Study on Thermal Conductivity of Accident Tolerant Fuels using Laser-based Thermoreflectance Technology

-

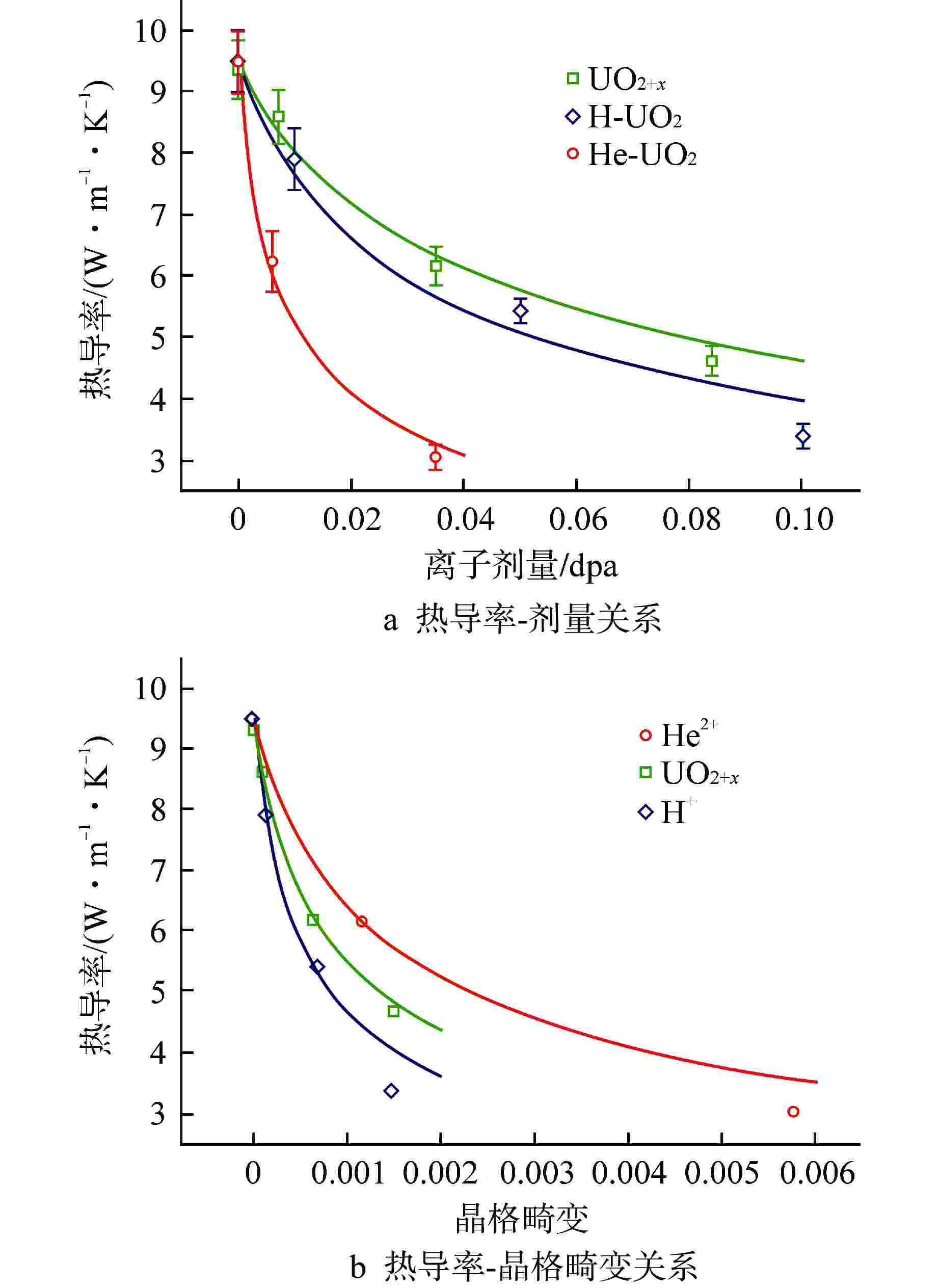

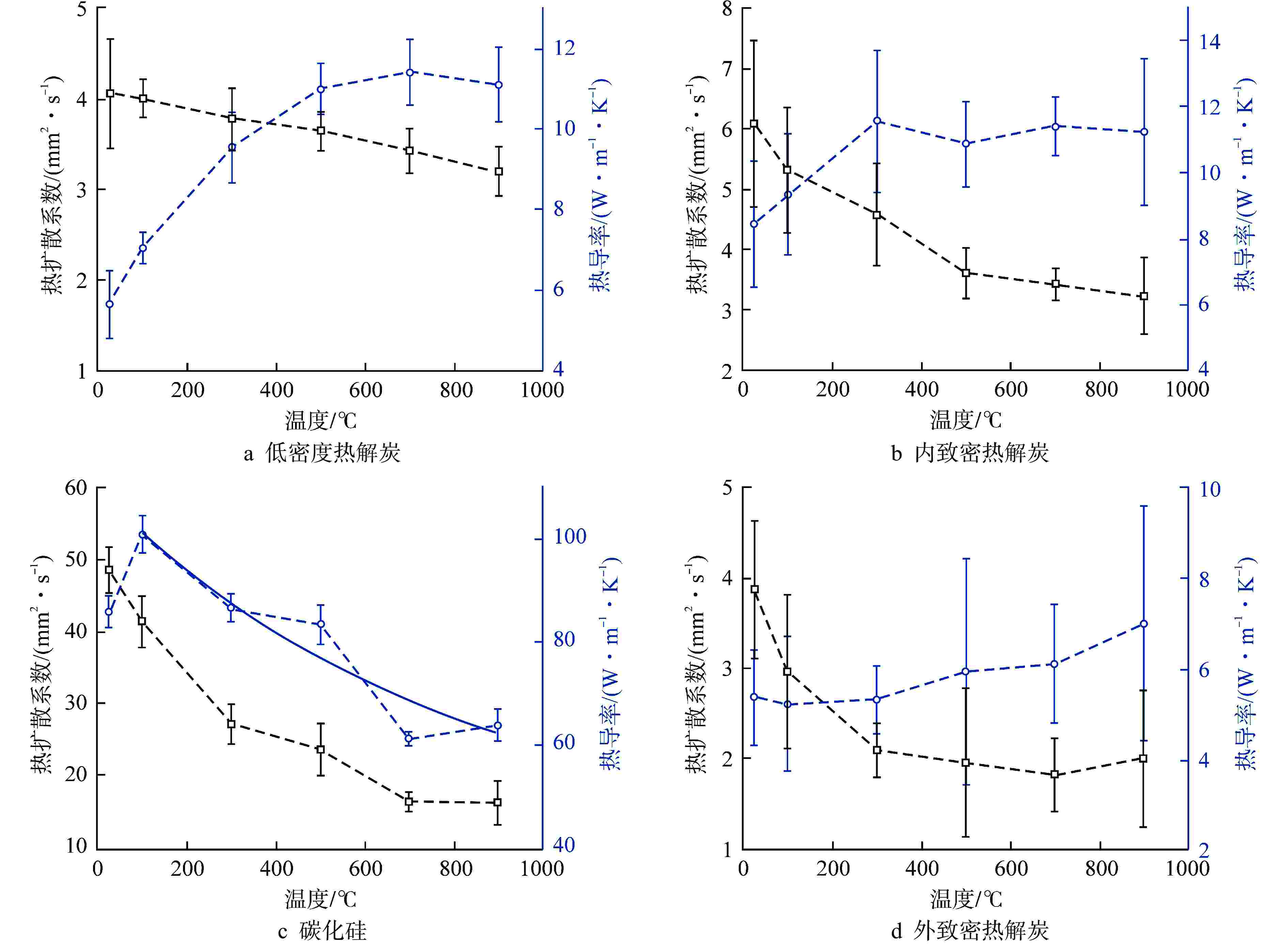

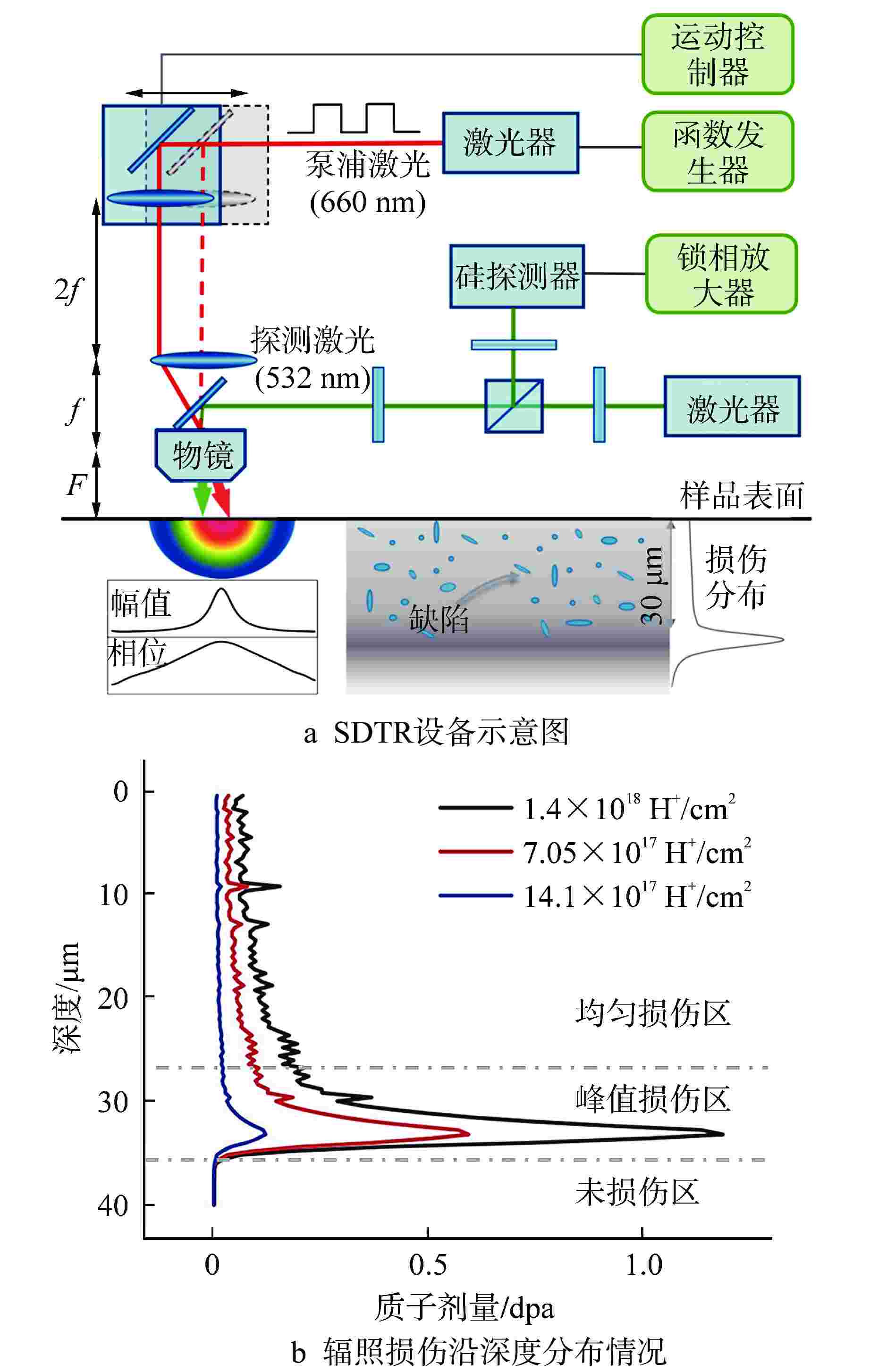

摘要: 为改善新型耐事故核燃料的导热性能,提高导热性能测试方法的检测效率和测试精度,本文介绍了具有高空间分辨率和高测试频率的光热反射技术,阐述了此类技术的基本原理、实验装置和测试方法,重点介绍了针对核燃料研究所发展的空间域光热反射技术。以离子辐照样品和包覆核燃料涂层为例,介绍了空间域光热反射技术在原位测试领域的应用场景。针对离子辐照样品的不均匀损伤分布,开发了多层传热模型用于更准确地表征材料导热性质,采用该技术获得了UO2燃料热导率随着离子注入剂量的定量衰减规律;准确表征了包覆核燃料微球各涂层在高温下的热输运性质,结合微结构研究揭示了缺陷相对于热解炭涂层热导率的影响。光热反射技术为探究辐照损伤和结构缺陷对于核燃料热量传输的作用机制提供了有力工具,为进一步改进燃料性能、开发高精度的燃料仿真模型提供了参考依据。Abstract: In order to improve the thermal conductivity of new accident tolerant nuclear fuel and improve the detection efficiency and accuracy of thermal conductivity testing methods, this paper introduces the laser-based thermoreflectance technology with high spatial resolution and high testing frequency, expounds the basic principle, experimental equipment and testing method of this technology, and emphatically introduces the space-domain thermoreflectance technology developed for nuclear fuel research. Taking ion irradiated samples and coated nuclear fuel coatings as examples, the application scenarios of space-domain thermoreflectance technology in the field of in-situ testing are introduced. Aiming at the inhomogeneous damage distribution of ion irradiated samples, a multi-layer heat transfer model was developed to characterize the thermal conductivity of materials more accurately, and the quantitative attenuation law of thermal conductivity of UO2 fuel with ion implantation dose was obtained by using this method. The heat transport properties of coatings in microencapsulated nuclear fuel particles at high temperature were accurately characterized, and the influence of defects on the thermal conductivity of pyrolytic carbon coatings was revealed by combining microstructure research. The thermoreflectance technology provides a powerful tool for investigating the impact of irradiation damage and structural defects on the thermal transport in nuclear fuel, and provides a reference for further improving fuel performance and developing high-fidelity simulation codes.

-

图 2 采用SDTR技术测量质子和氦离子辐照后UO2燃料的导热性能[20]

Figure 2. Employing SDTR to Obtain Thermal Conductivity of UO2 under Proton and Helium Ion Irradiation

图 3 TRISO燃料颗粒各涂层热导率和热扩散系数随温度的变化[24]

Figure 3. Changes of Thermal Conductivity and Thermal Diffusion Coefficient of Coatings on TRISO Fuel Particles with Temperature

-

[1] MALA M, MIKLOS M. Nondestructive testing of nuclear reactor components integrity[C]//Proceedings of International Conference on WWER Fuel Performance, Modelling and Experimental Support. Bulgaria: Helena Resort, 2011. [2] ZINKLE S J, TERRANI K A, GEHIN J C, et al. Accident tolerant fuels for LWRs: a perspective[J]. Journal of Nuclear Materials, 2014, 448(1-3): 374-379. doi: 10.1016/j.jnucmat.2013.12.005 [3] 焦拥军,于俊崇,周毅,等. 商用压水堆核燃料研发进展与应用展望[J]. 核动力工程,2022, 43(6): 1-7. [4] ZHOU W, ZHOU W Z. Enhanced thermal conductivity accident tolerant fuels for improved reactor safety – a comprehensive review[J]. Annals of Nuclear Energy, 2018, 119: 66-86. doi: 10.1016/j.anucene.2018.04.040 [5] 程亮,张鹏程. 事故容错热导率增强型UO2核燃料的研究进展[J]. 材料导报,2019, 33(11): 1787-1792. doi: 10.11896/cldb.18050107 [6] WHITE J T, TRAVIS A W, DUNWOODY J T, et al. Fabrication and thermophysical property characterization of UN/U3Si2 composite fuel forms[J]. Journal of Nuclear Materials, 2017, 495: 463-474. doi: 10.1016/j.jnucmat.2017.08.041 [7] 陆永洪,贾代坤,粟丹科,等. 真空烧结U3Si2燃料芯块的微观组织与导热性能[J]. 粉末冶金材料科学与工程,2022, 27(4): 436-441. [8] KREJČÍ J, KABÁTOVÁ J, MANOCH F, et al. Deve lopment and testing of multicomponent fuel cladding with enhanced accidental performance[J]. Nuclear Engineering and Technology, 2020, 52(3): 597-609. doi: 10.1016/j.net.2019.08.015 [9] MARUYAMA T, HARAYAMA M. Neutron irradiation effect on the thermal conductivity and dimensional change of graphite materials[J]. Journal of Nuclear Materials, 1992, 195(1-2): 44-50. doi: 10.1016/0022-3115(92)90362-O [10] KHAFIZOV M, CHAUHAN V, WANG Y, et al. Investigation of thermal transport in composites and ion beam irradiated materials for nuclear energy applications[J]. Journal of Materials Research, 2017, 32(1): 204-216. doi: 10.1557/jmr.2016.421 [11] PAVLOV T R, MIDDLEMAS S C, MILLER B D, et al. Understanding the local thermal conductivity evolution of neutron irradiated U3Si2 dispersion fuel via state-of-the-art thermo-reflectance measurements[J]. Journal of Nuclear Materials, 2021, 557: 153280. doi: 10.1016/j.jnucmat.2021.153280 [12] FAVALORO T, BAHK J H, SHAKOURI A. Characterization of the temperature dependence of the thermoreflectance coefficient for conductive thin films[J]. Review of Scientific Instruments, 2015, 86(2): 024903. doi: 10.1063/1.4907354 [13] HURLEY D H, SCHLEY R S, KHAFIZOV M, et al. Local measurement of thermal conductivity and diffusivity[J]. Review of Scientific Instruments, 2015, 86(12): 123901. doi: 10.1063/1.4936213 [14] WANG Y Z, CHAUHAN V, HUA Z L, et al. A square pulse thermoreflectance technique for the measurement of thermal properties[J]. International Journal of Thermophysics, 2022, 43(4): 53. doi: 10.1007/s10765-021-02949-z [15] ZHAO D L, QIAN X, GU X K, et al. Measurement techniques for thermal conductivity and interfacial thermal conductance of bulk and thin film materials[J]. Journal of Electronic Packaging, 2016, 138(4): 040802. doi: 10.1115/1.4034605 [16] RIYAD M F, CHAUHAN V, KHAFIZOV M. Implementation of a multilayer model for measurement of thermal conductivity in ion beam irradiated samples using a modulated thermoreflectance approach[J]. Journal of Nuclear Materials, 2018, 509: 134-144. doi: 10.1016/j.jnucmat.2018.06.013 [17] SCHMIDT A J, CHEAITO R, CHIESA M. A frequency-domain thermoreflectance method for the characterization of thermal properties[J]. Review of Scientific Instruments, 2009, 80(9): 094901. doi: 10.1063/1.3212673 [18] CAHILL D G. Analysis of heat flow in layered structures for time-domain thermoreflectance[J]. Review of Scientific Instruments, 2004, 75(12): 5119-5122. doi: 10.1063/1.1819431 [19] RONCHI C, SHEINDLIN M, STAICU D, et al. Effect of burn-up on the thermal conductivity of uranium dioxide up to 100.000 MWdt−1[J]. Journal of Nuclear Materials, 2004, 327(1): 58-76. doi: 10.1016/j.jnucmat.2004.01.018 [20] KHAFIZOV M, RIYAD M F, WANG Y Z, et al. Combining mesoscale thermal transport and x-ray diffraction measurements to characterize early-stage evolution of irradiation-induced defects in ceramics[J]. Acta Materialia, 2020, 193: 61-70. doi: 10.1016/j.actamat.2020.04.018 [21] GÜNAY S D. Swelling mechanisms of UO2 lattices with defect ingrowths[J]. PLoS One, 2015, 10(8): e0134500. doi: 10.1371/journal.pone.0134500 [22] LIU X Y, COOPER M W D, MCCLELLAN K J, et al. Molecular dynamics simulation of thermal transport in UO2 containing uranium, oxygen, and fission-product defects[J]. Physical Review Applied, 2016, 6(4): 044015. doi: 10.1103/PhysRevApplied.6.044015 [23] POWERS J J, WIRTH B D. A review of TRISO fuel performance models[J]. Journal of Nuclear Materials, 2010, 405(1): 74-82. doi: 10.1016/j.jnucmat.2010.07.030 [24] WANG Y Z, HUA Z H, SCHLEY R, et al. Thermal properties measurement of TRISO particle coatings from room temperature to 900 ℃ using laser-based thermoreflectance methods[J]. Journal of Nuclear Materials, 2022, 565: 153721. doi: 10.1016/j.jnucmat.2022.153721 [25] PAVLOV T R, LESTAK M, WENMAN M R, et al. Examining the thermal properties of unirradiated nuclear grade graphite between 750 and 2500 K[J]. Journal of Nuclear Materials, 2020, 538: 152176. doi: 10.1016/j.jnucmat.2020.152176 [26] LÓPEZ-HONORATO E, CHIRITESCU C, XIAO P, et al. Thermal conductivity mapping of pyrolytic carbon and silicon carbide coatings on simulated fuel particles by time-domain thermoreflectance[J]. Journal of Nuclear Materials, 2008, 378(1): 35-39. doi: 10.1016/j.jnucmat.2008.04.007 [27] SNEAD L L, NOZAWA T, KATOH Y, et al. Handbook of SiC properties for fuel performance modeling[J]. Journal of Nuclear Materials, 2007, 371(1-3): 329-377. doi: 10.1016/j.jnucmat.2007.05.016 [28] BALANDIN A A. Thermal properties of graphene and nanostructured carbon materials[J]. Nature Materials, 2011, 10(8): 569-581. doi: 10.1038/nmat3064 [29] LÓPEZ-HONORATO E, MEADOWS P J, XIAO P. Fluidized bed chemical vapor deposition of pyrolytic carbon–I. Effect of deposition conditions on microstructure[J]. Carbon, 2009, 47(2): 396-410. doi: 10.1016/j.carbon.2008.10.023 [30] 张建辉,夏文莉. 沉积条件对低温各向同性热解炭微观结构的影响[J]. 中国有色金属学报,2015, 25(1): 165-170. -

下载:

下载: