Study on Prediction and Diagnosis of Fuel Rod Break Size during Degassing Operation of PWR

-

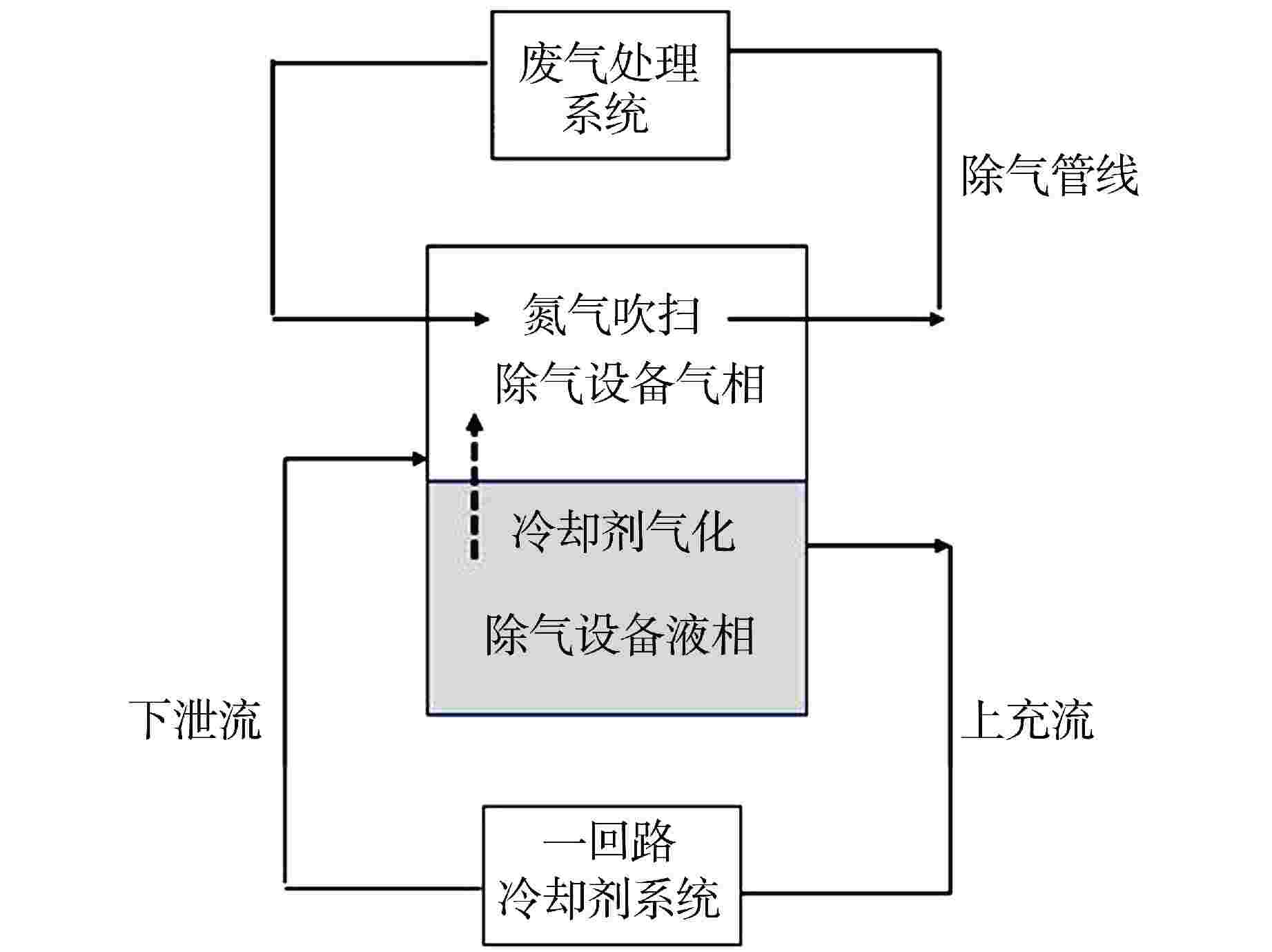

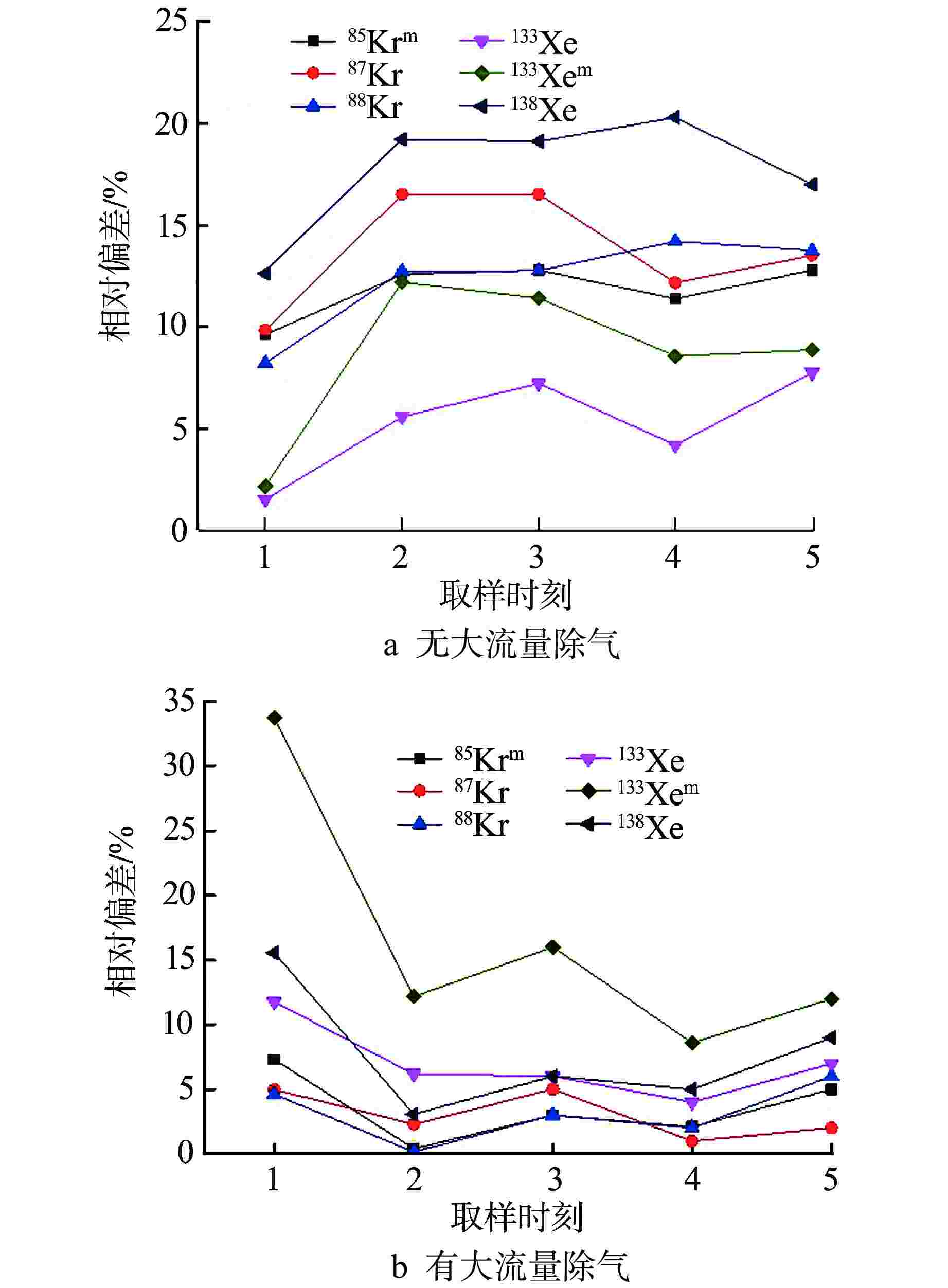

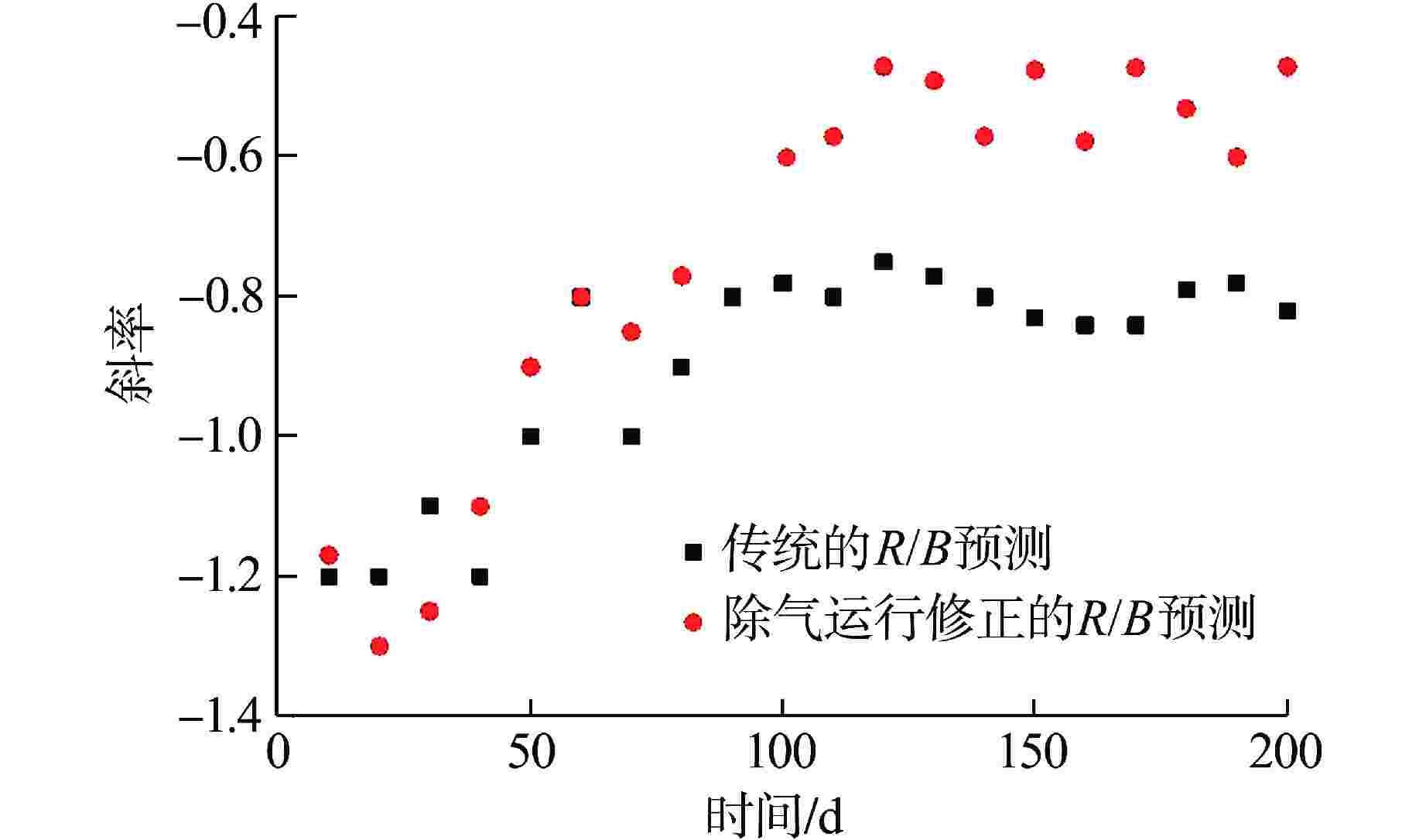

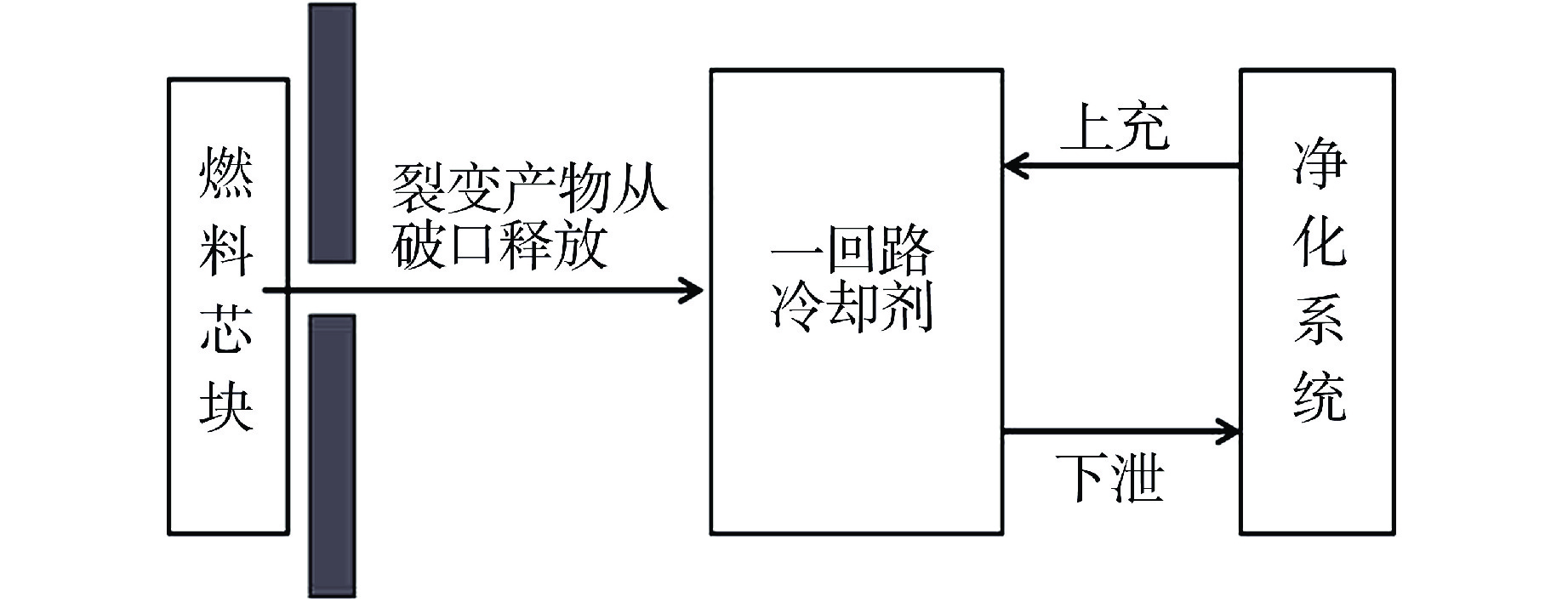

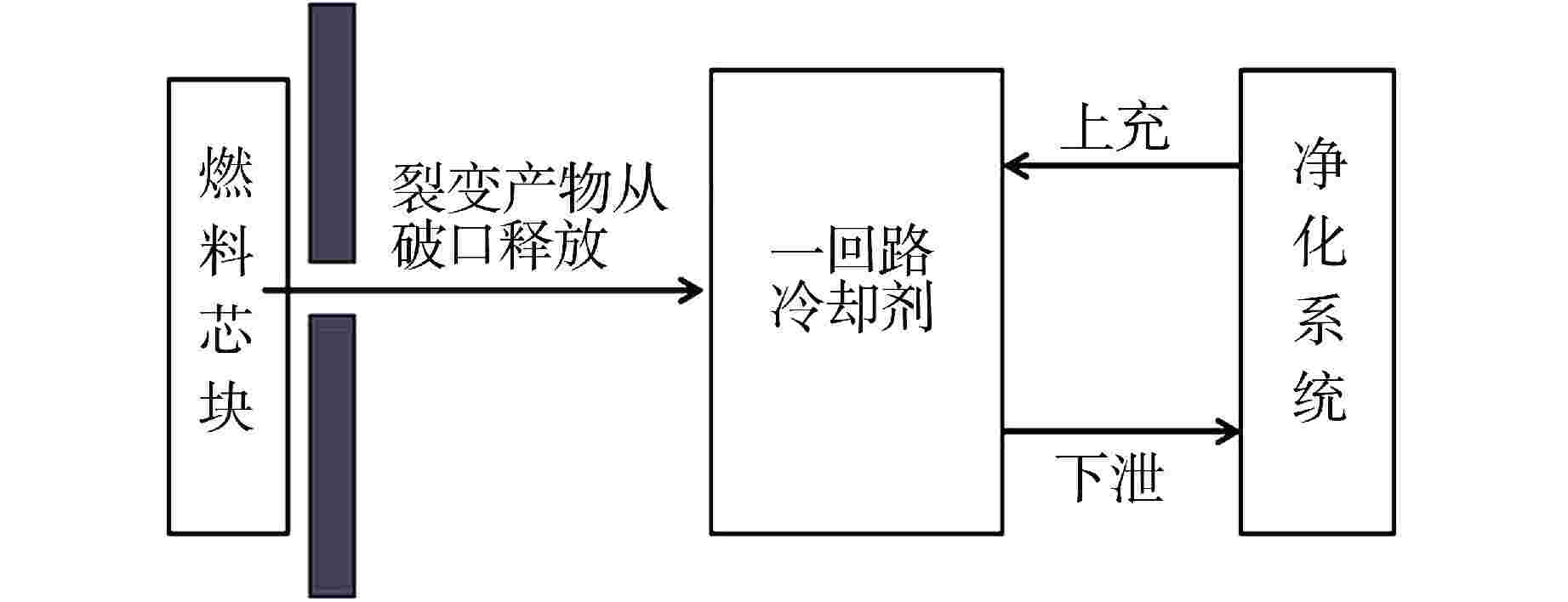

摘要: 压水堆核电厂运行数据表明,机组实施大流量除气运行后,一回路冷却剂裂变产物比活度在短时间内发生剧烈的震荡,使得基于堆芯平均状态裂变释放产生比(R/B)的燃料破损预测方法存在预测偏差。本文基于压水堆核电厂除气系统参数和惰性气体释放机理,建立除气运行修正的惰性气体释放预测分析模型,给出了除气条件下的除气因子和惰性气体释放率的计算方法,优化了基于R/B的燃料棒破口尺寸传统预测方法。该除气运行修正预测方法在某压水堆核电厂中进行了应用与验证,预测得到的6种常见惰性气体核素比活度最大相对偏差为33.4%,其余均不超过20%;预测得到燃料棒破口尺寸为大破口,该结果与停堆后的检查结果相符。Abstract: The operation data of PWR nuclear power plant show that after the unit implements large flow degassing operation, the specific activity of fission products of primary coolant oscillates violently in a short time, which makes the fuel damage prediction method based on the average core state fission release-to-birth ratio (R/B) have prediction bias. Based on the parameters of degassing system and the mechanism of inert gas release in PWR nuclear power plant, this paper establishes a modified prediction and analysis model of inert gas release in degassing operation, gives the calculation method of degassing factor and inert gas release rate under degassing conditions, and optimizes the traditional prediction method of fuel rod break size based on R/B. The modified prediction method of degassing operation has been applied and verified in a PWR nuclear power plant. The maximum relative deviation of specific activities of six common inert gas nuclides predicted is 33.4%, and the others are less than 20%. The predicted fuel rod break size is large, which is consistent with the inspection results after shutdown.

-

Key words:

- Fuel rod failure /

- Degassing operation /

- Fission product activity /

- PWR

-

-

[1] International Atomic Energy Agency. Fuel failure in water reactors: causes and mitigation: IAEA-TECDOC-1345[R]. Vienna: IAEA, 2003. [2] International Atomic Energy Agency. Review of fuel failures in water cooled reactors: No. NF-T-2.5[R]. Vienna: IAEA, 2010. [3] International Atomic Energy Agency. Fuel failure in normal operation of water reactors: experience, causes and mitigation: IAEA-TECDOC-2004[R]. Vienna: IAEA, 2022. [4] LEWIS B J, CHAN P K, EL-JABY A, et al. Fission product release modelling for application of fuel-failure monitoring and detection-an overview[J]. Journal of Nuclear Materials, 2017, 489: 64-83. doi: 10.1016/j.jnucmat.2017.03.037 [5] EL-JABY A, LEWIS B J, THOMPSON W T, et al. A general model for predicting coolant activity behaviour for fuel-failure monitoring analysis[J]. Journal of Nuclear Materials, 2010, 399(1): 87-100. doi: 10.1016/j.jnucmat.2010.01.006 [6] FU P T, LIANG S, LU S B, et al. Relationship between fuel reliability and I-131/I-133 in the primary coolant of CPR1000 PWRs[J]. Frontiers in Energy Research, 2022, 10: 860480. doi: 10.3389/fenrg.2022.860480 [7] 李兰,杨洪润. 压水堆核电厂燃料元件破损诊断方法[J]. 核动力工程,2008, 29(4): 135-139. [8] MENENDEZ M A T. Fuel failure detection, characterization and modelling: effect on radionuclide behaviour in PWR primary coolant[D]. Essonne: Université de Paris-Sud, 2009. [9] KLEVINSKAS G, JUODIS L, PLUKIENĖ R, et al. Analysis of iodine release from the defective fuel elements of the RBMK-1500 reactor[J]. Lithuanian Journal of Physics, 2007, 47(2): 211-219. doi: 10.3952/lithjphys.47208 [10] 肖维,尹楚轩,李宏轩,等. 基于人工神经网络的压水堆燃料破损状态监测[J]. 原子能科学技术,2020, 54(3): 481-487. doi: 10.7538/yzk.2019.youxian.0258 [11] BOOTH A H. A method of calculating fission gas diffusion from UO2 fuel and its application to the X-2-f loop test[Z]. Chalk River Project: Atomic Energy of Canada Ltd, 1957. [12] CHUN M H, TAK N I, LEE S K. Development of a computer code to estimate the fuel rod failure using primary coolant activities of operating PWRS[J]. Annals of Nuclear Energy, 1998, 25(10): 753-763. doi: 10.1016/S0306-4549(97)00126-6 [13] LEWIS B J. Fission product release from nuclear fuel by recoil and knockout[J]. Journal of Nuclear Materials, 1987, 148(1): 28-42. doi: 10.1016/0022-3115(87)90515-0 -

下载:

下载: