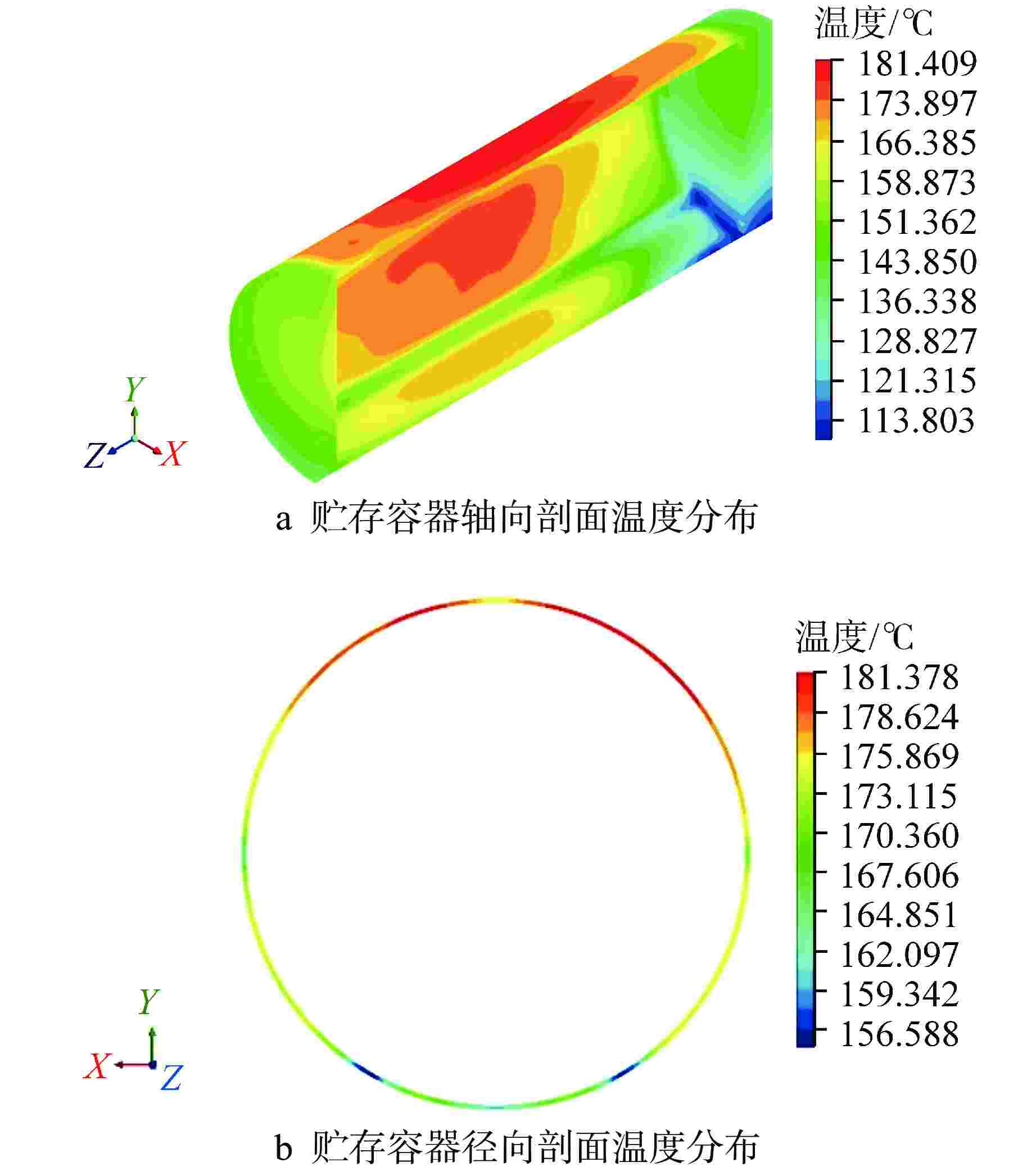

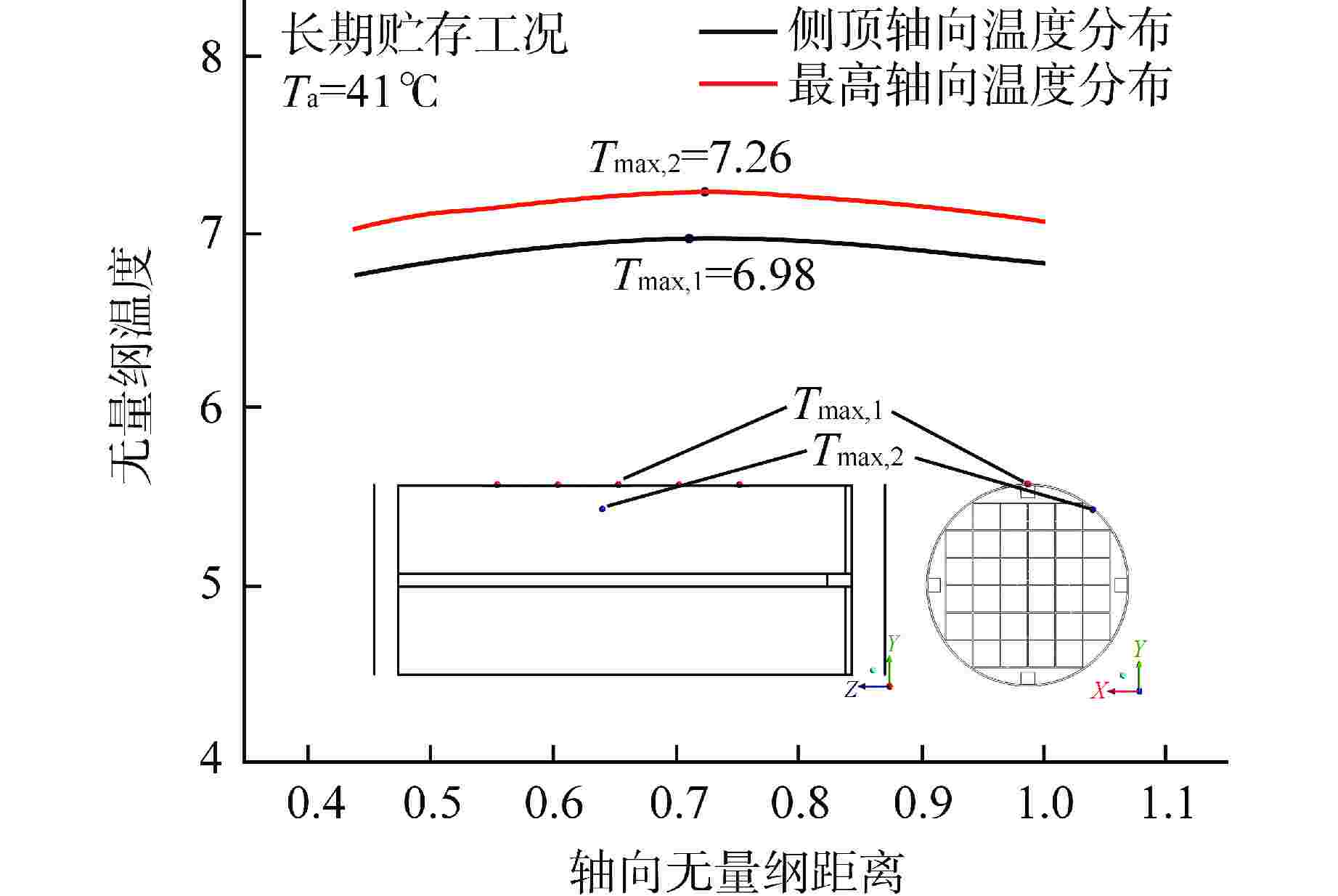

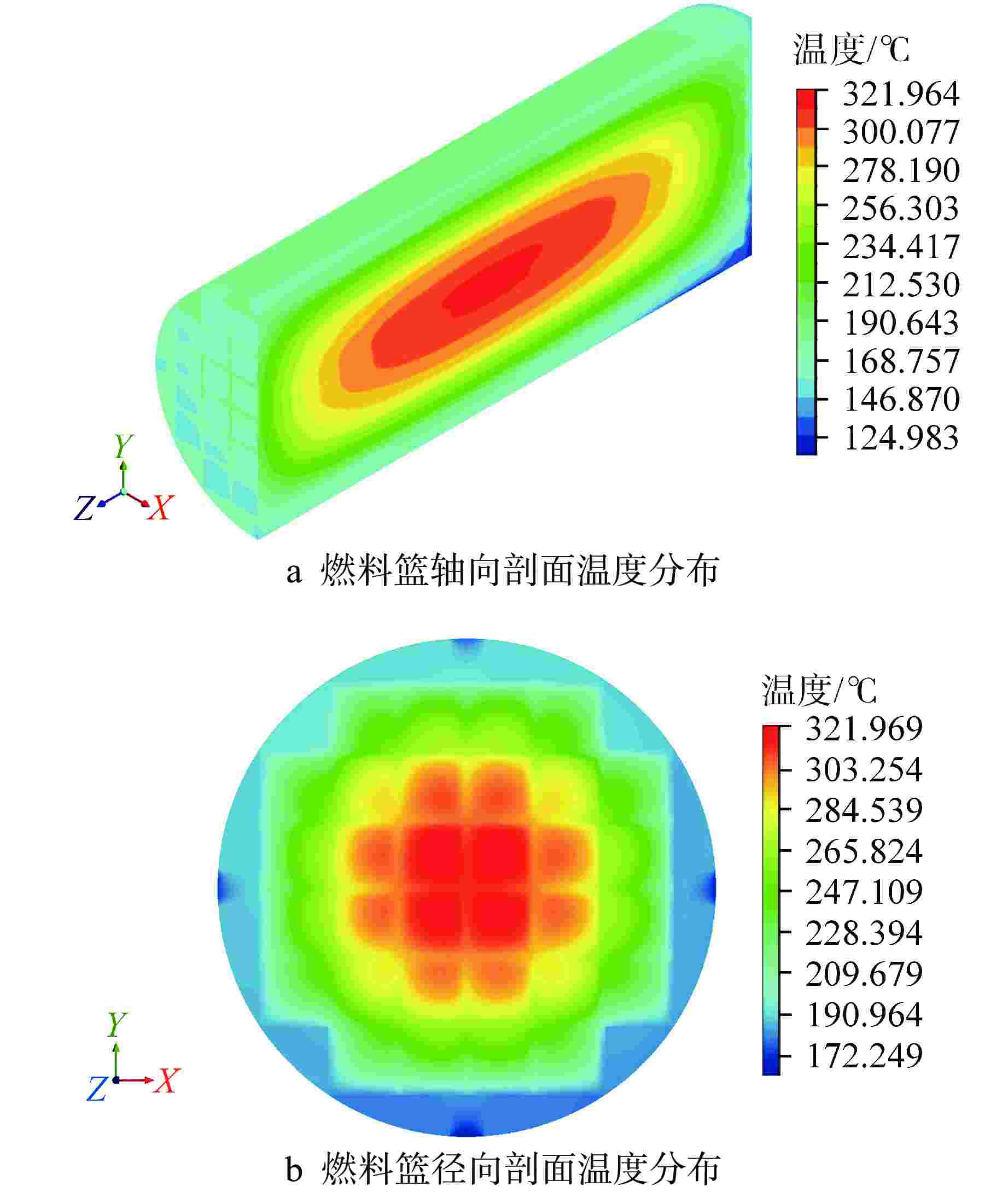

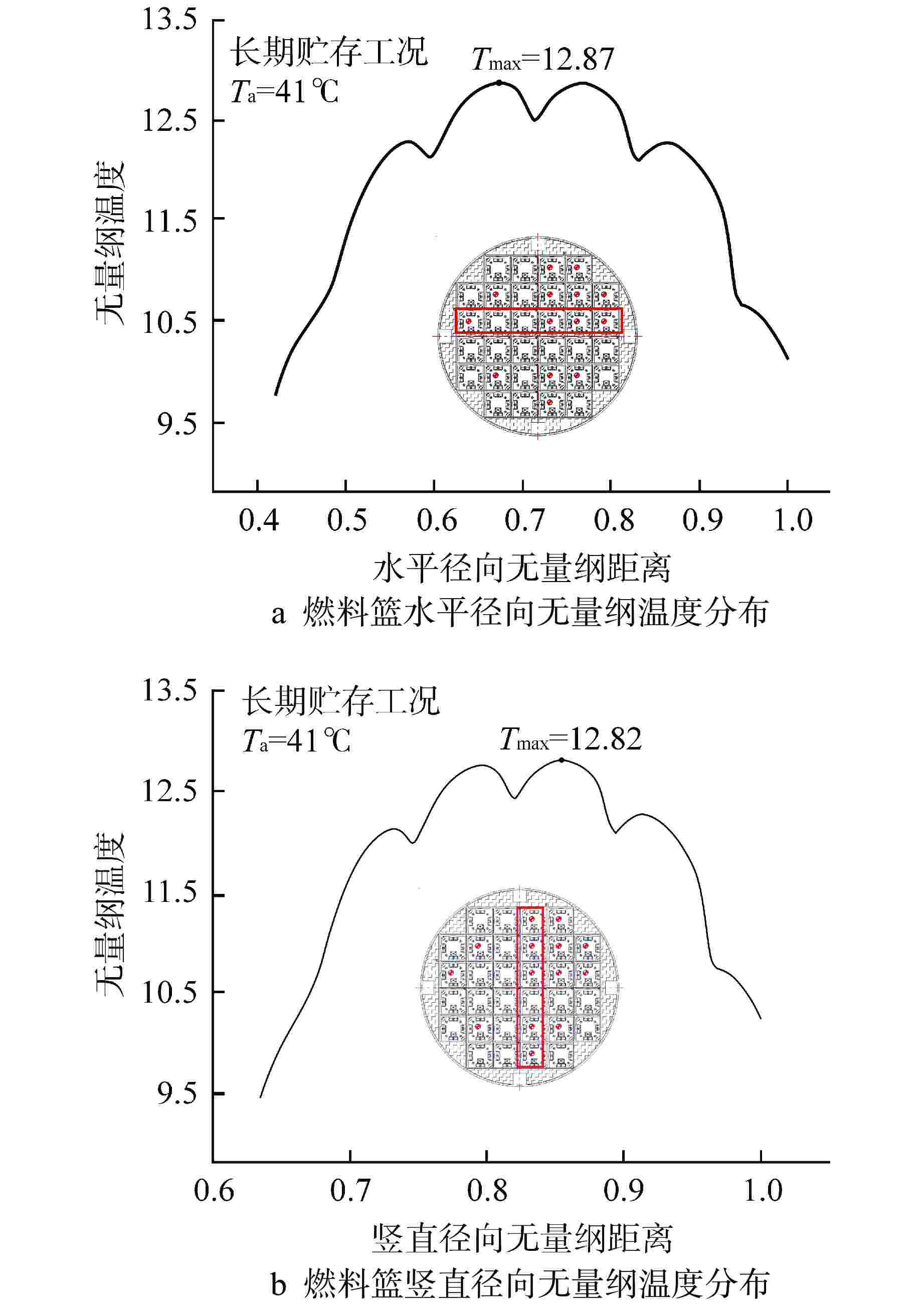

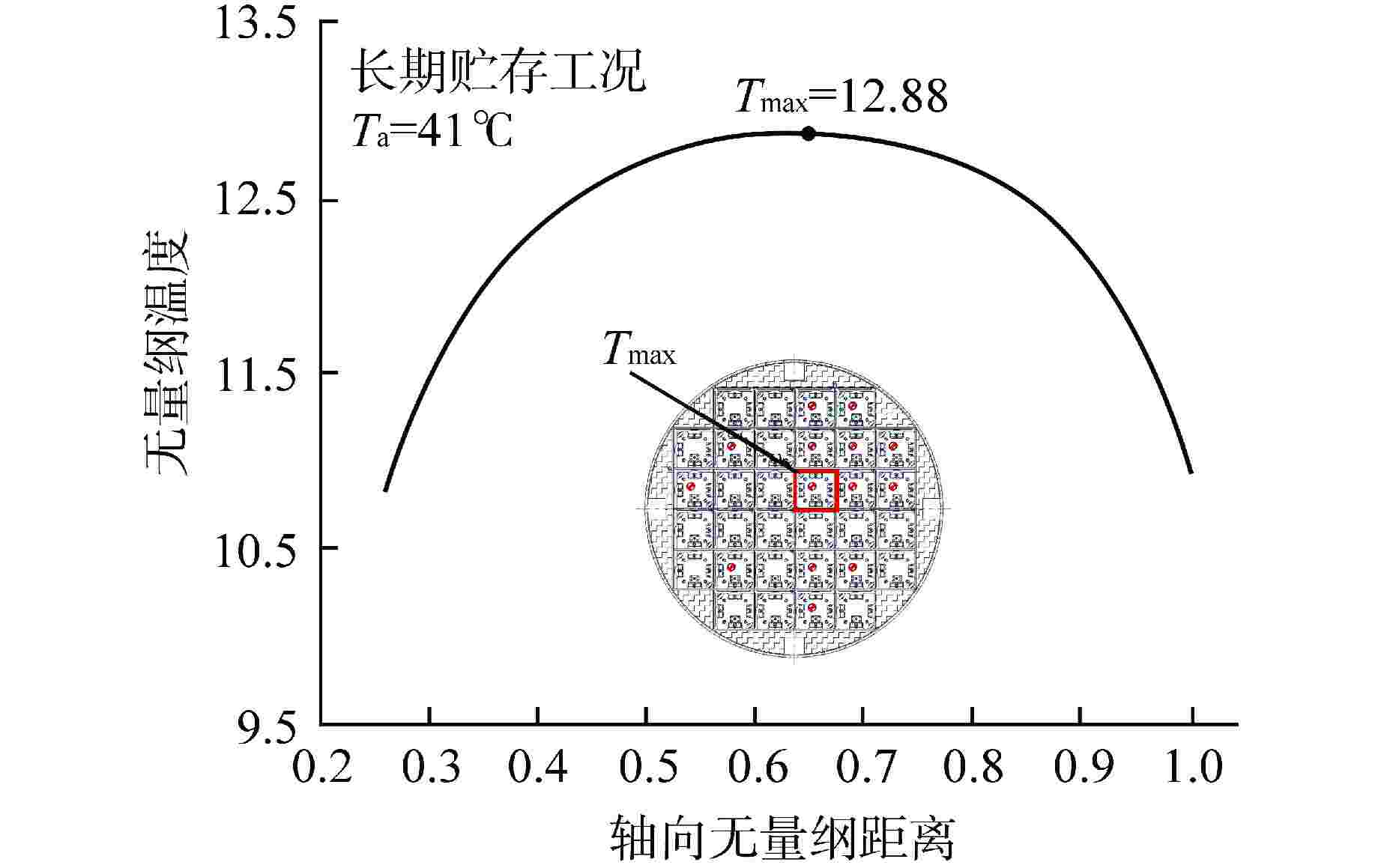

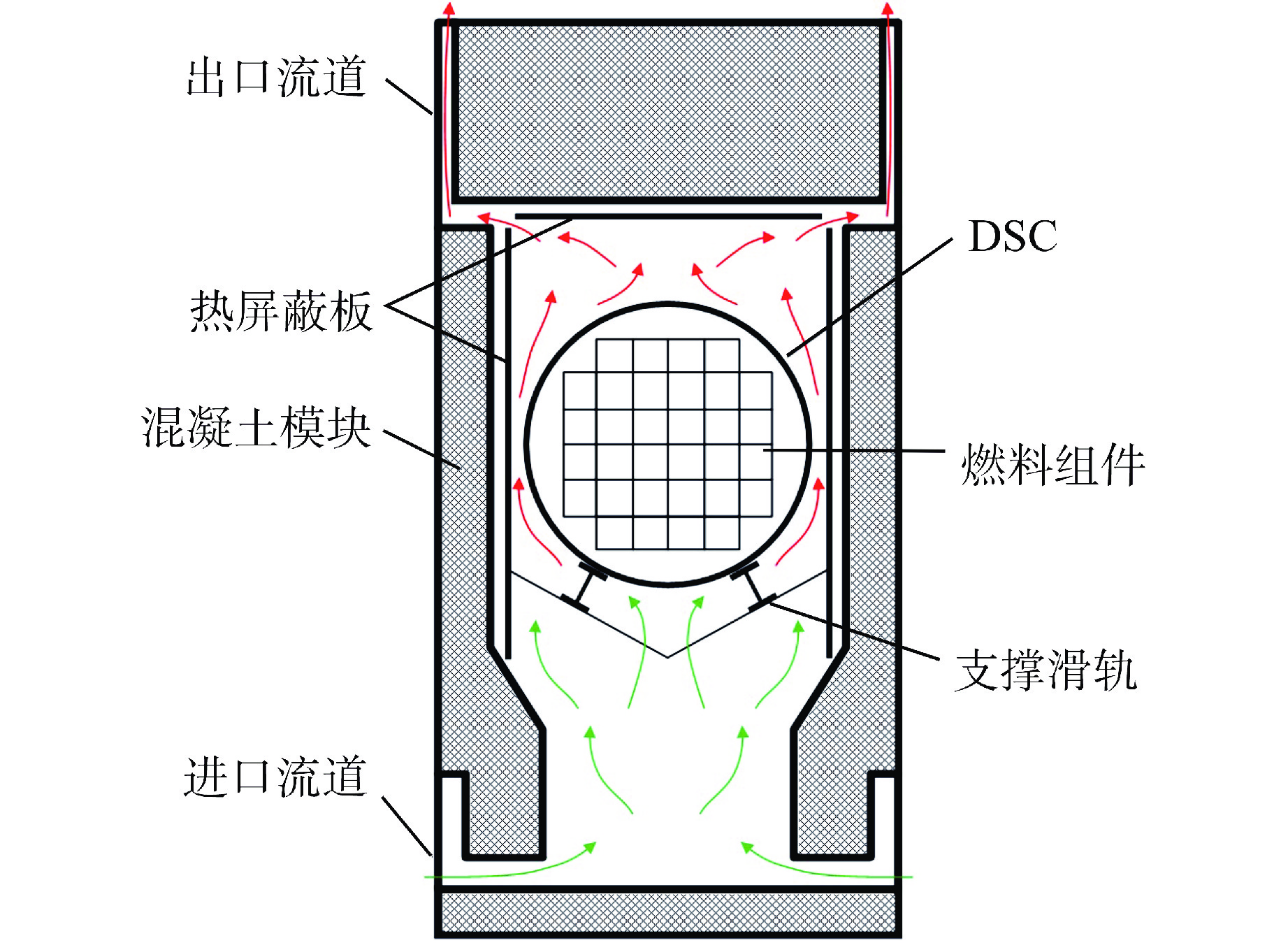

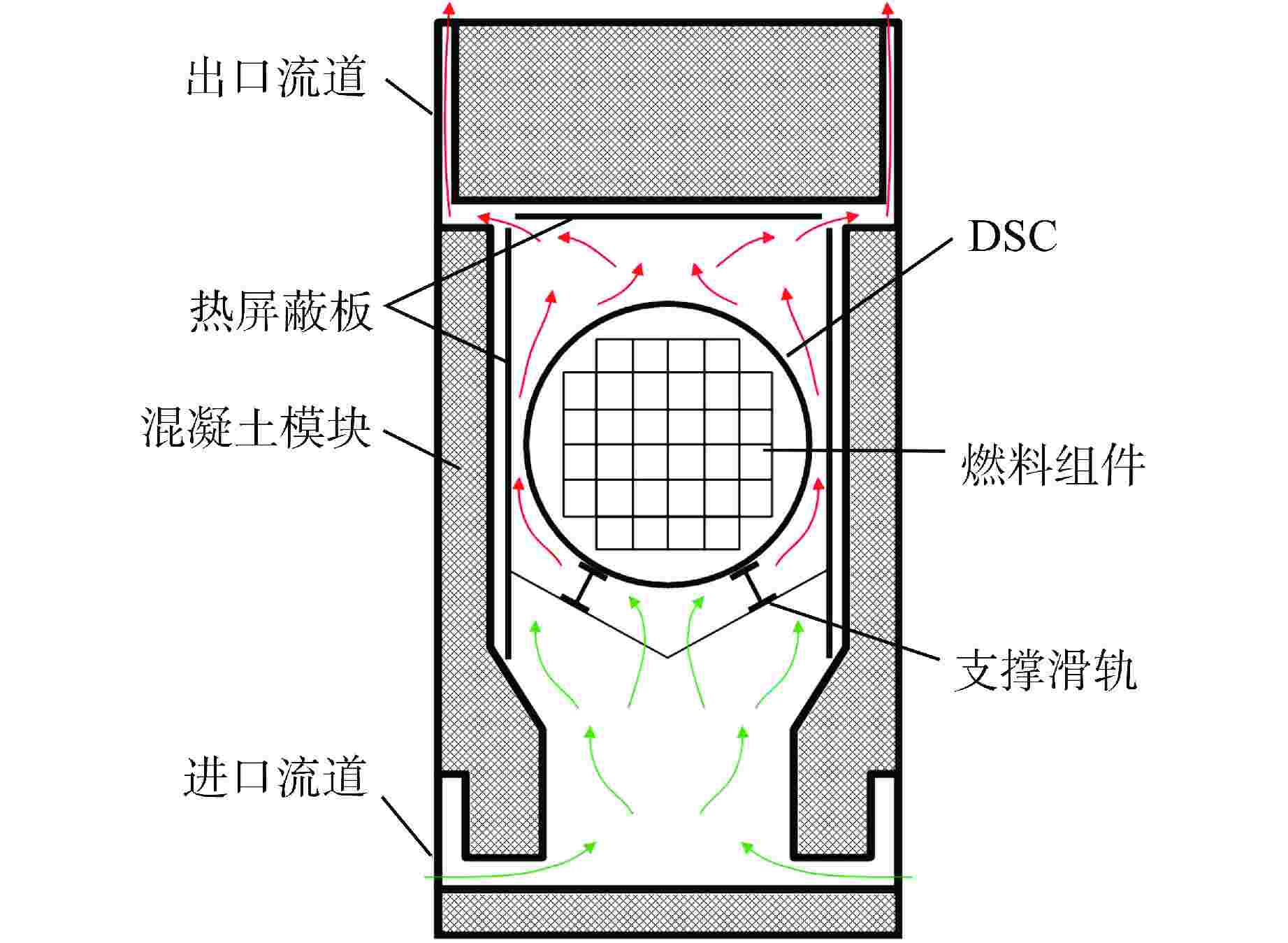

摘要: 乏燃料干法贮存具有安全、经济及灵活的优势,是当前核工业领域的研究热点之一。本研究以乏燃料干法贮存系统的水平贮存模块(HSM)为研究对象,采用计算流体动力学(CFD)共轭传热技术与多孔介质相结合的物理建模方法,建立了混凝土模块与贮存容器的1/2缩比模型的三维自然对流传热模型,在Fluent求解器中对模块内的流动传热过程进行了数值模拟。研究结果表明:混凝土模块底部入口处的收缩结构设计导致进口段的空气流速陡增,最大流速为1.98 m/s;混凝土模块内的热屏蔽板可有效降低混凝土的温度,高温区域分布在内部腔室的后墙上半部分,最高温度为108.05℃;燃料组件温度在轴向和水平径向上呈对称分布,最高温度为321.97℃;混凝土模块内自然对流换热量占总发热功率的82.3%,其结构设计具有良好的排热能力。该研究将为乏燃料干法贮存系统的缩比实验和样机设计提供重要参考。Abstract: Spent fuel dry storage system, with the advantages of safety, economy, and flexibility, is one of the research hotspots in the field of nuclear industry. In this study, the horizontal storage module (HSM) of the spent fuel storage system is taken as the research object, and a three-dimensional natural convection heat transfer model of the 1/2 scale model of the concrete module and the storage container is established by using the physical modeling method combining the conjugate heat transfer technology of computational fluid dynamics (CFD) with porous media, and the flow and heat transfer process in the module is numerically simulated in the Fluent solver. The results show that: the shrinkage structure design at the bottom of the concrete module leads to a sharp increase of the airflow velocity at the inlet section, and the maximum flow velocity is 1.98 m/s. The thermal shielding plate in the concrete module can effectively reduce the temperature of the concrete. The high-temperature area is distributed in the upper part of the back wall of the internal chamber, and the maximum temperature is 108.05℃. The temperature of the fuel assembly shows a symmetric distribution in the axial and horizontal radial direction, and the maximum temperature is 321.97℃. The natural convection heat exchange in concrete module accounts for 82.3% of the total heating power, and its structural design has good heat removal ability. This study will provide important references for scaling experiments and prototype design of spent fuel dry storage systems.

-

表 1 正常工况参数

Table 1. Normal Operating Condition Parameters

参数 类型 数值 进口压力/温度 通风进口 0 Pa/41℃ 出口压力/温度 压力出口 0 Pa/41℃ 壁面 对流边界 用户自定义函数(UDF) 内部接触面 耦合边界 固体材料发射率 功率/kW 内热源项 7.66 表 2 控制方程离散方法

Table 2. Discretization Methods of Governing Equations

离散项 离散格式 压力速度耦合算法 SIMPLE算法 梯度离散方法 基于格林高斯节点 压力 二阶迎风格式 动量 二阶迎风格式 能量 二阶迎风格式 DO辐射模型 二阶迎风格式 表 3 自然对流传热量计算结果

Table 3. Heat Transfer Calculation of Natural Convection

位置 流量/(kg·s−1) 焓/(J·kg−1) 传热量/W 传热量占比/% 左侧进口 0.0581 314557.00 3089.74 82.3 左侧出口 0.0579 368849.37 右侧进口 0.0581 314557.00 3214.53 右侧出口 0.0582 368975.73 -

[1] NISHIMURA M, SHIBAZAKI H, FUJII S, et al. Natural convection heat transfer in the horizontal dry storage system for the LWR spent fuel assemblies[J]. Journal of Nuclear Science and Technology, 1996, 33(11): 821-828. doi: 10.1080/18811248.1996.9732015 [2] XIE H, GAO Z Y, ZHOU Z W. A numerical investigation of natural convection heat transfer in horizontal spent-fuel storage cask[J]. Nuclear Engineering and Design, 2002, 213(1): 59-65. doi: 10.1016/S0029-5493(01)00454-X [3] LEE J C, CHOI W S, BANG K S, et al. Thermal-fluid flow analysis and demonstration test of a spent fuel storage system[J]. Nuclear Engineering and Design, 2009, 239(3): 551-558. doi: 10.1016/j.nucengdes.2008.12.015 [4] DAS K, BASU D, SOLIS J, et al. Computational fluid dynamics modeling approach to evaluate VSC–17 dry storage cask thermal designs[C]//CFD for Nuclear Reactor Safety Applications, Workshop Proceedings, CFD4NRS-3. Bethesda, Maryland, USA, 2010: 14-16. [5] KIM H M, NO H C, BANG K S, et al. Development of scaling laws of heat removal and CFD assessment in concrete cask air path[J]. Nuclear Engineering and Design, 2014, 278: 7-16. doi: 10.1016/j.nucengdes.2014.06.015 [6] WU Y, KLEIN J, ZHOU H, et al. Thermal and fluid analysis of dry cask storage containers over multiple years of service[J]. Annals of Nuclear Energy, 2018, 112: 132-142. [7] 蔡创广. 乏燃料卧式干法贮存热工安全数值模拟与分析[D]. 珠海: 中山大学,2019. [8] FLUENT A. Theory guide[Z]. Ansys Inc, 2015. [9] XU Y M, YANG J, XU C, et al. Thermal analysis on NAC-STC spent fuel transport cask under different transport conditions[J]. Nuclear Engineering and Design, 2013, 265: 682-690. doi: 10.1016/j.nucengdes.2013.07.034 [10] KIM H, KWON O J, KANG G U, et al. Comparisons of prediction methods for peak cladding temperature and effective thermal conductivity in spent fuel assemblies of transportation/storage casks[J]. Annals of Nuclear Energy, 2014, 71: 427-435. doi: 10.1016/j.anucene.2014.04.004 [11] DAS K, BASU D, WALTER G R. Thermal analysis of horizontal storage casks for extended storage applications[M]. Washington: United States Nuclear Regulatory Commission, Office of Nuclear Regulatory Research, 2014: 1-152. [12] 杨世铭,陶文铨. 传热学[M]. 第四版. 北京: 高等教育出版社,2006: 249-257. [13] LEMMON E, HUBER M L, MCLINDEN M O. NIST standard reference database 23: reference fluid thermodynamic and transport properties-REFPROP, version 8.0[R]. Gaithersburg: National Institute of Standards and Technology, 2007. -

下载:

下载: