Simulation Study on Concentration Polarization and Electrode Kinetics during Electrorefining of Uranium

-

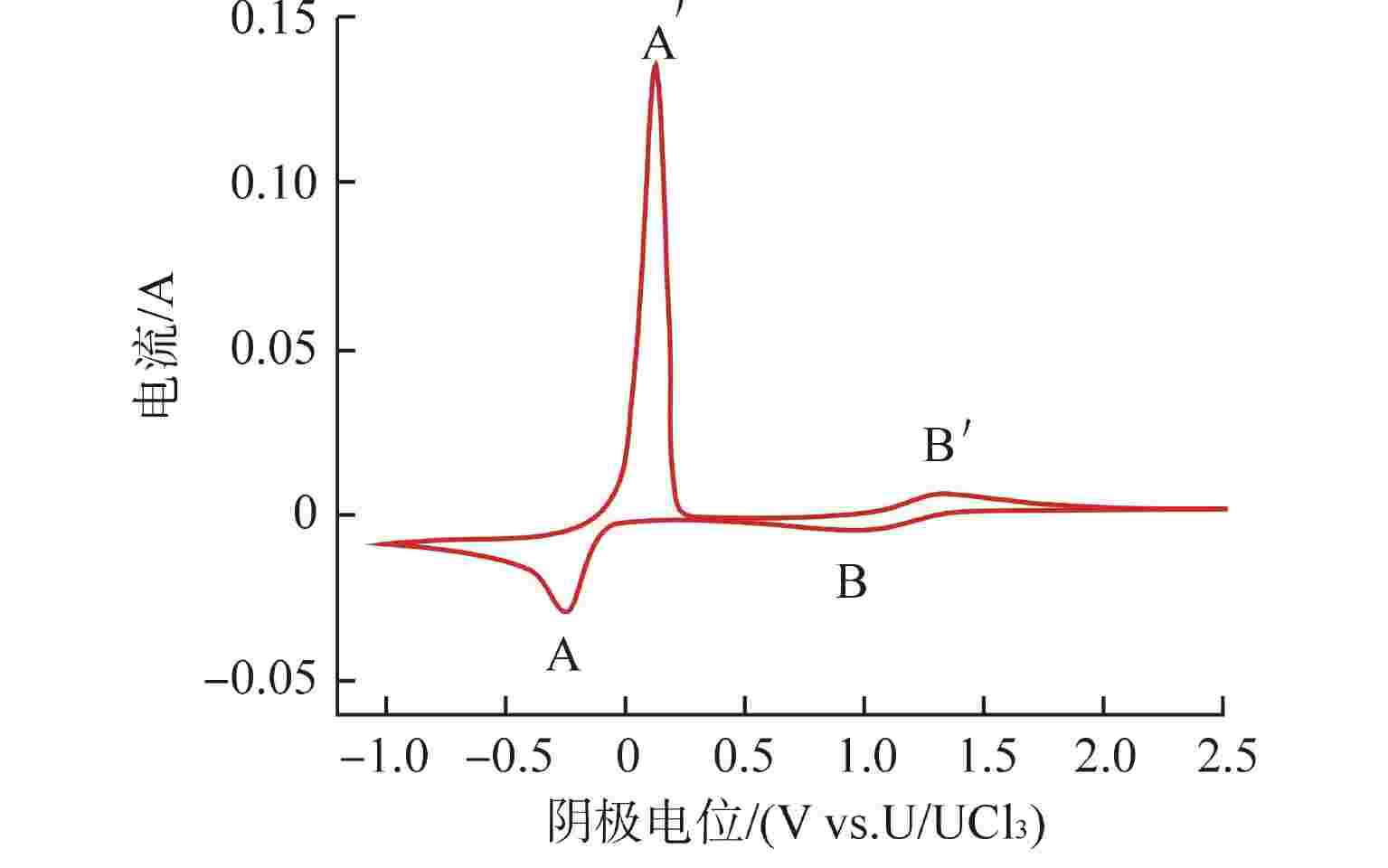

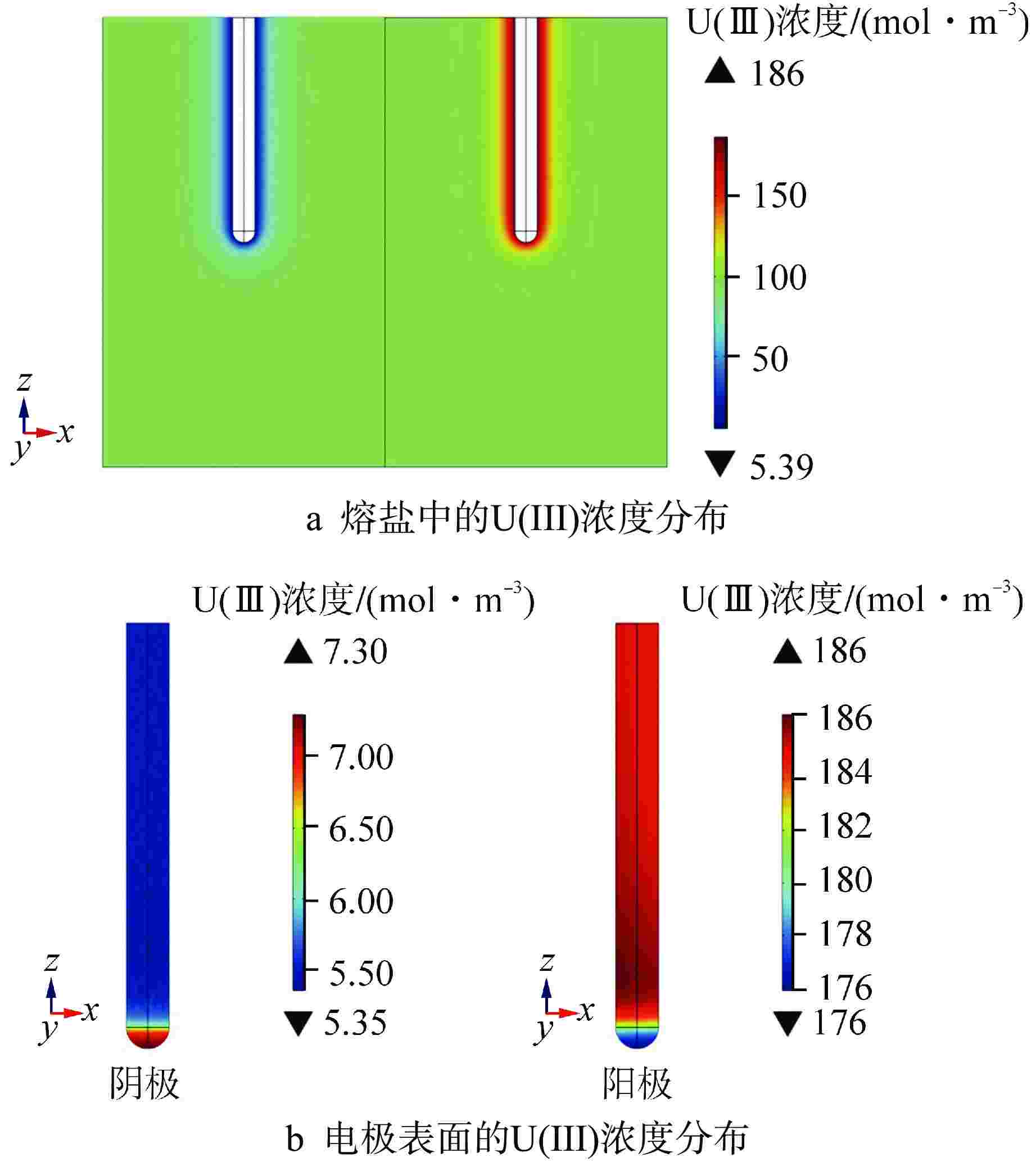

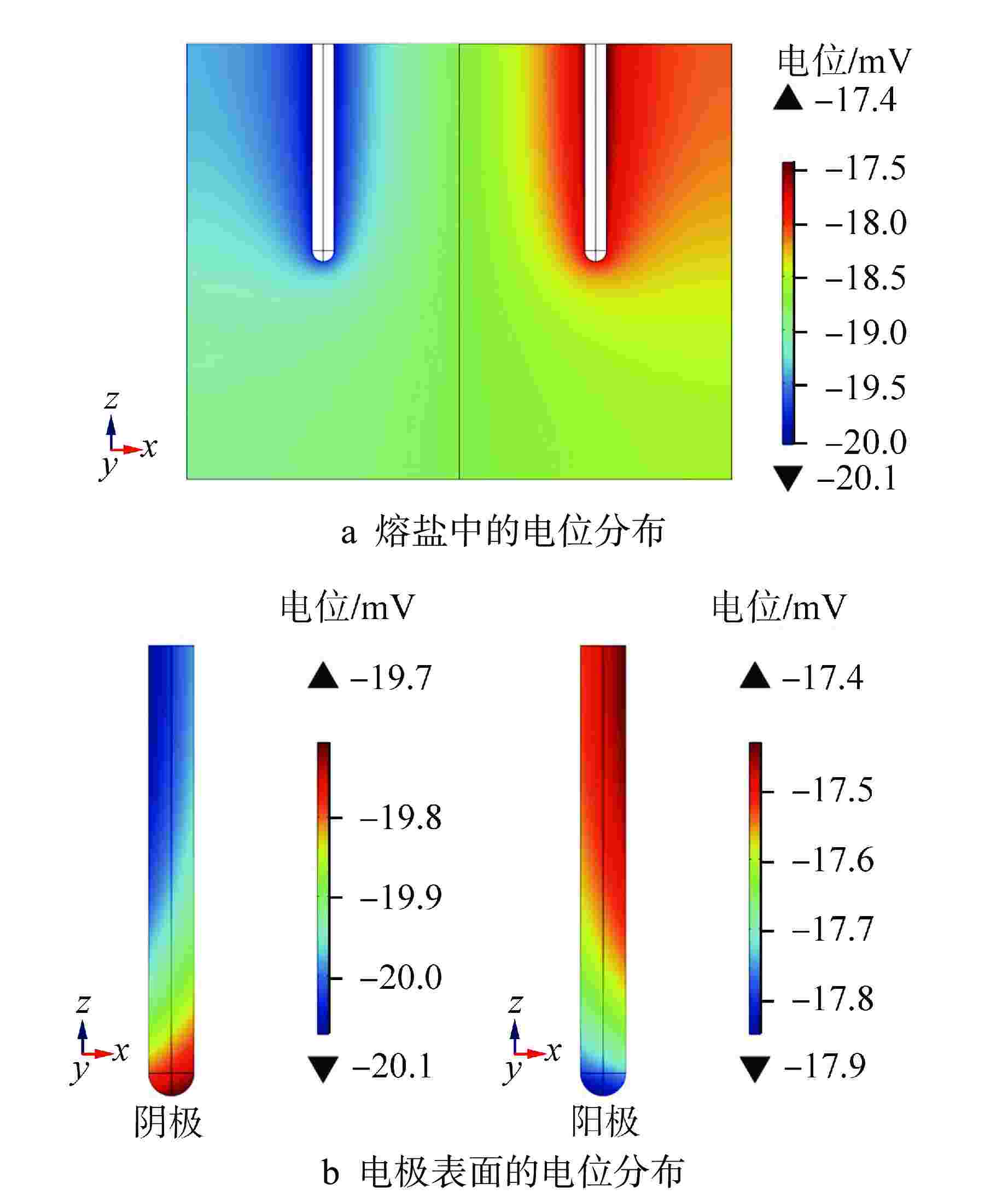

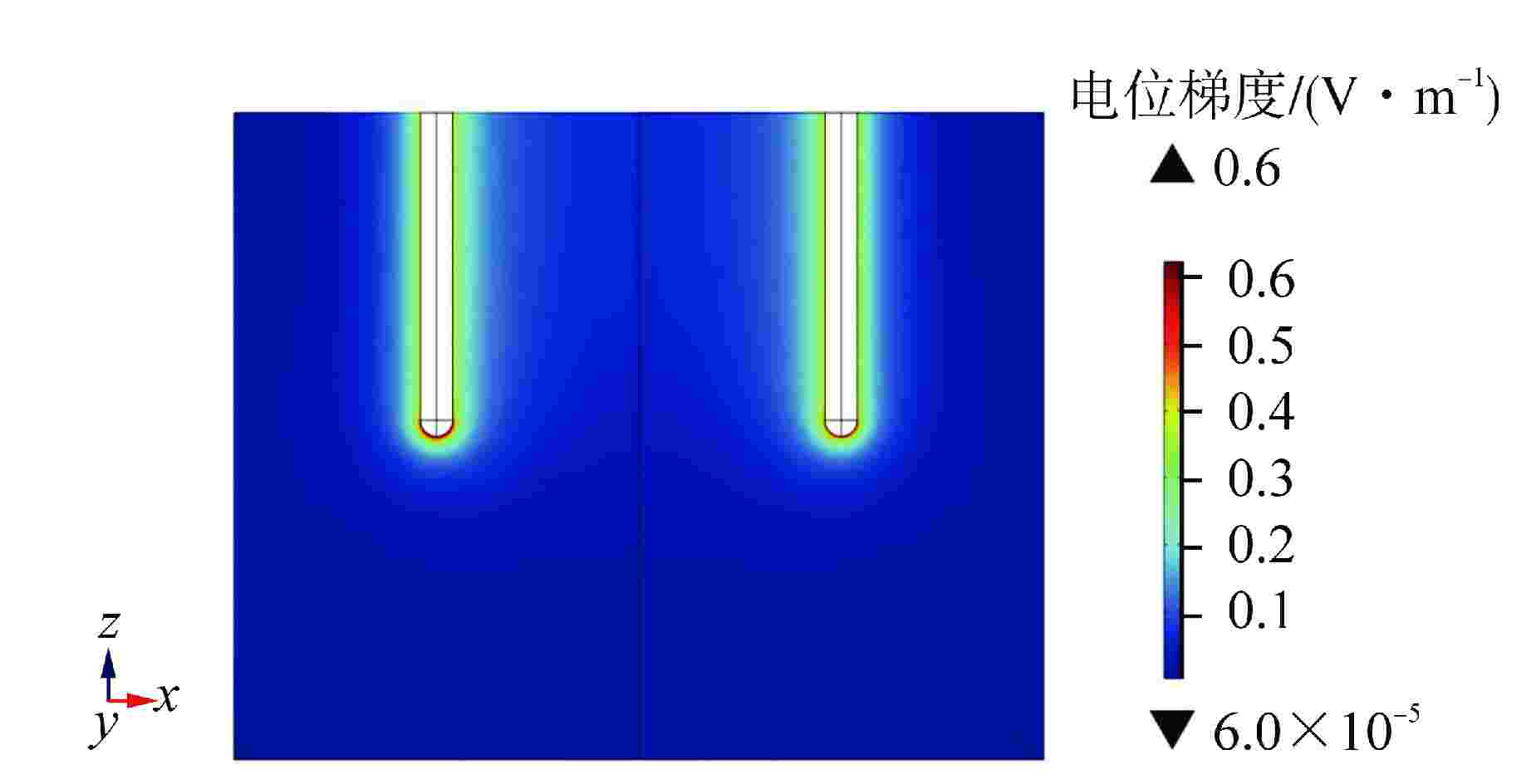

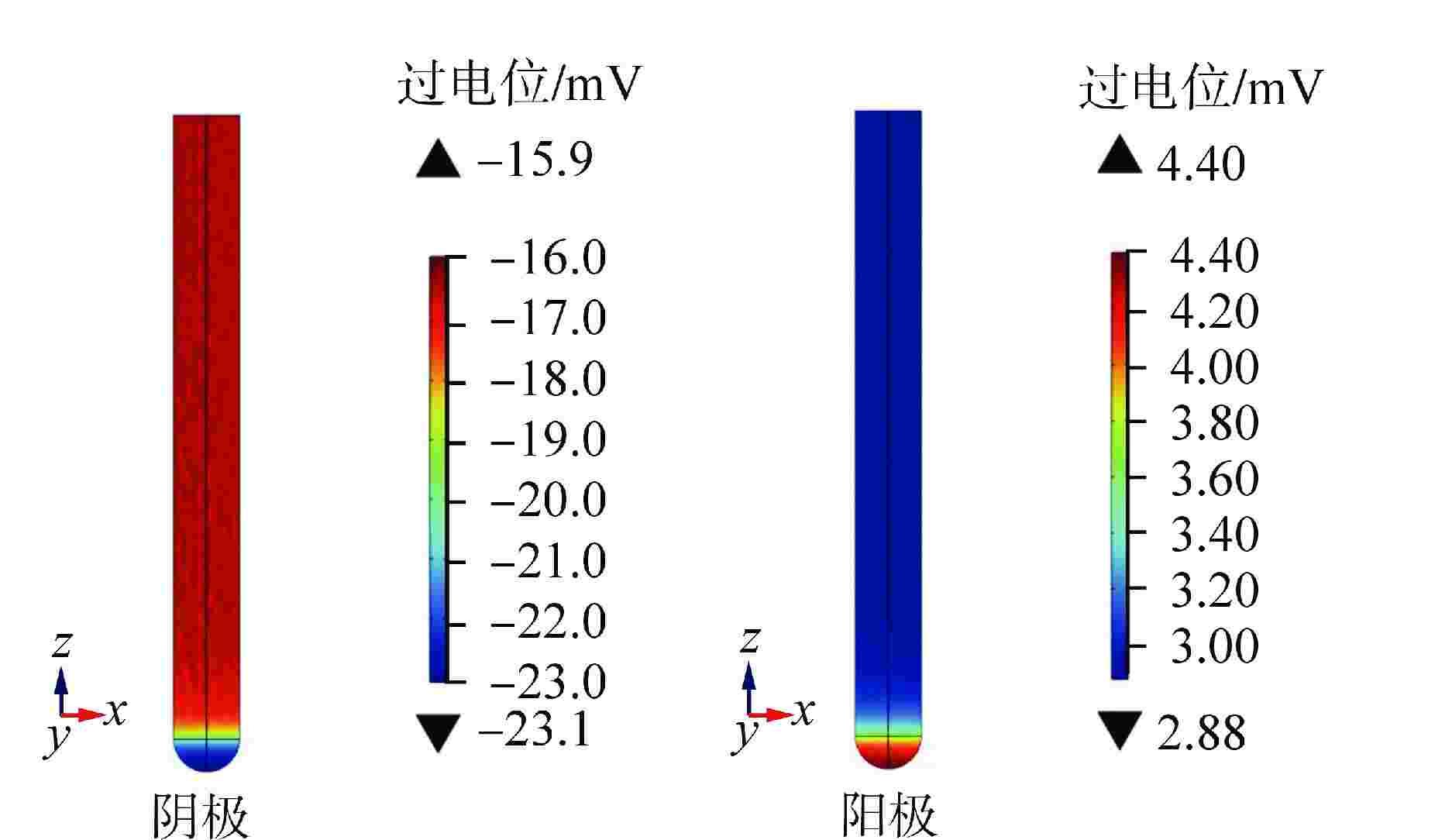

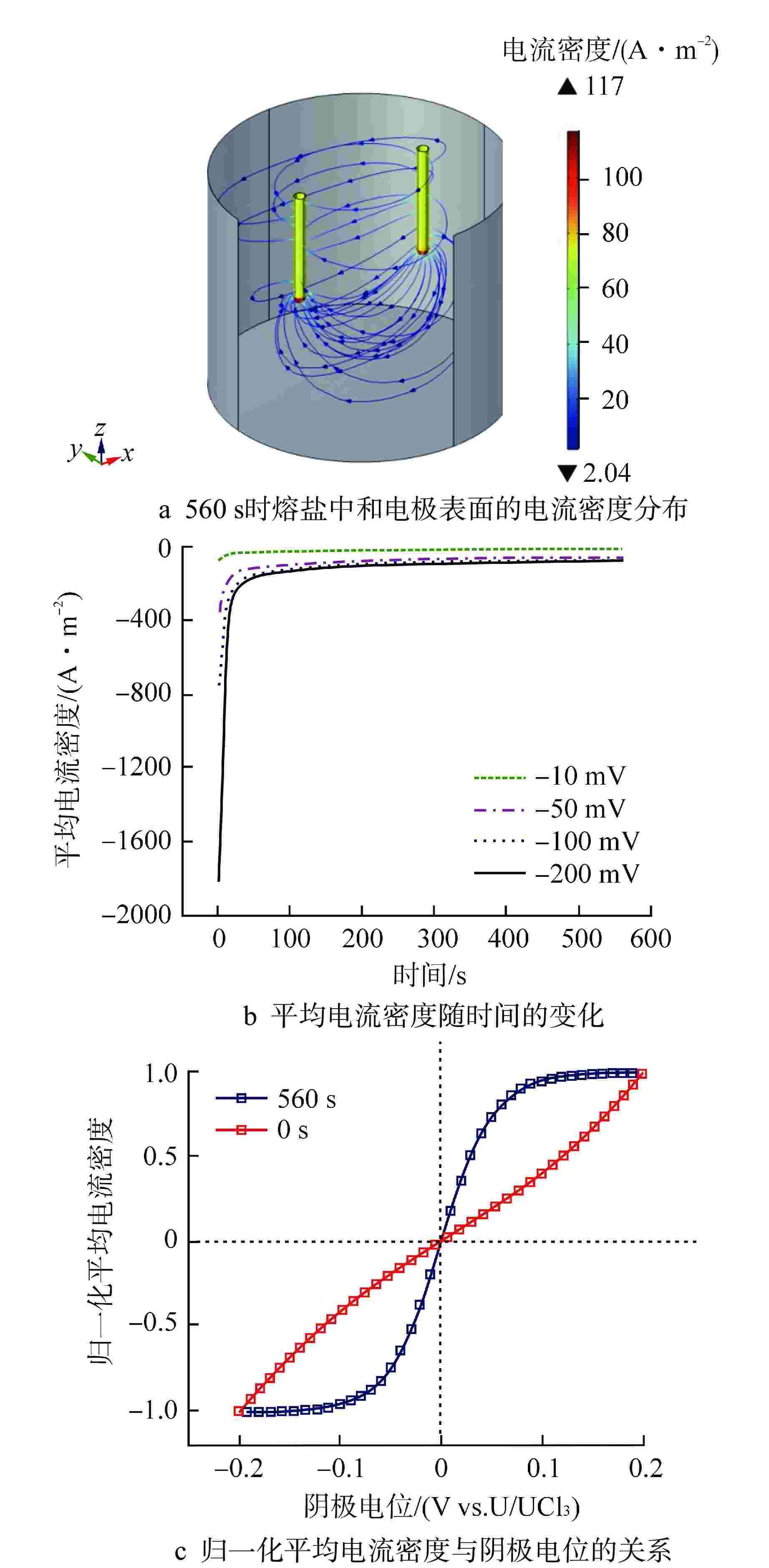

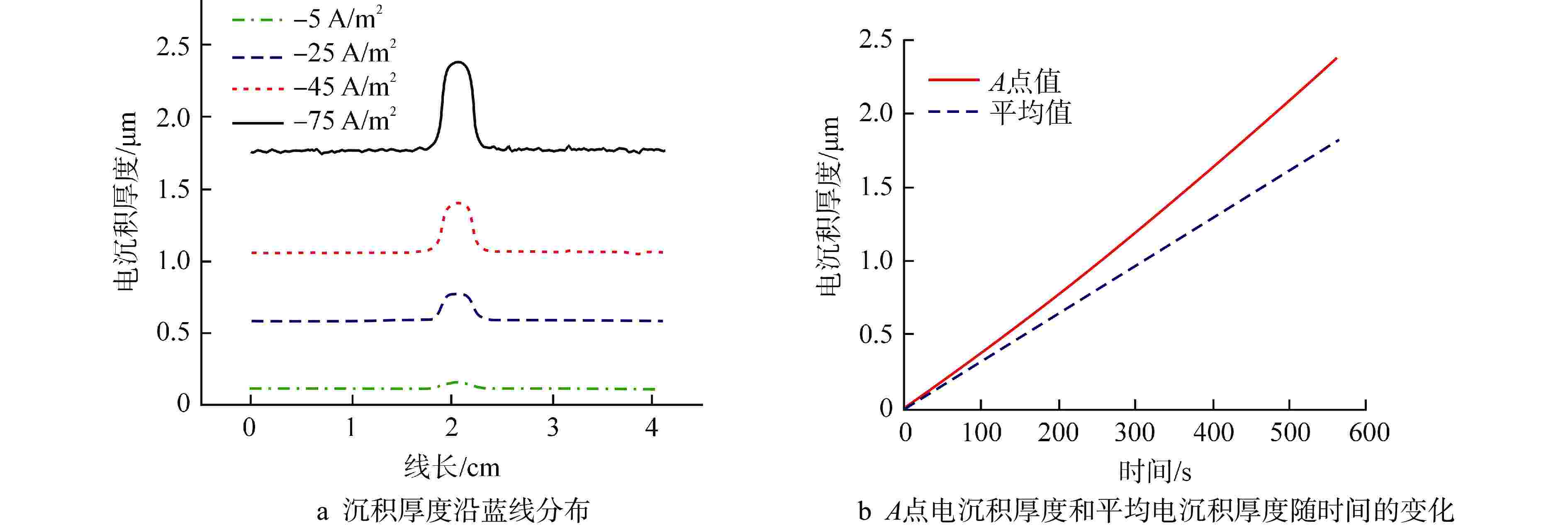

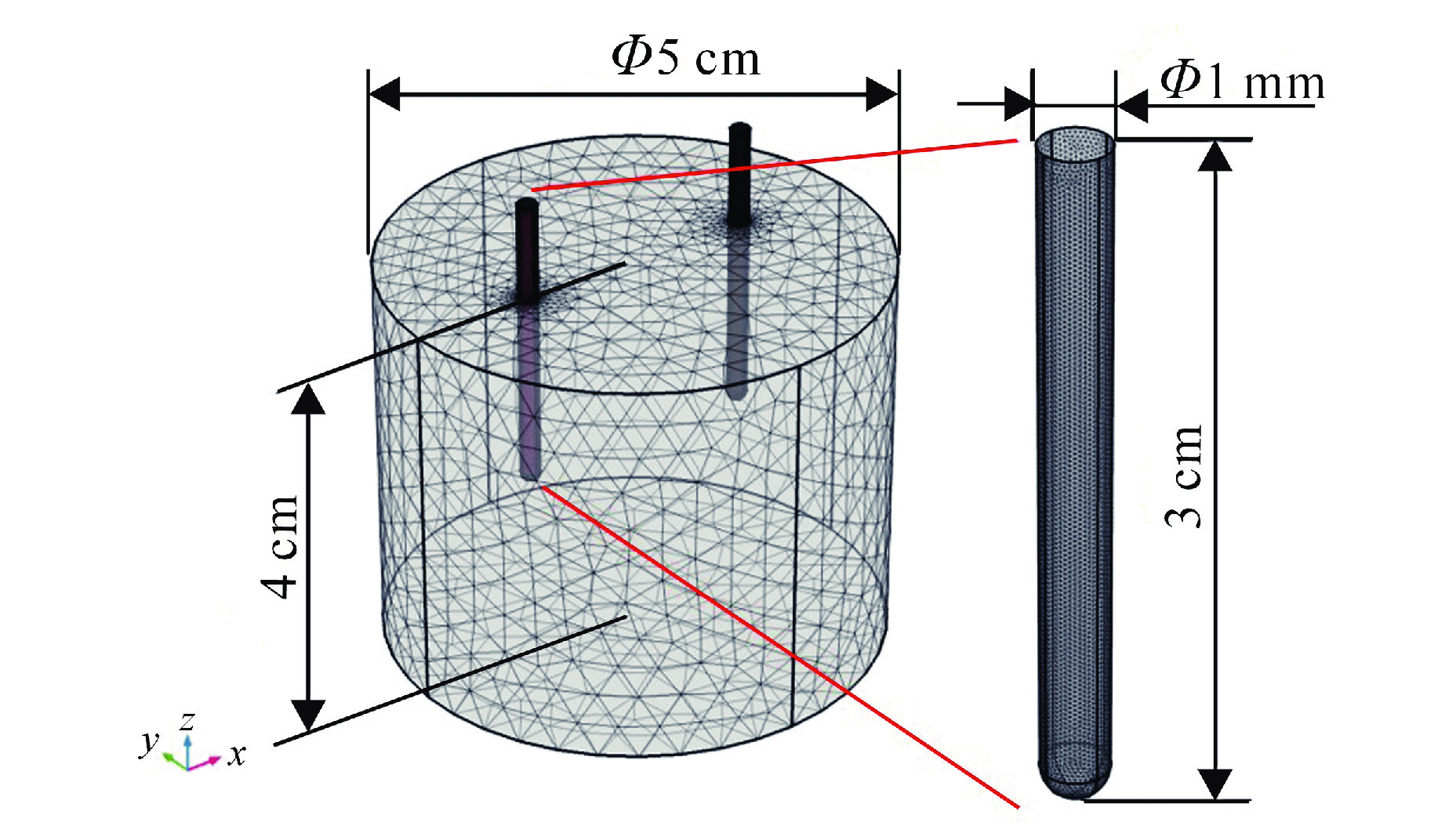

摘要: 通过Nernst方程将浓度与过电位相关联,构建了浓度依赖的Butler-Volmer电极动力学公式。基于支持电解质理论优化了传质方程和电位分布方程,改进了铀电解精炼模型。利用新模型分别模拟了循环伏安曲线、恒电位沉积过程和恒电流沉积过程,定量分析了不同电解条件下的浓差极化现象和电极动力学行为。模拟循环伏安曲线与实验结果吻合较好,验证了模型的准确性。通过模拟得到了U(III)浓度、电位和电流密度等在熔盐中和电极表面的分布,预测了扩散层厚度、极限扩散电流和沉积层厚度等关键参数,对比了恒电流沉积和恒电位沉积过程中浓差极化引起的驱动力变化。本研究建立的数值模型可作为优化工艺参数和设计工艺设备的有力工具,对深化理解铀电解精炼机理具有重要物理意义。Abstract: A concentration-dependent Butler-Volmer electrode kinetics equation was established by correlating concentration with the overpotential through the Nernst equation. The mass transfer equation and potential distribution equation were optimized based on the supporting electrolyte theory, and the uranium electrorefining model was improved. The cyclic voltammetry curve, constant potential deposition process and constant current deposition process were simulated by using the new model, and the concentration polarization phenomenon and electrode dynamic behavior under different electrolytic conditions were quantitatively analyzed. The simulated cyclic voltammetry curve is in good agreement with the experimental results, verifying the accuracy of the model. Through modeling, the distributions of U(III) concentration, potential, and current density in the molten salt and on the surface of electrode were obtained. The key parameters such as diffusion layer thickness, limiting diffusion current and deposition layer thickness were predicted, and the driving force changes caused by concentration polarization during constant current deposition and constant potential deposition were compared. The numerical model established in this study can be used as a powerful tool to optimize process parameters and design process equipment, and has important physical significance for deepening understanding of uranium electrorefining mechanism.

-

Key words:

- Uranium /

- Electrorefining /

- Concentration polarization /

- Electrode kineticss /

- Numerical simulation

-

表 1 控制方程边界条件

Table 1. Boundary Conditions of Control Equation

边界 恒电位法 恒电流法 阴极表面 $ -{\boldsymbol{n}}\cdot\boldsymbol{j}_i=\dfrac{i_{\mathrm{loc,c}}}{nF} $

$ \dfrac{\displaystyle\iint_{ }^{ }-{\boldsymbol{n}} \cdot\boldsymbol{i}\mathrm{_l}\mathrm{d}\mathrm{s}}{A}=i\mathrm{_{app\mathrm{ }}} $$ - {\boldsymbol{n}}\cdot\boldsymbol{j}_i=\dfrac{i_{\mathrm{loc,c}}}{nF} $

$\varphi_{\mathrm{s}}-\varphi_1=\varphi_{\mathrm{app}} $阳极表面 $ -{\boldsymbol{n}} \cdot\boldsymbol{j}_i=\dfrac{i_{\mathrm{loc,a}}}{nF} $

$ \displaystyle\iint_{ }^{ }- {\boldsymbol{n}} \cdot\boldsymbol{i}\mathrm{_{\mathrm{l}}}\mathrm{ds}=\displaystyle\iint_{ }^{ }-i\mathrm{_{loc,a}}\mathrm{d}\mathrm{s} $$ - {\boldsymbol{n}} \cdot\boldsymbol{j}_i=\dfrac{i\mathrm{_{\mathrm{loc,a}}}}{nF} $

$ \dfrac{\displaystyle\iint_{ }^{ }-\boldsymbol{n}\cdot\boldsymbol{i}\mathrm{_l}\mathrm{d}s}{A}=-i\mathrm{_{app_{ }}} $剩余边界 $ \quad- {\boldsymbol{n}} \cdot\boldsymbol{j}_i=0 $

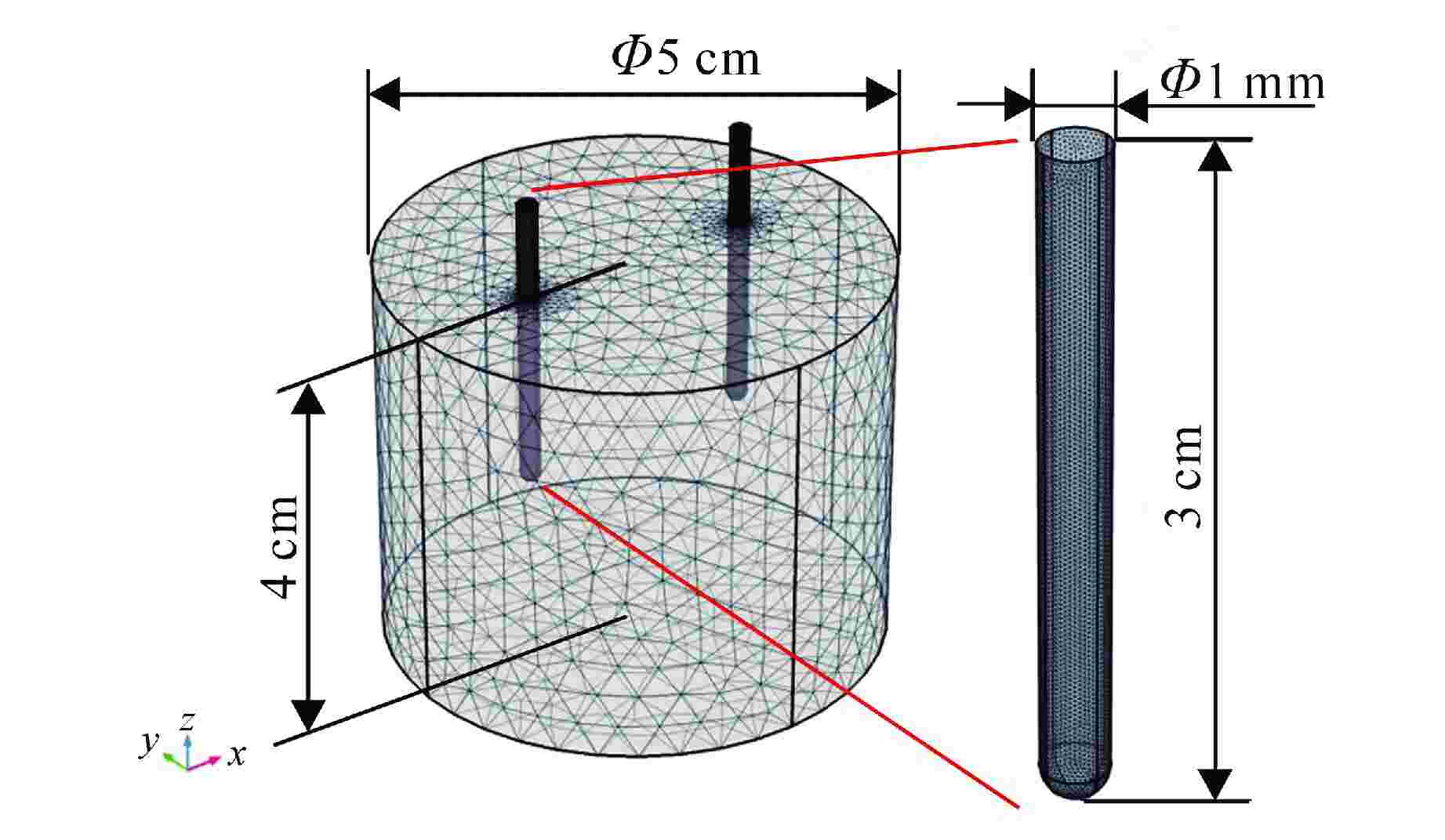

$ - {\boldsymbol{n}} \cdot\boldsymbol{i}\mathrm{_l}=0 $n—法向量;A—电极表面积,m2;iapp—外加电流密度,A/m2;φapp—外加电位,V;$ i\mathrm{_{loc,a}} $—阳极局部电流密度,A/m2;$ i\mathrm{_{loc,c}} $—阴极局部电流密度,A/m2 参数名 符号 参数值 阴极直径/mm rc 1 阳极直径/mm ra 1 阴极和阳极中心轴距离/m r0 0.025 系统温度/K T 773 U(III)初始浓度/(mol·m−3) c0 96 U(III)电荷数 z 3 铀金属密度/(kg·m−3) ρ 19100 铀原子摩尔质量/(kg·mol−1) M 0.238 阴极电荷传递系数 αc 0.5 阳极电荷传递系数 αa 0.5 交换电流密度/(A·m−2) i0 390 U(III)扩散系数/(m2·s−1) D 3.2×10−9 熔盐电导率/(S·m−1) σ 180 -

[1] KOYAMA T, IIZUKA M, SHOJI Y, et al. An experimental study of molten salt electrorefining of uranium using solid iron cathode and liquid cadmium cathode for development of pyrometallurgical reprocessing[J]. Journal of Nuclear Science and Technology, 1997, 34(4): 384-393. doi: 10.1080/18811248.1997.9733678 [2] 林如山,何辉,唐洪彬,等. 我国乏燃料干法后处理技术研究现状与发展[J]. 原子能科学技术,2020, 54(S1): 115-125. [3] NEA. Proceedings of the workshop on pyrochemical separations: Avignon, France 14-16 March 2000[M]. Paris: OECD, 2001: 3. [4] LEE J H, KANG Y H, HWANG S C, et al. Separation characteristics of a spent fuel surrogate in the molten salt electrorefining process[J]. Journal of Materials Processing Technology, 2007, 189(1-3): 268-272. doi: 10.1016/j.jmatprotec.2007.01.034 [5] SOUČEK P, MALMBECK R, MENDES E, et al. Exhaustive electrolysis for recovery of actinides from molten LiCl–KCl using solid aluminium cathodes[J]. Journal of Radioanalytical and Nuclear Chemistry, 2010, 286(3): 823-828. doi: 10.1007/s10967-010-0739-6 [6] LEE J H, KANG Y H, HWANG S C, et al. Application of graphite as a cathode material for electrorefining of uranium[J]. Nuclear Technology, 2008, 162(2): 135-143. doi: 10.13182/NT08-A3940 [7] LAIDLER J J, BATTLES J E, MILLER W E, et al. Development of pyroprocessing technology[J]. Progress in Nuclear Energy, 1997, 31(1-2): 131-140. doi: 10.1016/0149-1970(96)00007-8 [8] KIM G Y, YOON D, PAEK S, et al. A study on the electrochemical deposition behavior of uranium ion in a LiCl–KCl molten salt on solid and liquid electrode[J]. Journal of Electroanalytical Chemistry, 2012, 682: 128-135. doi: 10.1016/j.jelechem.2012.07.025 [9] LEE C H, KIM T J, PARK S, et al. Effect of cathode material on the electrorefining of U in LiCl-KCl molten salts[J]. Journal of Nuclear Materials, 2017, 488: 210-214. doi: 10.1016/j.jnucmat.2017.03.023 [10] LIU K, CHAI Z F, SHI W Q. Uranium dendritic morphology in the electrorefining: influences of temperature and current density[J]. Journal of The Electrochemical Society, 2018, 165(3): D98-D106. doi: 10.1149/2.0281803jes [11] ZHANG J S. Kinetic model for electrorefining, part I: Model development and validation[J]. Progress in Nuclear Energy, 2014, 70: 279-286. doi: 10.1016/j.pnucene.2013.03.001 [12] KIM S H, PARK S B, LEE S J, et al. Computer-assisted design and experimental validation of multielectrode electrorefiner for spent nuclear fuel treatment using a tertiary model[J]. Nuclear Engineering and Design, 2013, 257: 12-20. doi: 10.1016/j.nucengdes.2013.01.009 [13] CHOI S, PARK J, KIM K R, et al. Three-dimensional multispecies current density simulation of molten-salt electrorefining[J]. Journal of Alloys and Compounds, 2010, 503(1): 177-185. doi: 10.1016/j.jallcom.2010.04.228 [14] KIM K R, CHOI S Y, KIM J G, et al. Multi physics modeling of a molten-salt electrolytic process for nuclear waste treatment[J]. IOP Conference Series: Materials Science and Engineering, 2010, 9: 012002. [15] 张萌,王靖阳,孙兰昕,等. 乏燃料干法后处理中铀电沉积行为模拟研究[J]. 核动力工程,2019, 40(6): 72-76. [16] LIANG B, LI X S, ZHANG M, et al. A phase-field investigation of factors affecting the morphology of uranium dendrites during electrodeposition[J]. Electrochimica Acta, 2023, 465: 142958. doi: 10.1016/j.electacta.2023.142958 [17] ZHANG M, LIANG B, LUO J H, et al. A finite-element model for underpotential deposition of Ce(III) on an active aluminum electrode in LiCl–KCl melts[J]. Journal of The Electrochemical Society, 2022, 169(4): 042506. doi: 10.1149/1945-7111/ac6221 [18] SALYULEV A, POTAPOV A, KHOKHLOV V, et al. The electrical conductivity of model melts based on LiCl-KCl, used for the processing of spent nuclear fuel[J]. Electrochimica Acta, 2017, 257: 510-515. doi: 10.1016/j.electacta.2017.09.154 [19] LIU K, TAN T, ZHOU X P, et al. The dendrite growth, morphology control and deposition properties of uranium electrorefining[J]. Journal of Nuclear Materials, 2021, 555: 153110. doi: 10.1016/j.jnucmat.2021.153110 [20] LIN C, LIU K, RUAN H H, et al. Mechano-electrochemical phase field modeling for formation and modulation of dendritic Pattern: application to uranium recovery from spent nuclear fuel[J]. Materials & Design, 2022, 213: 110322. [21] YOON D, PHONGIKAROON S. Measurement and analysis of exchange current density for U/U3+ reaction in LiCl-KCl eutectic salt via various electrochemical techniques[J]. Electrochimica Acta, 2017, 227: 170-179. doi: 10.1016/j.electacta.2017.01.011 [22] MASSET P, BOTTOMLEY D, KONINGS R, et al. Electrochemistry of uranium in molten LiCl-KCl eutectic[J]. Journal of The Electrochemical Society, 2005, 152(6): A1109-A1115. doi: 10.1149/1.1901083 [23] CONOCAR O, DOUYERE N, GLATZ J P, et al. Promising pyrochemical actinide/lanthanide separation processes using aluminum[J]. Nuclear Science and Engineering, 2006, 153(3): 253-261. doi: 10.13182/NSE06-A2611 [24] ZHANG J S. Parametric studies of uranium deposition and dissolution at solid electrodes[J]. Journal of Applied Electrochemistry, 2014, 44(3): 383-390. doi: 10.1007/s10800-013-0650-2 [25] BARD A J, FUALKNER L R. Electrochemical methods fundamentals and applications[M]. America: John Wiley & Sons, Inc. , 2005: 114-116. [26] MARSHALL S L, REDEY L, VANDEGRIFT G F, et al. Electroformation of uranium hemispherical shells:ANL-89/26; ON: DE90004489[R]. Argonne: Argonne National Lab. (ANL), 1989. [27] RAPPLEYE D, SIMPSON M F. Application of the rotating cylinder electrode in molten LiCl-KCl eutectic containing uranium(III)- and magnesium(II)-chloride[J]. Journal of Nuclear Materials, 2017, 487: 362-372. doi: 10.1016/j.jnucmat.2017.02.037 -

下载:

下载: