Study on Fretting Wear Behavior of Pre-oxidized Zircaloy Cladding in High Temperature and High Pressure Water

-

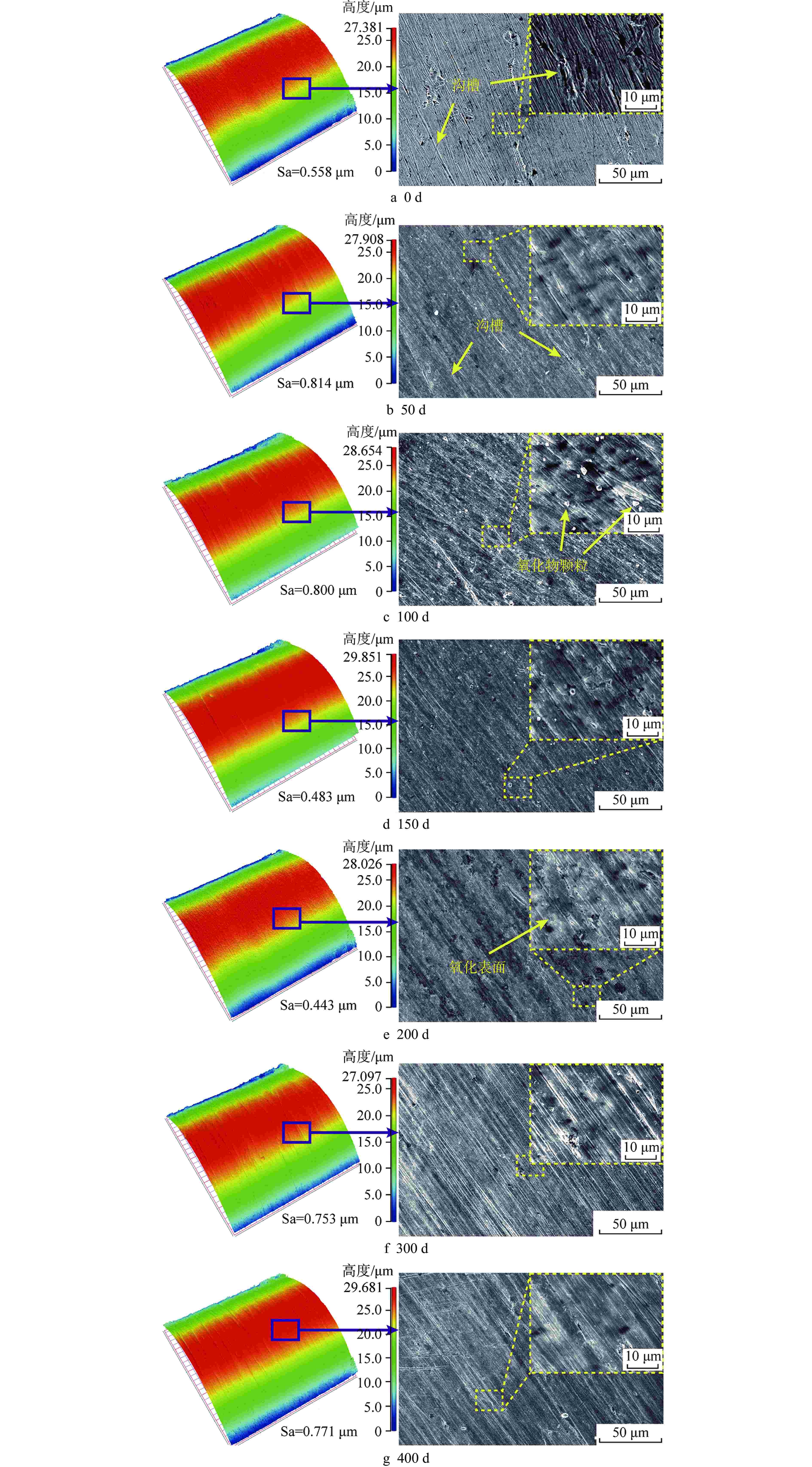

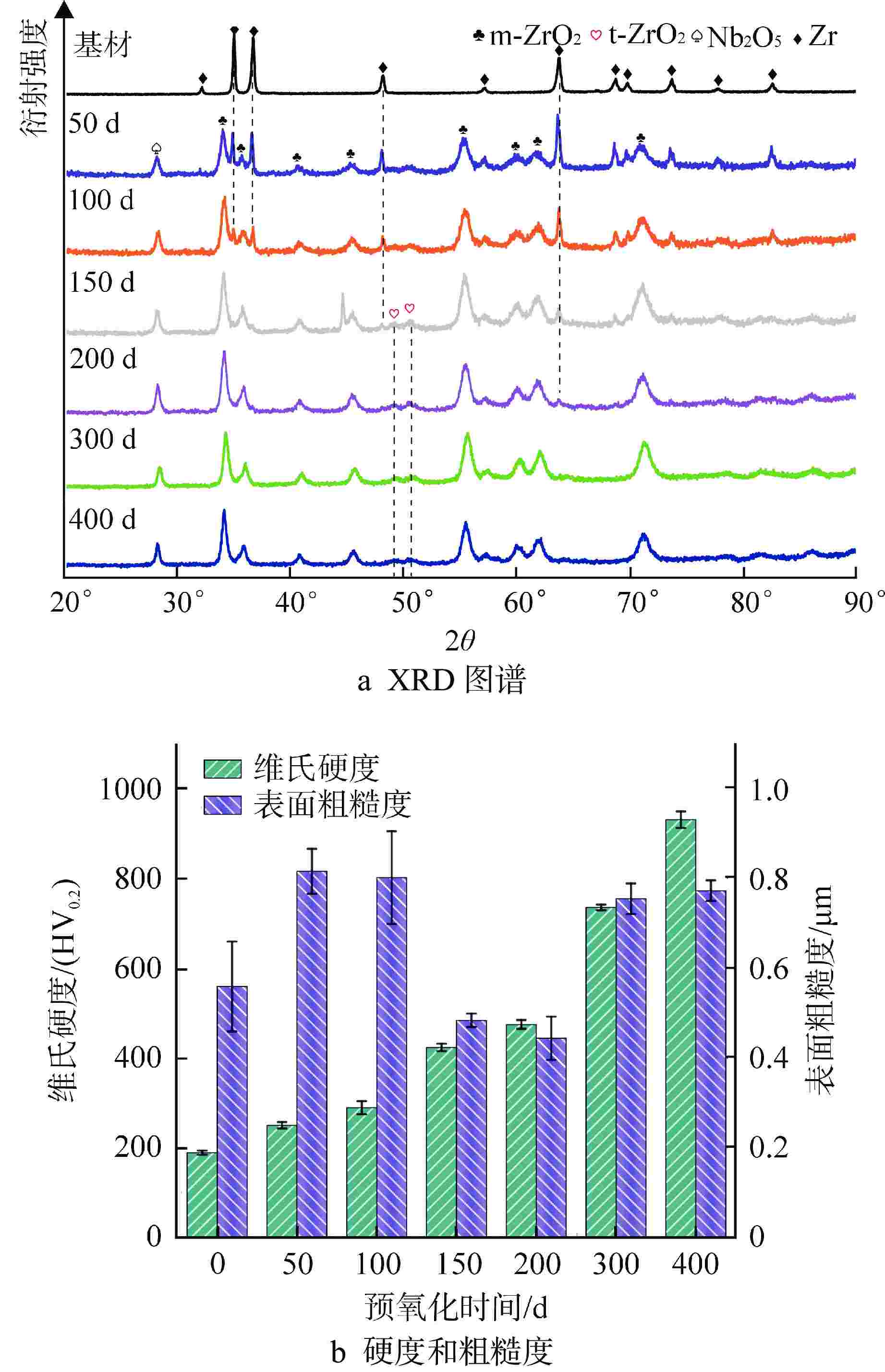

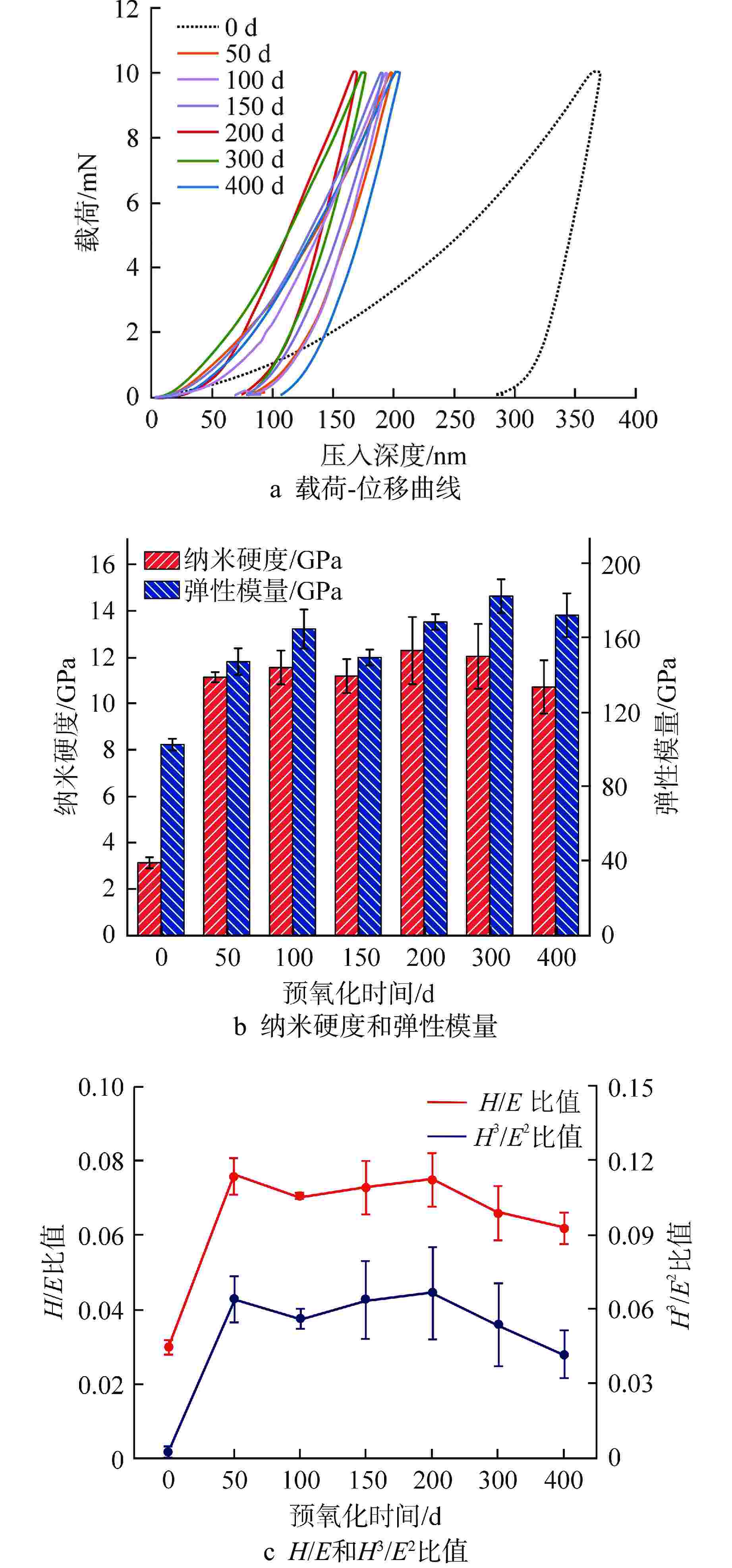

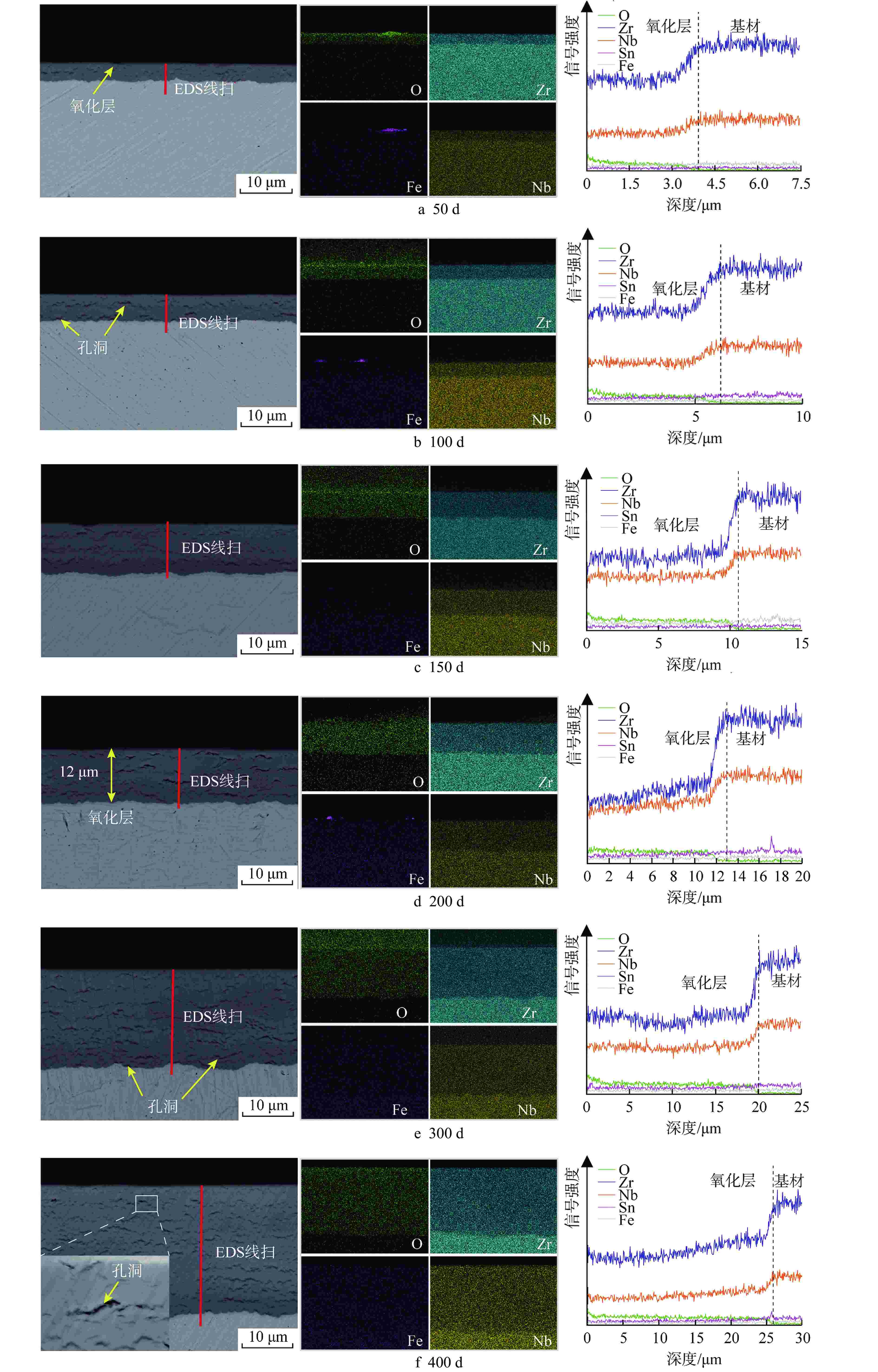

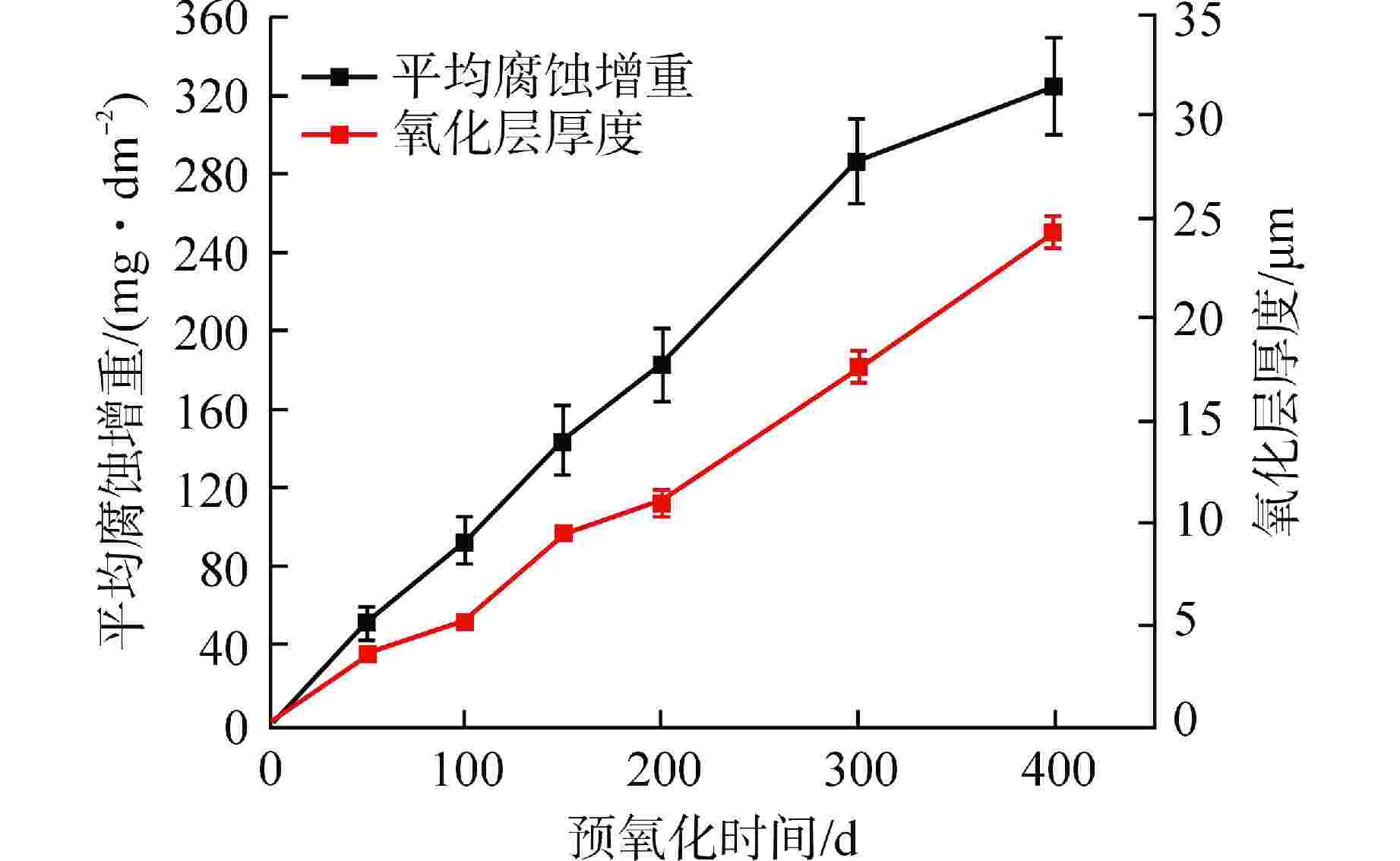

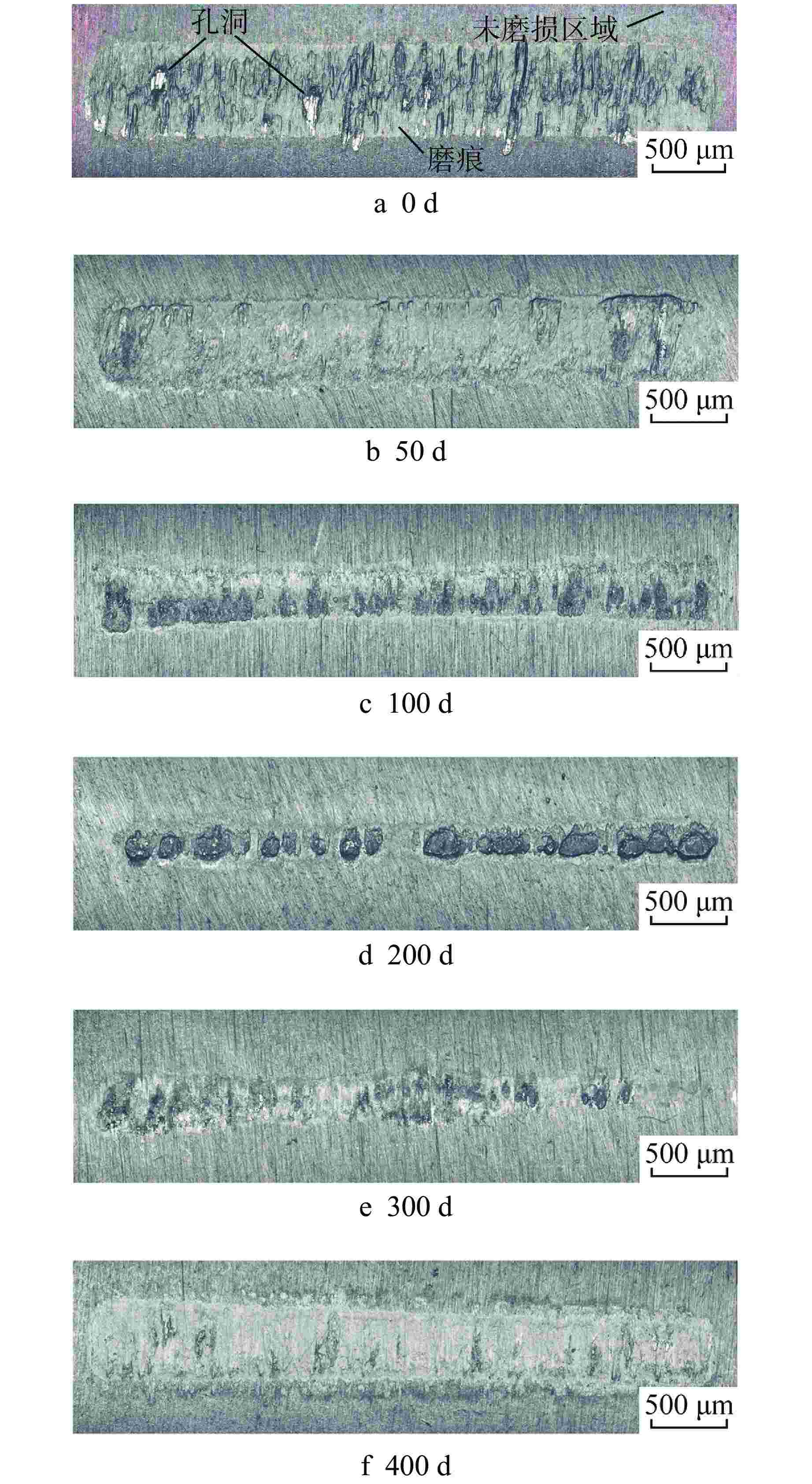

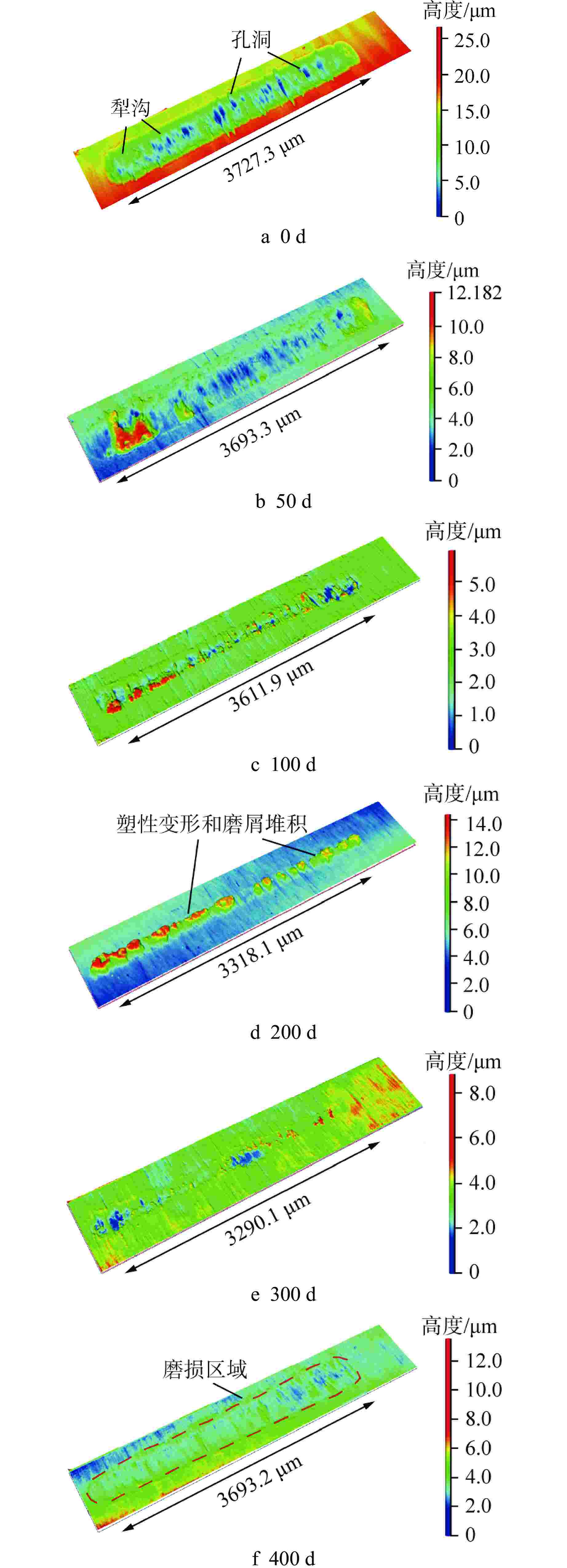

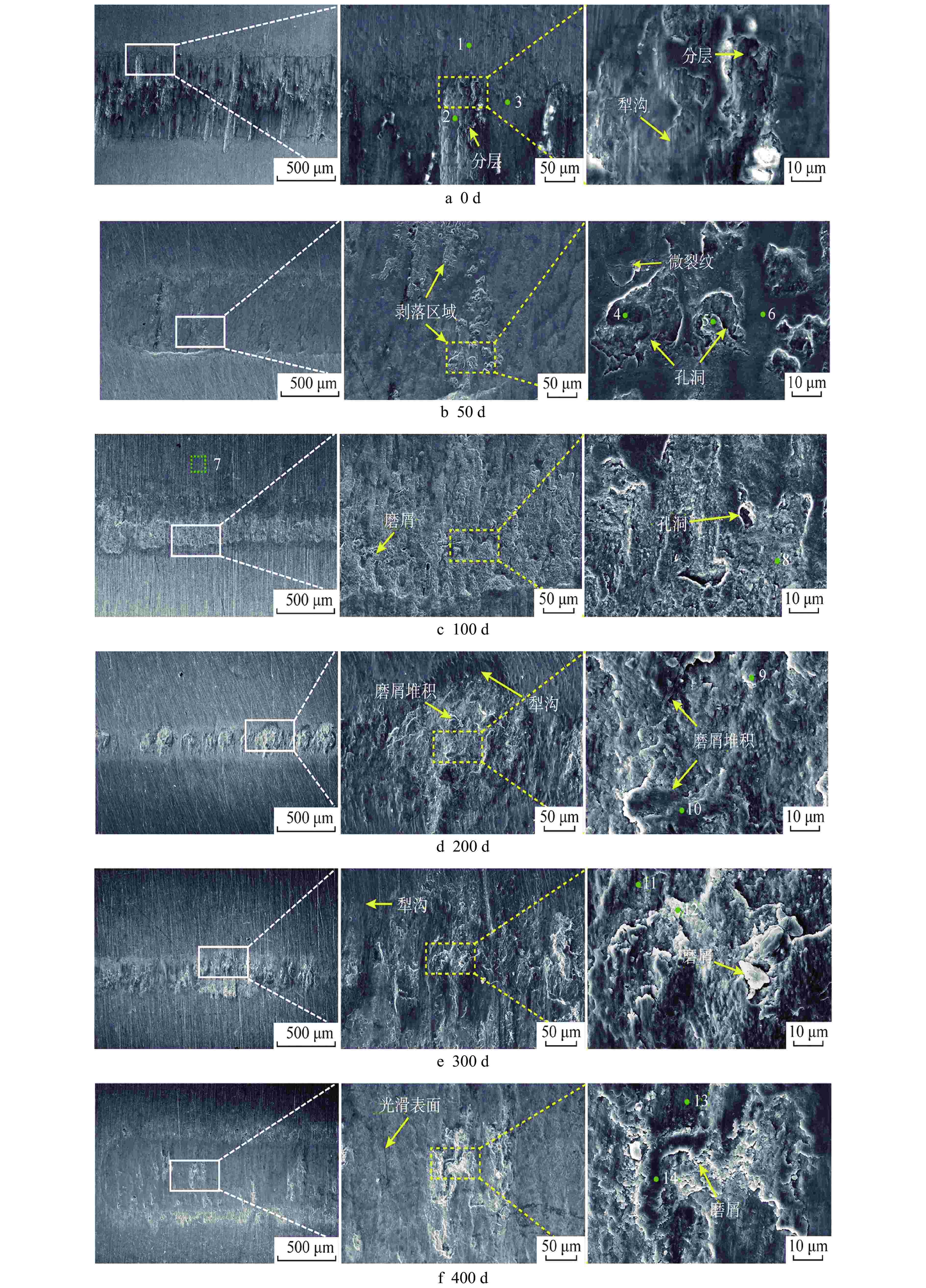

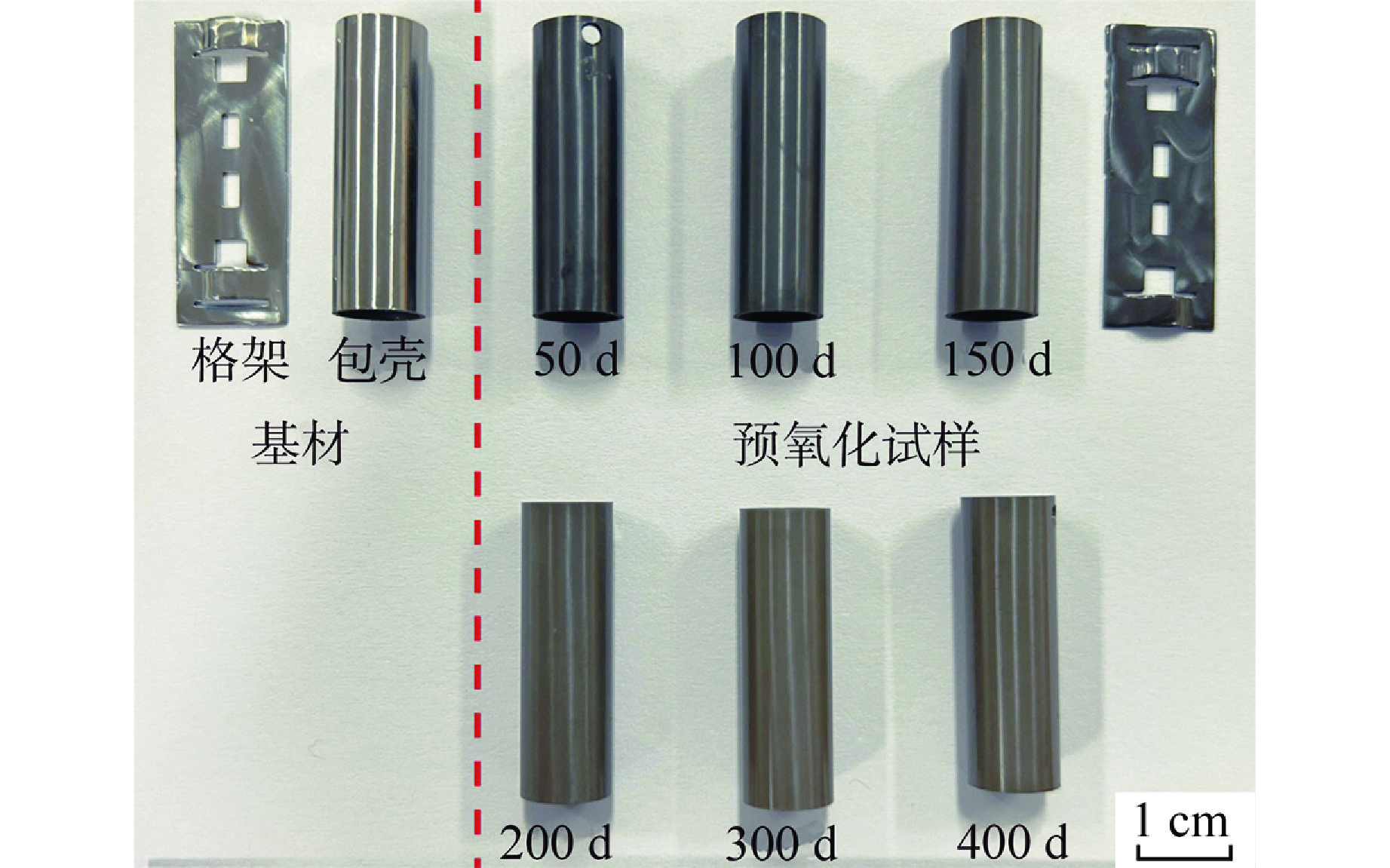

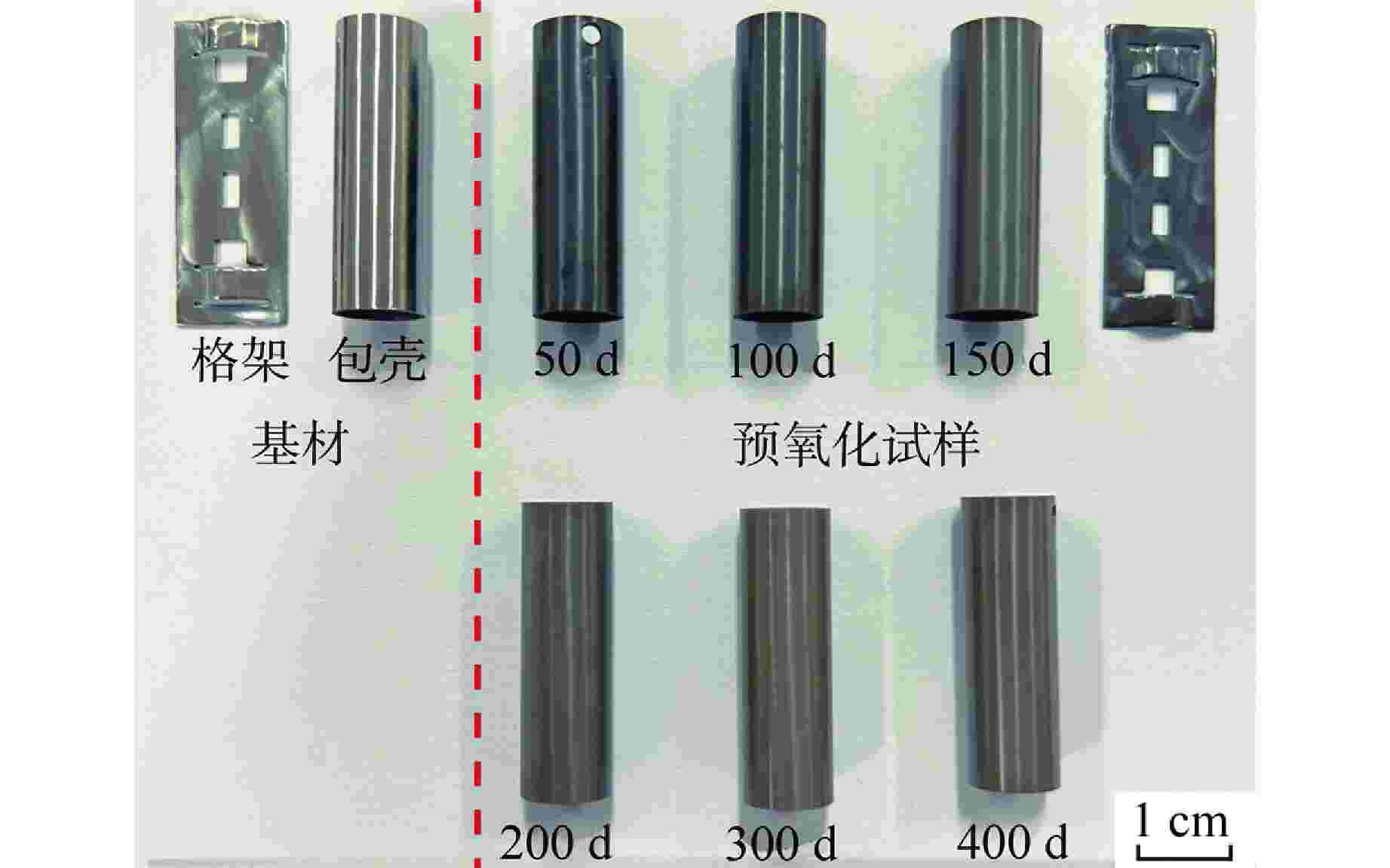

摘要: 为深入研究在实际服役过程中包壳随氧化时间变化后的微动磨损情况,采用过热水蒸气氧化的手段制备了多种预氧化包壳,并使用自制的高温高压切向微动磨损试验机开展了模拟压水堆运行工况的微动磨损试验,测量了基材以及经过不同时间预氧化后包壳的体积磨损系数。研究结果表明,预氧化之后包壳表面硬度比基体提高了2~3倍,而磨损系数降低了约90%。在包壳表层生成的一层致密氧化层是导致其磨损系数变化的重要原因,氧化时间越长,氧化层越厚,氧化时间为200 d的包壳磨损系数最低。此外,氧化层的存在导致锆合金包壳在高温高压水环境下的微动磨损机理从严重磨粒磨损和分层转变为轻微磨粒磨损和粘着磨损。Abstract: To further study the fretting wear of of claddings with the change of oxidation time in practical service, a variety of pre-oxidized claddings were prepared by superheated steam oxidation. In this study, a self-made high-temperature and high-pressure tangential fretting wear tester was used to carry out fretting wear tests simulating the operation conditions of PWR, and the volume wear coefficients of the substrate and the cladding after pre-oxidation at different times were measured. The results show that the surface hardness of the cladding is 2~3 times higher than that of the substrate, and the wear coefficient is reduced by about 90%. A dense oxide layer formed on the surface layer of cladding is an important reason for the change in its wear coefficient. The longer the oxidation time, the thicker the oxide layer, and the cladding with an oxidation time of 200 d has the lowest wear coefficient. In addition, the existence of oxide layer causes the fretting wear mechanism of zircaloy cladding to change from serious abrasive wear and layering to slight abrasive wear and adhesive wear in high temperature and high pressure water environment.

-

Key words:

- Pre-oxidation /

- Zircaloy /

- High temperature and high pressure water /

- Fretting wear

-

表 1 图10中点1~14的元素成分结果 (质量分数,%)

Table 1. EDS Results of Sites 1-14 in Figure 10 (mass fraction, %)

元素 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Zr 79.2 75.74 77.41 75.8 69.4 71.1 74.4 66.4 91.4 90.9 75.2 69.3 77.6 79.8 O 18.07 22.04 20.11 21.3 28.5 27.9 23.3 32.3 5.9 7.0 22.6 28.3 19.6 18.2 Sn 0.79 0.74 0.61 1.1 1.2 1.0 1.0 1.1 1.5 1.5 0.8 1.5 0.8 1.1 Nb 1.72 1.41 1.67 1.7 0.6 0 0.8 0.1 0.8 0.6 0.7 0.6 1.5 0.8 Fe 0.23 0.08 0.19 0.1 0.4 0 0.6 0.2 0.4 0 0.3 0.3 0.5 0.1 -

[1] CAI Z B, LI Z Y, YIN M G, et al. A review of fretting study on nuclear power equipment[J]. Tribology International, 2020, 144: 106095. doi: 10.1016/j.triboint.2019.106095 [2] 高雯. 锆合金包壳和GH4169镍基合金的微动摩擦磨损性能研究[J]. 核动力工程,2020, 41(4): 85-90. [3] KUMARA C, WANG R, LU R Y, et al. Grid-to-rod fretting wear study of SiC/SiC composite accident-tolerant fuel claddings using an autoclave fretting bench test[J]. Wear, 2022, 488-489: 204172. doi: 10.1016/j.wear.2021.204172 [4] 任全耀,蒲曾坪,焦拥军,等. 高温下锆合金包壳切向微动磨蚀行为研究[J]. 核动力工程,2022, 43(S2): 82-87. [5] ZINKLE S J, WAS G S. Materials challenges in nuclear energy[J]. Acta Materialia, 2013, 61(3): 735-758. doi: 10.1016/j.actamat.2012.11.004 [6] KIM K T. Evolutionary developments of advanced PWR nuclear fuels and cladding materials[J]. Nuclear Engineering and Design, 2013, 263: 59-69. doi: 10.1016/j.nucengdes.2013.04.013 [7] WANG J, LEI Y J, LI Z Y, et al. Effect of contact misalignment on fretting wear behavior between fuel cladding and Zr-4 grid[J]. Tribology International, 2023, 181: 108299. doi: 10.1016/j.triboint.2023.108299 [8] 江海霞,段泽文,马鹏翔,等. 核反应堆中锆合金包壳及其表面涂层的微动磨损行为研究进展[J]. 摩擦学学报,2021, 41(3): 423-436. [9] ZHU M H, ZHOU Z R. On the mechanisms of various fretting wear modes[J]. Tribology International, 2011, 44(11): 1378-1388. doi: 10.1016/j.triboint.2011.02.010 [10] 李好杰,宁闯明,李正阳,等. 904L不锈钢在不同气氛下微动磨损性能研究[J]. 摩擦学学报,2023, 43(10): 1128-1139. [11] 杨红艳,吕俊男,张瑞谦,等. 锆合金表面Cr涂层在高温水蒸气环境中氧化行为研究[J]. 核动力工程,2023, 44(S1): 168-175. [12] KIM T H, KIM S S. Fretting wear mechanisms of Zircaloy-4 and Inconel 600 contact in air[J]. KSME International Journal, 2001, 15(9): 1274-1280. doi: 10.1007/BF03185668 [13] YUAN X L, ZHANG X Y, ZHANG Q, et al. Study on the fretting maps of Zircaloy-4 alloy against Inconel 718 alloy[J]. Tribology International, 2021, 160: 107024. doi: 10.1016/j.triboint.2021.107024 [14] LEE Y H, KIM H K, JUNG Y H. Effect of impact frequency on the wear behavior of spring-supported tubes in room and high temperature distilled water[J]. Wear, 2005, 259(1-6): 329-336. doi: 10.1016/j.wear.2005.01.019 [15] KIM H K, LEE Y H. Influence of contact shape and supporting condition on tube fretting wear[J]. Wear, 2003, 255(7-12): 1183-1197. doi: 10.1016/S0043-1648(03)00068-1 [16] KIM H K, LEE Y H, LEE K H. On the geometry of the fuel rod supports concerning a fretting wear failure[J]. Nuclear Engineering and Design, 2008, 238(12): 3321-3330. doi: 10.1016/j.nucengdes.2008.08.010 [17] KIM K S, YOON K H, SONG K N, et al. Finite element analysis of the optimized H type grid spring by using gap elements[J]. Nuclear Engineering and Design, 2008, 238(9): 2239-2244. doi: 10.1016/j.nucengdes.2008.02.025 [18] LEE Y H, KIM H K. A study on the fretting wear resistance of a zirconium alloy with the variation of supporting spring properties[J]. Key Engineering Materials, 2007, 345-346: 1365-1368. doi: 10.4028/www.scientific.net/KEM.345-346.1365 [19] LEE Y H, KIM H K. Fretting wear behavior of a nuclear fuel rod under a simulated primary coolant condition[J]. Wear, 2013, 301(1-2): 569-574. doi: 10.1016/j.wear.2013.01.067 [20] PARK Y C, JEONG S H, KIM Y H, et al. Influence of temperature on the fretting wear of advanced nuclear fuel cladding tube against supporting grid[J]. Key Engineering Materials, 2007, 345-346: 705-708. doi: 10.4028/www.scientific.net/KEM.345-346.705 [21] ATTIA M H, DE PANNEMAECKER A, WILLIAMS G. Effect of temperature on tribo-oxide formation and the fretting wear and friction behavior of zirconium and nickel-based alloys[J]. Wear, 2021, 476: 203722. doi: 10.1016/j.wear.2021.203722 [22] WANG J, LI H J, LI Z Y, et al. Effect of temperature on the fretting wear behavior of Cr-coated Zircaloy cladding in high-temperature pressurized water[J]. Journal of Nuclear Materials, 2023, 584: 154516. doi: 10.1016/j.jnucmat.2023.154516 [23] QU J, COOLEY K M, SHAW A H, et al. Assessment of wear coefficients of nuclear zirconium claddings without and with pre-oxidation[J]. Wear, 2016, 356-357: 17-22. doi: 10.1016/j.wear.2016.02.020 [24] LEE Y H, KIM I H, KIM H K, et al. Role of ZrO2 oxide layer on the fretting wear resistance of a nuclear fuel rod[J]. Tribology International, 2020, 145: 106146. [25] WANG J, LI H J, LI Z Y, et al. Fretting wear characteristics of nuclear fuel cladding in high-temperature pressurized water[J]. Chinese Journal of Mechanical Engineering, 2023, 36(1): 101. doi: 10.1186/s10033-023-00931-4 [26] JIANG H, QU J, LU R Y, et al. Grid-to-rod flow-induced impact study for PWR fuel in reactor[J]. Progress in Nuclear Energy, 2016, 91: 355-361. doi: 10.1016/j.pnucene.2016.06.003 [27] LAZAREVIC S, LU R Y, FAVEDE C, et al. Investigating grid-to-rod fretting wear of nuclear fuel claddings using a unique autoclave fretting rig[J]. Wear, 2018, 412-413: 30-37. doi: 10.1016/j.wear.2018.06.011 [28] REED B, WANG R, LU R Y, et al. Autoclave grid-to-rod fretting wear evaluation of a candidate cladding coating for accident-tolerant fuel[J]. Wear, 2021, 466-467: 203578. doi: 10.1016/j.wear.2020.203578 [29] LAI P, GAO X C, TANG L C, et al. Effect of temperature on fretting wear behavior and mechanism of alloy 690 in water[J]. Nuclear Engineering and Design, 2018, 327: 51-60. doi: 10.1016/j.nucengdes.2017.12.007 [30] LIU X C, MING H L, ZHANG Z M, et al. Effects of temperature on fretting corrosion between alloy 690TT and 405 stainless steel in pure water[J]. Acta Metallurgica Sinica (English Letters), 2019, 32(12): 1437-1448. doi: 10.1007/s40195-019-00929-9 [31] GUO X L, LAI P, TANG L C, et al. Time-dependent wear behavior of alloy 690 tubes fretted against 405 stainless steel in high-temperature argon and water[J]. Wear, 2018, 414-415: 194-201. doi: 10.1016/j.wear.2018.08.009 [32] GUO X L, LU J Q, LAI P, et al. Understanding the fretting corrosion mechanism of zirconium alloy exposed to high temperature high pressure water[J]. Corrosion Science, 2022, 202: 110300. doi: 10.1016/j.corsci.2022.110300 [33] MAROTO A J G, BORDONI R, VILLEGAS M, et al. Growth and characterization of oxide layers on zirconium alloys[J]. Journal of Nuclear Materials, 1996, 229: 79-92. doi: 10.1016/0022-3115(95)00233-2 [34] ZHAO X S, SHANG S L, LIU Z K, et al. Elastic properties of cubic, tetragonal and monoclinic ZrO2 from first-principles calculations[J]. Journal of Nuclear Materials, 2011, 415(1): 13-17. doi: 10.1016/j.jnucmat.2011.05.016 [35] ZHANG Y, CHEN H X, DUAN L, et al. A comparison study of the structural and mechanical properties of cubic, tetragonal, monoclinic, and three orthorhombic phases of ZrO2[J]. Journal of Alloys and Compounds, 2018, 749: 283-292. doi: 10.1016/j.jallcom.2018.03.253 [36] ZHANG S M, ZHANG X M. Toughness evaluation of hard coatings and thin films[J]. Thin Solid Films, 2012, 520(7): 2375-2389. doi: 10.1016/j.tsf.2011.09.036 [37] LI Z C, WANG Y X, CHENG X Y, et al. Continuously growing ultrathick CrN coating to achieve high load-bearing capacity and good tribological property[J]. ACS Applied Materials & Interfaces, 2018, 10(3): 2965-2975. [38] ZHANG L, SHAO M H, WANG Z W, et al. Comparison of tribological properties of nitrided Ti-N modified layer and deposited TiN coatings on TA2 pure titanium[J]. Tribology International, 2022, 174: 107712. doi: 10.1016/j.triboint.2022.107712 [39] HE D Q, PU J B, LU Z B, et al. Simultaneously achieving superior mechanical and tribological properties in WC/a-C nanomultilayers via structural design and interfacial optimization[J]. Journal of Alloys and Compounds, 2017, 698: 420-432. doi: 10.1016/j.jallcom.2016.12.173 [40] XIN L, YANG B B, WANG Z H, et al. Microstructural evolution of subsurface on Inconel 690TT alloy subjected to fretting wear at elevated temperature[J]. Materials & Design, 2016, 104: 152-161. -

下载:

下载: