Preparation and Performance Evaluation of Fuel Elements for Ultra-high Temperature Gas-cooled Reactors

-

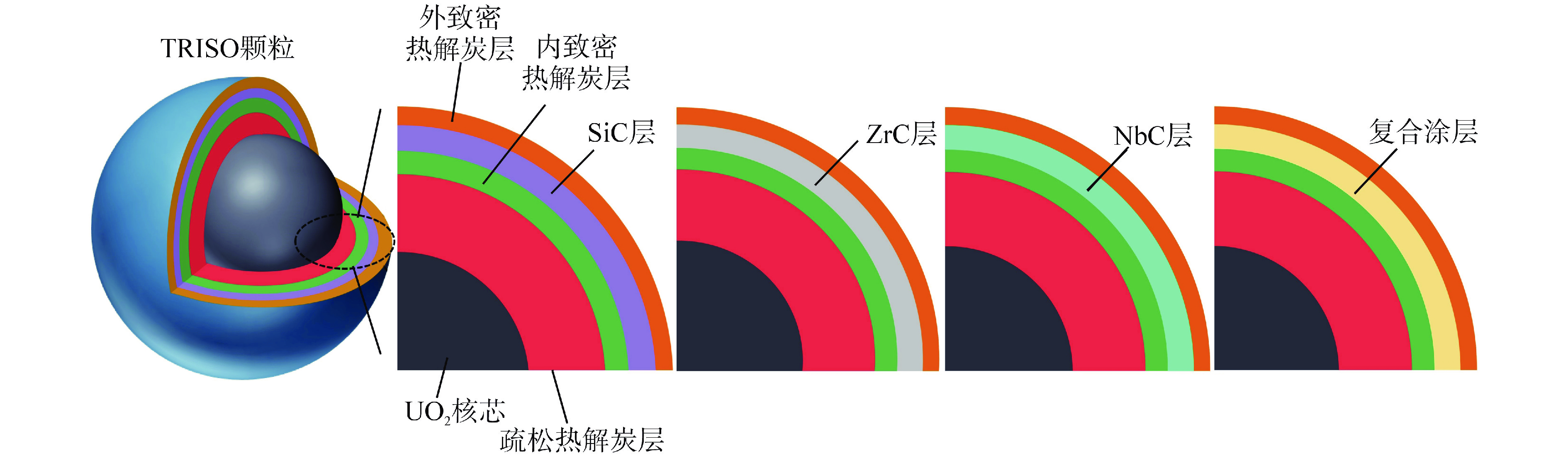

摘要: 针对未来超高温气冷堆的研发要求,开展了相关燃料元件的设计、新型包覆层制备、三层各向同性(TRISO)颗粒辐照前高温考验以及辐照后高温考验等多个方面的工作。具体包括对SiC包覆层、ZrC包覆层、NbC包覆层、碳化物复合包覆层的流化床-化学气相沉积制备方法进行了研究,并对SiC包覆层进行了辐照前超高温考验(最高达2500℃)和辐照后高温考验(最高达1770℃)研究。研究结果表明,采用流化床-化学气相沉积方法,分别以液体CH3SiCl3、固体ZrCl4、NbCl5为前驱体,采用气相载带输运,气体粉末输运等方法可以制备出单一物相的SiC包覆层、ZrC包覆层、NbC包覆层以及碳化物复合涂层,其中SiC包覆层的规模化制备已经成功实现。辐照前的高温考验发现TRISO颗粒的SiC包覆层可以承受短时2200℃的高温。在2100℃以上,发生了部分相变、晶粒长大和微量分解现象,整体包覆层仍然保持较为完整的结构。辐照后的1770℃高温考验表明,高温会加速Cs等裂变元素在TRISO颗粒内致密热解炭层中的扩散,没有发现SiC包覆层破损,即阻挡裂变产物的能力继续维持,同时采用分子模拟等手段对高温考验和辐照后的各种微观结构以及混合晶型的SiC包覆材料进行了数值模拟。以上研究结果为我国超高温气冷堆燃料元件的研发和性能评价提供了参考,对未来超高温气冷堆的发展具有重要意义。Abstract: According to the research and development requirements of future ultra-high temperature gas cooled reactors, the design of relevant fuel elements, preparation of new coating layers, high-temperature testing and evaluation of TRISO particles before and after irradiation have been carried out. Specifically, the preparation methods of fluidized bed chemical vapor deposition for SiC coating layers, ZrC coating layers, NbC coating layers, and carbide composite coating layers are studied. And the SiC coating layer was used in the ultra-high temperature testing, including pre irradiation (up to 2500℃) and post irradiation (up to 1770℃). The research results indicate that single-phase SiC coating, ZrC coating, NbC coating, and carbide composite coating can be prepared using fluidized bed chemical vapor deposition method with liquid methyltrichlorosilane, solid ZrCl4, and NbCl5 as precursors. The gas phase carrier transportation and gas powder transportation methods are developed. The large-scale preparation of SiC coating has been successfully obtained. It was found that the SiC coating layer of TRISO particles could withstand the high temperature of 2200℃ for a short time in the high-temperature test before irradiation. At temperatures above 2100℃, partial phase transformation, grain growth, and micro decomposition could be found, but the overall coating layer remained relatively intact. The high temperature test at 1770℃ after irradiation showed that high temperatures would accelerate the diffusion of some fission elements such as Cs in the dense pyrolysis carbon layer of TRISO particles. And no damage was found in the SiC coating layer, indicating that the ability to block fission products continued to be maintained. Besides, molecular simulations were used to simulate various microstructures and mixed crystal SiC coating materials after high-temperature testing and irradiation. The above research results provide reference for the research and development and performance evaluation of fuel elements in ultra-high temperature gas-cooled reactors in China, and are of great significance to the future development of ultra-high temperature gas-cooled reactors.

-

图 3 流化床-化学气相沉积方法制备ZrC包覆层的机理解释[6]

Figure 3. Mechanism of Preparing ZrC Coating Layer by Fluidized Bed Chemical Vapor Deposition Method

图 4 流化床-化学气相沉积方法制备NbC包覆层的2种途径[7]

Figure 4. Two Approaches for Preparing NbC Coating Layer by Fluidized Bed Chemical Vapor Deposition Method

图 5 新型A-TRISO包覆颗粒设计图与样品图[8]

Figure 5. Design and Sample of New A-TRISO Coated Particle

图 6 辐照后并高温考验后的TRISO包覆燃料颗粒的典型扫描电子显微镜(SEM)照片及裂变产物分布[10]

Figure 6. Typical SEM Images and Fission Product Distribution of TRISO Coated Fuel Particles after Irradiation and High-Temperature Testing

图 7 SiC包覆层典型晶型和辐照过程引起SiC非晶化以及力学行为变化[11]

Figure 7. Typical Crystal Structure of SiC Coating Layer and Changes in SiC Amorphization and Mechanical Behavior Caused by Irradiation Process

-

[1] LIU M L, WEN Y Y, LIU R Z, et al. Investigation of fluidization behavior of high density particle in spouted bed using CFD-DEM coupling method[J]. Powder Technology, 2015, 280: 72-82. doi: 10.1016/j.powtec.2015.04.042 [2] LIU M L, LIU R Z, LIU B, et al. Preparation of the coated nuclear fuel particle using the fluidized bed-chemical vapor deposition (FB-CVD) method[J]. Procedia Engineering, 2015, 102: 1890-1895. doi: 10.1016/j.proeng.2015.01.328 [3] 刘马林,邵友林,刘兵. 包覆燃料颗粒制备的自动化控制系统设计与研制[J]. 原子能科学技术,2013, 47(6): 1013-1018. doi: 10.7538/yzk.2013.47.06.1013 [4] LIU M L, CHEN Z, CHEN M, et al. Scale-up strategy study of coating furnace for TRISO particle fabrication based on numerical simulations[J]. Nuclear Engineering and Design, 2020, 357: 110413. doi: 10.1016/j.nucengdes.2019.110413 [5] CHEN Z, JIANG L, YANG X, et al. Experimental study on the scale-up of a multi-ring inclined nozzle spout-fluid bed by electrical capacitance tomography[J]. International Journal of Chemical Reactor Engineering, 2022, 20(9): 1003-1015. doi: 10.1515/ijcre-2022-0006 [6] CHENG X Y, YANG X, LIU M L, et al. Preparation of ZrC coating in TRISO fuel particles by precise transportation of solid precursor and its microstructure evolution[J]. Journal of Nuclear Materials, 2023, 574: 154222. doi: 10.1016/j.jnucmat.2022.154222 [7] YANG X, CHENG X Y, LIU R Z, et al. Preparation and high temperature performance of NbC layer in TRISO particles[J]. Journal of the European Ceramic Society, 2022, 42(15): 6889-6897. doi: 10.1016/j.jeurceramsoc.2022.07.050 [8] LIU R Z, LIU M L, CHANG J X, et al. An improved design of TRISO particle with porous SiC inner layer by fluidized bed-chemical vapor deposition[J]. Journal of Nuclear Materials, 2015, 467: 917-926. doi: 10.1016/j.jnucmat.2015.10.055 [9] LIU Z B, CHENG X Y, YANG X, et al. Ultra-high temperature microstructural changes of SiC layers in TRISO particles[J]. Ceramics International, 2024, 50(1): 2331-2339. doi: 10.1016/j.ceramint.2023.11.007 [10] 王桃葳,刘马林,刘兵. 包覆燃料颗粒超高温运行条件下的结构完整性研究报告:2017ZX06901027-05.3[R]. 北京:清华大学核能与新能源技术研究院,2023. [11] 严泽凡,刘泽兵,田宇,等. TRISO颗粒SiC层辐照行为与力学性能的分子动力学模拟[J]. 原子能科学技术,2024, 58(4): 856-867. -

下载:

下载: